Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "High toughness and good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Artificial tooth base resin-nano zirconium oxide composite material and preparation thereof

InactiveCN101214196AImprove wear resistanceImprove the finishImpression capsDentistry preparationsPink colorFlexural strength

The present invention provides false tooth base resin applied to the oral cavity repair, which is nanometer zirconia composite material. Firstly, silane coupling agent Z-6030 is used to decorate the surface of the nanometer zirconia. The raw material components are 0.5 percent to 5.0 percent of silane coupling agent Z-6030 and 95 percent to 99.5 percent of the nanometer zirconia. The nanometer zirconia decorated by the coupling agent is obtained. Then the nanometer zirconia decorated by the coupling agent is synthesized with polymethyl methacrylate. The material components are 1 percent to 5 percent of the nanometer zirconia decorated by the coupling agent and 95 percent to 99 percent of the polymethyl methacrylate. The nanometer zirconia composite material is obtained, the flexural strength of which can be 95.61MPa. The nanometer zirconia composite material manufactured by the present invention has high flexural strength, easy polishing, good finish degree, pink color, easy adjustment and good biological compatibility and is the novel resin with good biological and mechanical performance, which can be widely applied to the dentistry.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE +1

Tungsten-based plasma facing material and preparation method thereof

ActiveCN102560292ALow sputtering yieldLow hydrogen isotope retentionMelting Point TemperaturePlasma-facing material

The invention discloses a tungsten-based plasma facing material and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing tungsten powder and tungsten fiber by a powder mixing method which does not damage the tungsten fiber; and sintering to prepare a bulk fiber toughened tungsten-based material by a hot isostatic pressing process. The tungsten powder is one of pure tungsten powder, tungsten-rhenium alloy powder, and tungsten powder doped with carbide and oxide; and the tungsten fiber is a pure tungsten wire, a tungsten-rhenium alloy wire or the like. The tungsten-based plasma facing material has the advantages of high thermal conductivity, high melting point temperature, low sputtering yield, low hydrogen isotope retention and low vapor pressure, as well as low cost and greater toughness.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Tungsten inert gas welding method of austenitic heat-resistant steel

InactiveCN108788405AImprove mechanical propertiesReduce brittlenessArc welding apparatusSteel pipelineAustenite

The invention discloses a tungsten inert gas welding method of austenitic heat-resistant steel. According to the tungsten inert gas welding method, for the austenite heat-resistant steel, a 22Cr25NiWCoCu (UNSS31035) seamless steel tube is selected is welded, a welding joint adopts a single-side 30-degree V-shaped groove, and cleaning is carried out; firstly, positions are fixed by using spot welding of tungsten-electrode argon arc welding before welding is carried out, and combined pairing is carried out; and then single-side welding and double-face forming are carried out by using tungsten-electrode argon arc welding, preheating is not carried out before welding, no heat treatment is carried out after welding, and meanwhile full-argon protection is adopted. According to the austenite ic heat-resistant steel pipeline welding process, welding stress and deformation are reduced, the brittleness of the welded joint can be reduced, the occurrence of thermal cracks is inhibited, the improvement of the plasticity and the toughness of the welded joint is realized, and then that the mechanical property of the pipeline after welding is comprehensively improved.

Owner:TIANJIN UNIV

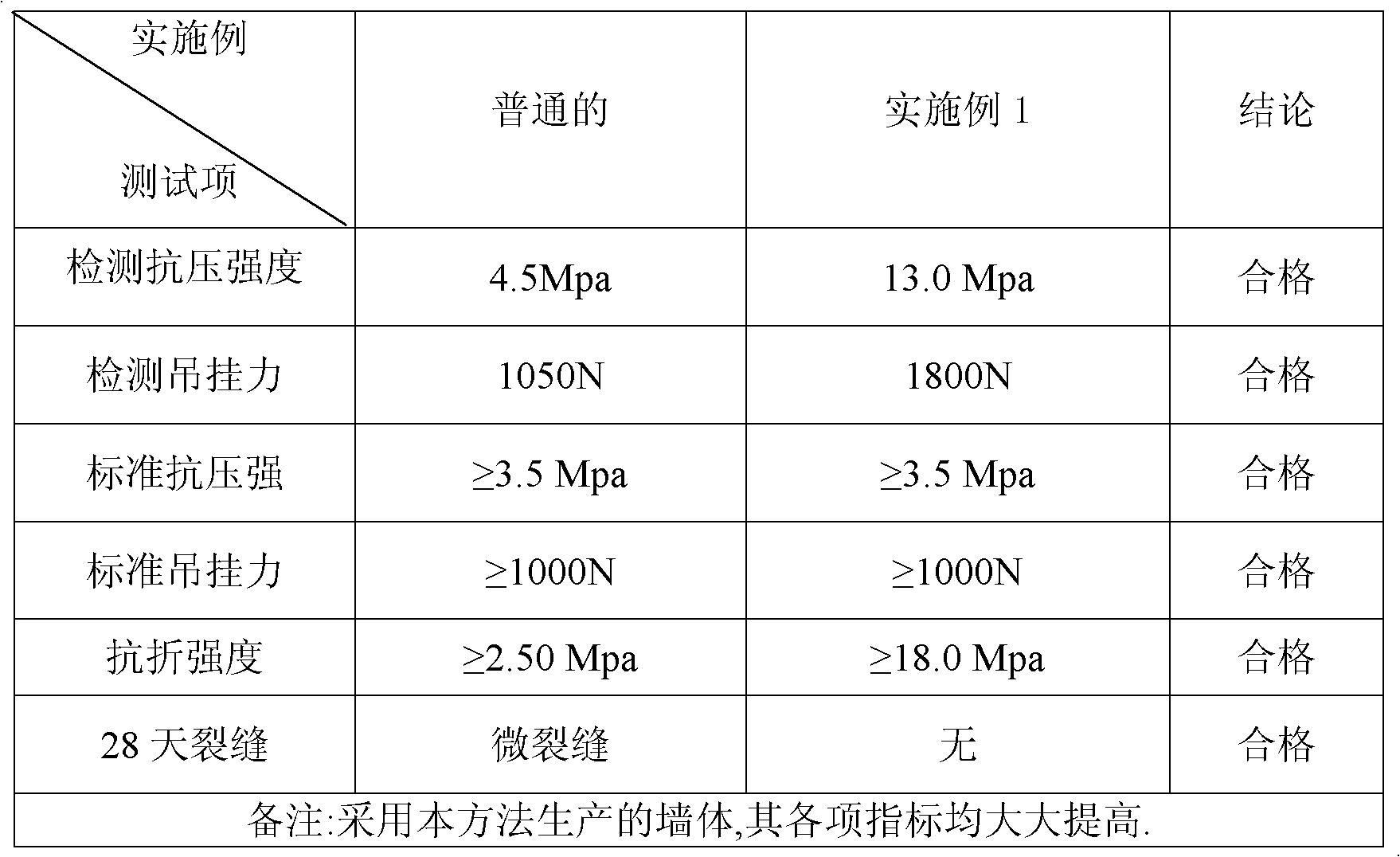

Method for preparing high-performance concrete and application

The invention discloses a method for preparing high-performance concrete and application. The method comprises the following steps of: designing a concrete mixing proportion; sequentially adding fine aggregate, engineering fibers and gel material into a stirrer, and stirring till the engineering fibers are uniformly distributed; and adding water to prepare mortar, adding coarse aggregate, stirring uniformly, and adding an admixture to obtain the high-performance concrete required by design. The prepared high-performance concrete can be used for preparing high-performance concrete products. The method is simple and convenient for processing; the length of the utilized engineering fibers is easily controlled, so that the concrete has good workability, the forming velocity and the production efficiency are improved, the concrete has the advantages of tensile resistance, shearing resistance, cracking resistance, fatigue resistance, high toughness and the like, and concrete cracks caused by temperature stress can be reduced; the microstructure of the cement slurry is improved, and the compactness of the concrete is increased, so that the strength and the durability of the concrete are improved, and the service life of the concrete is prolonged; and the concrete has good safety and economic and social benefits.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

