Hall circuit board fixing structure

A technology for fixing structures and circuit boards, applied in structural connections, shape/style/structure of winding insulation, electrical components, etc., can solve problems such as inconvenient installation methods, cumbersome processes, and low efficiency, and achieve fast installation speed and reduce obstacles Interference and cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

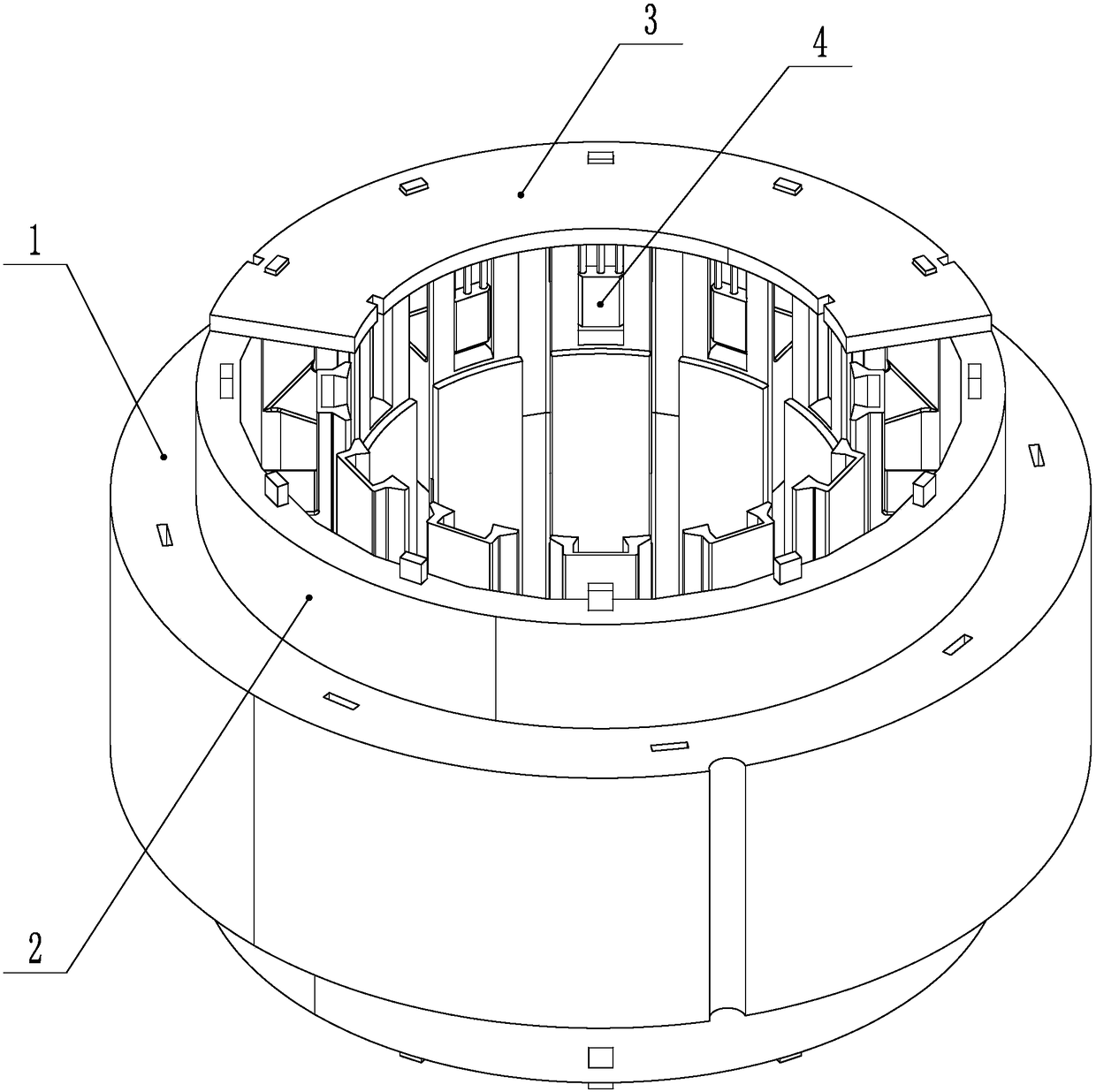

