Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Improve insulation stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flexible high-current-carrying direct-current cable insulation material and cable

InactiveCN105244079AImprove high temperature resistance and flexibilityGood high temperature resistancePlastic/resin/waxes insulatorsClimate change adaptationCross-linked polyethyleneRare-earth element

The invention discloses a flexible high-current-carrying direct-current cable insulation material and a cable. The insulation material comprises the following components: crosslinked polyethylene, ethylene-ethylene-vinlacetate copolymer, sodium dodecyl sulfate, calcium chloride, barium titanate, magnesium oxide, silicon dioxide, an NX2040 curing agent and composite rare earth. A semi-conductive wrapping band and a semi-conductive conductor shielding layer successively wrap an alloy conductor of the cable. An external layer of the insulation material is provided with a corrugated copper sheath, a polyethylene sheath and a semi-conductive water-blocking buffer band. An outer side of the semi-conductive water-blocking buffer band is provided with two layers of extrusion molding steel wires. An outer side of each extrusion molding steel wire is provided with a flame-retardant protection sleeve. Through improving components of a cable insulation layer, high temperature resistance performance and flexibility performance are effectively increased; because a rare earth element is added in ingredients of the insulation layer, the cable possesses good high temperature resistance performance, a wear-resisting property and traction resistance performance; and a service life of the cable in a severe environment is prolonged.

Owner:WUXI HUAHONG INFORMATION TECH

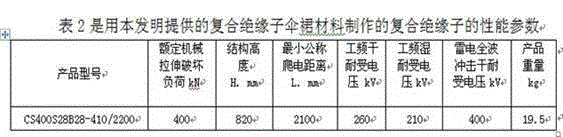

Shed material of composite insulator

The invention relates to a shed material of a composite insulator. The shed material is made from the following raw materials in parts by weight: 100 parts of component A, 80-120 parts of component B and 200-400 parts of component C, wherein the component A comprises diglycidyl cyclohexane dicarboxylate and flexible epoxy resin in the weight ratio of (70-90):(30-10); the component B comprises a curing agent and an accelerator in the weight ratio of 100:(1-5); and the component C comprises at least one of silicon dioxide or aluminium hydroxide. The shed material of the composite insulator, provided by the invention, is not prefabricated and is fabricated on site when pouring the shed mould of the insulator in the process of fabricating the insulator. The shed sheath of the composite insulator, fabricated by adopting the material provided by the invention, has the advantages of good toughness, tread resistance, difficulty in damage and good sealing property.

Owner:甘肃省电力公司检修公司 +2

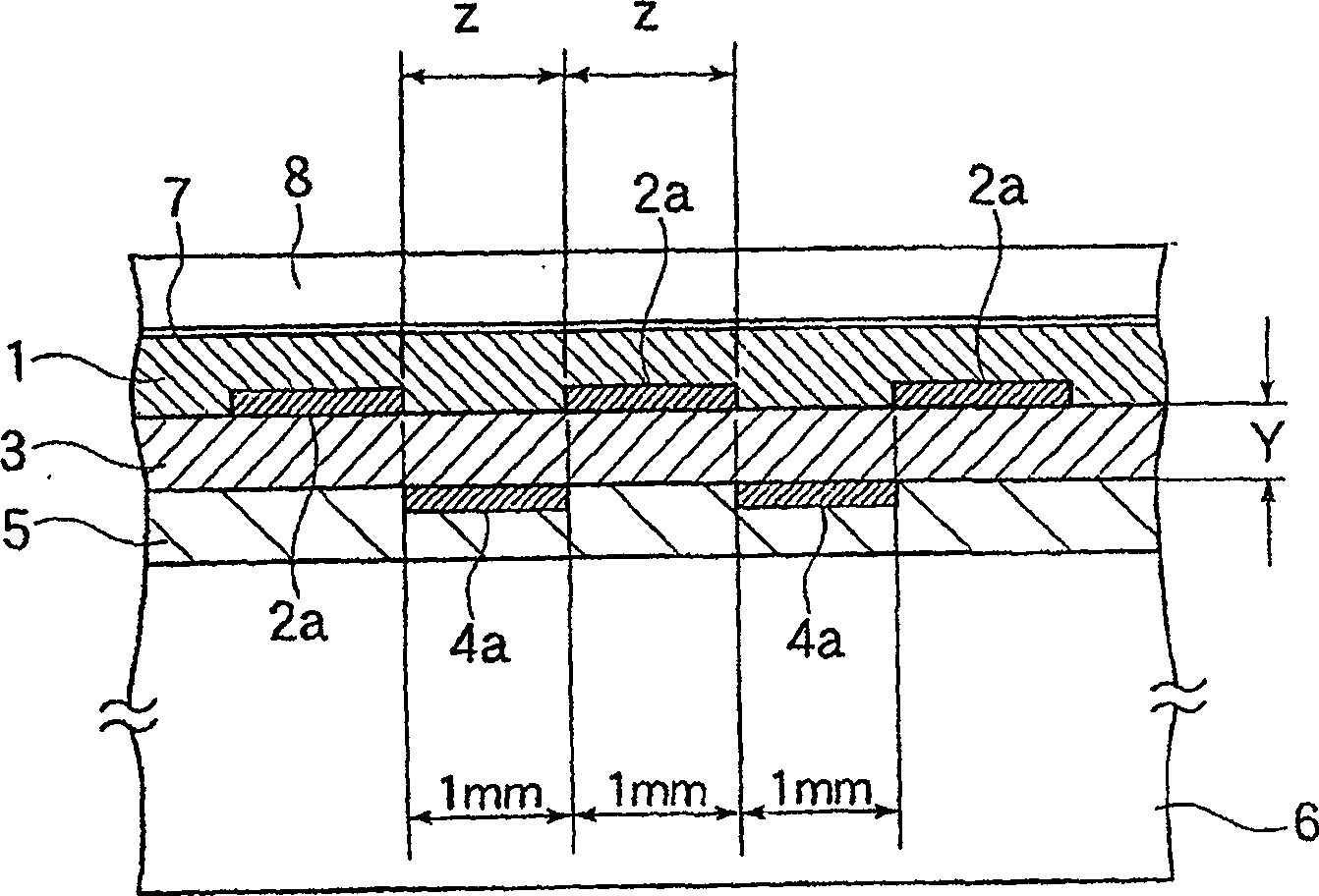

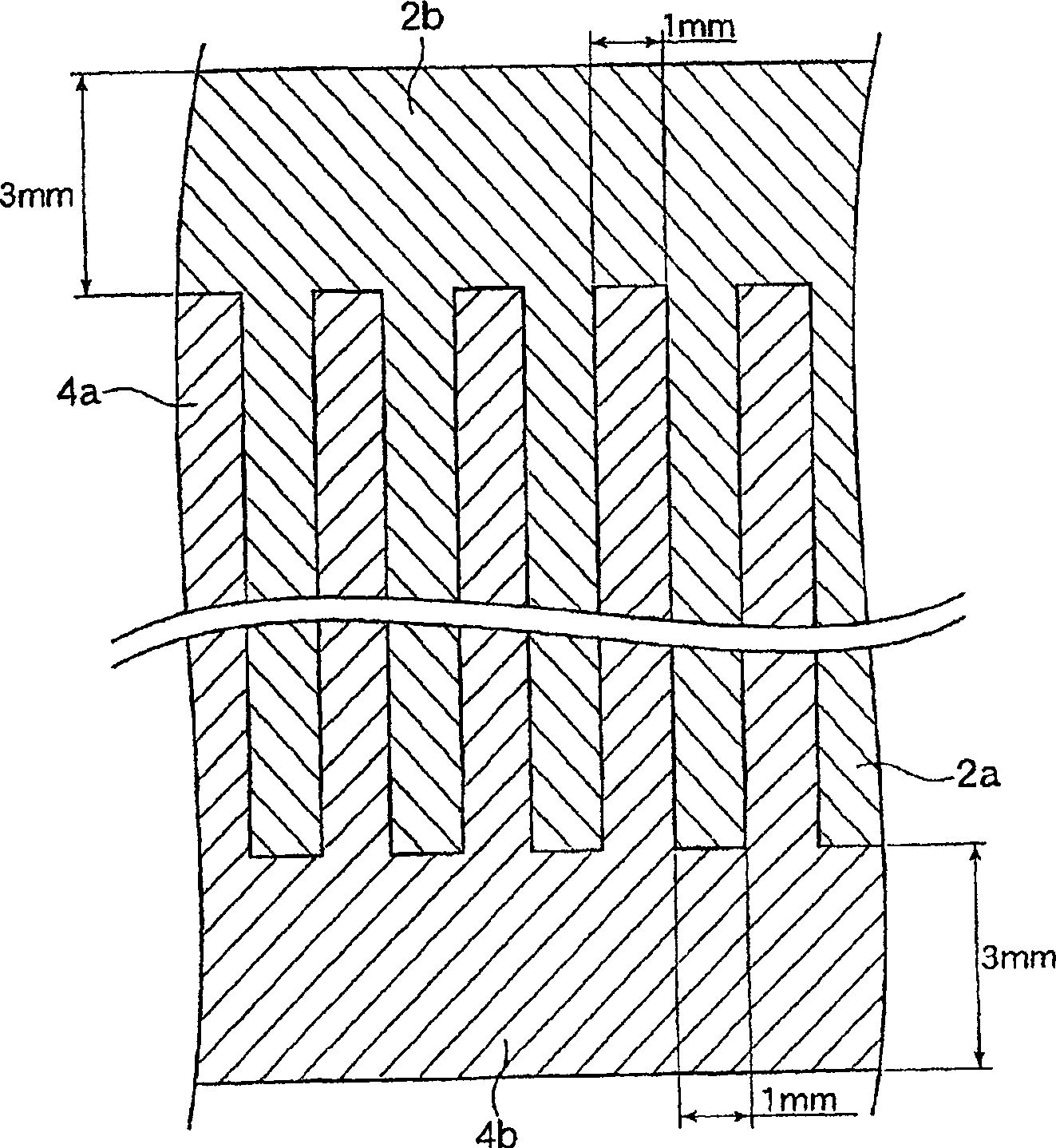

Bipolar electrostatic chuck

InactiveCN1934693AImprove insulation stabilityImprove reliabilitySemiconductor/solid-state device manufacturingElectrostatic holding devicesPhysicsVoltage

A bipolar electrostatic chuck which has excellent dielectric breakdown strength and provides excellent attracting performance. The bipolar electrostatic chuck eliminates difficulty in peeling off a sample from a sample attracting plane as much as possible after application of a voltage to electrodes is finished. The bipolar electrostatic chuck is provided with a first electrode and a second electrode in an insulator and permits a surface of the insulator to be the sample attracting plane. The insulator has the first electrode, an interelectrode insulating layer and the second electrode in this order from the sample attracting plane in the depth direction. The second electrode has a region not overlapping with the first electrode in a normal line direction of the sample attracting plane.

