A kind of production method of heat insulating canvas fabric

A production method and canvas technology, which can be used in knitting, weft knitting, textiles and paper making, etc., can solve the problems of poor fit between insulating materials and canvas fabric surface materials, affecting the bending properties of canvas fabrics, and increasing fabric costs. , to facilitate dipping and film formation, improve thermal insulation effect and stability, and improve thermal insulation stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A production method of heat-insulating canvas fabric, the production method is as follows:

[0034] (1) Yarn feeding: the cotton thread and chemical fiber are sent to the weaving area of the weaving machine by traction;

[0035] (2) Knitting back: the knitting needle rises, and the sinker throat of the knitting machine holds the old coil, so that the old coil is detached from the needle hook to the needle bar;

[0036] (3) Narrowing: the knitting needle retreats from the highest point to the narrowing plane, and retracts the cotton thread, hemp thread or chemical fiber transferred to the needle knitting arc due to the retraction;

[0037] (4) Laying yarn: the yarn guide edge of the knitting machine is located between the knitting needle and the nose of the sinker, and the knitting needle draws new cotton thread, hemp thread or chemical fiber from the yarn guide and inserts it under the needle hook;

[0038] (5) Yarn bending: the knitting needle descends so that the n...

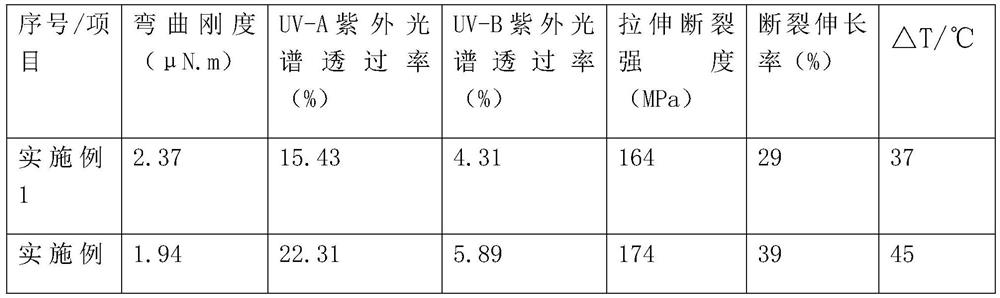

Embodiment 2

[0051] A production method of heat-insulating canvas fabric, the production method is as follows:

[0052] (1) Yarn feeding: the hemp thread and chemical fiber are sent to the weaving area of the weaving machine by traction;

[0053] (2) Knitting back: the knitting needle rises, and the sinker throat of the knitting machine holds the old coil, so that the old coil is detached from the needle hook to the needle bar;

[0054] (3) Narrowing: the knitting needle retreats from the highest point to the narrowing plane, and retracts the cotton thread, hemp thread or chemical fiber transferred to the needle knitting arc due to the retraction;

[0055] (4) Laying yarn: the yarn guide edge of the knitting machine is located between the knitting needle and the nose of the sinker, and the knitting needle draws new cotton thread, hemp thread or chemical fiber from the yarn guide and inserts it under the needle hook;

[0056] (5) Yarn bending: the knitting needle descends so that the nee...

Embodiment 3

[0070] A production method of heat-insulating canvas fabric, the production method is as follows:

[0071] (1) Yarn feeding: the cotton thread and chemical fiber are sent to the weaving area of the weaving machine by traction;

[0072] (2) Knitting back: the knitting needle rises, and the sinker throat of the knitting machine holds the old coil, so that the old coil is detached from the needle hook to the needle bar;

[0073] (3) Narrowing: the knitting needle retreats from the highest point to the narrowing plane, and retracts the cotton thread, hemp thread or chemical fiber transferred to the needle knitting arc due to the retraction;

[0074] (4) Laying yarn: the yarn guide edge of the knitting machine is located between the knitting needle and the nose of the sinker, and the knitting needle draws new cotton thread, hemp thread or chemical fiber from the yarn guide and inserts it under the needle hook;

[0075] (5) Yarn bending: the knitting needle descends so that the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com