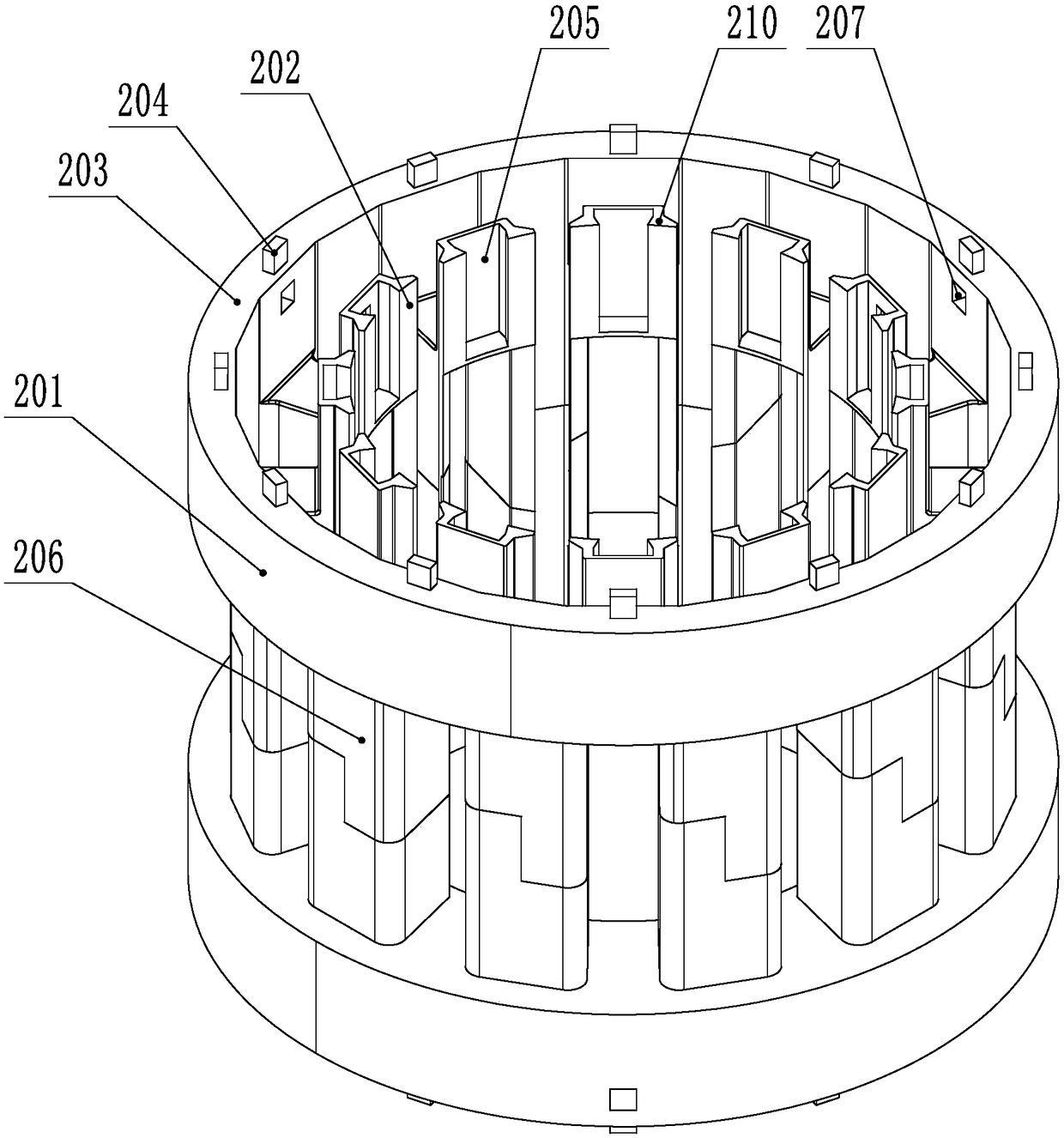

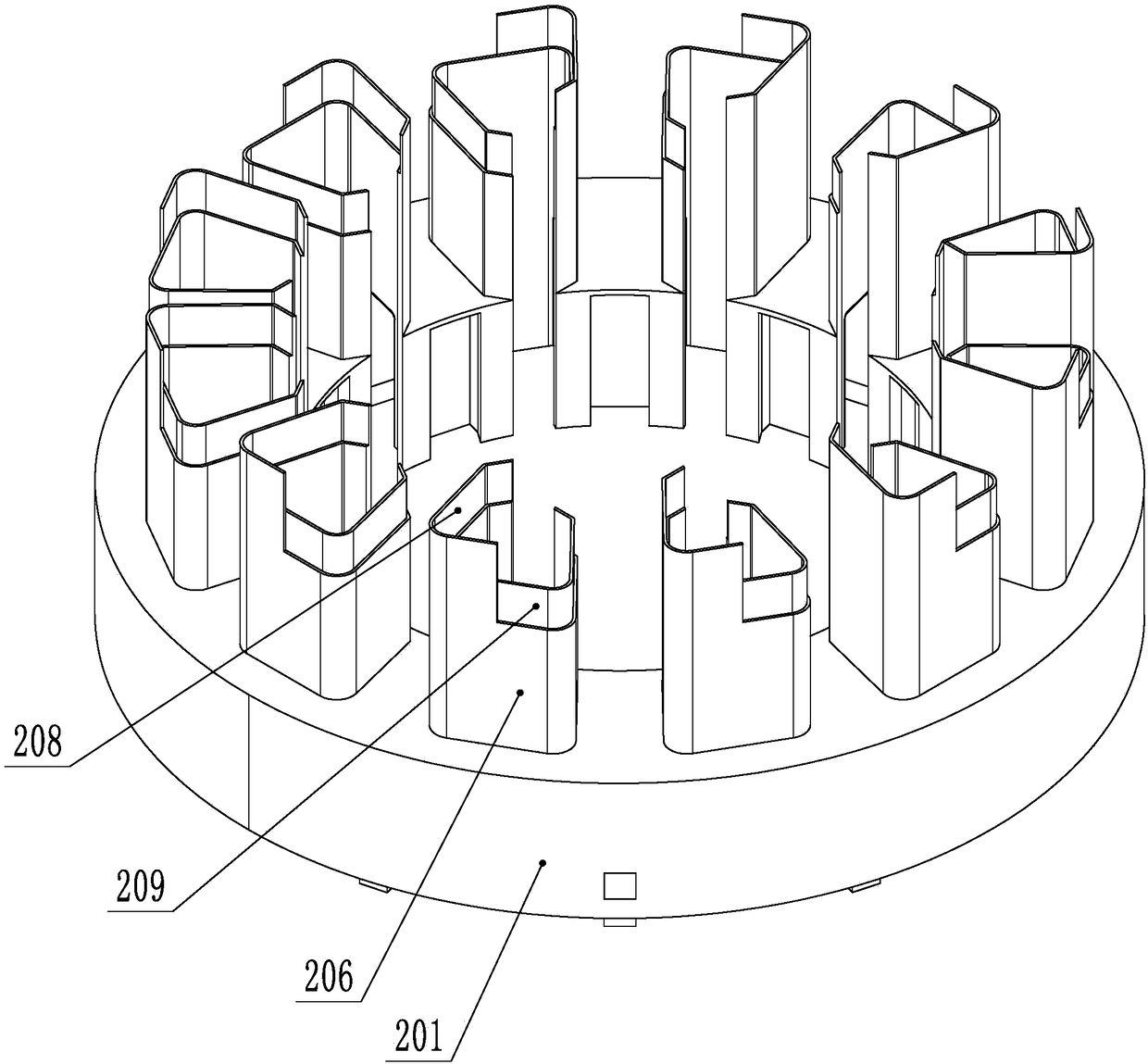

[0032] like Figure 1-3 As shown, a Hall circuit board fixing structure, the Hall circuit board is set on the stator core, the stator core 1 is provided with yokes, teeth and slots, the inner side between the teeth is the opening of the slots, and the stator core is provided with Fixed frame 2, the Hall circuit board is fixed on the fixed frame 2, the fixed frame 2 is provided with the positioning installation structure of the Hall circuit board 3, the mounting frame 202 for positioning and installing the Hall 4 and is used to isolate the stator iron The insulating slot cover 206 of the core 1 and the winding coil, the insulating slot cover 206 covers the inner surface of the yoke, the side surfaces of the teeth and the upper and lower end surfaces, so that the slot is isolated from the yoke and the teeth, and opens at the opening of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com