Owner:CREATIVE TECH CORP

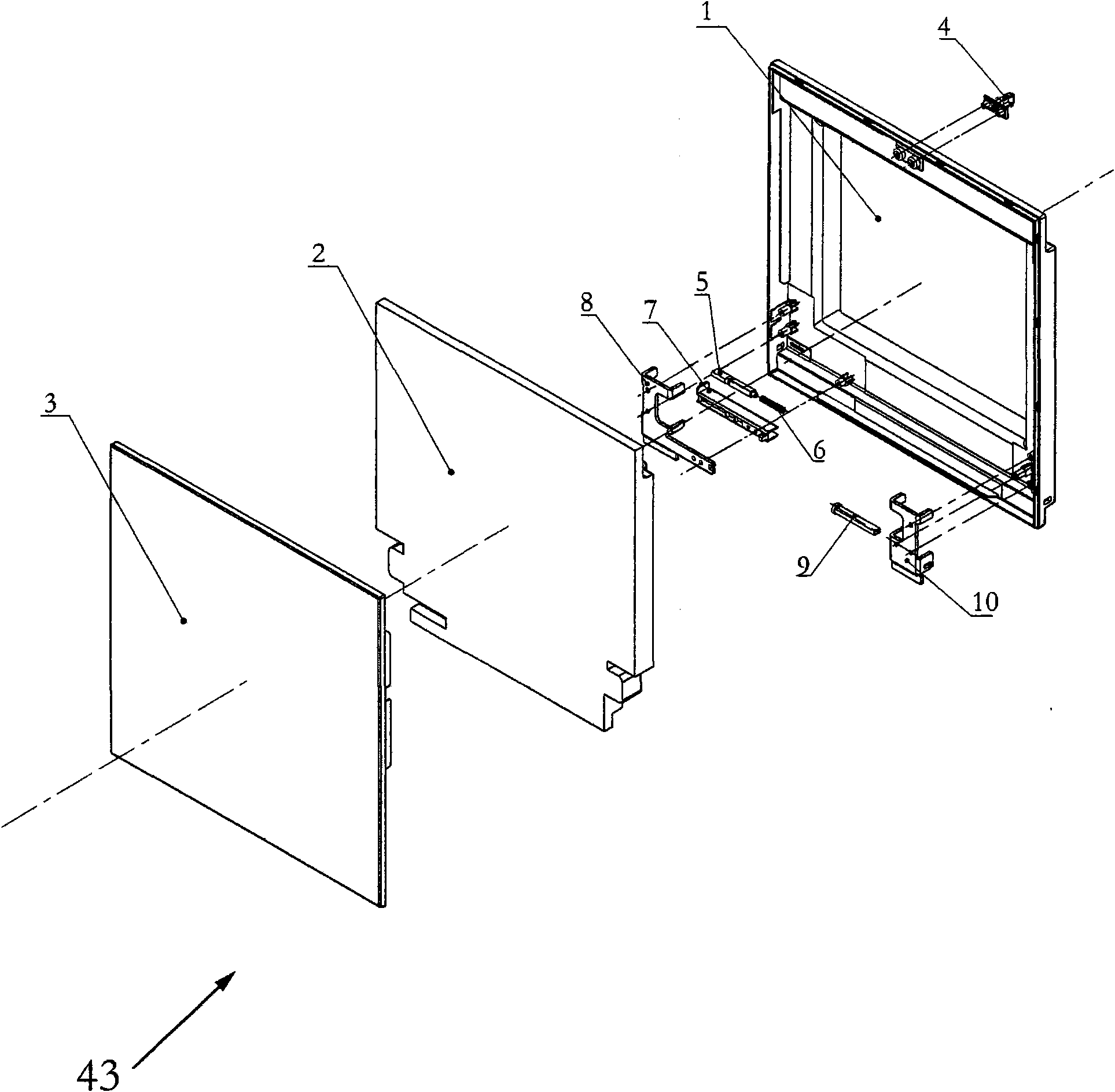

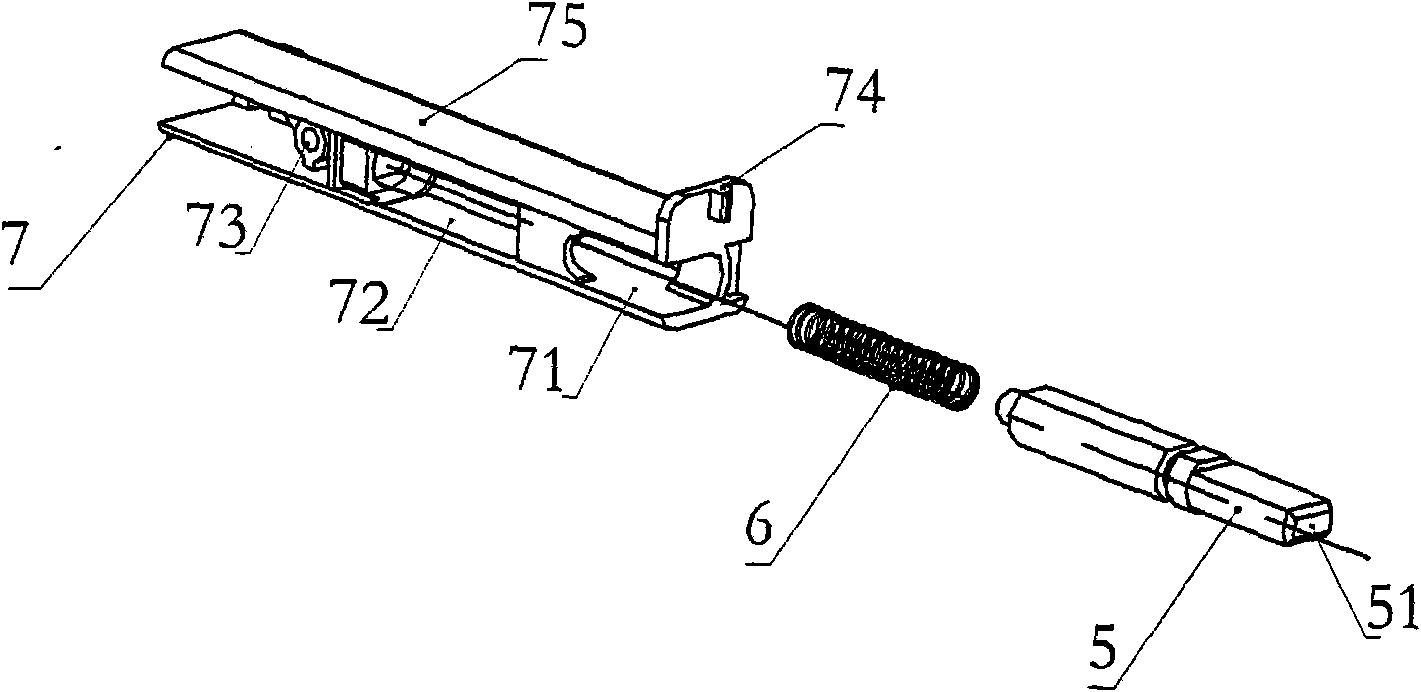

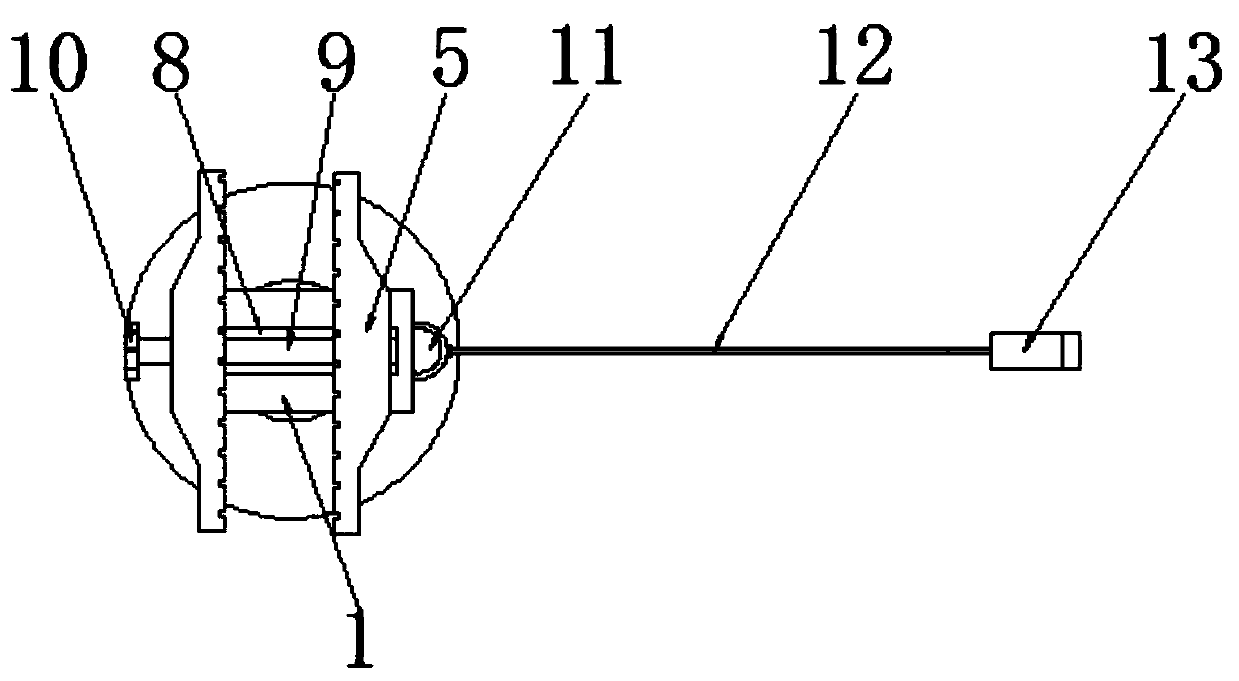

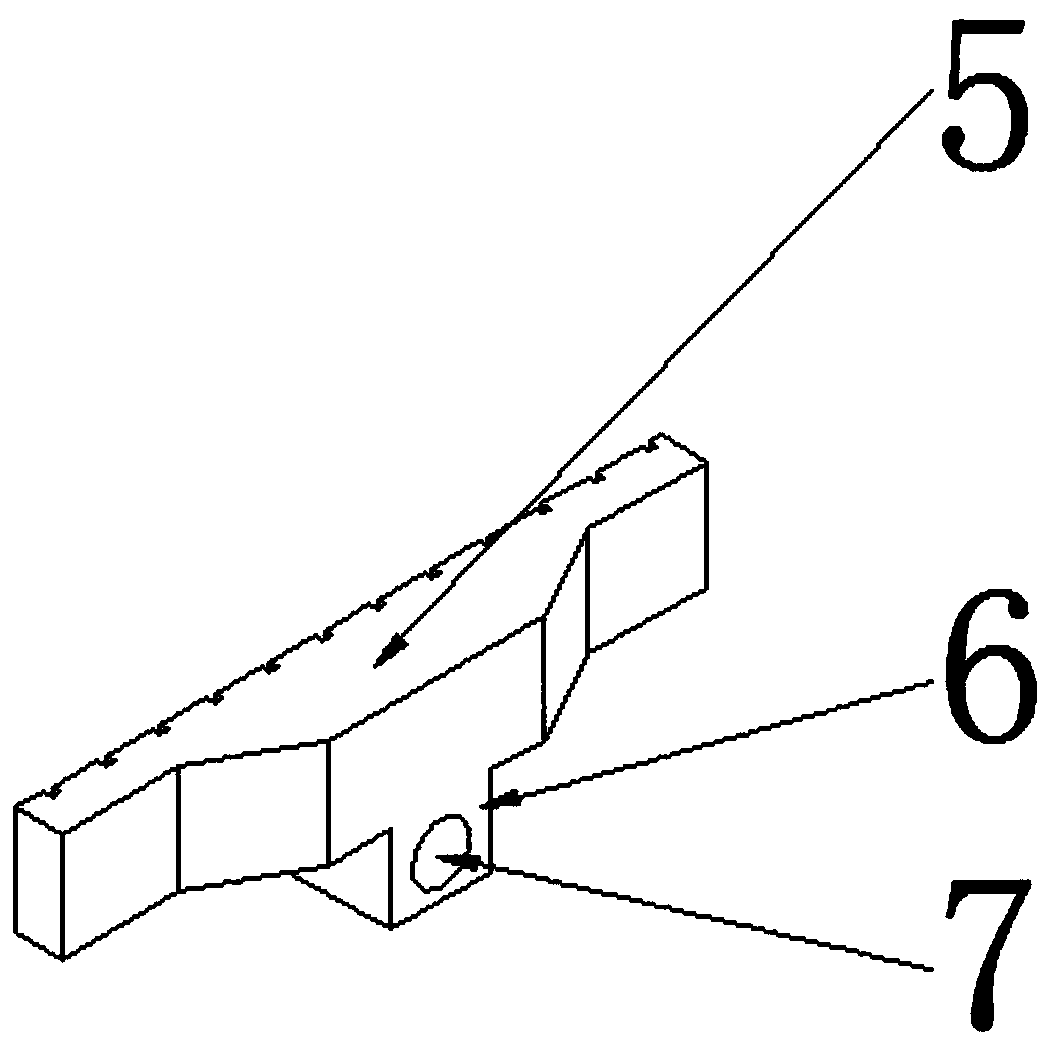

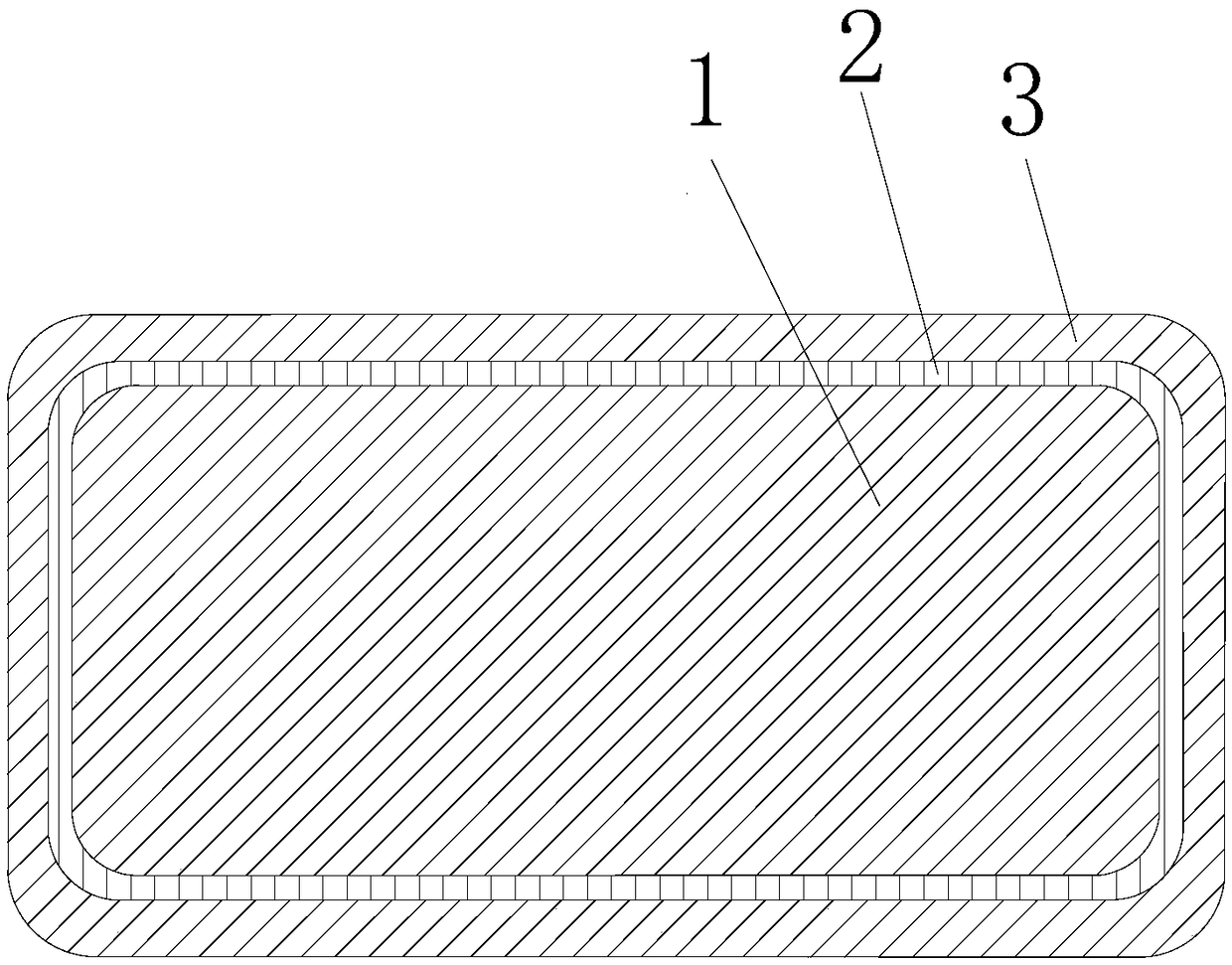

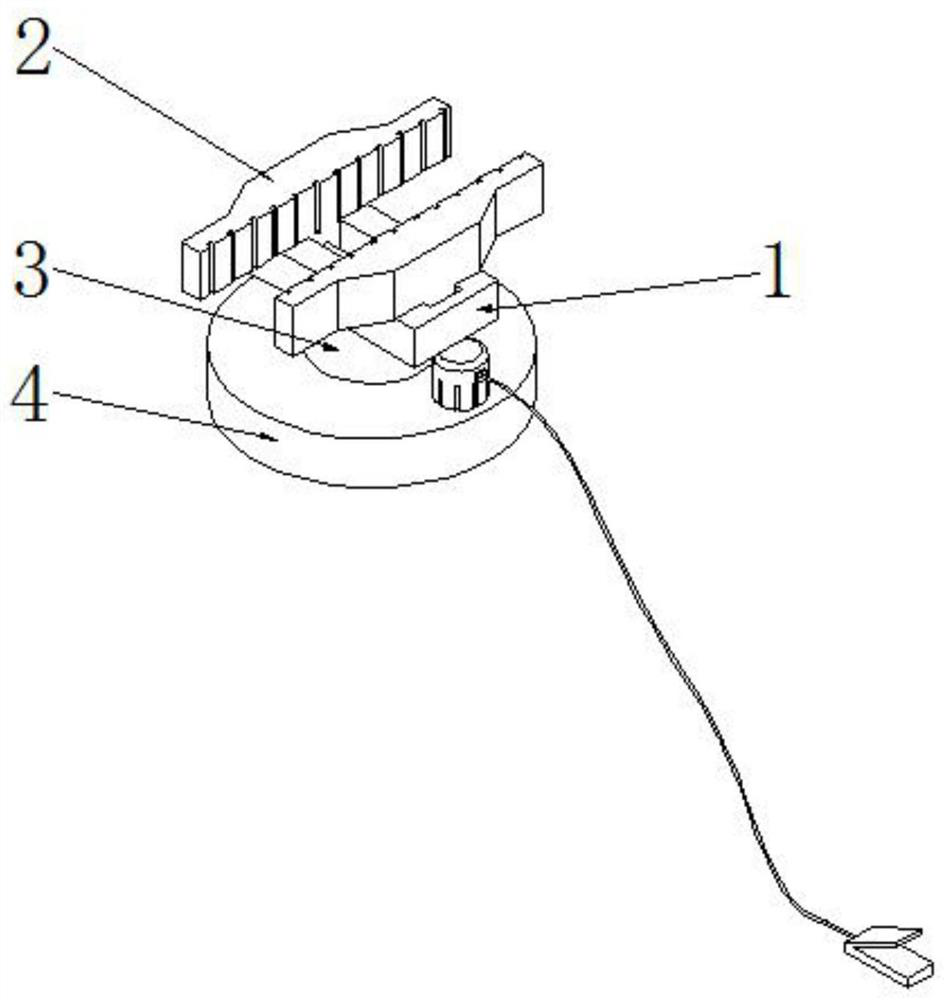

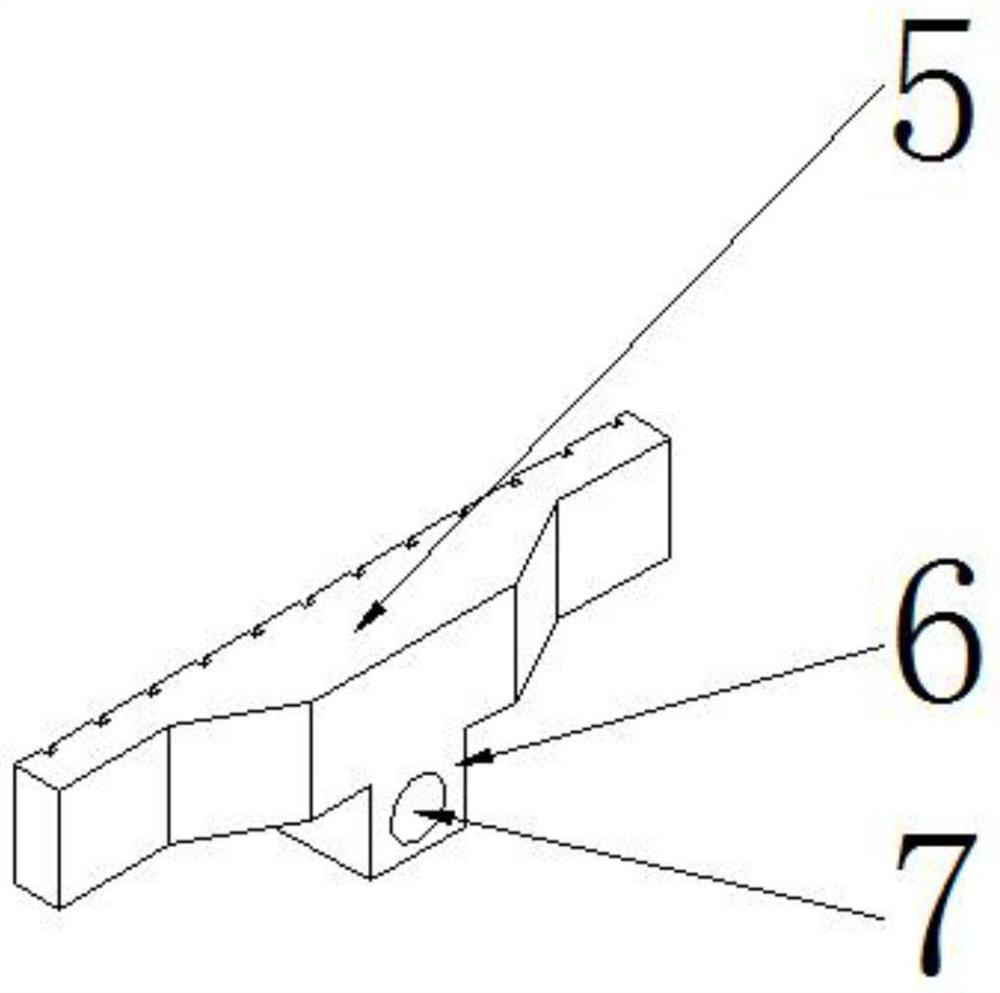

Refrigerator heat insulation bar door

InactiveCN101922840AIncrease productionImprove insulation stabilityDomestic cooling apparatusLighting and heating apparatusEngineeringHigh intensity