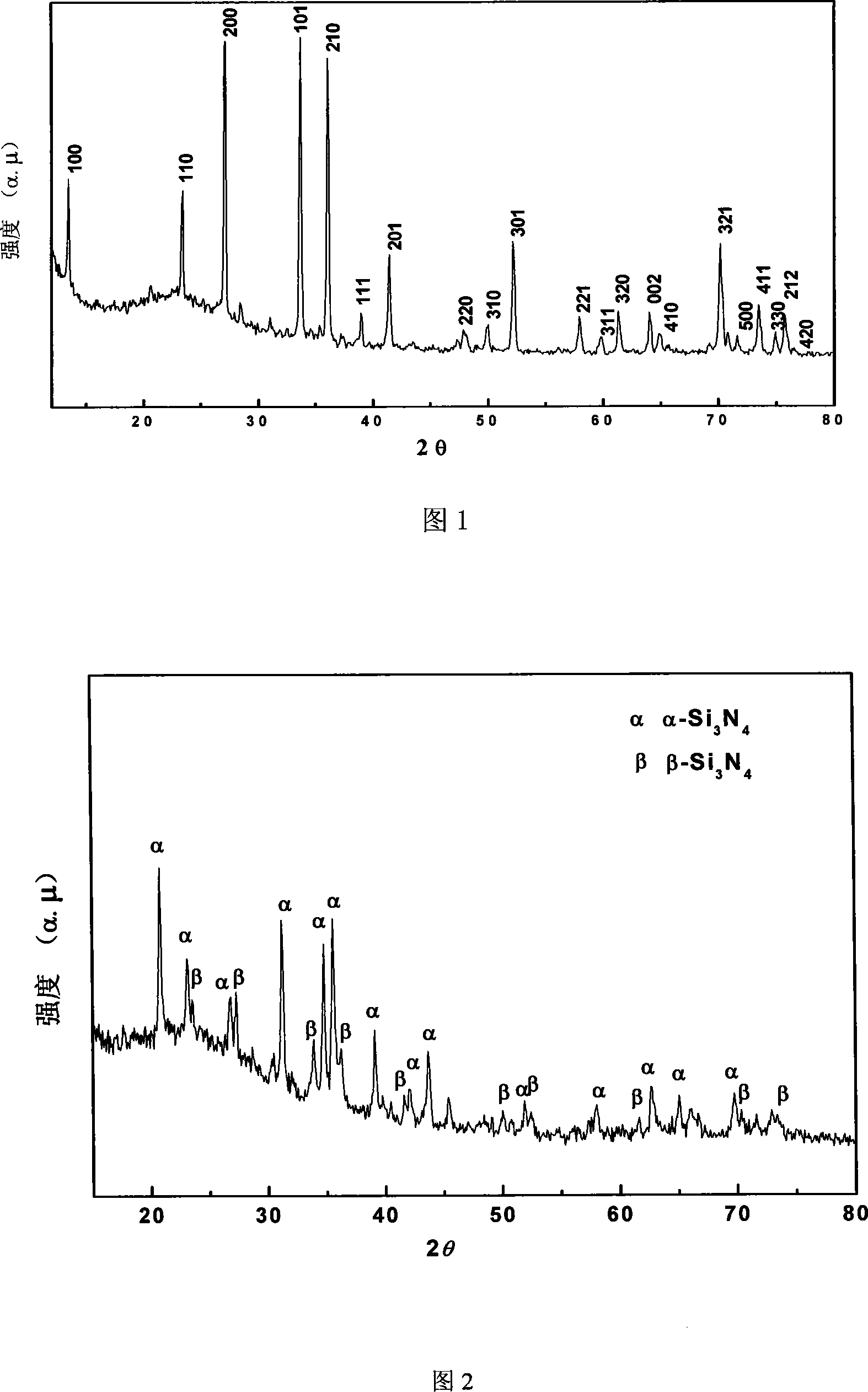

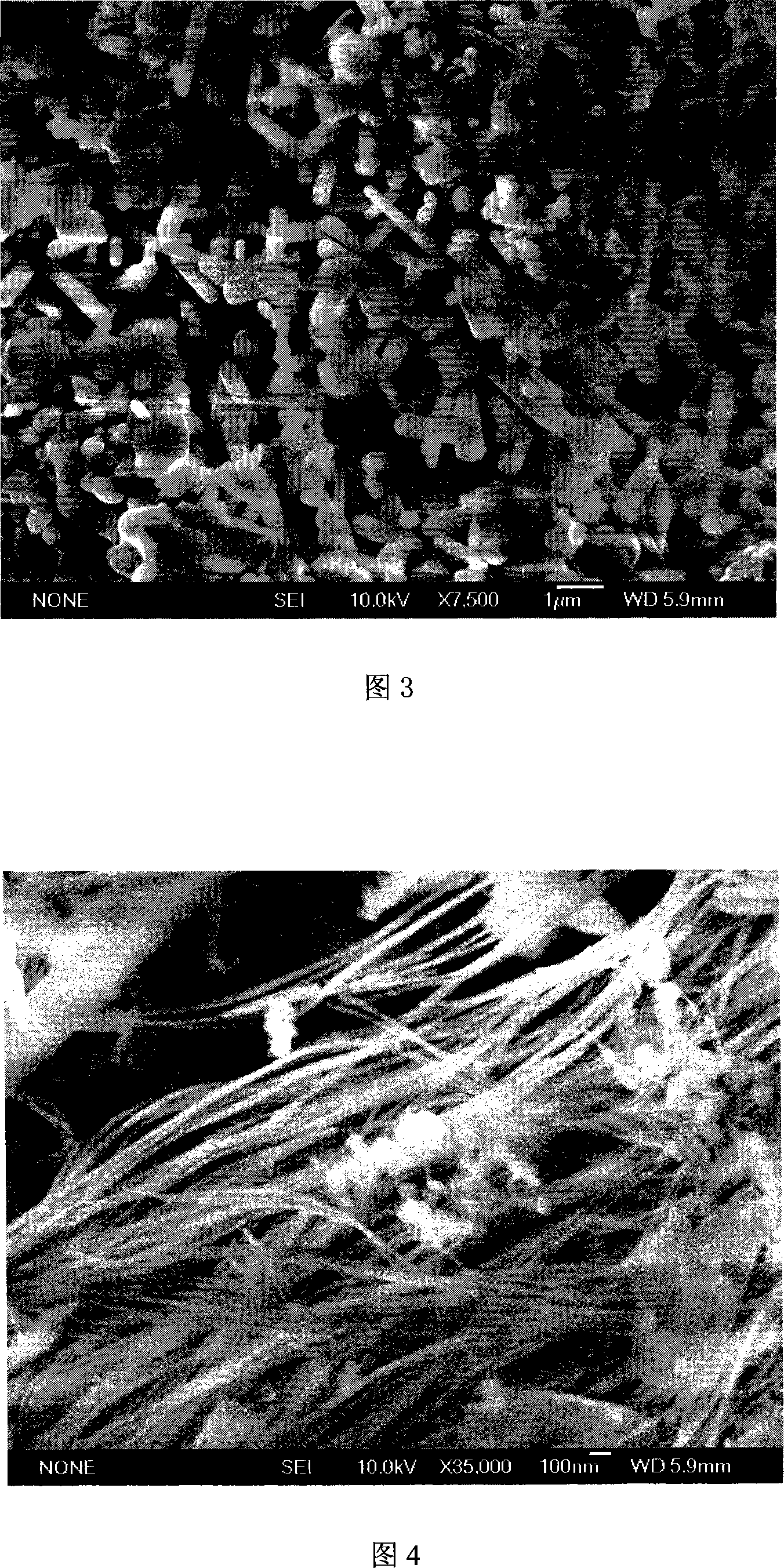

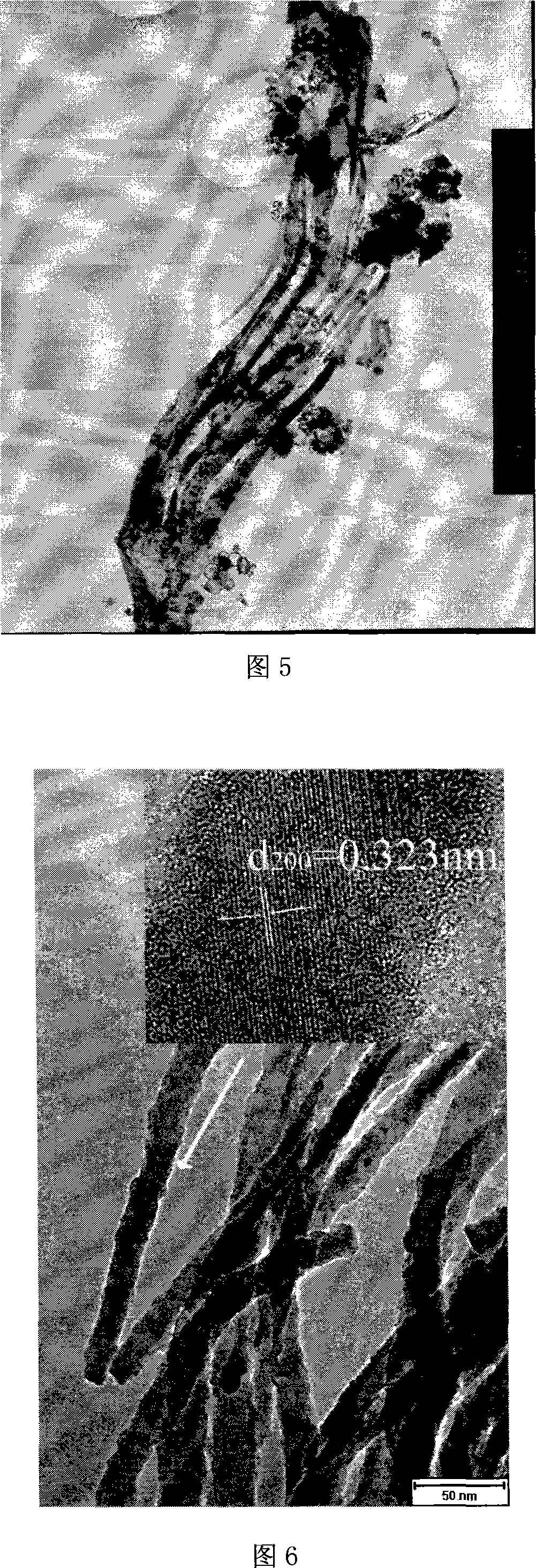

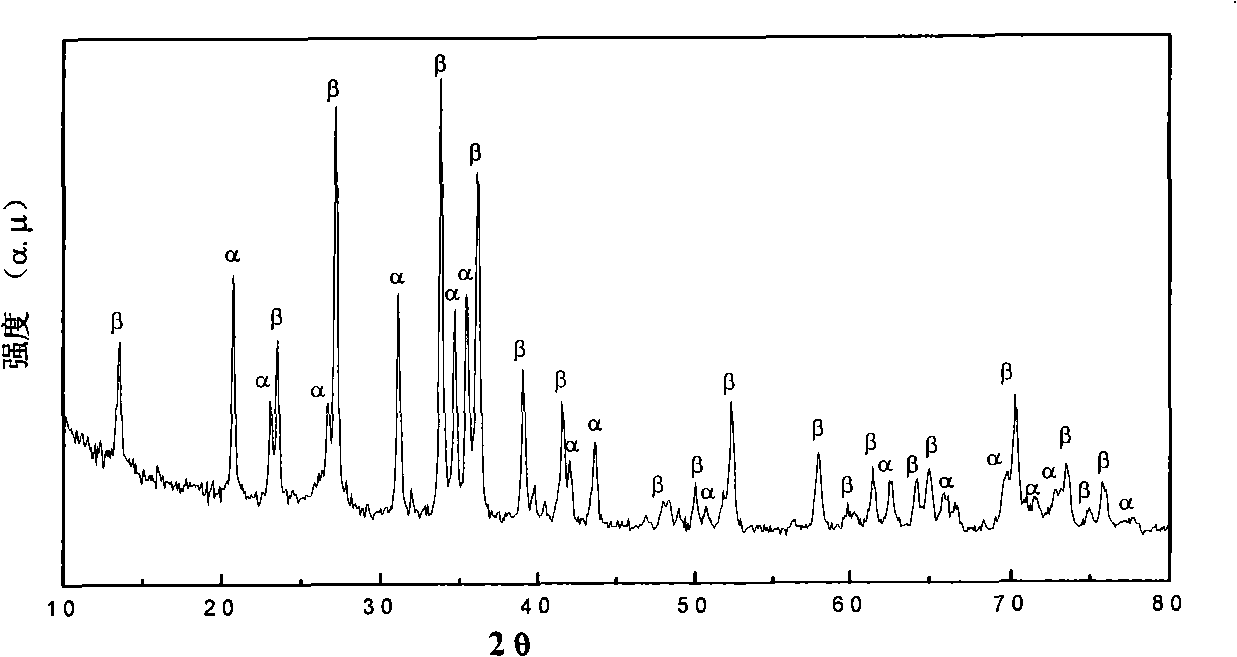

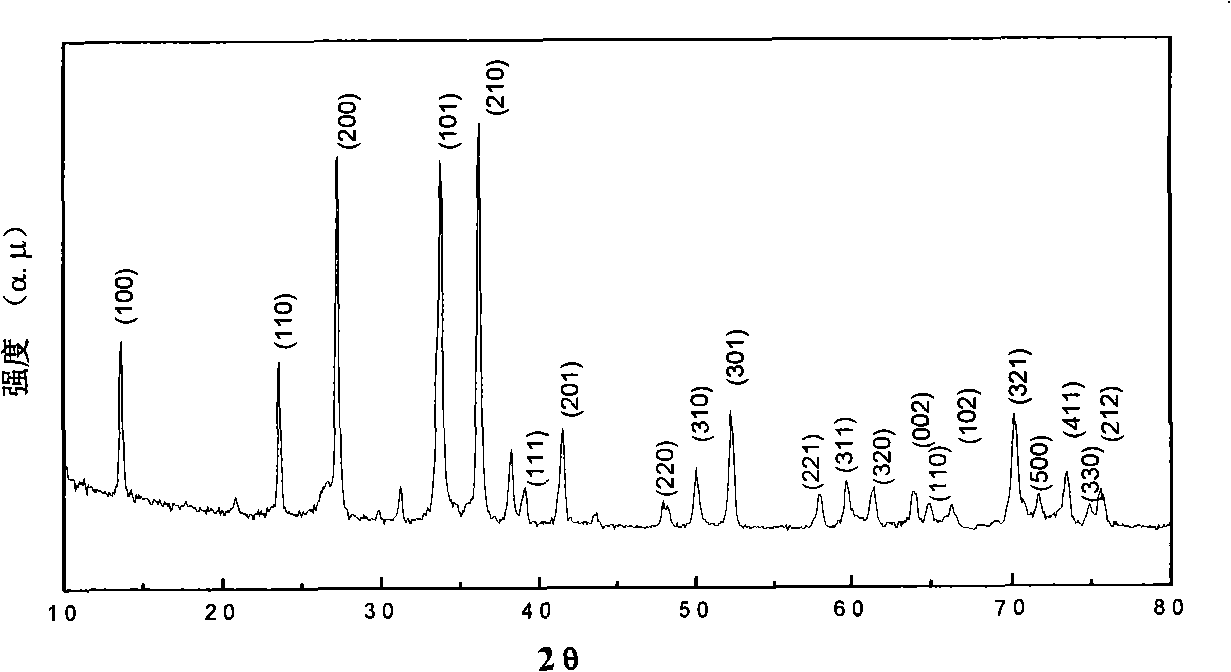

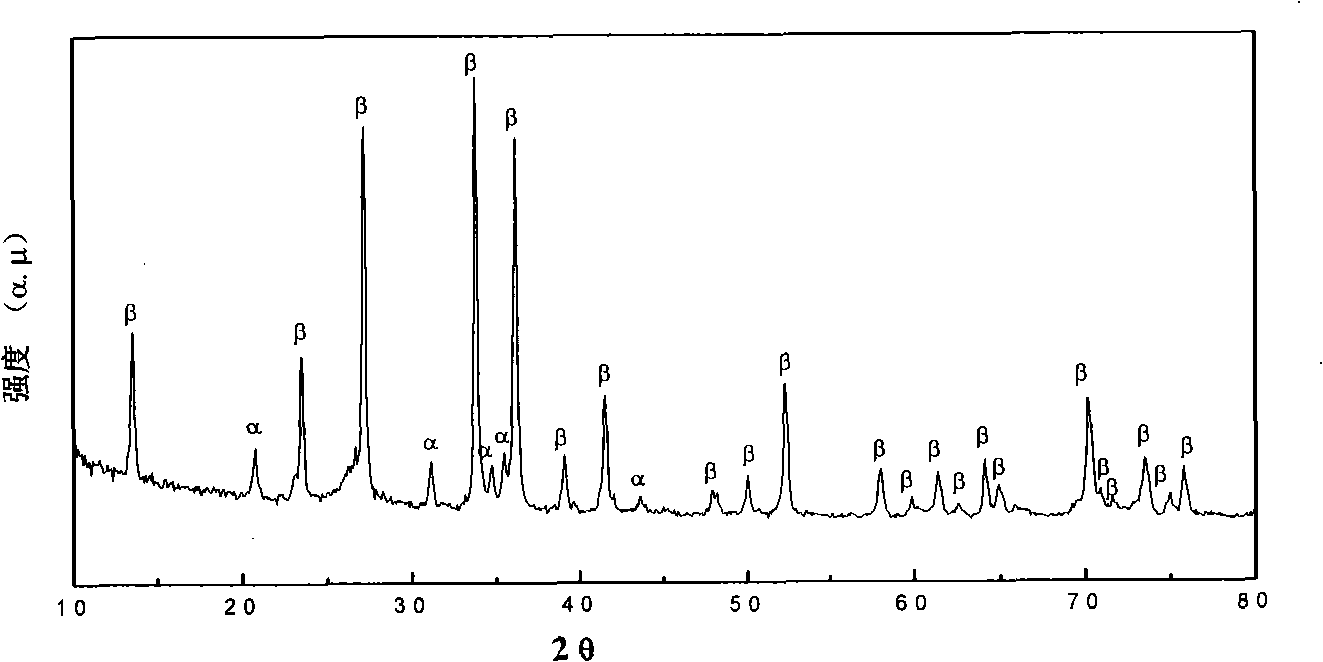

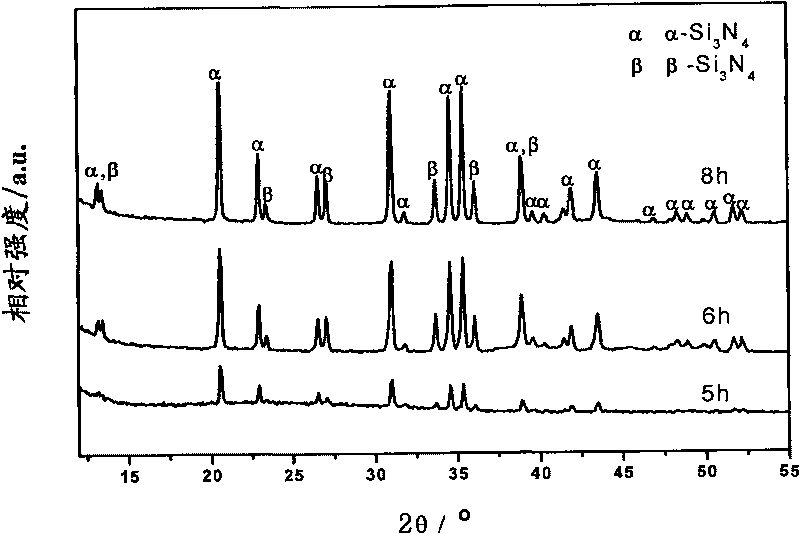

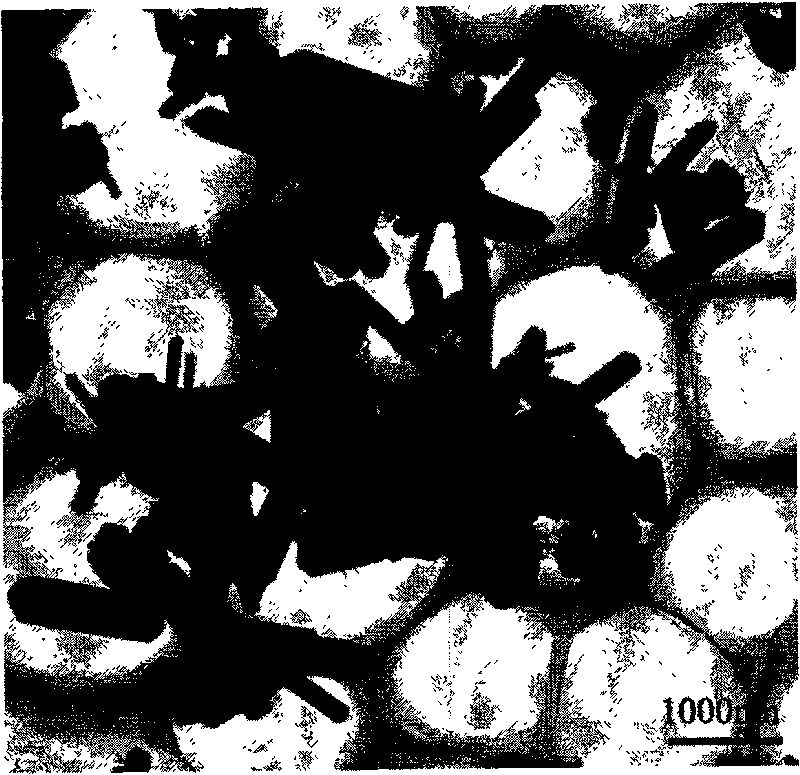

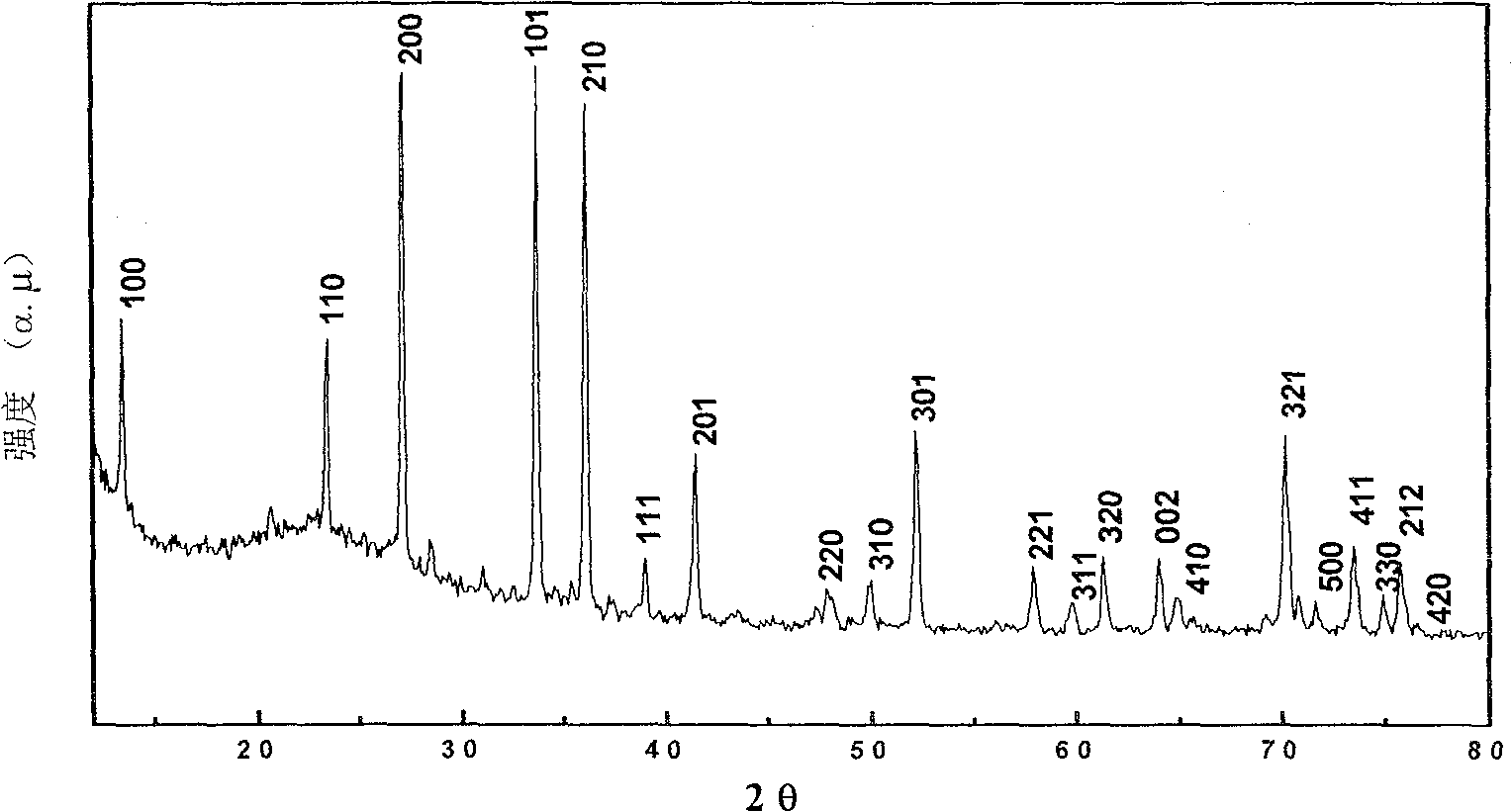

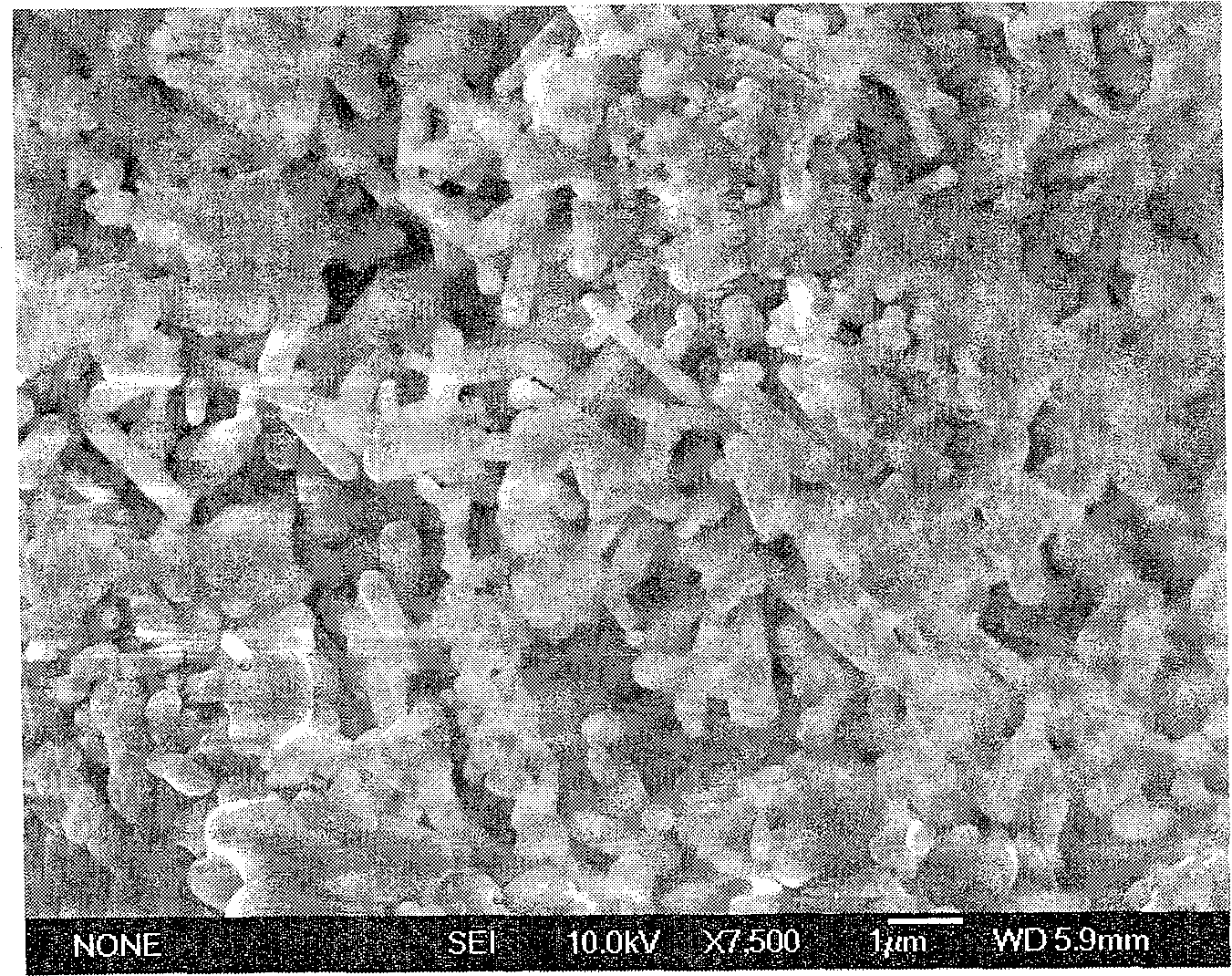

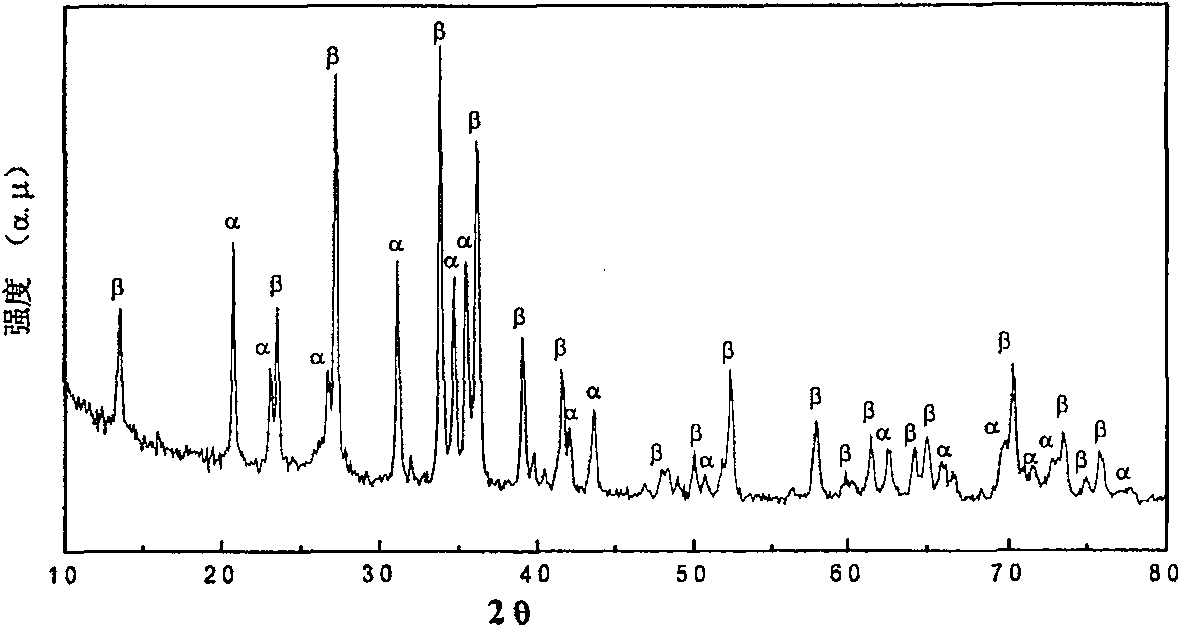

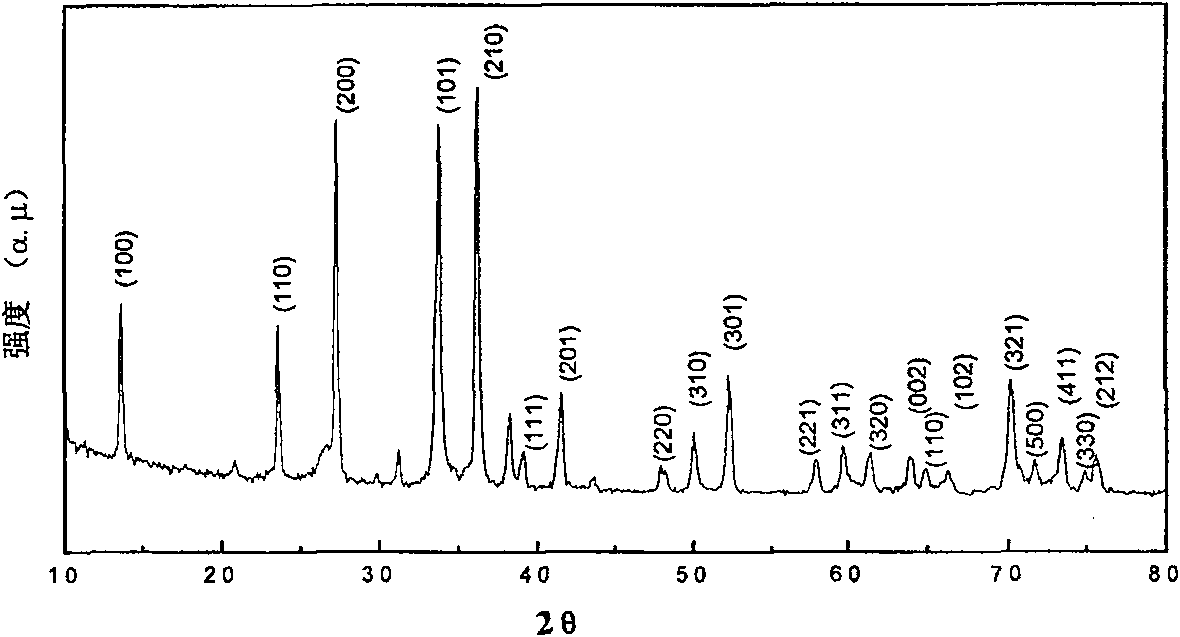

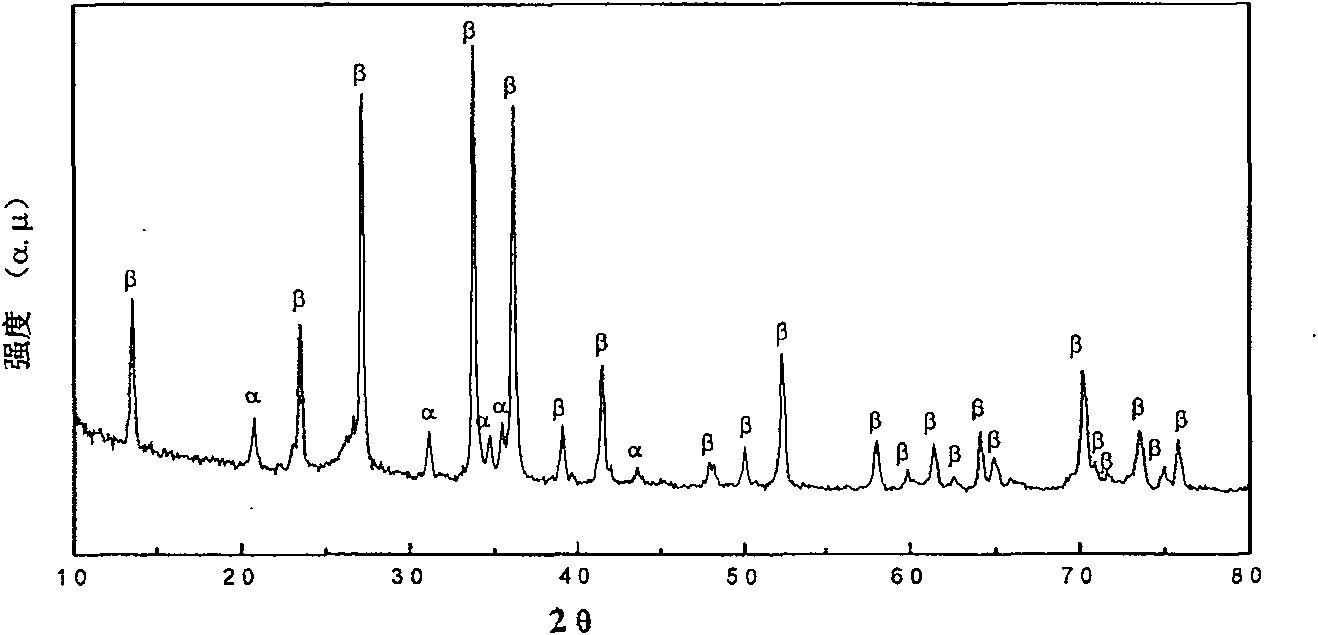

Method for synthesizing silicon nitride nano material under low temperature by solvent hot reaction

InactiveCN101134569AEasy to realize industrial productionGood lookingNanostructure manufactureAcid washingReaction temperature

The present invention is low temperature thermal reaction process in solvent to synthesize nanometer silicon nitride material. The process includes the following steps: mixing SiCl4, NaN3 and Mg powder in the molar ratio of 2.8-5.8 to 1 to 0.8-2.7, or mixing SiCl4, NaN3 and Fe powder in the molar ratio of 5.8-6.0 to 1 to 0.58-0.60; reacting in a sealed