Waterproof and air-permeable shoe and production method thereof

A technology for waterproof, breathable and breathable shoes, which is applied to uppers, footwear, footwear, etc., can solve the problem of high cost of waterproof and breathable shoes, achieve the effect of reducing material costs, improving the breathable effect, and the method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

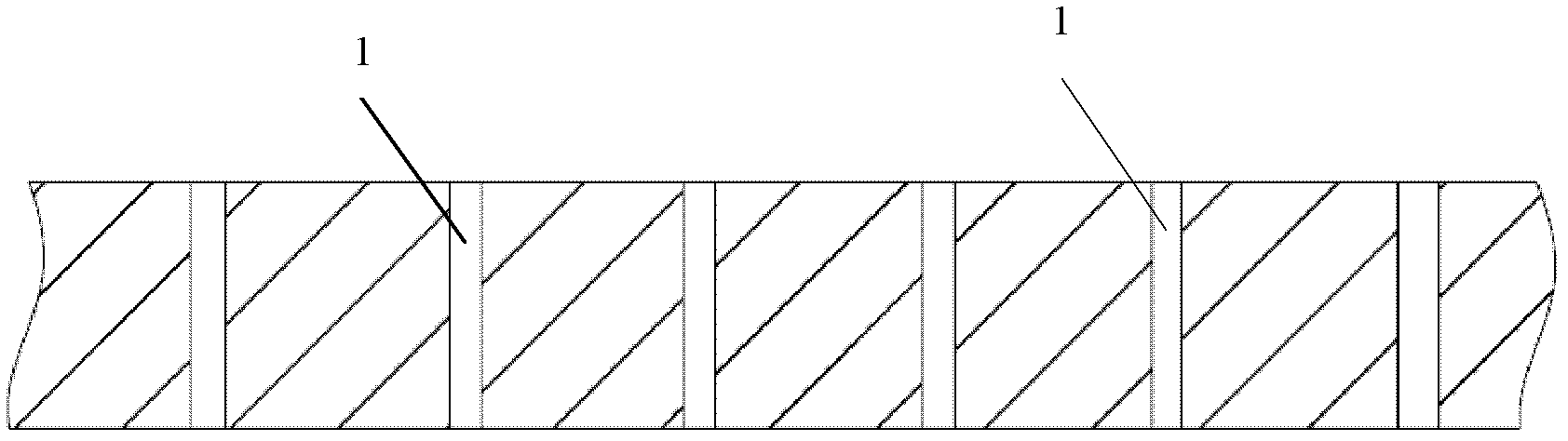

[0039] Such as figure 1 , figure 2 Shown:

[0040] A waterproof and breathable shoe, comprising a waterproof and breathable upper, the upper surface of the shoe upper is distributed with micropores 1 passing through its upper and lower surfaces, and the micropores 1 are breathable and impervious to water. The material of the upper is elastic waterproof material. The elastic waterproof material includes EVA, of course, the elastic waterproof material can also be composed of other components. The diameter of the micropores 1 is small enough to prevent water from seeping through the micropores 1 into the shoe due to tension.

[0041] Preferably, the thickness range of the shoe upper with the microholes 1 is 3mm-6mm, such as 4mm, 5mm.

[0042] Preferably, 200-300 micropores 1 are evenly distributed on the whole shoe upper, such as 220, 240, 260, 280.

[0043] The manufacturing method of the waterproof breathable shoes of the present embodiment comprises the following steps: ...

Embodiment 2

[0050] Such as figure 1 , figure 2 Shown:

[0051] On the basis of Example 1, another elastic waterproof material is selected for the shoe upper of this example, and the other elastic waterproof material comprises the following components in parts by weight: 70 parts of EVA, and 30 parts of elastomer.

[0052] Since the elastic waterproof material includes two components, it is necessary to knead the components.

[0053] The manufacturing method of the waterproof breathable shoes of the present embodiment comprises the following steps:

[0054]1. Mix the components together to obtain the elastic waterproof material, mold the elastic waterproof material into a semi-finished product of the upper of the waterproof and breathable shoe, the semi-finished product has the shape and size of the upper of the shoe, the Molding is preferably injection molding using an injection molding machine;

[0055] 2. Perform cooling treatment on the semi-finished shoe upper, preferably, reduce...

Embodiment 3

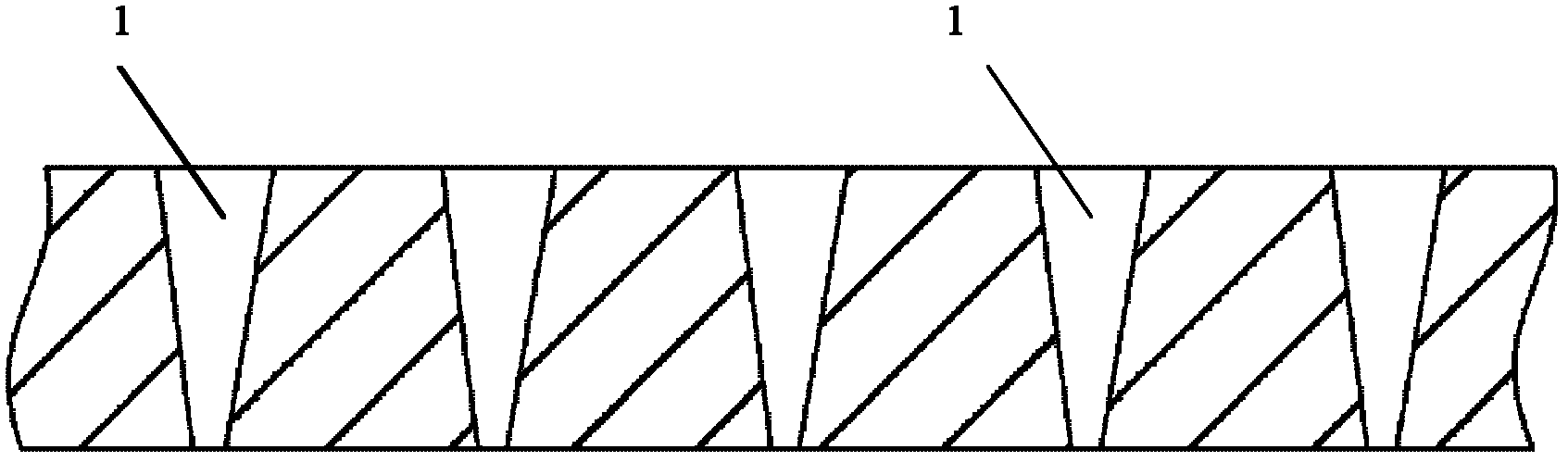

[0059] Such as image 3 , Figure 4 Shown:

[0060] A waterproof and breathable shoe, comprising a waterproof and breathable upper, the upper is distributed with micropores 1 passing through its upper and lower surfaces, the micropores 1 are breathable and impervious to water, the upper is made of elastic waterproof material, and the elastic waterproof The material includes the following components by weight: 28.5-38 parts of Eva, 4.75-9.5 parts of light calcium, 2.375-4.75 parts of talcum powder, 0.95-3.8 parts of water-absorbing agent, 2.375-4.75 parts of pottery clay, and 0.3325-0.57 parts of dcp bridging agent 1.425-2.85 parts of ac foaming agent, 1.425-2.85 parts of stearic acid, 1.425-2.375 parts of zinc oxide, 9.5 parts of poe elastomer, 33.25 parts of Eva vinyl acetate. The apertures of the micropores 1 gradually shrink from one side of the upper surface to the other side. The micropores 1 whose pore diameters shrink gradually widen the ventilation channel between t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com