The invention discloses a refrigerator heat insulation bar door and relates to the field of a heat insulation bar door in which a heat insulation block is arranged between the inner shell and the outer shell of a refrigerator. The refrigerator heat insulation bar door (43) consists of the inner shell (1), the heat insulation block (2) and the outer shell (3), the heat insulation block (2) is inserted in a left hinge bracket assembly (11) and a right hinge bracket assembly (41) and is arranged in the inner shell (1), lugs (26) around the inner shell (1) are blocked in grooves (31) around the outer shell (4), the left hinge bracket assembly (11) and the right hinge bracket assembly (41) are respectively arranged at the left lower side and the right lower side of the inner shell (1), wherein the left hinge bracket assembly (11) consists of a left bearing (5), a spring (6), a spring bracket (7) and a left hinge bracket (8), and the right hinge bracket assembly (41) consist of a right bearing (9) and a right hinge bracket (10). The refrigerator heat insulation bar door is provided with a high-intensity heat insulation block and has the advantages of high heat insulation stability and simple assembling process.

Owner:TAIZHOU LG ELECTRONICS REFRIGERATOR CO LTD

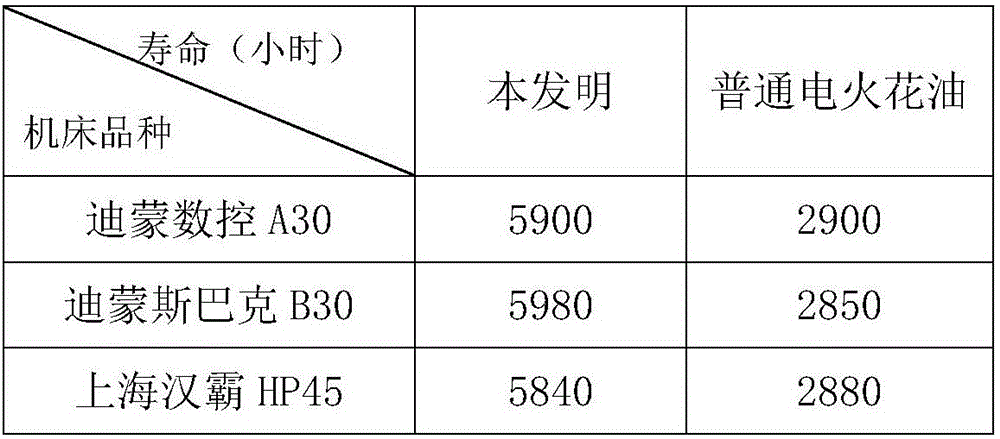

EDM oil for mirror EDM and preparation method therefor

The invention discloses an electric discharge machining (EDM) oil for mirror EDM. The oil comprises the following raw materials in parts by weight: 6 to 10 parts of solvent oil D110 (Nanjing Beautychem Co.Ltd), 0.7 to 1 parts of poly epoxy succinic acid, 2 to 3 parts of dodecyl phenyl succinic acid, 0.1 to 0.14 parts of triallyl isocyanurate, 0.02 to 0.04 parts of 1,2,3 - benzotriazole, 0.1 to 0.2 parts of polyimide, 1 to 2 parts of polyacrylamide, 75 to 85 parts of n-alkanes solvent oil, 0.6 to 1 parts of isopropyl oleate, 1.5 to 2 parts of corrosion inhibitor, 0.05 to 0.06 parts of zinc acetylacetonate, 0.01 to 0.02 parts of polyglycerol fatty acid ester, 2 to 4 parts of N - vinyl pyrrolidone, 0.3 to 0.4 parts of ethyl orthosilicate and 0.1 to 0.2 parts of simethicone. The finished product produced by the invention is high in chemical stability, relatively long in service life, good in environmental protection and outstanding in comprehensive performance.