autoclave at 200-300 deg.c for 10 hr; acid washing and water washing the product, centrifugally separating and drying to obtain 1D nanometer silicon nitride material. The process can produce nanometer beta-Si3N4 rod of 100-800 nm diameter, nanometer beta-Si3N4 line of 30-125 nm diameter, and nanometer alpha-Si3N4 line of 50-165 nm diameter. The process has low reaction temperature and good product form, and is suitable for industrial production.

Owner:SHANDONG UNIV

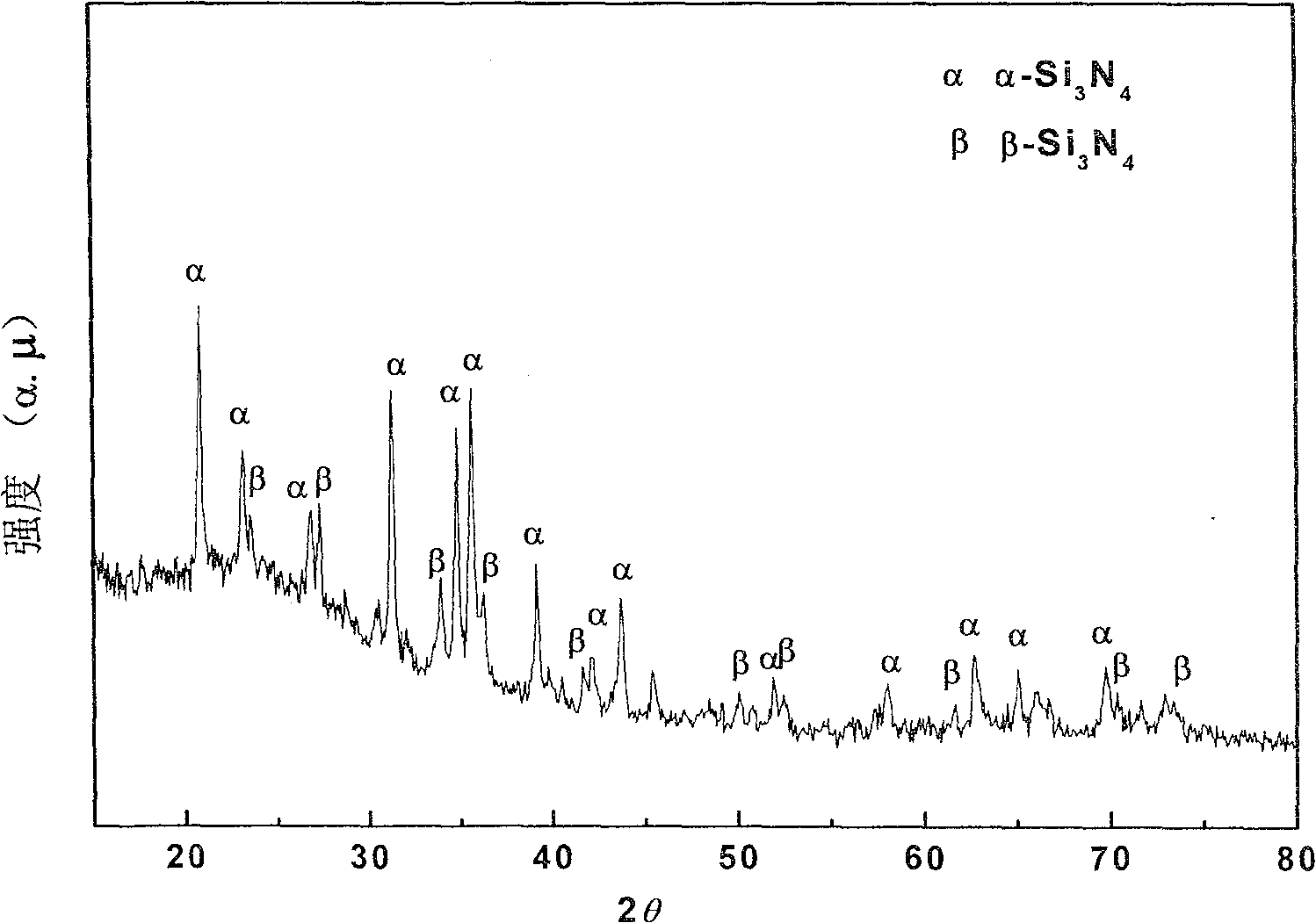

Low-temperature solid phase reaction preparation of silicon nitride nano-material

InactiveCN101294303AImprove toughnessThe method is simplePolycrystalline material growthFrom solid stateSilica fumeSilicon nitride

The invention discloses a method for preparing a silicon nitride nano-material by using solid phase reaction at a low temperature. The method comprises the following steps: silicon powder, powdery thiosemicar bazide, sodium azide and iodine are evenly mixed according to the mole ratio of 0.386 to 0.926:0.476 to 0.953:1:0.171 to 0.256 and sealed in a high-pressure autoclave, and react for 12 plus or minus 0.5 hours at the temperature of 60 plus or minus 5 DEG C; or the silicon powder, the powdery thiosemicar bazide, the sodium azide and alluminium powder are evenly mixed according to the mole ratio of 0.386 to 0.926:0.716 to 1.193:1:0.804 and sealed in the high-pressure autoclave, and react for 10 plus or minus 0.5 hours at the temperature of 170 plus or minus 5 DEG C; or the silicon powder, the powdery thiosemicar bazide and the sodium azide are evenly mixed according to the mole ratio of 0.386 to 0.926:0.716 to 1.193:1 and sealed in the high-pressure reactor, and react for 10 plus or minus 0.5 hours at the temperature of 170 plus or minus 5 DEG C; the pH of the product is neutral though water cleaning and water washing; centrifugal separation and drying are performed; then acid is added for scrubbing, monatomic silicon is removed; and the silicon nitride nano-materials are obtained. The method has the advantages that the reaction temperature is lower; the appearance of the obtained product is good; the diameters of the nano-rods are even; and the method is suitable for large-scale industrial production.

