Preparation method and device of rubber and plastic heat preservation pipeline system

A technology for thermal insulation pipes and thermal insulation pipes, which is applied to tubular articles, other household appliances, household appliances, etc., can solve the problems of inconsistent foam density, foam thickness, poor thermal insulation stability of foam thermal insulation layer, and high requirements for injection molding equipment, so as to improve thermal insulation stability. performance, overall quality stability, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

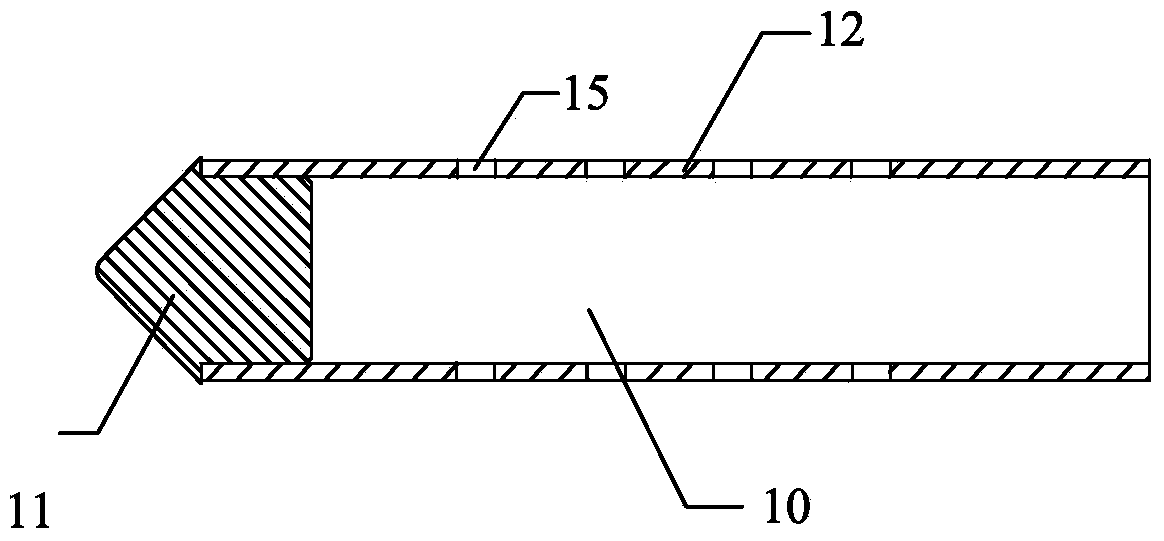

[0034] 1. Prepare the water supply pipeline

[0035] According to the specific fluid medium to be transported, select the appropriate water supply pipeline, and factors such as pressure, flow rate, heat resistance, and corrosion resistance should be considered when selecting. Commonly used water supply pipes are: plastic water supply pipes, such as chlorinated polyvinyl chloride (CPVC) water supply pipes, polyvinyl chloride (UPVC) water supply pipes, random copolymerized polypropylene (PPR) water supply pipes, polyethylene (PE) water supply pipes, etc. ; and metal water supply pipes, such as copper water supply pipes, stainless steel water supply pipes, galvanized water supply pipes or steel-plastic composite water supply pipes, etc.

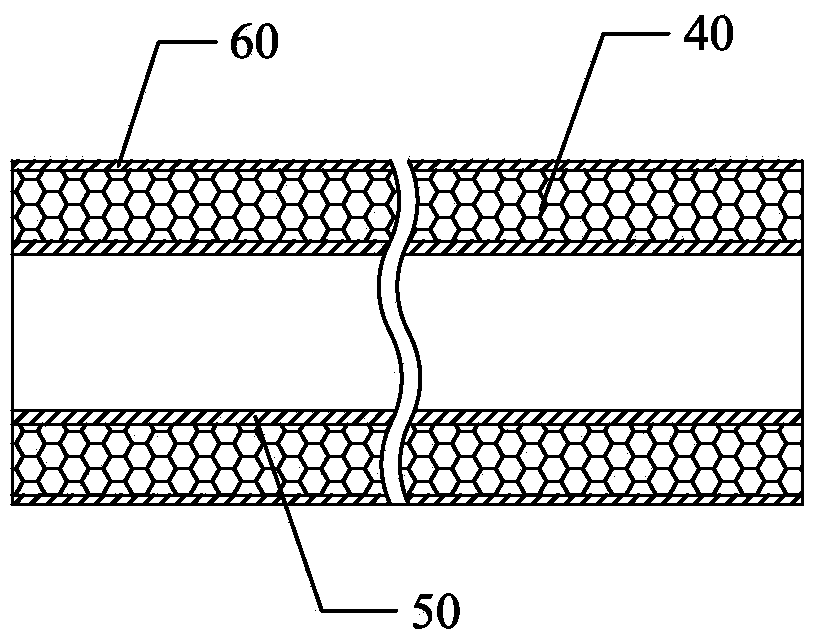

[0036] 2. Preparation of rubber-plastic foam insulation pipe

[0037] According to the temperature of the fluid medium to be transported, the ambient temperature, the fire protection coefficient and other factors, the thickness of the rubber-pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com