Owner:浙江模德科技有限公司

Motor

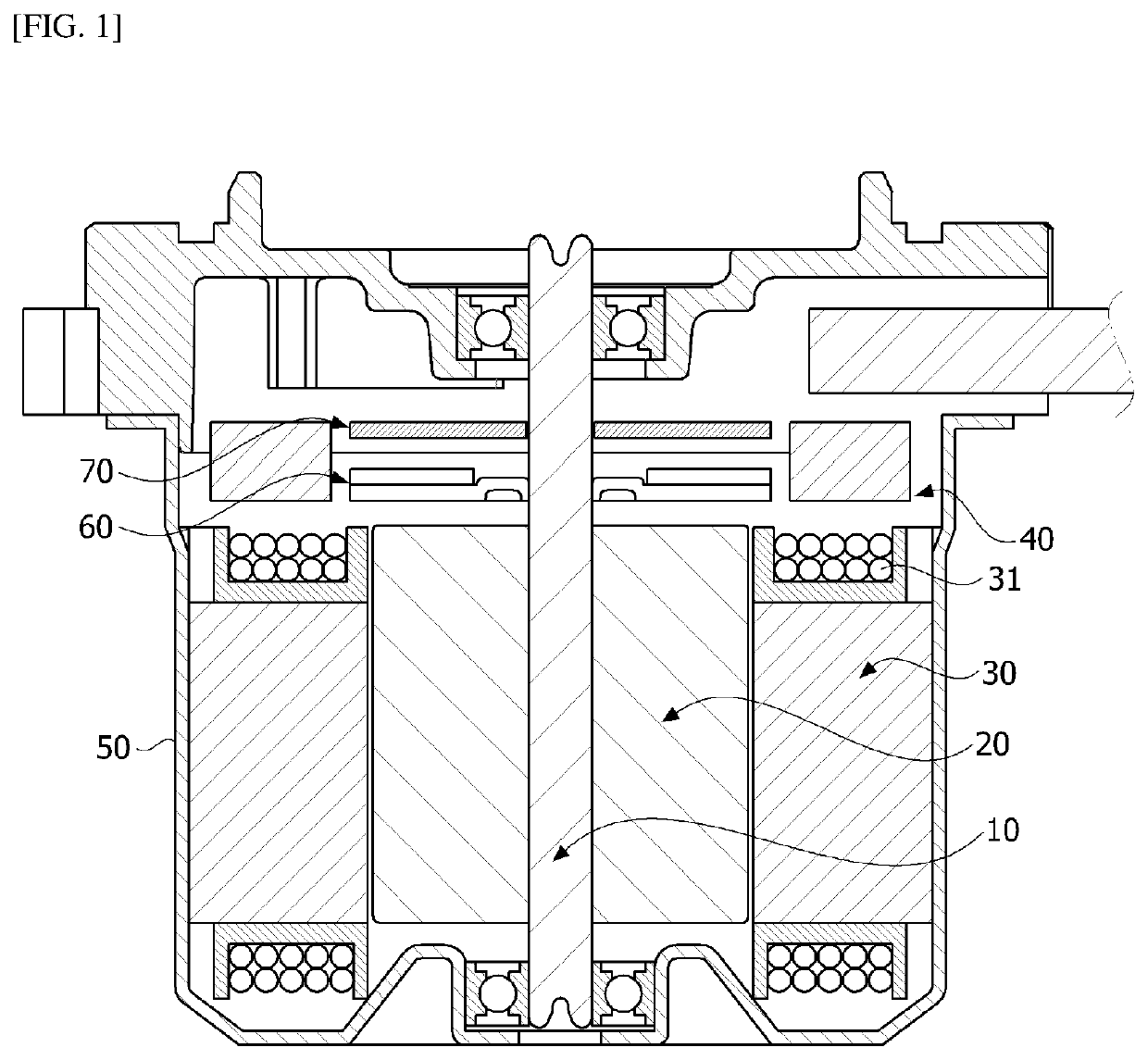

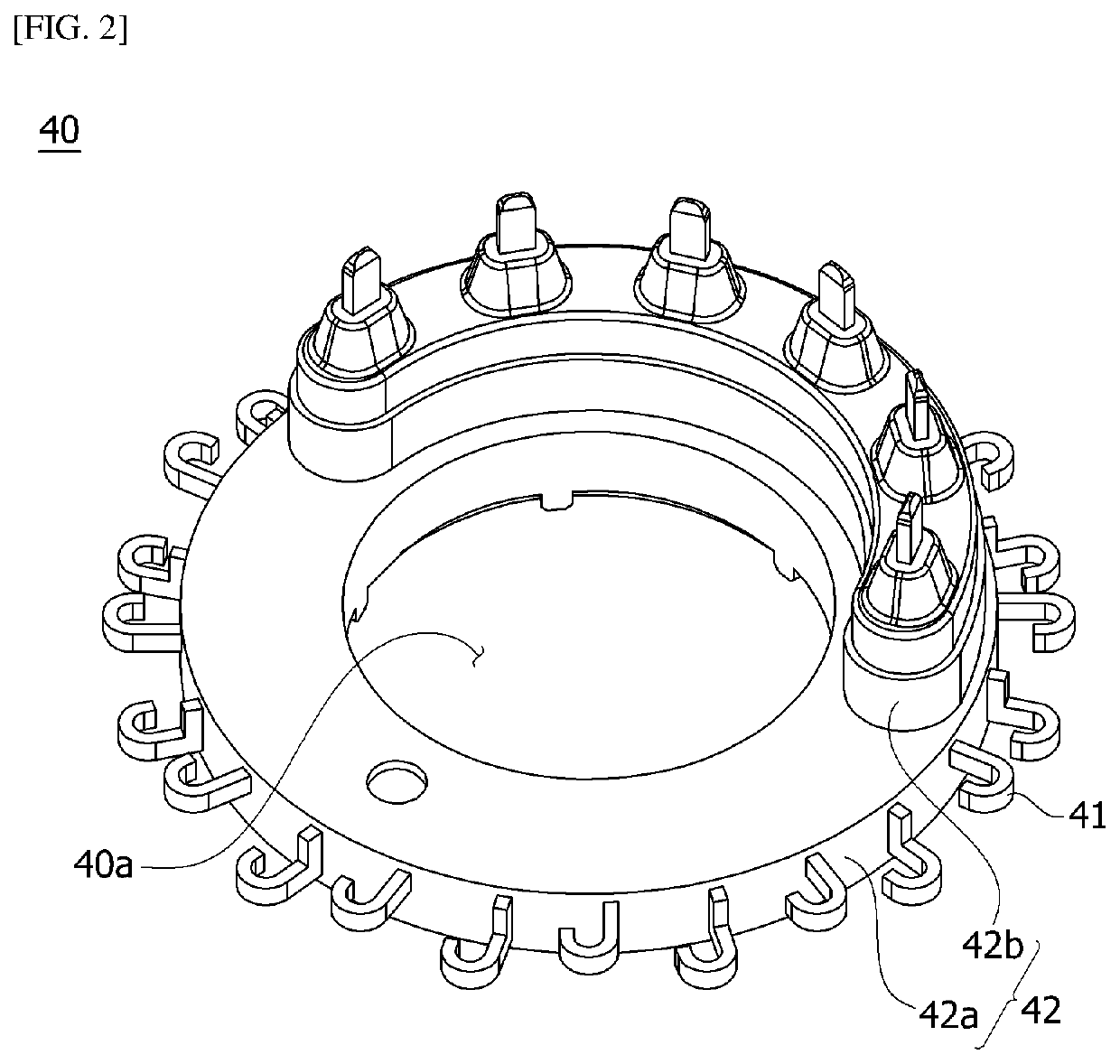

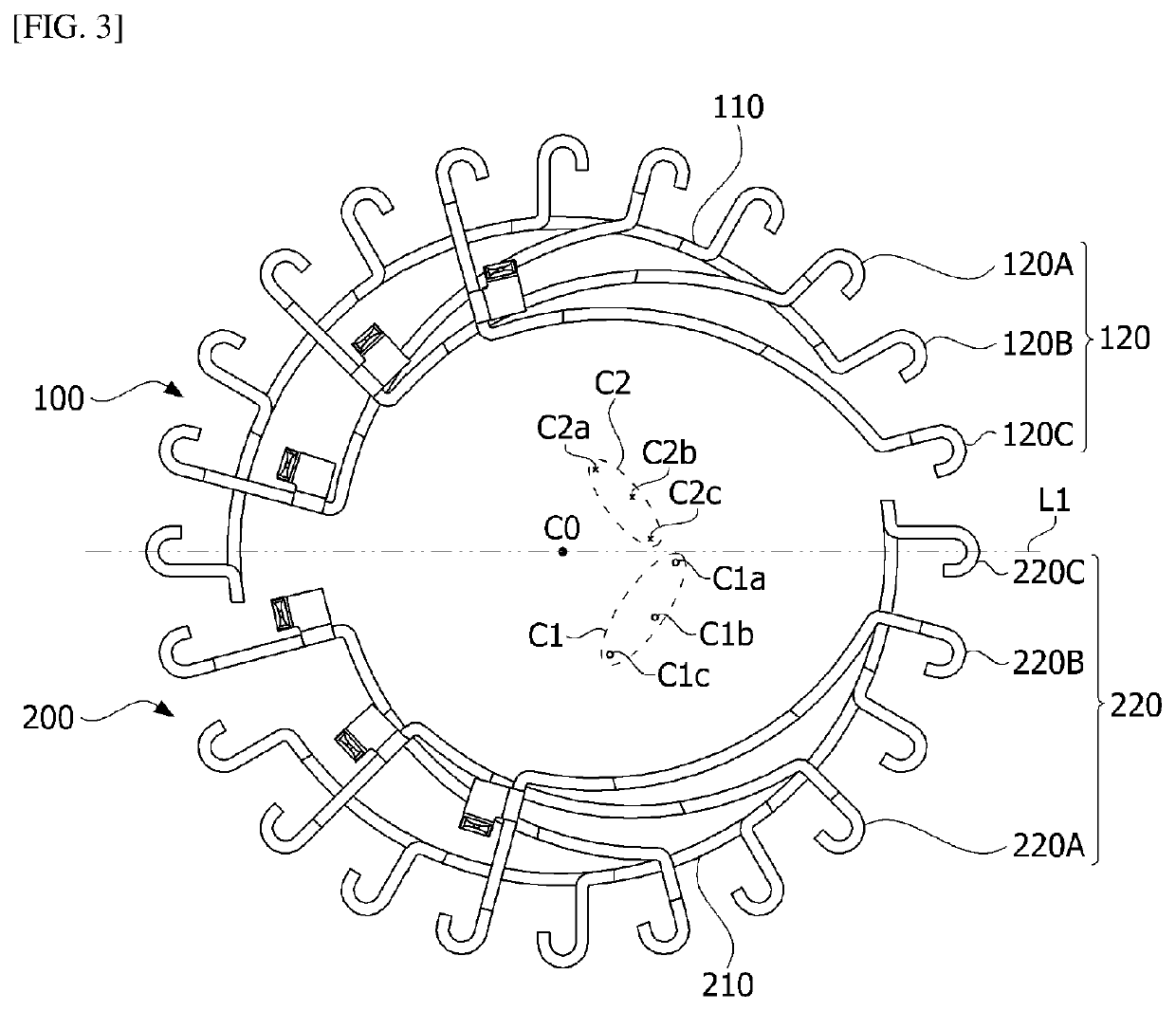

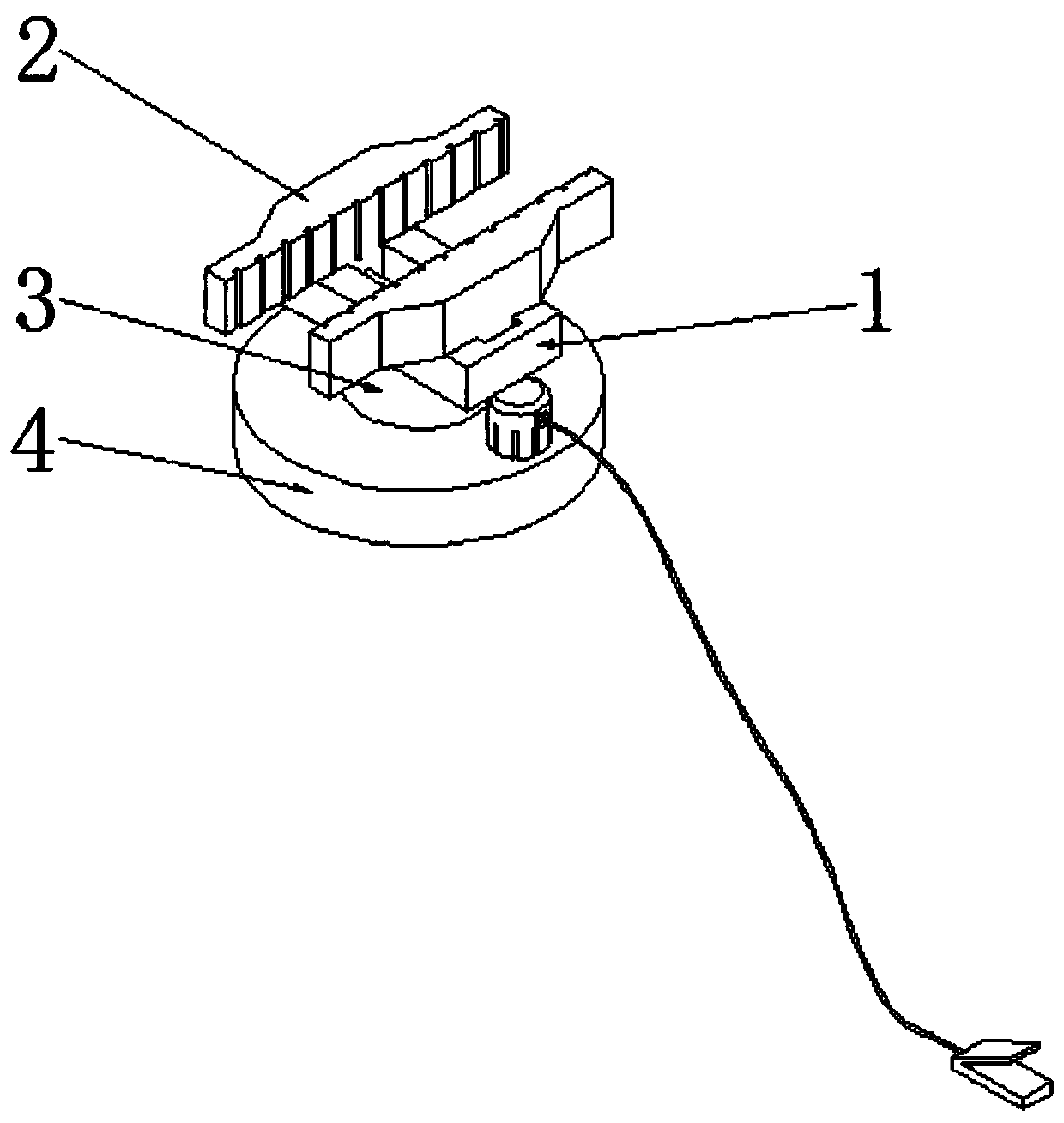

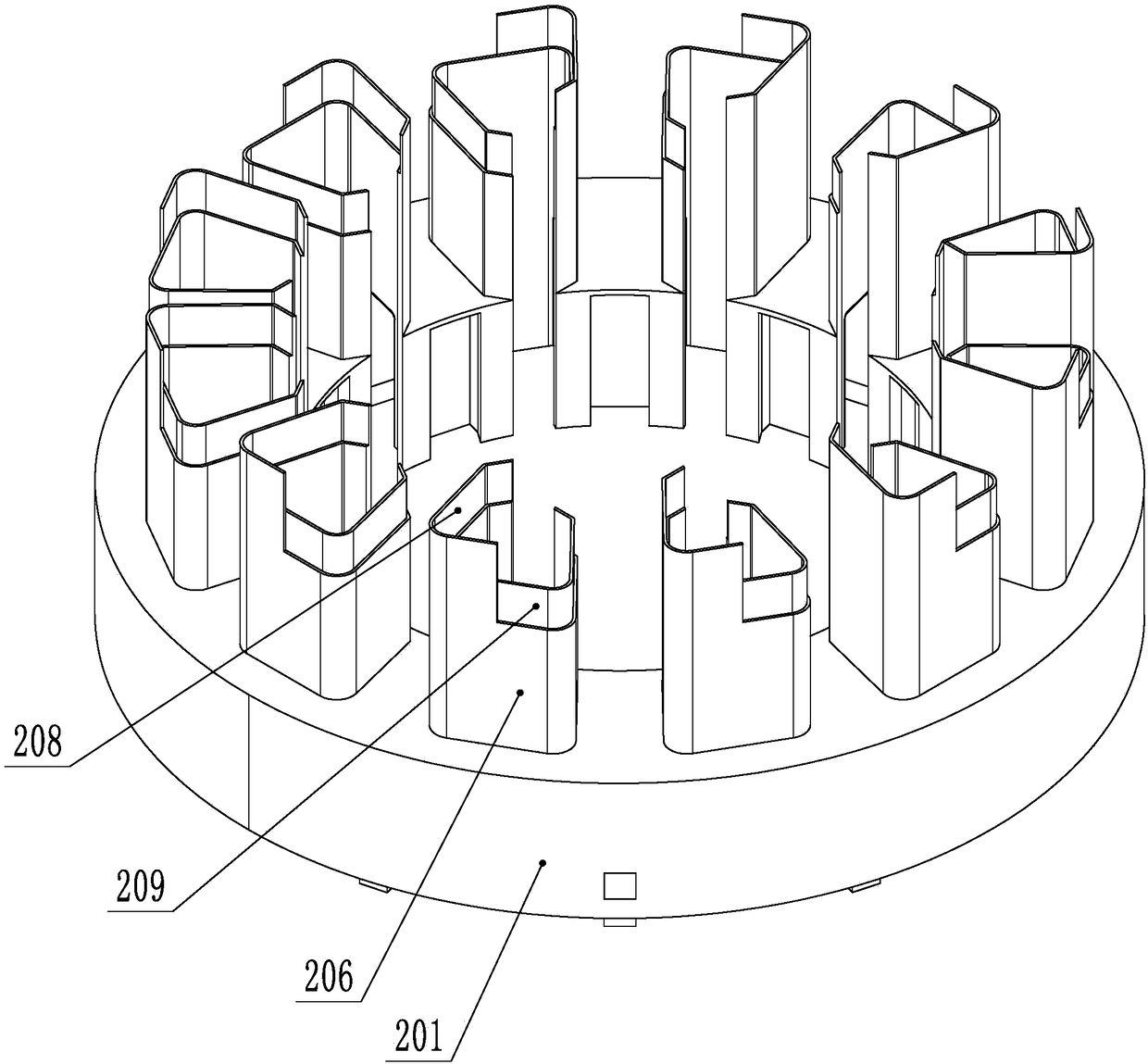

ActiveUS20210057955A1Simplify the assembly processPrecise positioningWindingsMagnetic circuit stationary partsElectric machineEngineering

The present invention may provide a motor including a shaft, a rotor coupled to the shaft, a stator disposed outside the rotor, and a bus bar disposed on the stator, wherein the bus bar includes a terminal connected to a coil of the stator, the terminal includes a first terminal and a second terminal which are separated from each other in a circuit manner, the first terminal includes a first neutral terminal and a plurality of first phase terminals, the second terminal includes a second neutral terminal and a plurality of second phase terminals, first curvature centers of the plurality of first phase terminals are disposed to be different, second curvature centers of the plurality of second phase terminals are disposed to be different, and a position of a curvature center of the first neutral terminal is the same as a position of a curvature center of the second neutral terminal.

Owner:LG INNOTEK CO LTD

Textile heat-insulating coating and preparation method and using method thereof

ActiveCN102808330ANo pollution in the processImprove stabilityFibre treatmentLiquid/gas/vapor removalN dimethylformamideDimethyl siloxane

The invention relates to a textile heat-insulating coating, and a preparation method and a using method thereof. The textile heat-insulating coating mainly comprises, by weight percent, 20-35% of film-forming base material, namely polydimethylsiloxane, 10-25% of heat-insulating functional filling, namely rutile titanium oxide, 60-80% of N, N-dimethylformamide, and 1-2% of sodium hexametaphosphate. Compared with the prior art, the textile heat-insulating coating has the advantages that the raw materials are environment-friendly, easy to obtain and low in cost, processing technology is simple, and the heat-insulating coating is high in adhesion, high in weatherability and excellent in heat insulation.

Owner:常熟新泰港务有限公司

Preparation technology of durable vehicle window sealing strip detecting tool

The invention discloses a preparation technology of a durable vehicle window sealing strip detecting tool. The preparation method comprises the processing steps of material selection of the detectiontool, accessory machining and forming, surface processing, and assembling. When fixation is achieved by a clamping device, and after deburring and polishing processing for one surface are achieved, disassembling and positioning changing for secondary mounting for processing are not needed. A foot switch is adopted to control to finish rotating positioning adjusting, efficiency is high and operation is flexible. Stoving varnishing is conducted before accessory assembling. Most of harmful substances are volatilized during the stoving varnishing process. The paint cracks in high temperature conditions, the harmful substances are fully volatilized. Application is achieved after subsequent assembling. Non-stickiness, heat resistance, slippage, moisture resistance, abrasion resistance, corrosionresistance and other performance of the whole detection tool are improved. Compared with ordinary paint, the finishing coat is excellent in moisture resistance, abrasion resistance, and corrosion resistance.

Owner:江苏雨顺自动化科技有限公司

Thermosetting resin material for automotive relay shell and preparing method of thermosetting resin material

The invention discloses a thermosetting resin material for an automotive relay shell. The thermosetting resin material is characterized in by comprising the following raw materials including, by weight, 100-130 parts of epoxy resin E40, 10-12 parts of methylhexahydrophthalic anhydride, 3-4 parts of trimellitate, 2-3 parts of PTMG, 10-12 parts of zirconium carbonate, 0.7-1 part of ethoxylated alkyl phenol ammonium sulfate, 0.1-0.2 part of hexamethyl cyclotrisiloxane, 6-9 parts of maleic anhydride, 0.1-0.5 part of dicumyl peroxide, 17-20 parts of 3-(trifluoromethyl) benzophenone, 2-3 parts of hydroquinone, 0.1-0.4 part of 2-thiol group truxene imidazole and 3-4 parts of straw powder. The resin material has very good toughness and impact resistance, and is high in surface intensity, waterproof, good in corrosion resistance, high in protectiveness on a relay and good in insulation stability; and according to the thermosetting resin material, an acid anhydride grafting reaction is adopted, so that the dispersibility of fillers between the resin is effectively improved, and the comprehensive performance of the finished product material is improved.