Owner:SHANDONG UNIV

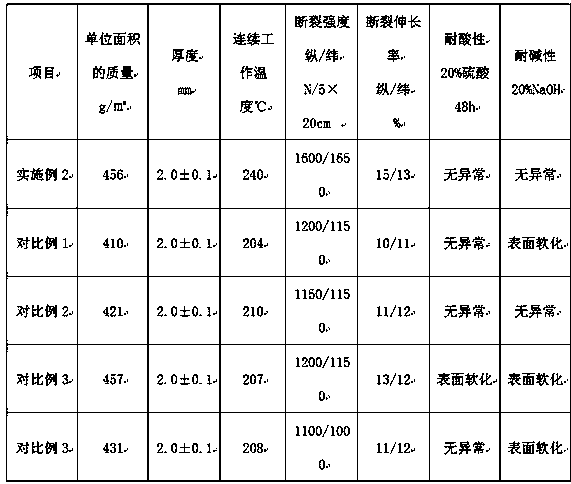

High-temperature resistant and acid-and-alkali resistant industrial filter cloth material

InactiveCN108993027AGuaranteed tensile strengthImprove bending resistanceMembrane filtersFiltration separationYarnPolyester

The invention discloses a high-temperature resistant and acid-and-alkali resistant industrial filter cloth material. The high-temperature resistant and acid-and-alkali resistant industrial filter cloth material is prepared from the following raw materials in parts by weight: 30 to 60 parts of tetrafluoroethylene-hexafluoropropylene copolymer, 30 to 60 parts of polyphenylene sulfide, 20 to 30 partsof ethyl alcohol, 20 to 30 parts of distilled water ethanol, 10 to 15 parts of polyester, 1 to 5 parts of polytetrafluoroethylene powder, 1 to 3 parts of chromic oxide, 10 to 15 parts of polydiphenylterephthalate propane ester, and 1 to 5 parts of graphite powder. Besides specific advantages of a common filter cloth material, the industrial filter cloth prepared by the treatment process providedby the invention has very high wear resistance, very high cost performance, high resilience and good anti-static property; the cloth which is woven by doubling and twisting multi-strand yarns is dense, high in particle retaining property, and high in stripping property and air permeability. The series of products have the characteristics of acid resistance, alkali resistance, high strength, highfiltering capacity and the like; dust is extremely cleaned; the strength, the wear resistance and the water leakage property are excellent.

Owner:ANHUI YUANYE FILTER MATERIAL

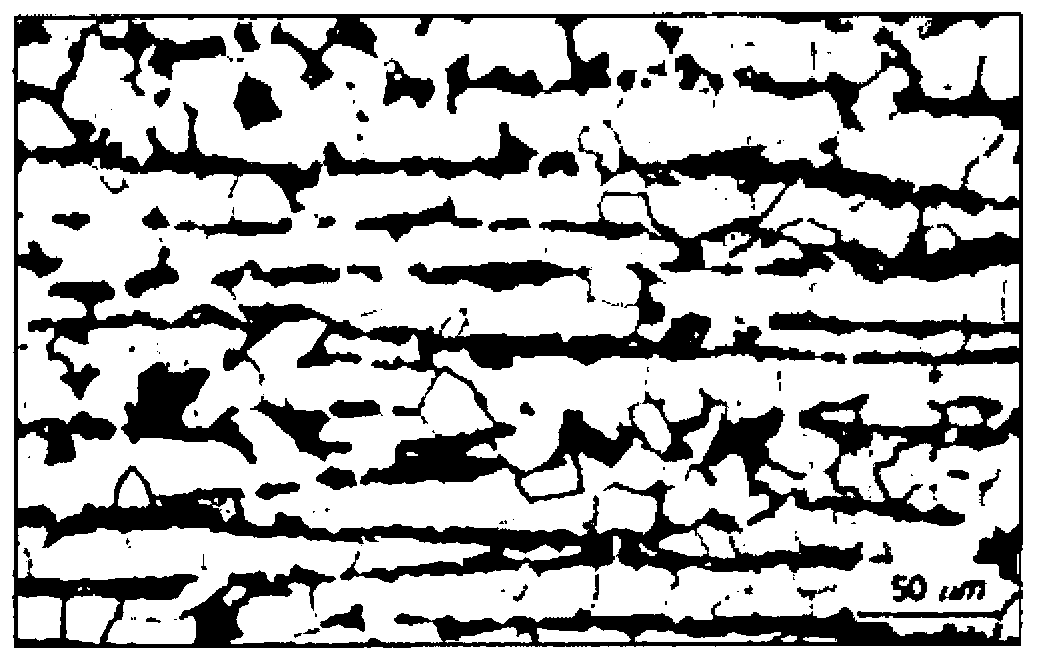

High-performance TA1 bar wire and preparation method thereof

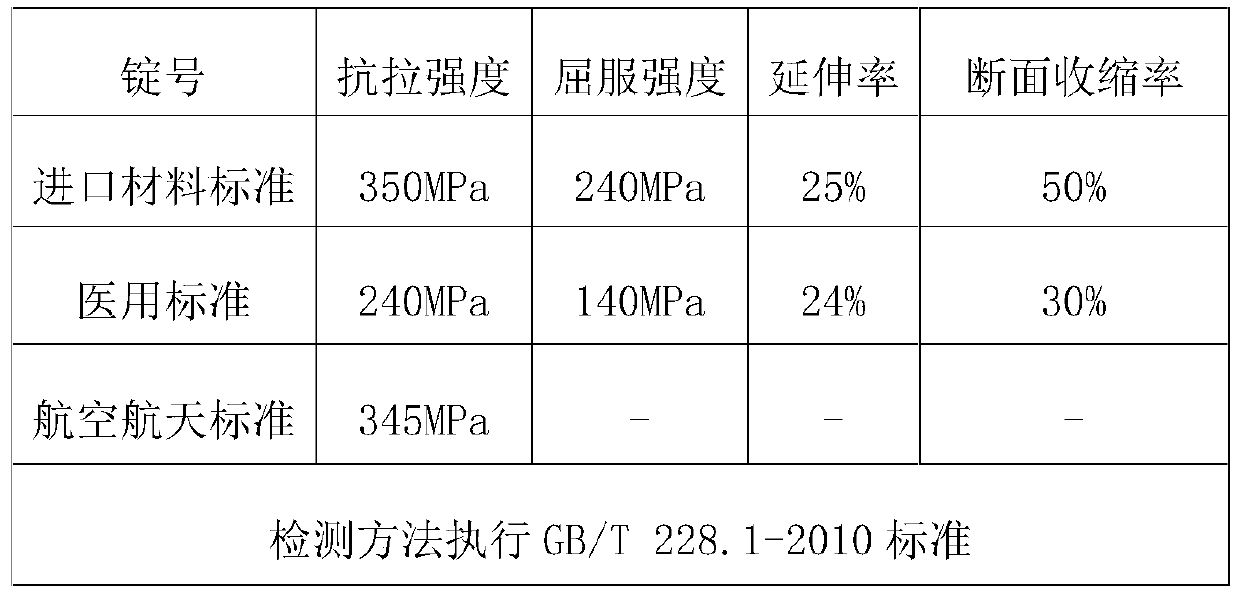

ActiveCN111020293AHigh toughness and goodIncrease usage intensityProcess efficiency improvementTitaniumTitanium alloy

The invention belongs to the field of titanium and titanium alloy preparing and machining, and particularly relates to a high-performance TA1 bar wire and a preparation method thereof. The high-performance TA1 bar wire contains smaller than or equal to 0.15 wt% of Fe, smaller than or equal to 0.15 wt% of O, smaller than or equal to 0.05 wt% of N, smaller than or equal to 0.10 wt% of C, smaller than or equal to 0.008 wt% of H and the balance titanium and unavoidable impurities. According to the high-performance TA1 bar wire, the tensile strength is between 350 MPa and 450 MPa, the yield strength is between 240 MPa and 380 MPa, the percentage elongation after fracture is larger than or equal to 25%, and the percentage reduction of area is larger than or equal to 60%. The high-strength, high-toughness and excellent-comprehensive performance TA1 pure titanium bar wire which is suitable for the medical field and the aerospace field and reaches the standards of imported wires is obtained bycontrolling raw material alloy elements and a heat treatment system, the use intensity of TA1 pure titanium is further improved while the excellent service performance is shown, and the wide application prospect is achieved in the engineering field.

Owner:宝鸡鑫诺特材股份有限公司

Preparation method of boron-carbide-based metal ceramic composite material

The invention discloses a preparation method of a boron-carbide-based metal ceramic composite material. The method comprises the following steps that (1) the raw materials including, by weight, 76-96.9 parts of boron carbide, 1-5 parts of zirconium oxide, 1-4 parts of yttrium oxide, 1-5 parts of chrome carbide and 0.1-10 parts of cobalt-nickel alloy are weighed; (2) firstly, the boron carbide andchrome carbide are subjected mixed ball milling until the average particle size is 10-50 microns; a spray drying tower is used for pelletizing, particles are added into a sintering furnace for sintering for 5-12 hours at 1,400-1,600 DEG C, heat preservation is conducted for 1-3 hours, and after cooling is conducted, ball milling is conducted again until the average particle size is 15-30 microns,so that a sintering material is obtained. The prepared boron-carbide-based metal ceramic composite material has good isotropy, structure uniformity, thermal conductivity, oxidation resistance and high-temperature creep resistance.

Owner:NINGBO DONGLIAN MECHANICAL SEAL

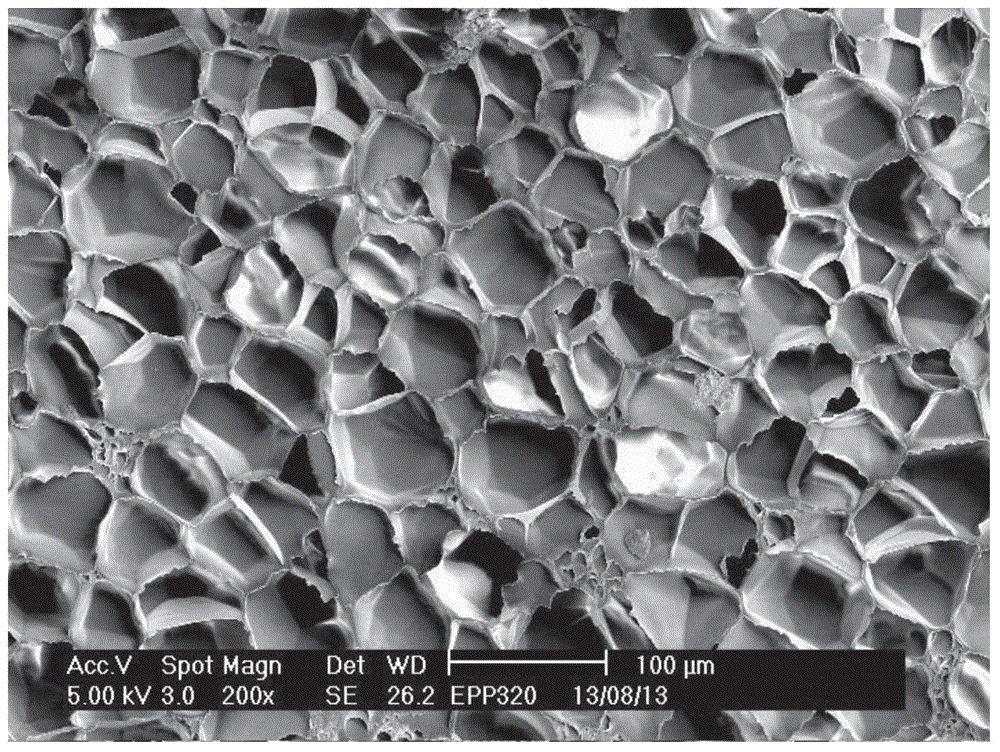

Impact-resistant polypropylene foaming material with high-melt strength and preparation method thereof

The invention discloses an impact-resistant polypropylene foaming material with high-melt strength. According to the invention, impact-resistant polypropylene with high-melt strength taken as matrix resin is obtained by foaming, The impact-resistant polypropylene with high-melt strength comprises a propylene homopolymer component and an ethylene / 1-butylene copolymer component; wherein the propylene homopolymer component comprises at least a first propylene homopolymer and a second propylene homopolymer; the ethylene content in the ethylene / 1-butylene copolymer is 20-45 wt%; the weight ratio of the ethylene / 1-butylene copolymer component to the propylene homopolymer component is 11-80: 100; and the ratio of room-temperature trichlorobenzene soluble Mw of the material to room-temperature trichlorobenzene insoluble Mw of the material is greater than 0.5 and is smaller than or equal to 1. The invention also relates to a preparation method of the foaming material. The foaming material has the characteristics of good shock resistance at high and low temperature, high physical heat resistance, high closed porosity, good insulation and sound insulation performances, controllable foaming multiplying power and foam structure, and easy recovery and utilization.

