Semi-hard state winding wire and manufacturing method thereof

A winding wire, semi-hard technology, applied in plastic/resin/wax insulators, organic insulators, conductors, etc., can solve the problems of poor application process, poor electrical performance of products, poor electrical conductivity, etc., to achieve good solvent resistance, Excellent insulation stability and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] a. Add 0.08wt% pure silver of the copper mass to the copper with a purity of 99.90% for smelting, and then draw it up into a soft copper rod;

[0072] b. Rolling the above soft copper rod;

[0073] c. The die is physically drawn to the blank size;

[0074] d. Copper wire winding;

[0075] e. Perform bright oxygen-free annealing on the coiled copper wire;

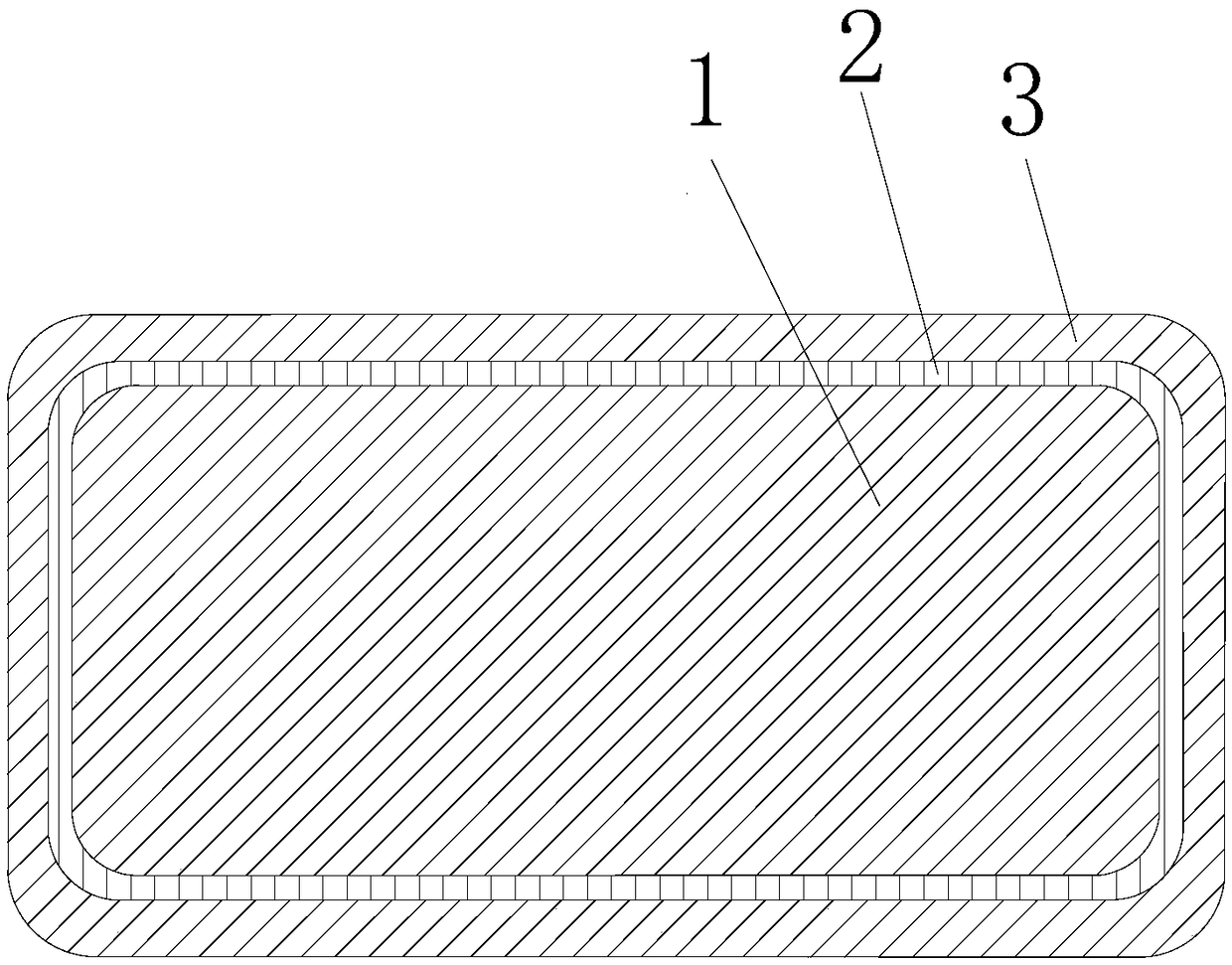

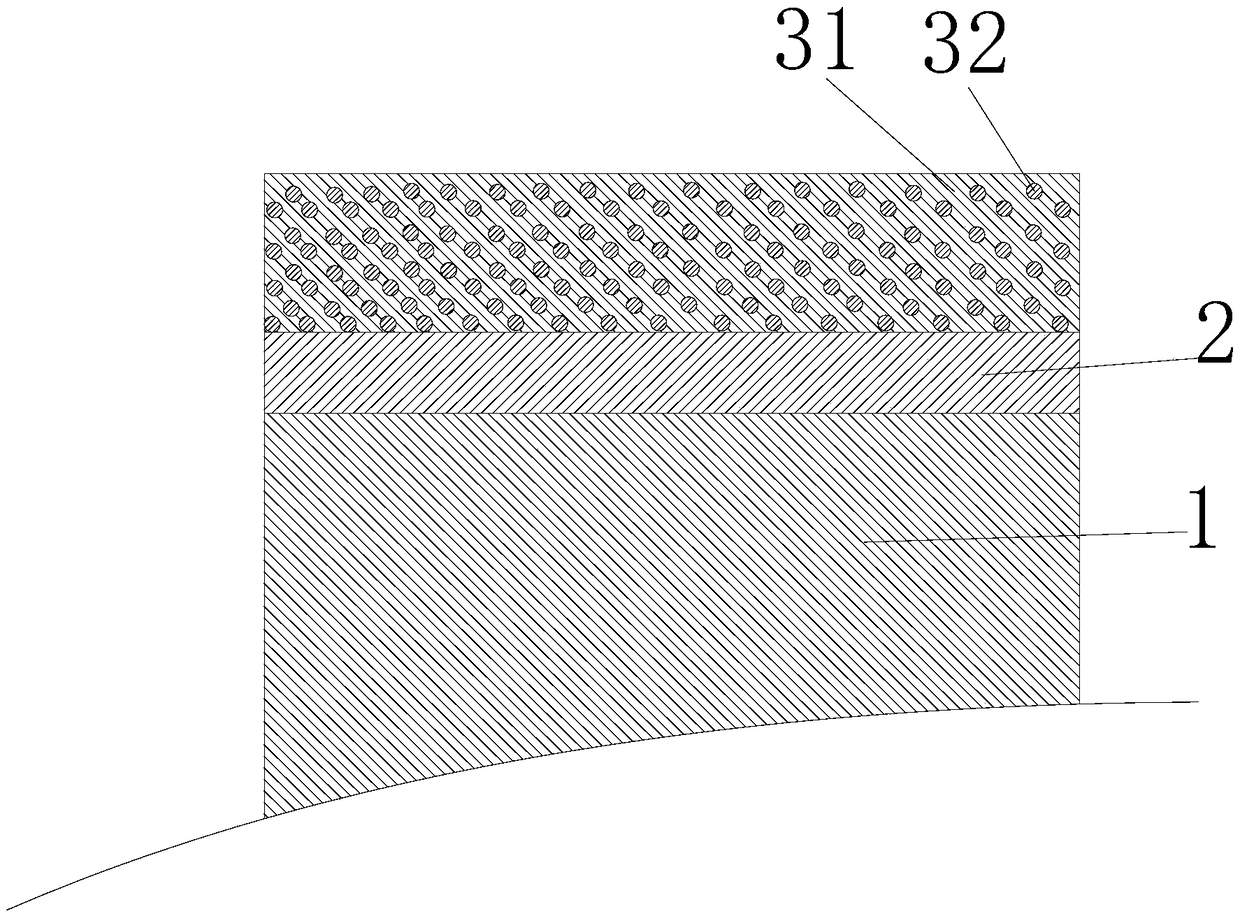

[0076] f. The mold is physically drawn to the final size to obtain a rectangular rectangular bare conductor 1. The thickness of the conductor 1 is 0.5mm, the width is 2mm, and the radius of the arc is 0.36mm;

[0077] g. Use ultrasonic cleaning to blow dry the obtained rectangular rectangular wire bare conductor 1 to prepare for subsequent insulation coating work;

[0078] h. Use a paint scraping mold to coat the polyamide-imide insulating varnish on the rectangular rectangular wire bare conductor 1 to form a coating;

[0079] i. Oven radiation drying;

[0080] Steps h and i are repeated 10 times to make the thickness of the polyam...

Embodiment 2

[0085] a. Add 0.10wt% pure silver of the copper mass to the red copper with a purity of 99.90% for smelting, and then draw it up into a soft copper rod;

[0086] b. Rolling the above soft copper rod;

[0087] c. The die is physically drawn to the blank size;