Owner:宁波永的电子科技有限公司

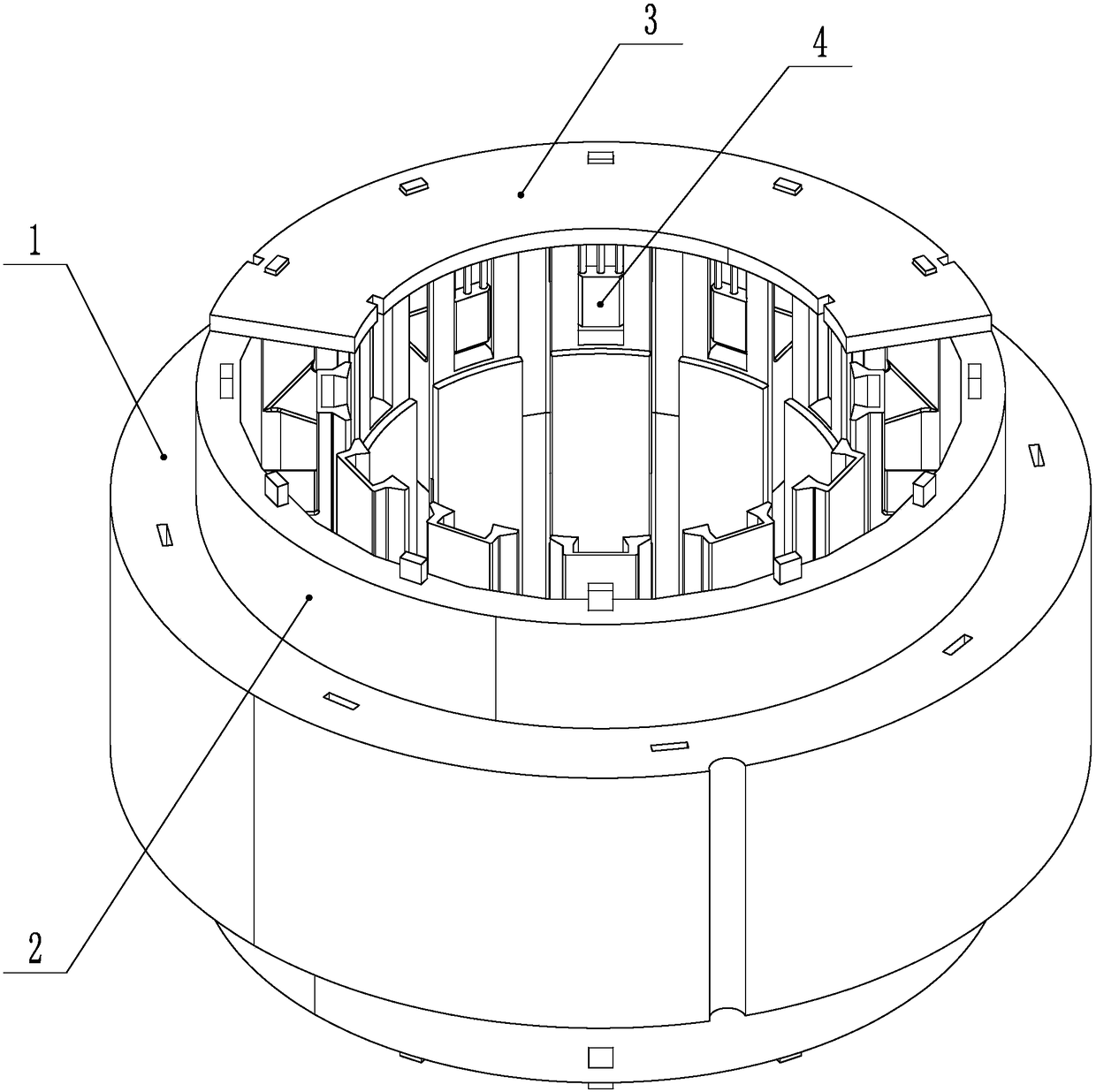

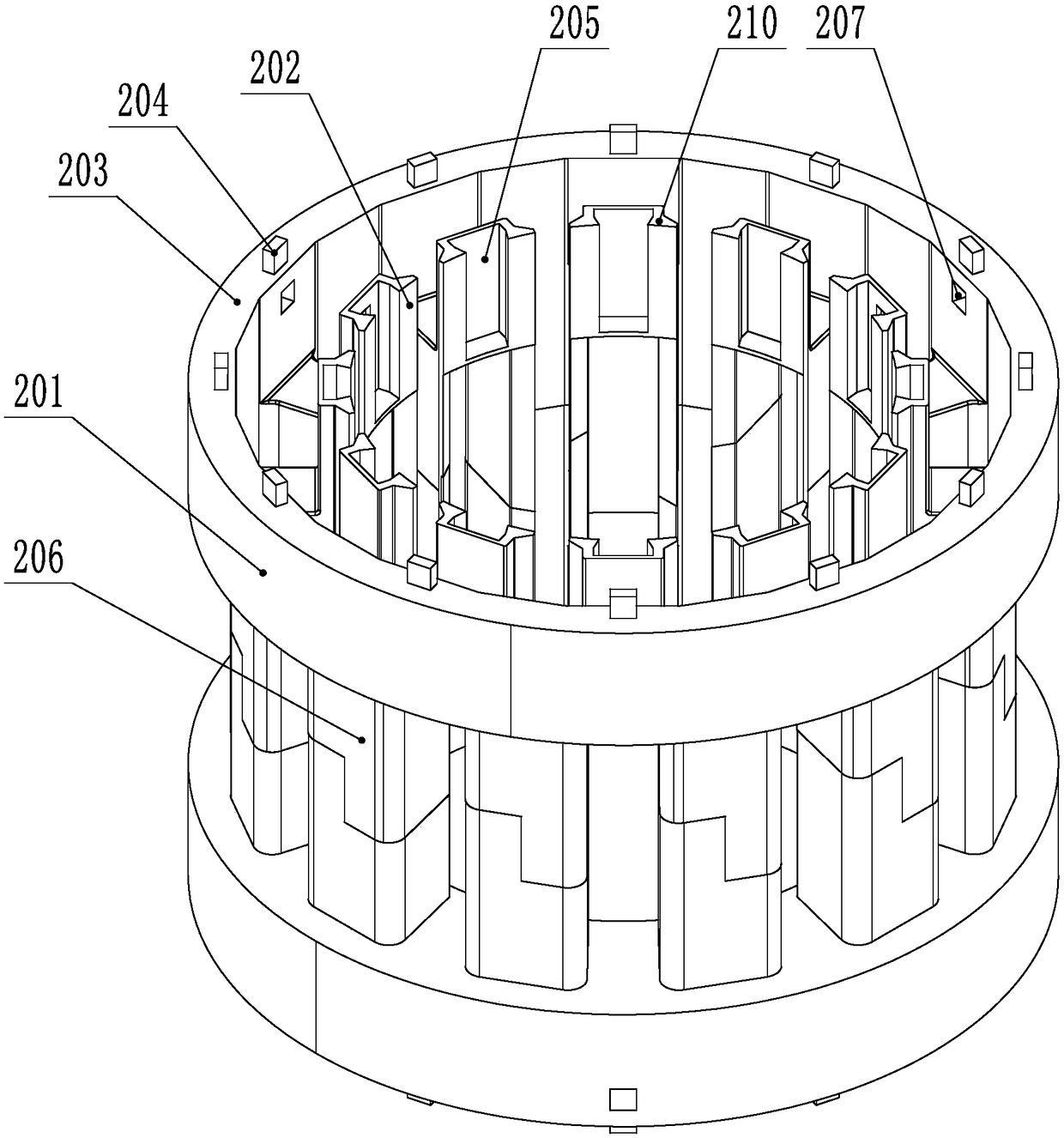

Hall circuit board fixing structure

PendingCN108462327AAchieve positioningAchieve fixationWindings insulation shape/form/constructionStructural associationFixed frameEngineering

The invention relates to a Hall circuit board fixing structure, and relates to the field of motors. Currently, a fixing mode of a brushless DC motor Hall circuit board is troublesome in installation.A Hall circuit board is disposed on a stator core, wherein the stator core is provided with a yoke, teeth and a slot hole, and an inner side between the teeth is a slot opening. The stator core is provided with a fixed frame. The Hall circuit board is fixed on the fixed frame, and the fixed frame is provided with a positioning and mounting structure of the Hall circuit board, a mounting frame forpositioning and mounting a Hall, and an insulating slot hole sleeve for isolating the stator core and a winding coil. The insulating slot hole sleeve covers the inner side surface of the yoke and theside surface and upper and lower end surfaces of the teeth, so that the slot hole is separated from the yoke and the teeth, and is opened at the slot opening. The structure improves the insulating property between a winding stator iron core coil and the stator core, is convenient to install, is firm in structure, and is good in stability.

Owner:WOLONG ELECTRIC GRP CO LTD +1

Preparation method and device of rubber and plastic heat preservation pipeline system

The invention discloses a preparation method of a rubber and plastic heat preservation pipeline system. The assembly of the rubber and plastic heat preservation pipeline system is finished under the action of pressure through adopting a negative pressure guiding pipe assembly and an air pressure balance guiding head. The preparation method provided by the invention has the advantages that the installation is simple, convenient and rapid, the degree of mechanization is high and the like; the rubber and plastic heat preservation pipeline has good heat retaining property, weather ability and stability, and the service life of the rubber and plastic heat preservation pipeline is prolonged.

Owner:广东乐安家建材有限公司

High-voltage incoming wire sheath material with excellent insulation stability

PendingCN109705433AImprove insulation stabilityEasy to processPlastic/resin/waxes insulatorsCis-Butenedioic AcidCarbon black

The invention discloses a high-voltage incoming wire sheath material with excellent insulation stability, which comprises the following raw materials in weight proportion: 7-10 parts of modified silicone rubber, 25-30 parts of medium density polyethylene resin, 12-16 parts of polyvinylidene chloride, 2.1-2.3 parts of precipitated white carbon black, 13-16 parts of ceramic powder, 1.2-1.6 part of magnesium oxide, 0.6-0.8 part of vulcanization accelerator, 1.5-1.8 part of antioxidant RD, 3.5-4.5 parts of dicumyl peroxide, 3.2-4.5 parts of rare earth stabilizer, 2.1-3.2 parts of 2,6-di-tert-butyl-4-methylphenol, 5.0-7.0 parts of dibutyl maleate and 14-16 parts of reaction adjuvant. The invention combines the advantages of modified silicone rubber, medium density polyethylene, polyvinylidene chloride and other raw materials and makes it have good processability and mechanical properties. By using the physical properties of modified silicone rubber, LSR adopts platinum catalyst to avoid by-products, and LSR has good hydrophobicity and stable hydrophobic migration properties to improve its insulation performance.

Owner:ANHUI EFARAD ELECTRIC POWER TECH

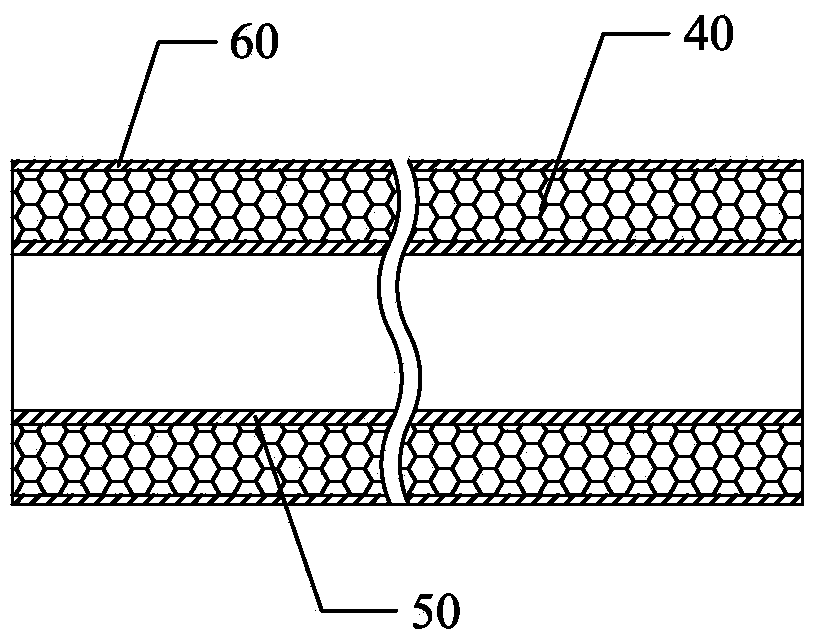

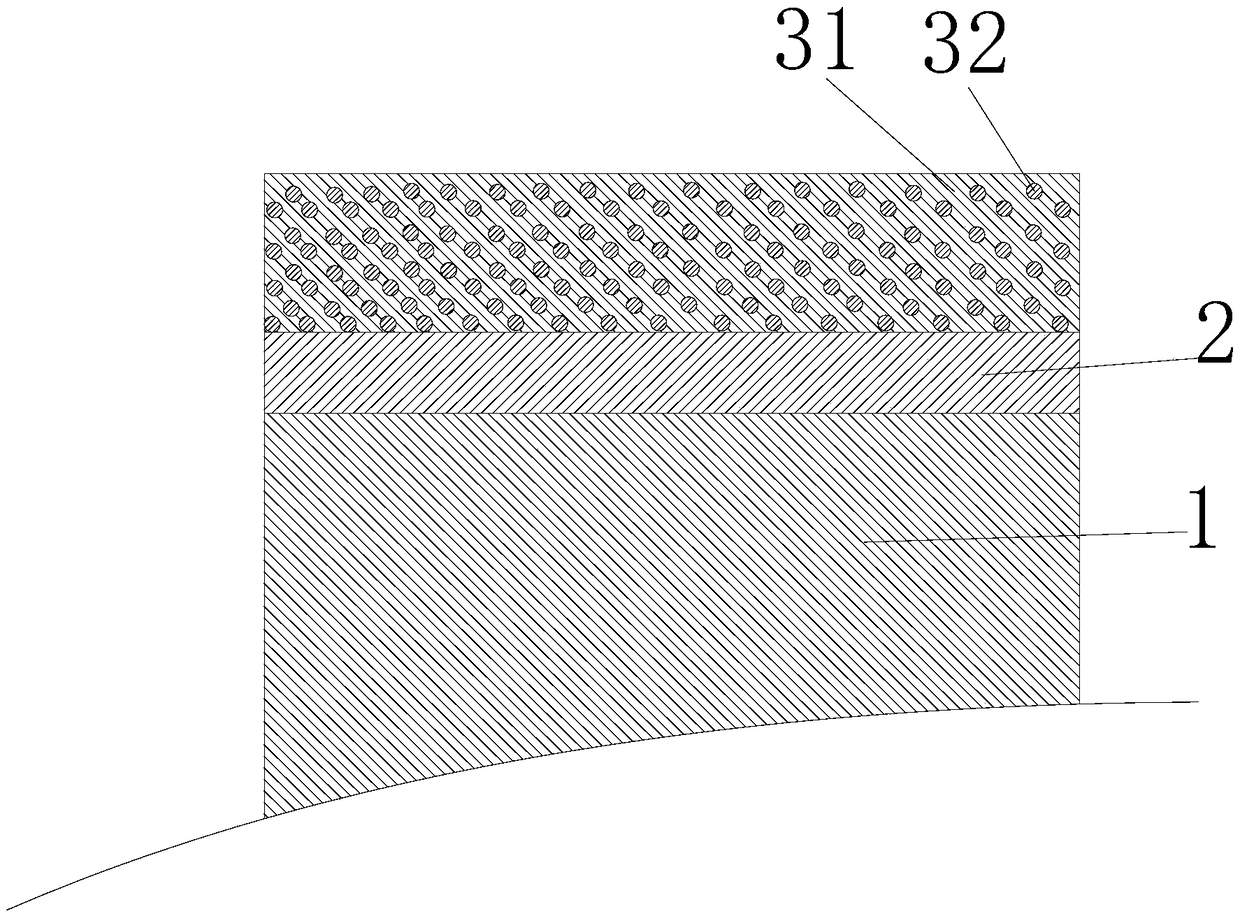

Modified glass fiber winding wire and reinforced composite material prepared from same

ActiveCN114717849AGood dispersionImprove bindingClimate change adaptationFibre treatmentGlass fiberYarn

The invention discloses a modified glass fiber winding wire and a reinforced composite material prepared from the modified glass fiber winding wire, and relates to the technical field of glass fiber reinforced materials. The method is used for solving the technical problems that the heat insulation and compression resistance of the glass fiber winding wires cannot be improved in a continuous treatment mode, and the glass fiber winding wires, thermoplastic resin and auxiliaries are subjected to extrusion injection molding to obtain the composite material with excellent strength, heat insulation and corrosion resistance. According to the modified glass fiber winding wire, the dispersity and interface bonding force of glass fiber yarn are improved through chemical bond grafting; the chemical modifier changes the surface structure of the glass fiber yarn, a rough surface layer structure is formed on the surface of the glass fiber yarn, and hot pressing is performed during heat setting to fully dehumidify and improve the tensile property. According to the reinforced composite material, the moisture-proof heat-preservation middle layer material and the reinforced heat-resisting outer layer material are sequentially coated on the periphery of the reinforced insulation inner layer, and a reinforced composite material finished product with excellent strength, heat insulation and corrosion resistance is obtained through traction and winding.

Owner:五河县维佳复合材料有限公司

Laminated solid wood board and preparation process thereof

ActiveCN114347202AImprove product qualityReduce residual stressWood compressionInsulation improvementSolid woodProcess engineering

The invention discloses a preparation process of a laminated solid wood board, which comprises the following steps: performing one-step polishing treatment on a log board, and performing carbonization treatment to obtain a board A; after dipping maintenance treatment is completed on the plate A, second-step polishing treatment is conducted, and a plate B is obtained; after the board B is coated with an insulating layer, one-step hot pressing treatment is conducted to obtain a board C; after the board C is coated with a waterproof layer, two-step hot pressing treatment is conducted, and a board D is obtained; after veneers are attached in the wood grain direction of the plate D, one-step cold pressing treatment is conducted, and a plate E is obtained; after painting and transfer printing are conducted on the board E, two-step cold pressing treatment and three-step polishing treatment are conducted, and a laminated solid wood board is obtained; a laminated solid board is also disclosed. A specific process system is disclosed, the problem that the comprehensive performance of a conventional laminated solid wood board is affected due to large residual internal stress is solved, in the whole preparation process, the water content of the board is strictly controlled, the internal residual stress of the board is eliminated, the defects of warping, internal cracking and the like of the board are overcome, and the product quality of the board is further improved.