Owner:CHINA PETROLEUM & CHEM CORP +1

Tailing-containing heat-dissipating coating

The invention discloses a tailing-containing heat-dissipating coating. The coating is prepared from the following raw materials in parts by weight: 90-97 parts of polypropylene, 0.6-1 part of 6-butylated hydroxytoluene, 0.5-1 part of vanadium boride, 1-2 parts of glucose, 2-4 parts of tailing, 1-2 parts of 2-phenylimidazoline, 10-13 parts of sepiolite powder, 0.8-1 part of an antioxidant 1010, 1-2 parts of sodium potassium tartrate, 5-7 parts of glycerol triacetate, 4-6 parts of light calcium carbonate and 10-12 parts of a composite filler. As the tailing serving as a main component in solid industrial waste is added into the raw materials, the production resources are saved, the production cost is reduced, the waste is recycled, the physical property of the powder coating can be enhanced, and the toughness and impact resistance of the finished powder coating are well enhanced. The coating has a good heat dissipating effect, and can be widely applied to coating of LED lamps.

Owner:WUHU BAOYI AMUSEMENT EQUIP

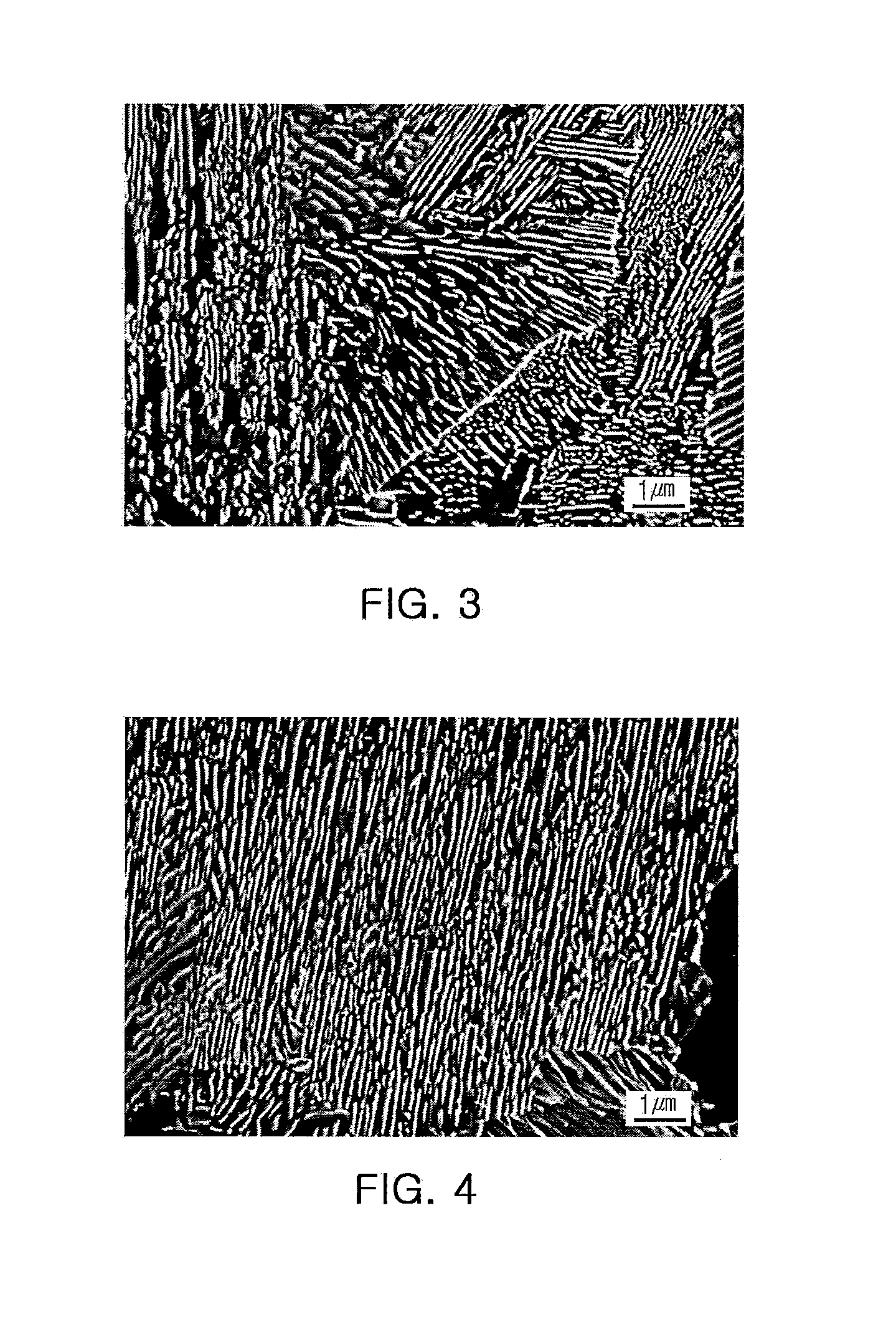

High-Toughness Cold-Drawn Non-Heat-Treated Wire Rod, and Method for Manufacturing Same

ActiveUS20130174947A1High toughness and goodLow tensile strengthFurnace typesHeat treatment furnacesWire rodSulfur

Provided is a wire rod for use in mechanical structure connections, vehicle components, or the like, and more particularly, to a wire rod which has superior toughness without being subjected to a heat treatment, and the strength of which is ensured through a cold-drawing process. Tot his end, provided are a high-toughness cold-drawn non-heat-treated wire rod and a method for manufacturing the same, wherein the wire rod comprises in % by weight: 0.2 to 0.3% of carbon (C), 0.1 to 0.2% of silicon (Si), 2.5 to 4.0% of manganese (Mn), 0.035% or less (but not 0%) of phosphorus (P), 0.04% or less (but not 0%) of sulfur (S), the remainder being iron (Fe) and unavoidable impurities.

Owner:POHANG IRON & STEEL CO LTD

Preparation method of C/C-SIC ceramic composite material

The invention discloses a preparation method of a C / C-SIC ceramic composite material, comprising the following steps: using a cheap low-density PAN-based flat carbon felt as a precursor, and preparing a protective layer on the surface of carbon fibers through chemical vapor deposition; preparing phenolic resin, acetone, ethanol and silicon carbide powder in proportion into a slurry, immersing the carbon felt with the protective layer in the slurry and vacuumizing, then pressing for impregnating; pressing the pre-impregnated carbon felt into shape, then carrying out solidification and carbonization; then putting the carbonized precursor in a furnace, carrying out high temperature siliconizing reaction and filling to obtain a compact base substrate, and then removing residual silicon from the surface to obtain the high-performance high-density C / C-SIC ceramic composite material having a density of 2.30-2.70 g / cm<3>. According to the invention, the preparation process is simple, the raw materials are cheap, the production time and procedures are greatly reduced. The invention can be suitable for batch production and is easy to industrialization.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

High-pressure rubber hose material with high toughness

The invention provides a high-pressure rubber hose material with high toughness. The high-pressure rubber hose material comprises modified polypropylene and rubber and further comprises 10 to 15 parts of zinc oxide, 1 to 5 parts of EPDM rubber, 5 to 10 parts of chlorinated polyethylene rubber and 1 to 5 parts of stearic acid. Compared with the prior art, the high-pressure rubber hose material provided by the invention has the advantage of good high toughness through addition of zinc oxide, EPDM rubber, chlorinated polyethylene rubber and stearic acid.

Owner:SHENYANG XINDA INFORMATION SCI & TECH

High-ductility rubber film

The invention provides a high-ductility rubber film. The adopted technical scheme is that the rubber film comprises a common rubber component and is characterized by further comprising the following components in parts by weight: 2-4 parts of polymer emulsion powder, 0.3-0.5 part of zinc borate, 4-6 parts of silicon dioxide, and 6-10 parts of acrylate particles. Compared with the prior art, the rubber film has the benefit that an excellent high-ductility effect is achieved by adding the polymer emulsion powder, zinc borate, silicon dioxide and acrylate particles.

Owner:马楠

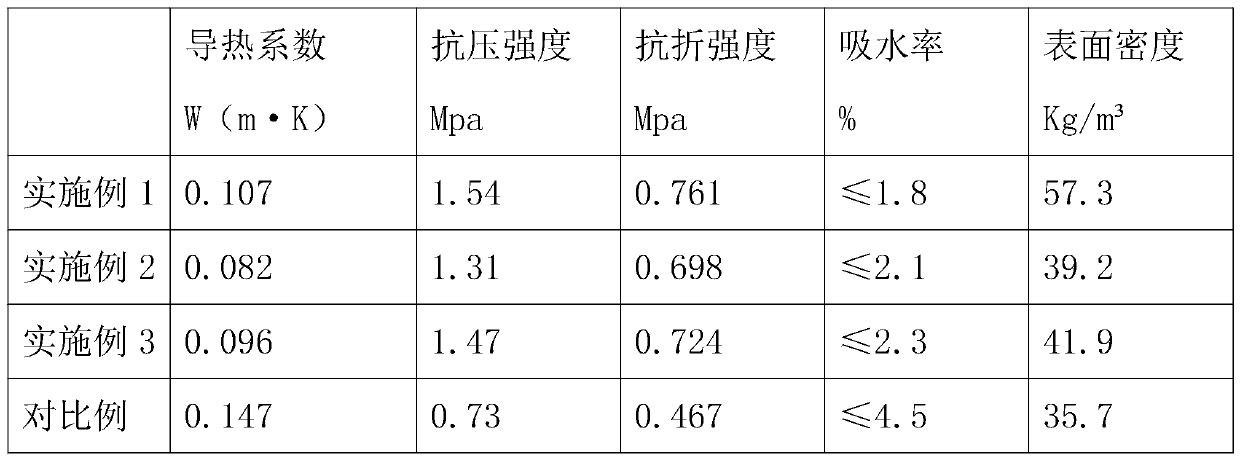

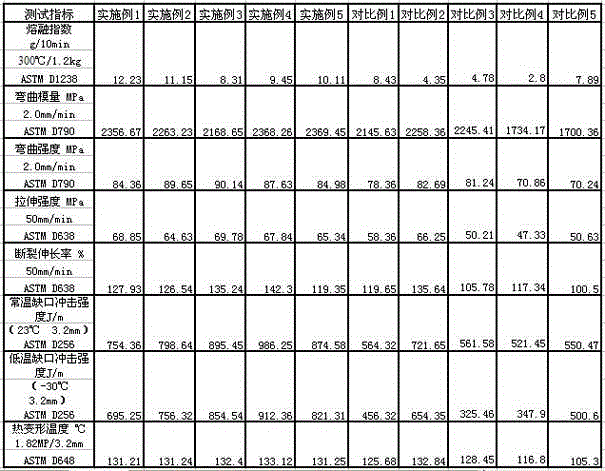

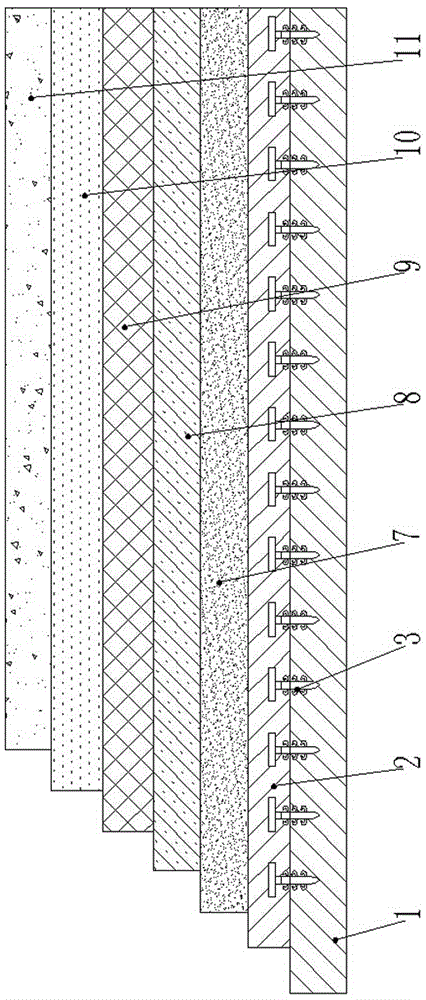

Novel cement-based particle blend non-combustible light composite heat preservation board and processing method thereof