[0088] d. Copper wire winding;

[0089] e. Perform bright oxygen-free annealing on the coiled copper wire;

[0090] f. The mold is physically drawn to the final size to obtain a rectangular rectangular wire bare conductor 1. The thickness of the conductor 1 is 2.0mm, the width is 5mm, and the radius of the arc is 0.81mm;

[0091] g. The obtained rectangular rectangular wire bare conductor 1 is cleaned and dried by ultrasonic to prepare for the subsequent insulation coating work;

[0092] h. Use a paint scraper to coat the polyamide-imide insulating varnish on the rectangular rectangular wire bare conductor 1 to form a coating;

[0093] i. Oven radiation drying;

[0094] Steps h and i are repeated 10 times to make the thickness of the ...

Embodiment 3

[0099] a. Add 0.12wt% pure silver of the copper mass to the red copper with a purity of 99.90% for smelting, and then draw it up into a soft copper rod;

[0100] b. Rolling the above soft copper rod;

[0101] c. The die is physically drawn to the blank size;

[0102] d. Copper wire winding;

[0103] e. Perform bright oxygen-free annealing on the coiled copper wire;

[0104] f. The mold is physically drawn to the final size to obtain a rectangular rectangular bare conductor 1. The thickness of the conductor 1 is 3.5mm, the width is 8mm, and the radius of the arc is 1.25mm;

[0105] g. The obtained rectangular rectangular wire bare conductor 1 is cleaned and dried by ultrasonic to prepare for the subsequent insulation coating work;

[0106] h. Use a paint scraping mold to coat the polyamide-imide insulating varnish on the rectangular rectangular wire bare conductor 1 to form a coating;

[0107] i. Oven radiation drying;

[0108] Steps h and i are repeated 10 times to make the thickness of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com