Owner:佳米艾家居(广东)股份有限公司

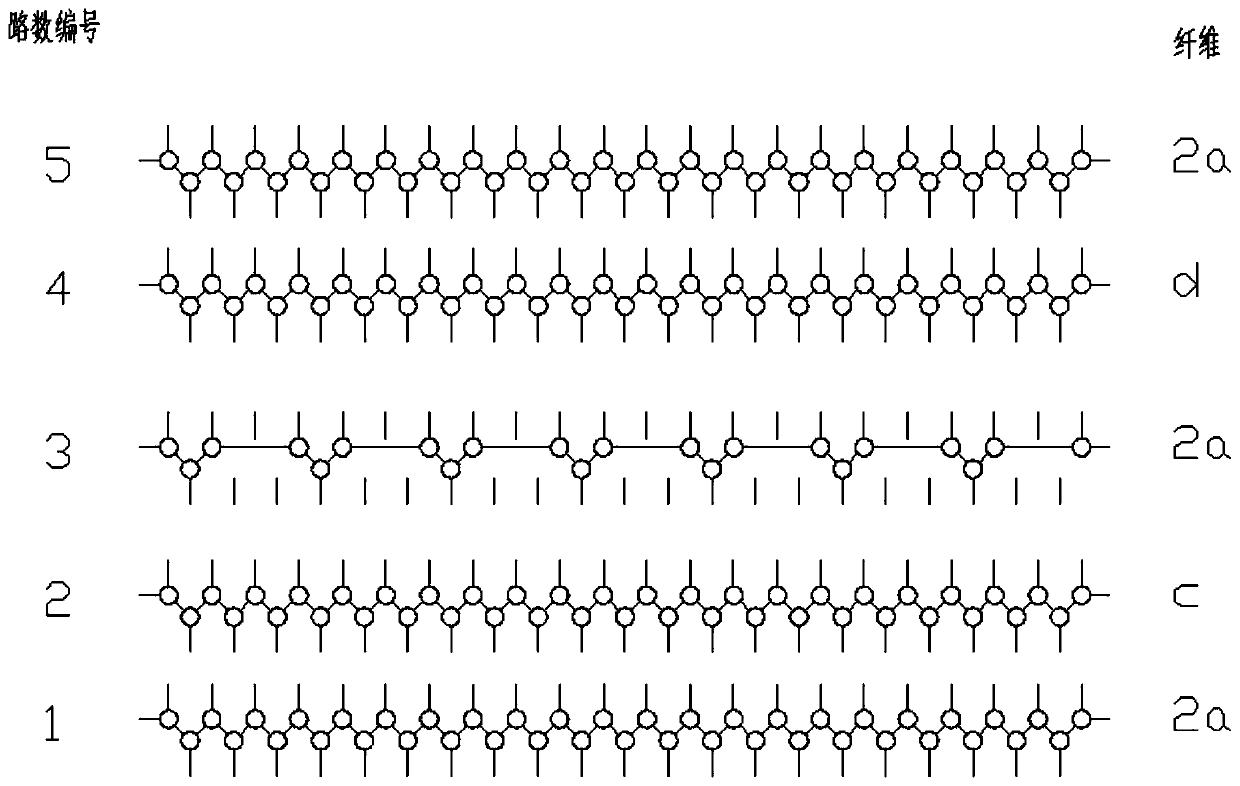

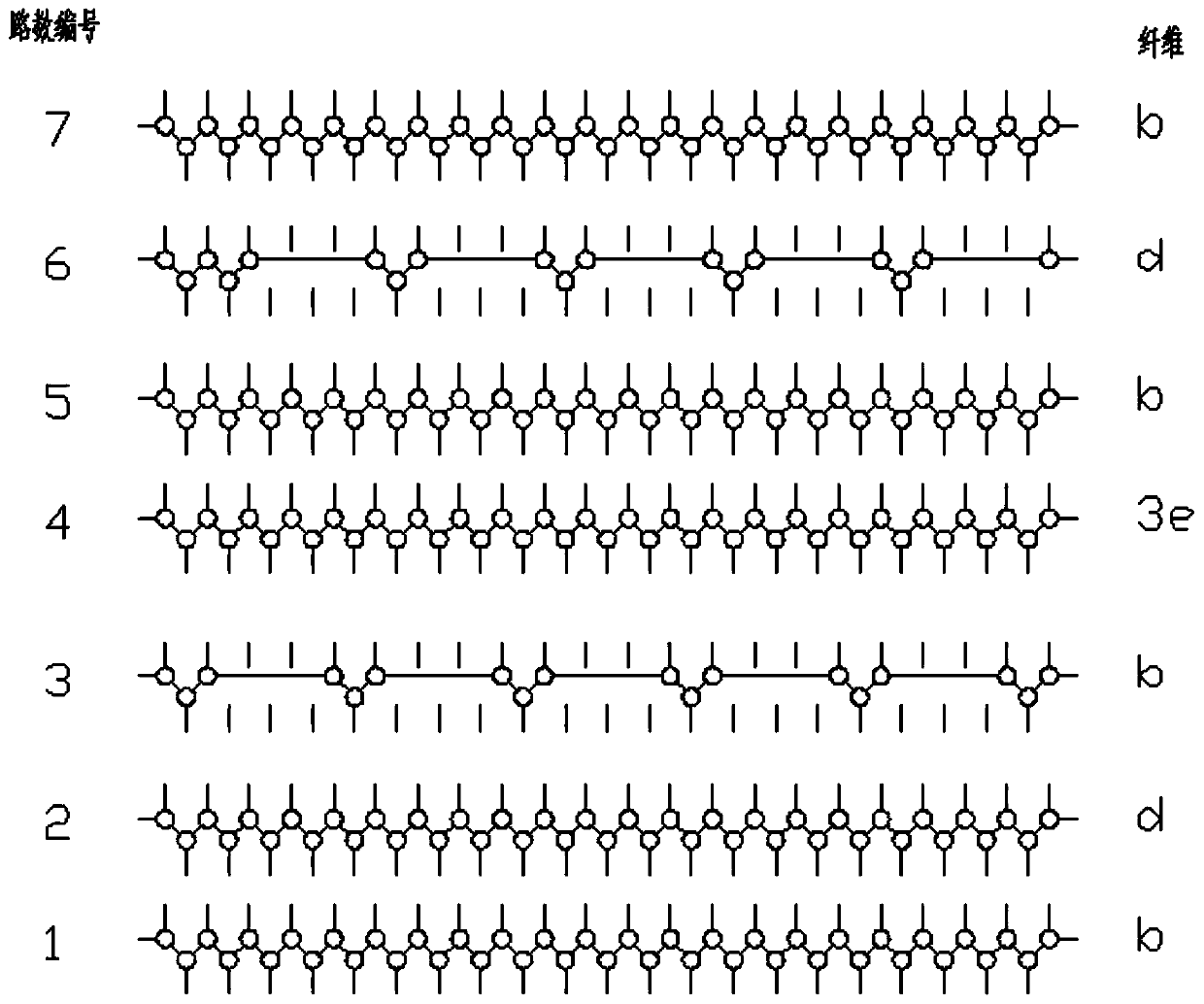

Method for producing heat insulation canvas fabric

ActiveCN110804874AYarn loops are stable and tightReliable operationWeft knittingChemistryCotton thread

The invention relates to a method for producing a heat insulation canvas fabric, which comprises the steps: feeding yarns, clearing, narrowing, guiding out new cotton threads from a yarn guide by knitting needles, laying hemp threads or chemical fibers under needle beards, bending the yarns, and looping, to be specific, selecting the adjacent needles with 1 or 2 needle spacing to involve in knitting; clearing, laying new cotton threads, hemp threads or chemical fibers, and allowing 1 or 2 needles, not selected, between the adjacent needles to stop operating; reserving an old loop in each needle beard, and carrying out repeated knitting via N single weaves to obtain a gray canvas fabric, wherein cotton threads or hemp threads are knitted to odd ones of the N single weaves, chemical fibers are knitted to even ones of the N single weaves, and repeating is performed on every multiples of 3 of the N single weaves until the needle selecting step is reached. After the fabric is dehydrated andheat-set through a glue groove of heat-insulating coating glue, the releasability is small; the fabric surface is flat, defects are reduced, transverse and longitudinal structures are compact, the shrinkage rate is low, the production steps can be decreased, and the heat insulation effect and the stability are improved.

Owner:江苏翔宇工艺编织有限公司

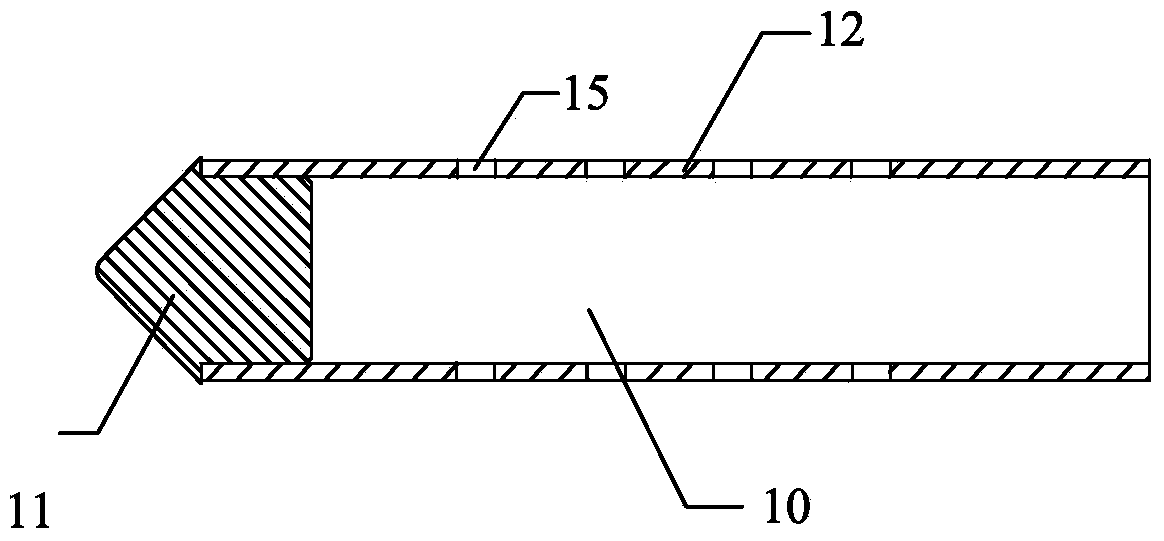

Semi-hard state winding wire and manufacturing method thereof

PendingCN108615576AImprove protectionDoes not affect electrical performancePlastic/resin/waxes insulatorsInsulated cablesPolyesterGlass fiber

The invention discloses a semi-hard state winding wire, which sequentially comprises a conductor, a first insulation layer and a second insulation layer from inside to outside, wherein the first insulation layer adopts a polyamide-imide coating; the second insulation layer adopts mixed fiber formed by polyester fiber and glass fiber through laying to be wrapped on the first insulation layer, pre-heating is firstly carried out, baking is then carried out to enable the polyester fiber to be melted to liquid, the liquid fills pores and the gap of the glass fiber, the mixed fiber forms a non-loosecompact structure and is well attached outside the polyamide-imide coating, and thus, the electrical properties of a product are not influenced even if the product is subjected to friction and knocking. The thickness of a product insulation layer is 0.18 mm to 0.22 mm, and an inorganic content is 22% to 32%. According to the semi-hard state winding wire obtained in the above method, 4a and 4b bending insulation without cracking are achieved, the bending breakdown voltage is no smaller than 1300 V, the linear breakdown voltage is no smaller than 2500V, the insulation layer with 20% stretchingdoes not lose adhesion, 30 min heating in an oven of 180 DEG C and taking out to cool to room temperature for 6a and 6b bending are carried out, the insulation layer does not crack, the insulation stability is excellent, and the conductivity is no smaller than 100%IACS.

Owner:SUZHOU GUANLONG MAGNET WIRE

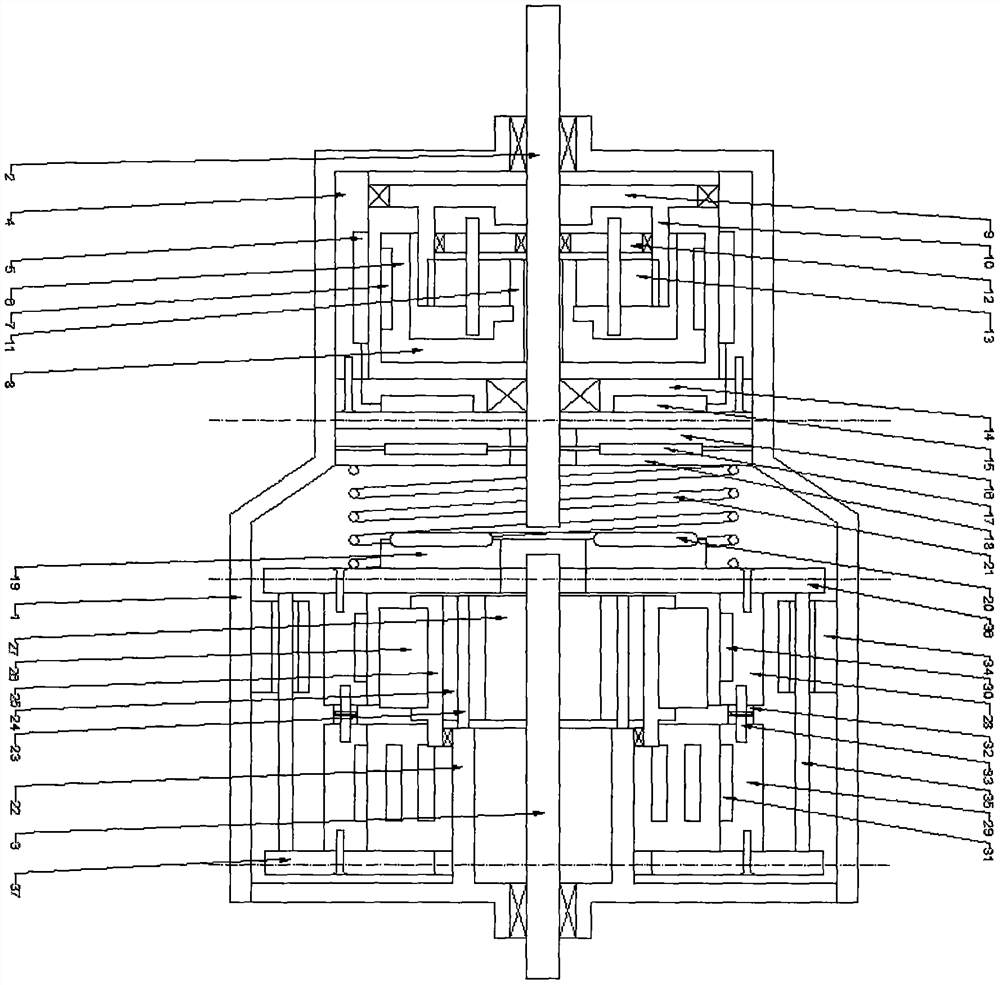

Built-in differential mechanism of new energy automobile motor

PendingCN112693308AStable structureImprove unityElectric propulsion mountingControl devicesStatorElectrical and Electronics engineering

The invention relates to a built-in differential mechanism of a new energy automobile motor. The built-in differential mechanism comprises a differential mechanism shell, a right output shaft and a left output shaft are rotatably connected to the two ends of the differential mechanism shell respectively, and a right output assembly, a floating connection assembly and a left output assembly are sequentially arranged in the differential mechanism shell; the floating connection assembly comprises a magnetic floating assembly and a torque conversion assembly; and a drive circuit is also included. Two groups of permanent magnets and stator windings which are symmetrically arranged are utilized to realize equal-speed and equal-torque output of double wheels when a vehicle is in a common mode, and when the vehicle is trapped or slips, an iron core for wheel output can be switched by controlling an output circuit on the premise that power supply is not cut off, that is, wheel power is not lost. The two groups of stator windings connected in parallel are switched into the two groups of stator windings connected in series, and the current in a series circuit is equal, so that the two groups of stator windings can be forced to work under the same working condition.

Owner:WUXI OPEN UNIV

Bipolar electrostatic chuck

InactiveCN100470755CImprove insulation stabilityImprove reliabilitySemiconductor/solid-state device manufacturingElectrostatic holding devicesDielectric breakdown strengthDepth direction

A bipolar electrostatic chuck which has excellent dielectric breakdown strength and provides excellent attracting performance. The bipolar electrostatic chuck eliminates difficulty in peeling off a sample from a sample attracting plane as much as possible after application of a voltage to electrodes is finished. The bipolar electrostatic chuck is provided with a first electrode and a second electrode in an insulator and permits a surface of the insulator to be the sample attracting plane. The insulator has the first electrode, an interelectrode insulating layer and the second electrode in this order from the sample attracting plane in the depth direction. The second electrode has a region not overlapping with the first electrode in a normal line direction of the sample attracting plane.