InactiveCN110342872AImproved integrity and toughnessReduced surface dustingCeramicwareEmulsionOrganosilicon

Particularly relating to the field of composite heat preservation boards, the invention discloses a novel cement-based particle blend non-combustible light composite heat preservation board and a processing method thereof. The composite heat preservation board comprises the following components by weight: 80-100 parts of Portland cement, 30-50 parts of modified montmorillonite, 10-15 parts of flyash, 1-5 parts of a composite foaming agent, 1-5 parts of a polycarboxylic acid water reducer, 3-5 parts of polypropylene fiber, 0.5-1.5 parts of a styrene acrylic emulsion, 1.5-5 parts of an organosilicon hydrophobic agent, 4-8 parts of a coagulant, 0.5-1.5 parts of sodium metaaluminate, 0.5-1.5 parts of an early strength agent, 1-3 parts of nano boron fiber, 1-3 parts of nickel nanowire and 1-3parts of a water repellent. According to the invention, the integrity and toughness of the product are significantly improved, the surface powdering phenomenon is significantly reduced, the compressive strength of the product can be significantly improved and the thermal conductivity is reduced, thus reaching the effect of efficient heat preservation.

Owner:卓冠(江苏)新材料科技有限公司

Method for preparing silicon nitride nanometer rod by using sulfur auxiliary reaction under low temperature

Owner:SHANDONG UNIV

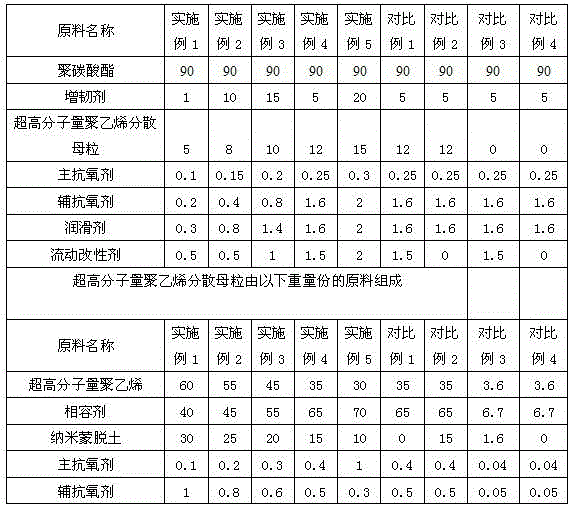

High-impact resistance polycarbonate composite material and preparation method for same

ActiveCN103665817BImprove impact resistanceImprove heat deformation resistanceAntioxidantMontmorillonite

The invention relates to the technical field of preparation of modified polycarbonate resin, in particular to a high-impact resistance polycarbonate composite material and a preparation method for the same. The preparation method comprises the following steps of pre-dispersing, mixing and granulating ultrahigh molecular weight polyethylene, a compatilizer, nano-montmorillonite, a primary antioxidant and a secondary antioxidant, and mixing and granulating the granulated mixture, polycarbonate, a toughening agent, ultrahigh molecular weight polyethylene dispersed master batches, the primary antioxidant, the secondary antioxidant, a lubricating agent and a flow modifier to obtain the high-impact resistance polycarbonate composite material. The high-impact resistance polycarbonate composite material has stronger mechanical strength, ultra-strong impact strength, strong mechanical strength and high processibility, and can be applied to the high-end helmet market and explosion-proof armor materials instead of fiberglass-reinforced plastics.

Owner:DONGGUAN HONOUR E P

Method for synthesizing silicon nitride nano material under low temperature by solvent hot reaction

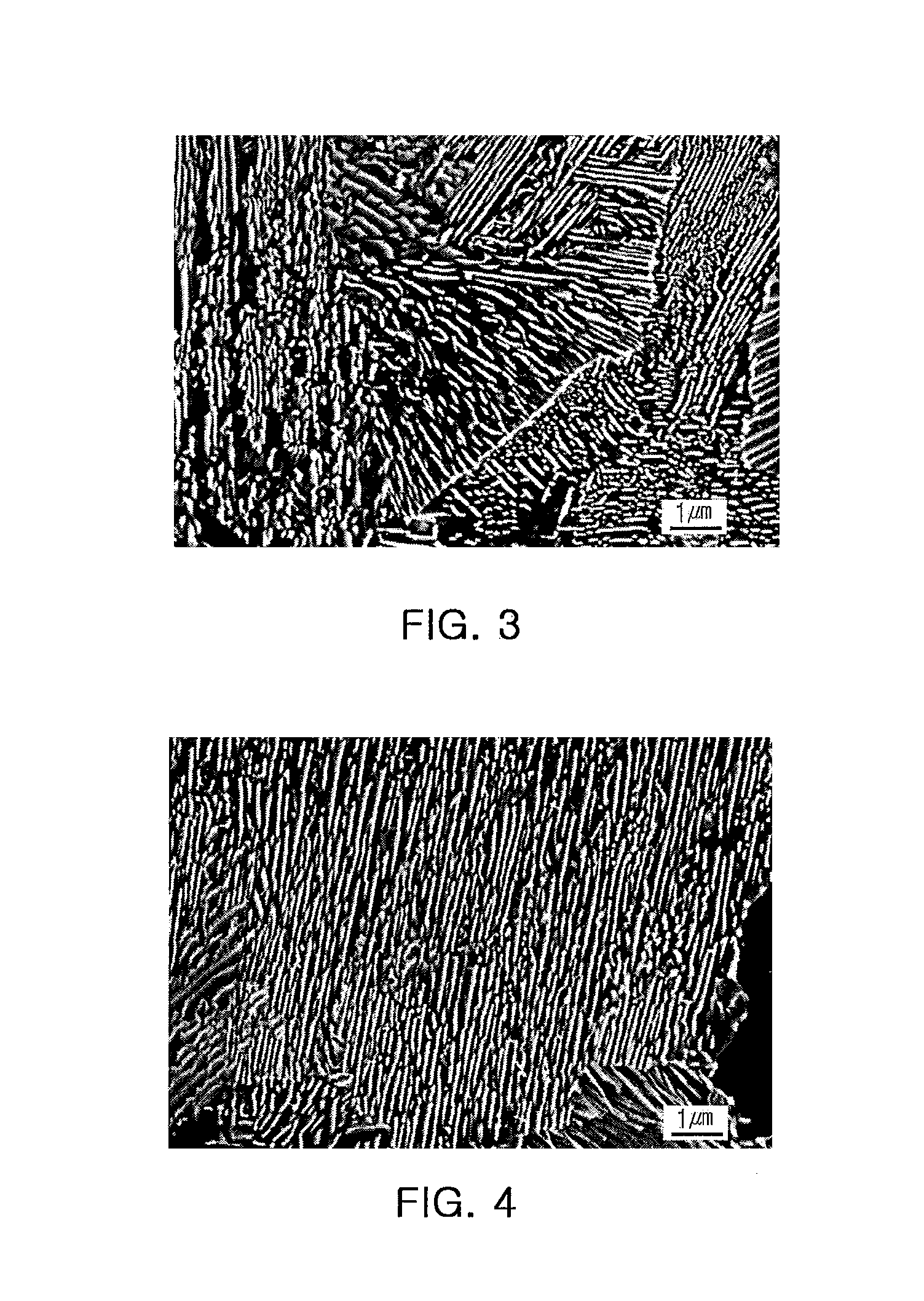

InactiveCN100560485CGood lookingHigh toughness and goodNanostructure manufactureNanowireAcid washing

The invention discloses a method for synthesizing silicon nitride nanometer material at low temperature by using solvothermal reaction, which is to mix SiCl4, NaN3 and magnesium powder according to the molar ratio of 2.8-5.8:1:0.8-2.7, or use iron powder as the reducing agent. The agent is mixed with SiCl4, NaN3 and iron powder in a molar ratio of 5.8-6.0:1:0.58-0.60, sealed in an autoclave, and reacted at 200°C-300°C for 10 hours ± 0.5 hours; the product is pickled, washed, Centrifugal separation and drying to obtain silicon nitride one-dimensional nanomaterials. The diameter of the β-Si3N4 nanorods prepared by the method of the invention is about 100 nanometers to 800 nanometers, the diameter of the nanowires is 30 nanometers to 125 nanometers; the diameter of the α-Si3N4 nanometer wires is 50 nanometers to 165 nanometers. The reaction temperature of the method of the invention is low, the obtained product has good appearance, and is suitable for large-scale industrial production.