Owner:CREATIVE TECH CORP

Thermal insulation material for building

InactiveCN109896821AImprove insulation stabilityImprove adhesionClimate change adaptationHeat proofingGypsumThermal insulation

The invention relates to a thermal insulation material for a building. The thermal insulation material comprises a base body and a thermal insulation layer which is arranged on the surface of the basebody, wherein the base body consists of cement, high-adhesive attapulgite clay, building gypsum, carbon fibers, water glass and polystyrene particles, the thermal insulation layer is applied to the base body, and the surface of the thermal insulation layer is provided with a waterproof layer. According to the thermal insulation material provided by the invention, the raw materials are reasonablyselected, the formed thermal insulation material is arranged as a plurality of layers including the base body, the thermal insulation layer and the waterproof layer, and actual tests show that very good thermal insulation performance is realized; at the same time, a certain change is made to a thermal insulation product formed by the thermal insulation material, so that the polystyrene particles protrude from the base body to improve the adhesion between the base body and the thermal insulation layer, thereby further improving the heat preservation stability of the thermal insulation material,so that the thermal insulation material can keep stable performance for a longer time, and a very good practical effect is achieved.

Owner:江苏鞍重重工有限公司

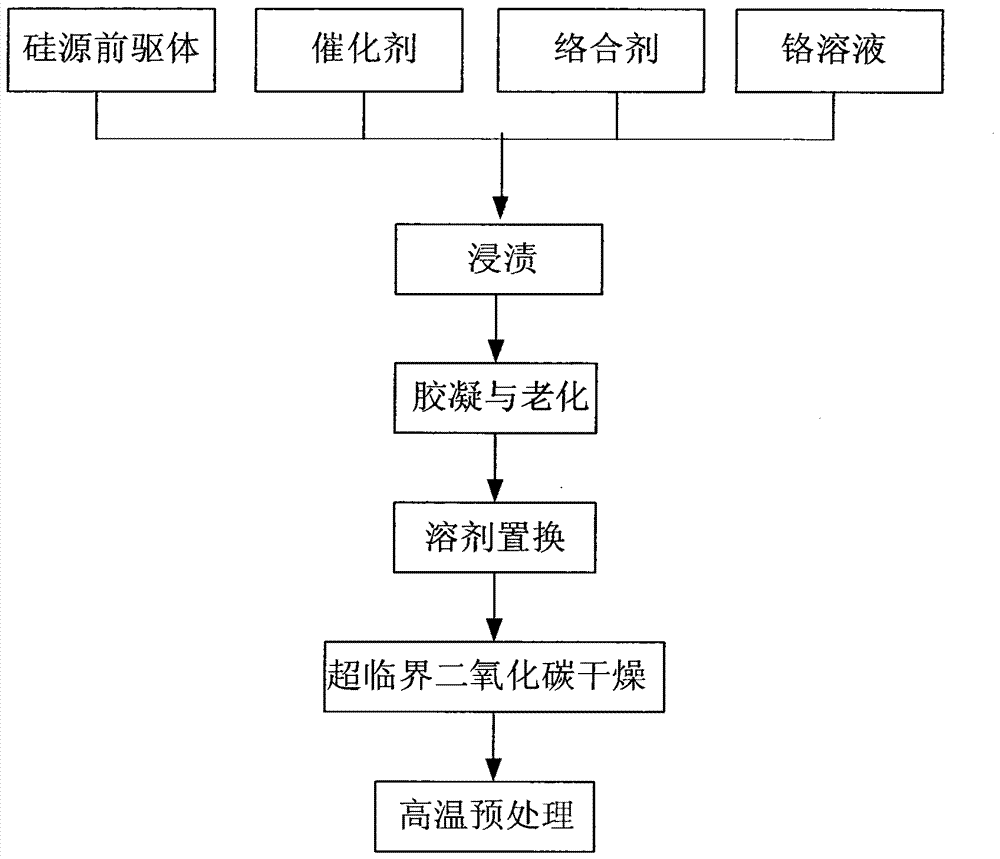

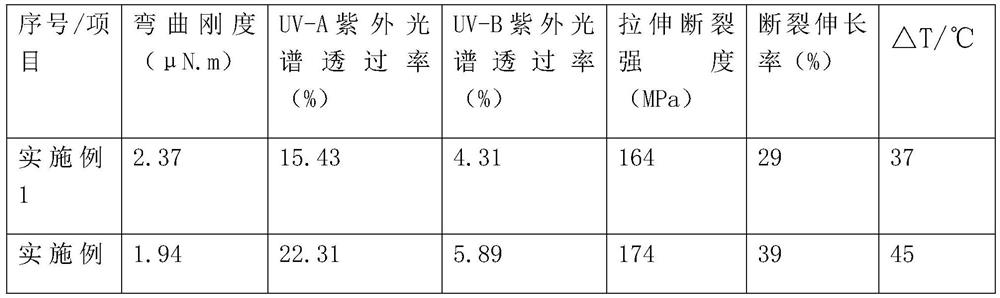

a cr 2 o 3 Doped silica airgel material and preparation method thereof

The invention provides a Cr2O3 doped silicon dioxide aerogel material and a preparation method thereof. The preparation method of the Cr2O3 doped silicon dioxide aerogel material comprises the following steps: taking a silicon source as a precursor, adopting an inorganic compound containing the Cr element and an organic compound as doping ions, mixing the compounds with a solvent, a complexing agent and a catalyst to form a composite sol, conducting impregnation technology to be compounded with reinforced fibers, carrying out gelatinizing, ageing, solvent replacement, supercritical carbon dioxide drying, high-temperature pretreatment and other technologies to obtain the product. The preparation method disclosed by the invention is to conduct metal Cr doping and modification on the aerogel through a complexing-gelatinizing method, skillfully combine the complexing reaction with the gelatinizing reaction to increase the complexing force of the metal Cr doping ions in the gel system, effectively restrain the phenomenon that the Cr is not uniform in distribution as the Cr ions are migrated during the follow-up treatment process of the gel, so that the diffusion effect of the complexing-gelatinizing method is uniform and stable, and the complexing-gelatinizing method is better than the in-situ doping method. The aerogel obtained by the complexing-gelatinizing method is treated in advance at high temperature, so as to enable the internal reaction to be conducted thoroughly under high-temperature action, then transform the aerogel to be the Cr2O3 doped stable aerogel structure, and facilitate the pore structure and the heat-insulating property to be stable.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

A kind of production method of heat insulating canvas fabric

The invention relates to a production method of a heat-insulating canvas fabric. The production method is as follows: yarn feeding, loop withdrawal, needle narrowing, knitting needles leading out new cotton thread, hemp thread or chemical fiber from the yarn guide and inserting it under the needle hook, bending the yarn, forming The adjacent knitting needles with an interval of 1 or 2 needles are selected to participate in knitting. The circle is withdrawn and new cotton thread, hemp thread or chemical fiber is padded. The 1 or 2 needles between the adjacent knitting needles are not selected and quit the work, so that the old The coil is kept in the needle hook, and the canvas blank is obtained by circular weaving with N-way single-way weaves. The odd number of N-way single-way weaves is woven with cotton thread or hemp thread, and the even number of N-way single-way weaves is woven with chemical fiber. N-way single-way Repeat every 3 multiples of the tissue to the needle selection step, pass through the glue tank of the heat-insulating coating glue, and then dehydrate and heat-set, with less dispersibility, smooth fabric surface, lower defect rate, tight horizontal and vertical structure, and small shrinkage rate , can reduce the production process, improve the heat insulation effect and stability.

Owner:江苏翔宇工艺编织有限公司

A kind of flux for lead-free solder and preparation method thereof

ActiveCN103286477BHigh activityImprove solubilityWelding/cutting media/materialsSoldering mediaEnvironmental resistanceSolvent

The invention relates to soldering flux for lead-free solder and a preparation method of the soldering flux. The soldering flux comprises, by mass, 2.0-4.0% of activating agent, 0.05-0.5% of surfactant, 0.4-1.0% of film-forming agent, 18-30% of cosolvent, 0.1-0.4% of corrosion inhibitor and the balance deionized water. The soldering flux is free of rosin and less than 3% in solid content, so that solid residual quantity is less during soldering, ionic contamination degree is low, and cleaning is avoided after soldering. By using the deionized water as solvent, the water-soluble no-clean soldering flux is colorless, transparent, free of pungent smell, easy in raw material getting approach and low in cost. Activating components in the soldering flux are halogen-free, so that insulativity of a soldered circuit board is improved; by the aid of the film-forming agent, a dense protecting film is formed on the surface of the circuit board after the film-forming agent is subjected to a soldering procedure, and accordingly, electromigration of soldered residues is lowered, and insulation stability of the circuit board is improved effectively; and harm caused when organic soldering flux is used for soldering can be reduced, and the soldering flux meets the environment-friendly requirements.

Owner:CENT SOUTH UNIV

A kind of flux and preparation method thereof

ActiveCN107150190BLess residueHigh insulation resistanceWelding/cutting media/materialsSoldering mediaFatty amineSolvent

The invention discloses a novel soldering flux which is prepared from the following raw materials in parts by weight: 1 to 2 parts of hexadecylsulfonic acid, 0.8 to 1.7 parts of fatty amine polyoxyethylene ether, 12 to 18 parts of a hydrazine hydroxycarboxylic acid compound, 3 to 5 parts of ammonia chloride, 17 to 26 parts of modified rosin, 2 to 4 parts of an activator, 0.5 to 1.5 parts of a surfactant, 0.6 to 1.3 parts of a film forming agent, 2 to 3 parts of a corrosion inhibitor, 0.6 to 1 part of an anti-oxidization agent and 35 to 65 parts of deionized water. According to the novel soldering flux, the deionized water is used as a solvent, so that the production cost is reduced, and the aims of environmental protection, stabilization and safety are fulfilled; and the novel soldering flux is high in adaptability to lead-free welding. Due to the relatively low solid content, a few of residues are retained after the novel soldering flux assists in soldering; the novel soldering flux is high in insulation resistance and meets the no-cleaning requirement.

Owner:湖南省东安夏力焊材有限公司

Superfine denier acrylic fiber and wool blended yarn and preparation method thereof

ActiveCN111636126AFunction increaseReduce the probability of exposureLubricating devicesFibre mixingTextile technologyPolymer science

The invention belongs to the technical field of textiles, and particularly relates to a superfine denier acrylic fiber and wool blended yarn and a preparation method thereof. The blended yarn comprises the raw material components of, in percentage by mass, 60%-70% of superfine denier acrylic fibers and 30%-40% of wool, and the preparation method comprises the steps that B412 worsted sliver mixingis conducted twice; B432 is worsted for the first time; B432 is worsted two needles; the B442 is worsted three needles; B452 is worsted four needles; FB461 is worsted six needles; FB441 roving is prepared; spinning is prepared; a AC6 automatic winder carries out spooling; FA705 is subjected to high doubling; VTS-08 is subjected to Saurer two-for-one twisting. According to the superfine denier acrylic fiber and wool blended yarn and the preparation method thereof, the yarn is high in strength and has good anti-radiation, anti-static, deodorizing, antibacterial and waterproof performance.

Owner:JIANGYIN HAOYE TEXTILE

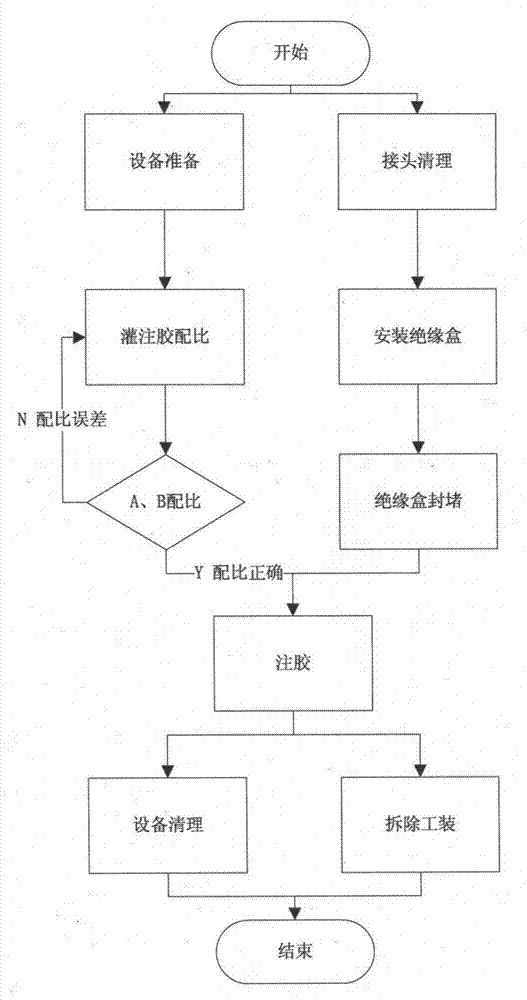

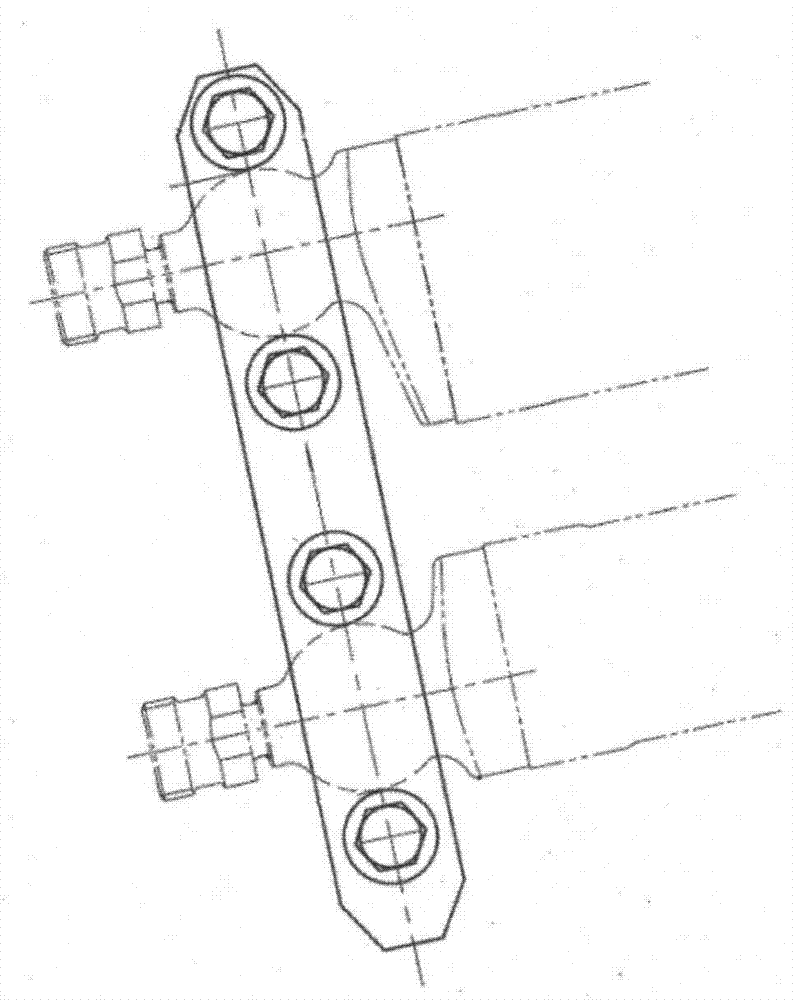

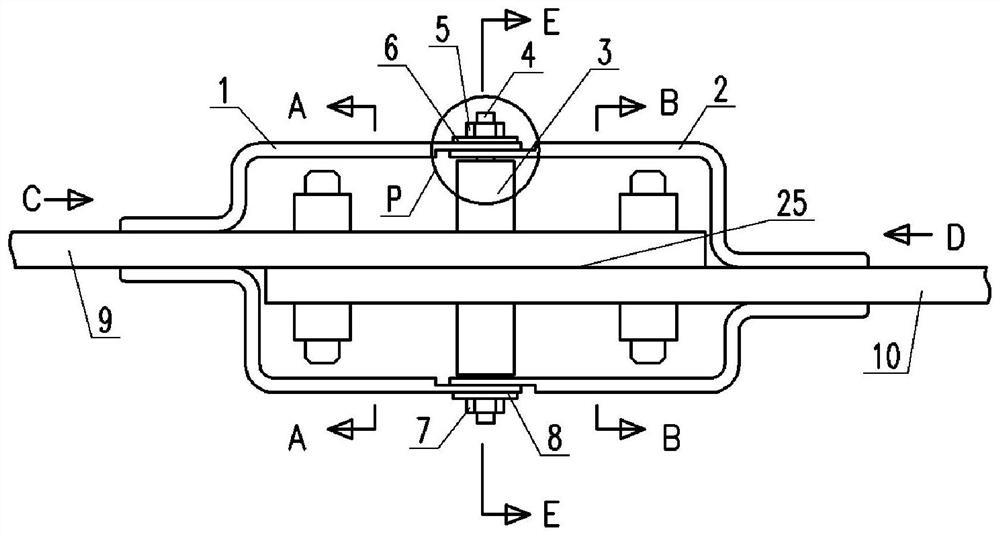

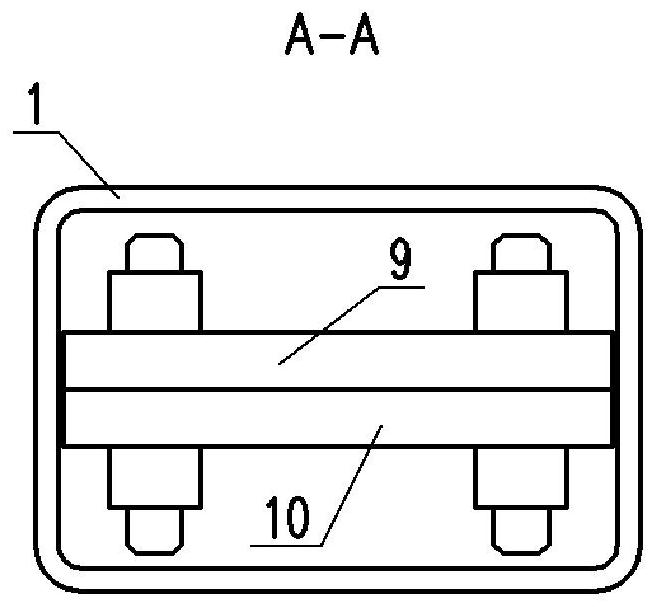

A method for filling the insulation box at the end of a generator with glue

ActiveCN103546000BImprove insulation performanceImprove insulation stabilityApplying solid insulationRoom temperatureEngineering

The invention provides an epoxy potting method for an insulation box on an end portion of an electric generator. The method includes the steps of closing a connector through the mica insulation box and a tool, sealing the seam between the mica insulation box and the tool through epoxy putty, forming epoxy injection holes in the mica insulation box in advance, injecting potted epoxy into the epoxy injection holes through an epoxy potting device, solidifying the potted epoxy at the room temperature, and enabling the mica insulation box and the potted epoxy to form a whole after the tool is removed. The method overcomes the detects in the prior art, the insulation box obtained through the method is reliable in performance and simple in structure, production efficiency can be improved, labor intensity can be lowered, and the insulation effect is ensured.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

Hydro-generator box sleeve type all-insulation isolation protection device

ActiveCN113178838AReduced risk of corrosionImprove insulation stabilityHydro energy generationCable junctionsStructural engineeringUltimate tensile strength

The invention discloses a hydro-generator box sleeve type all-insulation isolation protection device which is composed of an upper insulation shell, a lower insulation shell, an insulation sleeve, an insulation double-end stud, a locking nut A, an insulation spacer A, a locking nut B and an insulation spacer B. The hydro-generator box sleeve type all-insulation isolation protection device performs all-covering type insulation protection on the connection position of a main outgoing line of a hydro-generator, so that the insulation level at the position is effectively improved, and the local corrosion at the joint of the main outgoing line is prevented. Meanwhile, an exoskeleton type structural support can be formed, so that the structural strength at the joint of the main outgoing line is enhanced, the silver welding surface at the joint of the main outgoing line can be fixed and protected, the local cracking of the silver welding surface caused by external force impact is prevented, and the deformation risk of the main outgoing line caused by external bumping can be effectively blocked. The hydro-generator box sleeve type all-insulation isolation protection device has the characteristics of being simple in structure, being convenient to mount and dismount, being low in cost and good in stability and the like.

Owner:HARBIN ELECTRIC MASCH CO LTD

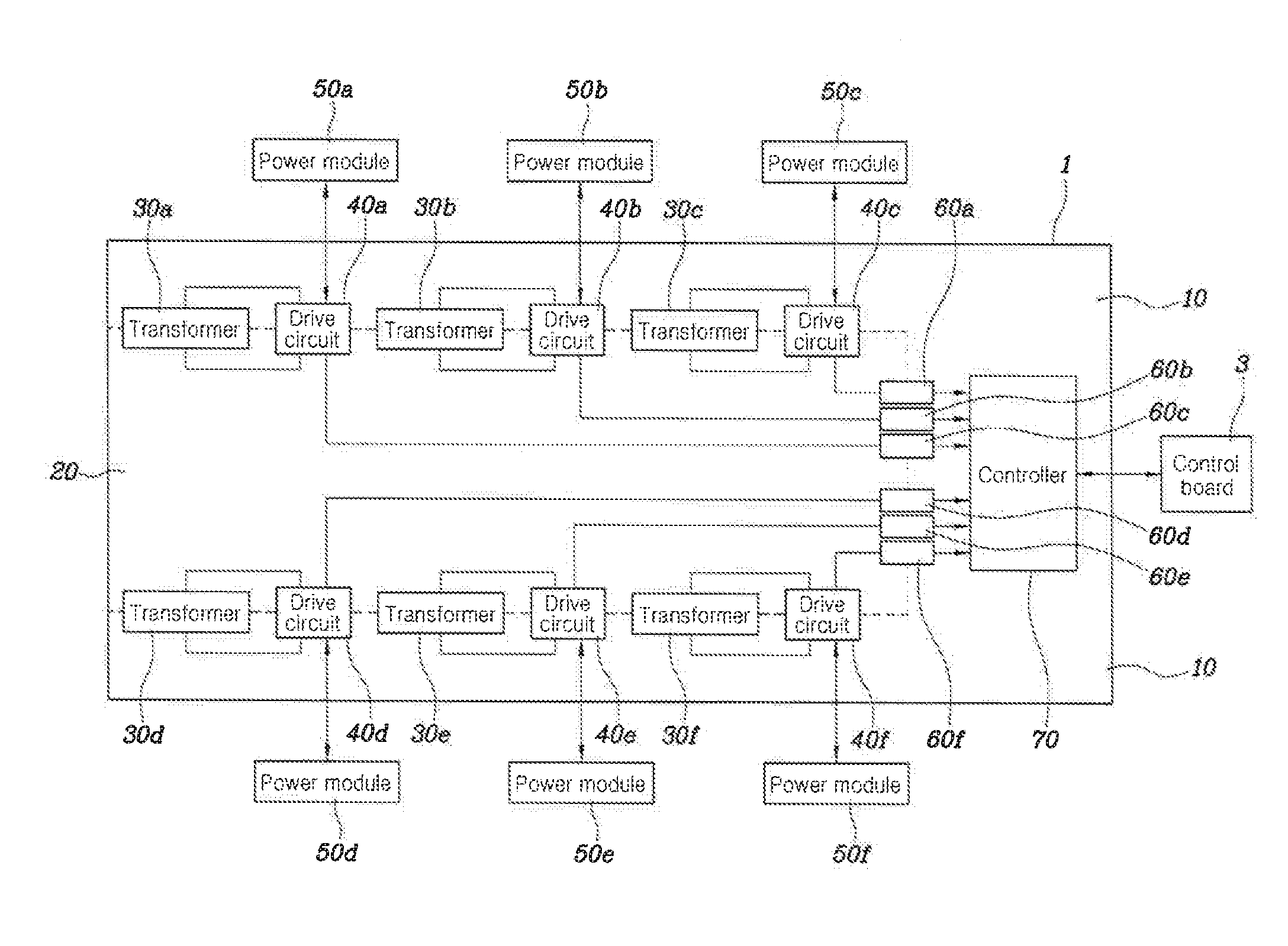

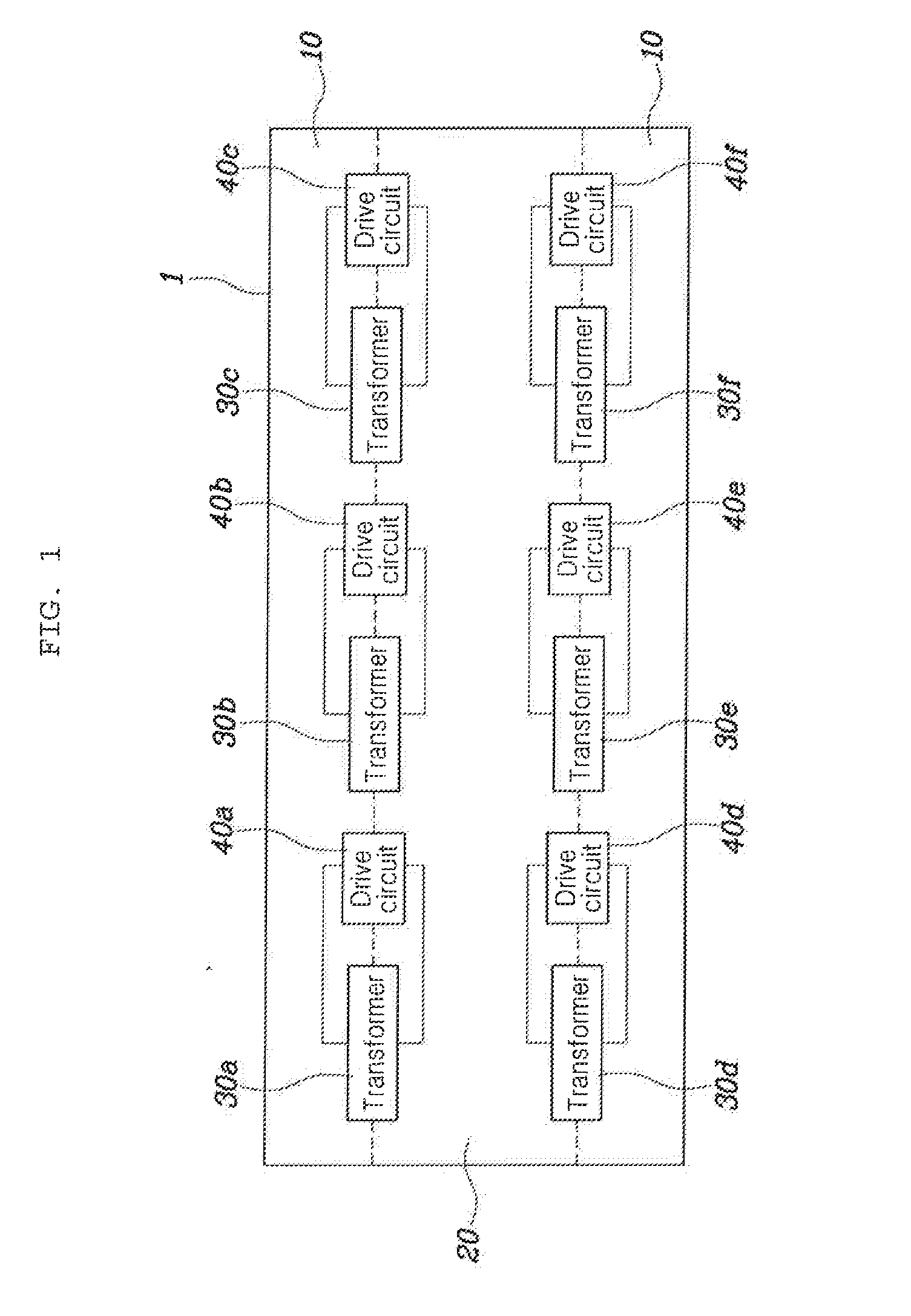

Inverter gate board

InactiveUS20150349623A1Improve insulation stabilityImprove stabilityElectric signal transmission systemsConversion constructional detailsSurface mountingLow voltage

An inverter gate board divided into a low-voltage region and a high-voltage region includes a plurality of drive circuits surface-mounted between the low-voltage region and the high-voltage region, each having a single main power source (SMPS) controller, and a plurality of transformers surface-mounted between the low-voltage region and the high-voltage region so as to supply a transformed voltage to each of the plurality of drive circuits, respectively.

Owner:HYUNDAI MOTOR CO LTD

Novel armored cable

InactiveCN104425065AImprove insulation stabilityHigh tensile strengthInsulated cablesInsulated conductorsEngineeringCompressive strength

The invention relates to a novel armored cable. The novel armored cable comprises five insulated cable cores, wherein a wrapping tape layer is wound outside the insulated cable cores, an inner sheath layer is extruded outside the wrapping tape layer, a steel wire armor layer in the same direction of the insulated cable cores is arranged outside the inner sheath layer, an outer sheath layer is extruded outside the steel wire armor layer and filling layers are arranged in gaps in the wrapping tape layer. The insulation stability of the cross-linked polyethylene insulating layers and the silicon rubber outer sheath layer is good, the tensile strength and compressive strength of the galvanized medium-carbon steel wire armor layer are high, the bending radius is large, the novel armored cable can be effectively prevented from being bitten by animals such as mice, and the service life is long.

Owner:WUXI YIXIANG CABLE

Composite material used for shell of automotive relay and preparation method thereof

The invention discloses a composite material used for a shell of an automotive relay. The composite material is composed of, by weight, 100-130 parts of epoxy resin E40, 2-3 parts of polytetrahydrofuran ether glycol, 10-12 parts of calcium powder, 0.7-1 part of ethoxylated alkylphenol ammonia sulfate, 0.1-0.2 parts of hexamethyl cyclotrisiloxane, 6-9 parts of maleic anhydride, 0.1-0.5 parts of dicumyl peroxide, 17-20 parts of 3-(trifluoromethyl)diphenylketone, 2-3 parts of hydroquinone, 0.1-0.4 parts of 2-thiolbenzimidazole, 1-1.5 parts of nano silicon dioxide, 1-2 parts of sodium tripolyphosphate, 1-1.3 parts of aluminum dihydrogen phosphate, 0.02-0.1 parts of magnesium oxide, 1-2 parts of zinc stearate, 0.5-0.7 parts of meso-benzene polyester, and 0.1-0.3 parts of erucyl amide. The resin material has good toughness and anti-impact property, is high in surface strength, is waterproofing and is good in anti-corrosion performance, has strong protective performance on a relay and is stable in insulation stability. Through anhydride grafting reaction, dispersibility of the fillers in the resin is effectively improved, thereby improving comprehensive performances of the finish product material.

Owner:宁波永的电子科技有限公司

A kind of durable automobile window sealing strip inspection tool preparation process

The invention discloses a preparation process of a durable inspection tool for automobile window sealing strips, which includes the process steps of material selection of the inspection tool-parts processing and molding-surface treatment-assembly process; after the invention is fixed by a clamping device, the After finishing the deburring and grinding treatment, there is no need to reinstall and reinstall after changing the position. The rotation and adjustment of the position is completed through the control of the foot switch, which is efficient and flexible in operation; at the same time, the parts are painted before assembly. Most of the harmful substances will be volatilized, and the paint will be cracked under high temperature conditions, so that the toxic substances can be fully volatilized, and it can be used after the later assembly is completed, which enhances the overall non-stickiness, heat resistance, sliding properties, and Moisture resistance, wear resistance, corrosion resistance and other properties, while the topcoat has better moisture resistance, wear resistance and corrosion resistance than ordinary paint.

Owner:江苏雨顺自动化科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com