Owner:SHANDONG UNIV

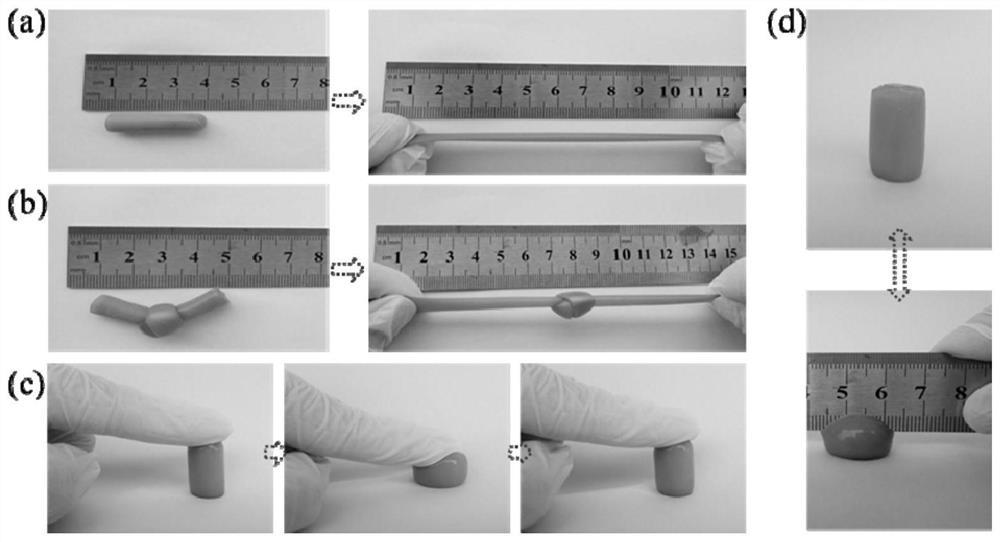

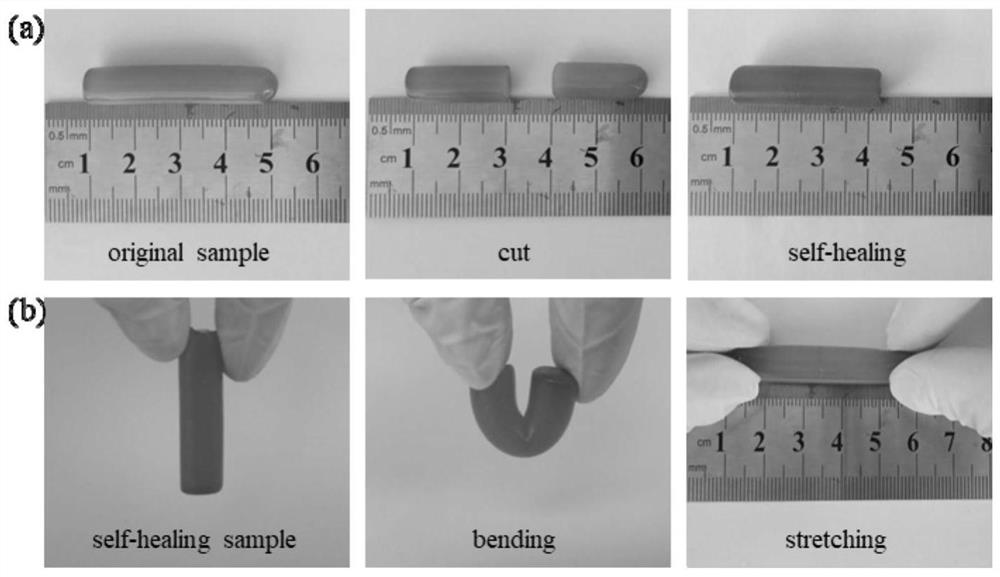

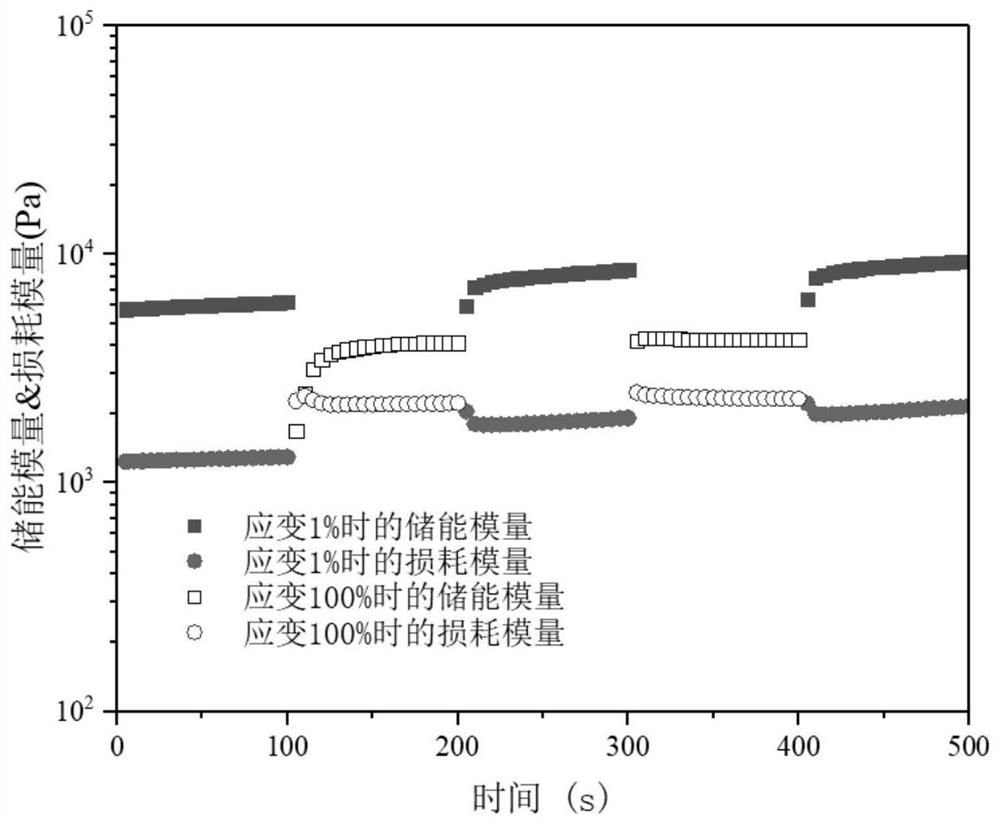

A kind of double network hydrogel and its preparation method and application

ActiveCN109971101BExcellent self-healing performanceHigh compressive strengthProsthesisPolymer scienceDouble network

The invention discloses a double network hydrogel, its preparation method and application. The hydrogel is composed of a first network and a second network, wherein the first network is formed by cross-linking polyvinyl alcohol and borax, and the second network is formed by cross-linking poly(acrylic acid-co-acrylamide) and iron ions. The first network and the second network are interspersed with each other. The present invention constructs the first network of polyvinyl alcohol by reacting the hydroxyl group of polyvinyl alcohol with borax, and the carboxyl anion on the poly(acrylic acid-co-acrylamide) molecular chain formed by the copolymerization of acrylic acid and acrylamide and Fe 3+ The formed ionic bond and the hydrogen bond formed between the amide group and the carboxyl group construct the second network. The hydrogel has excellent self-healing performance, high strength and high toughness, and can be applied in the field of tissue engineering.

Owner:GUANGDONG OCEAN UNIVERSITY

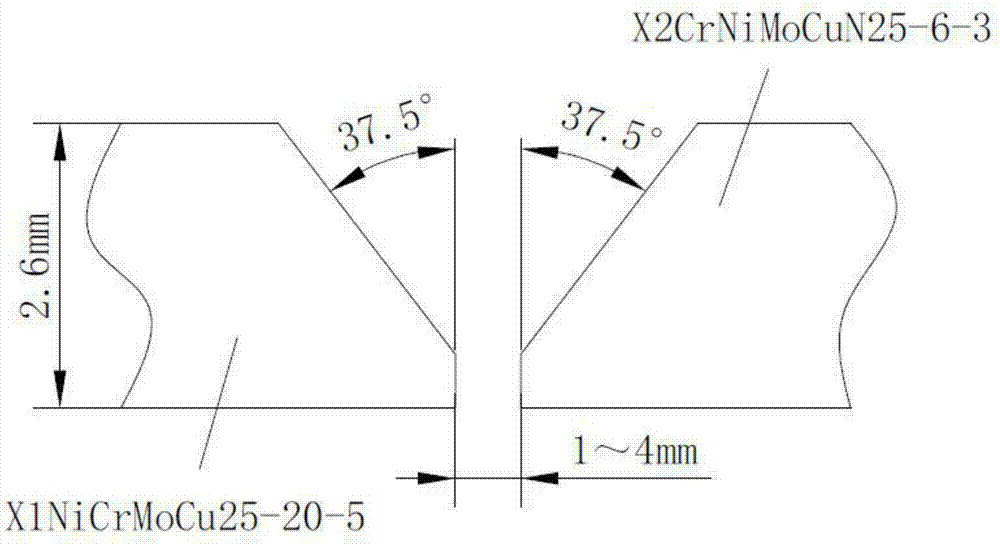

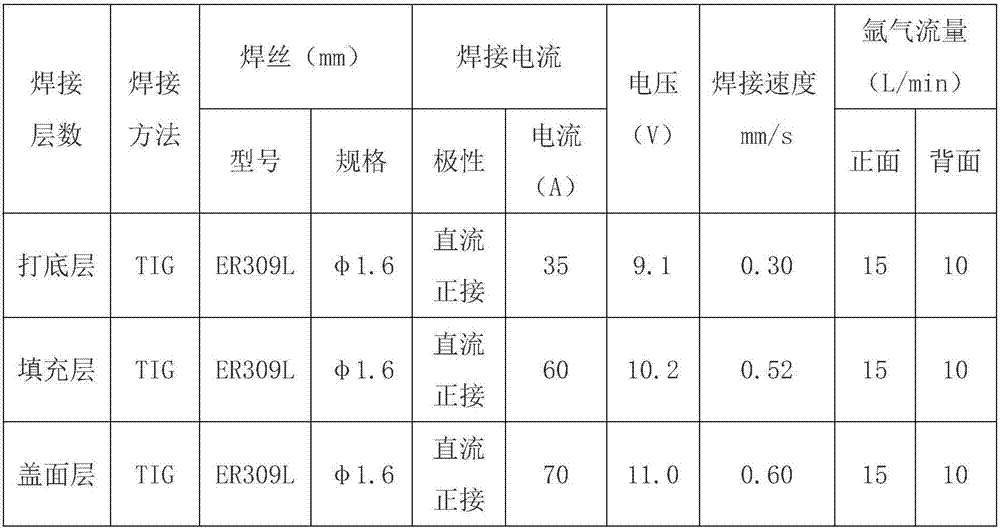

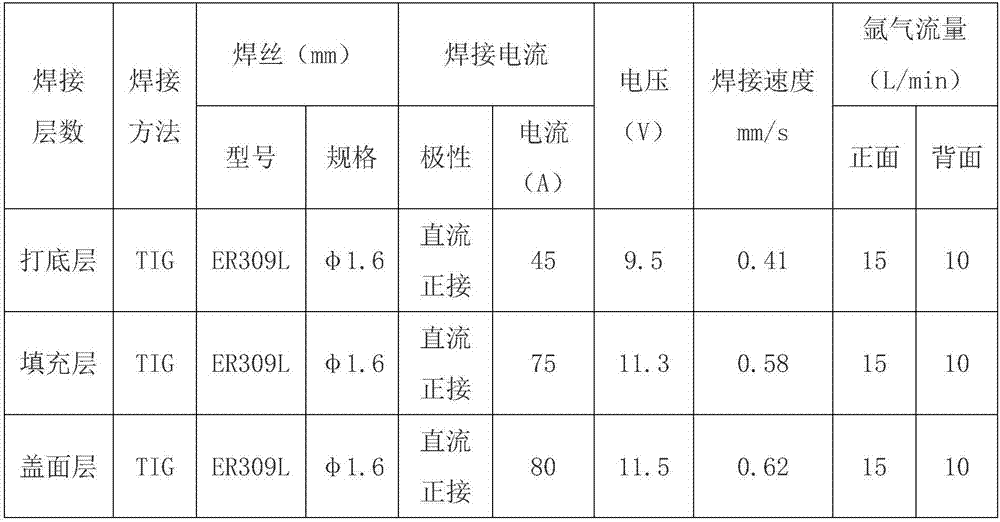

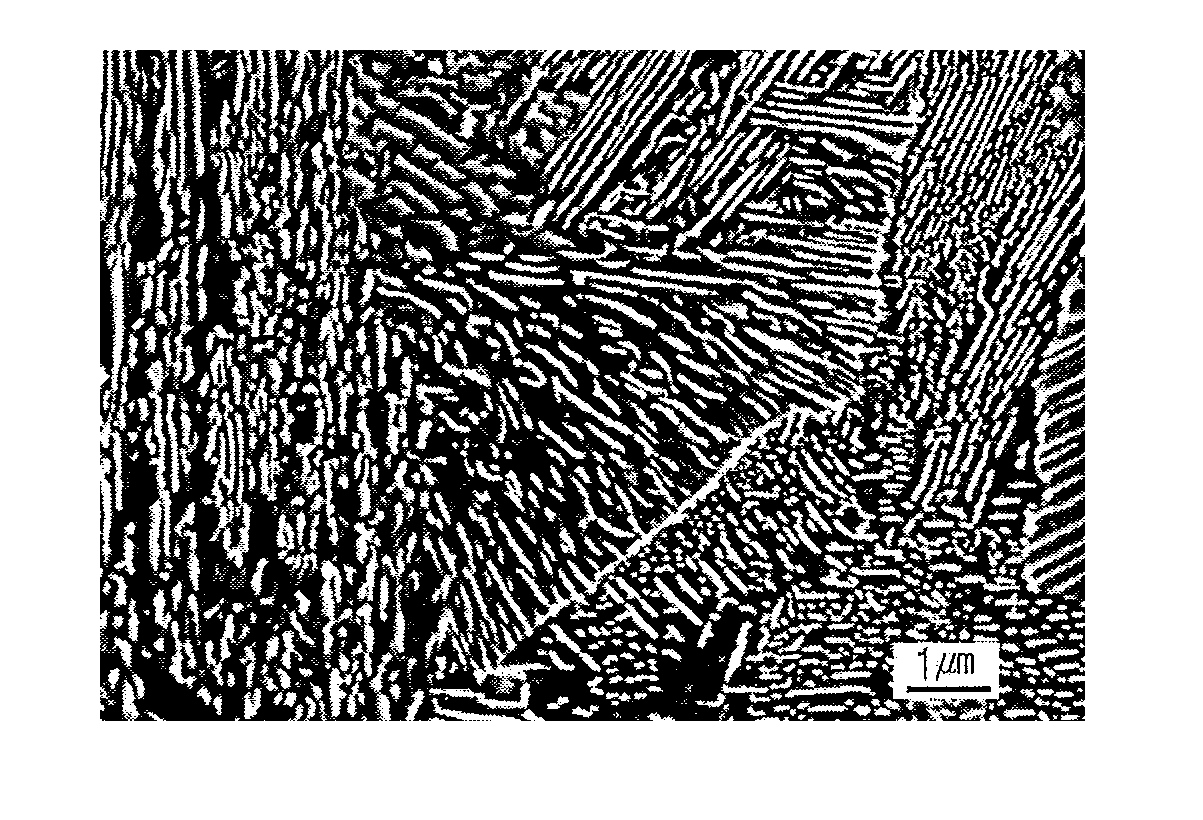

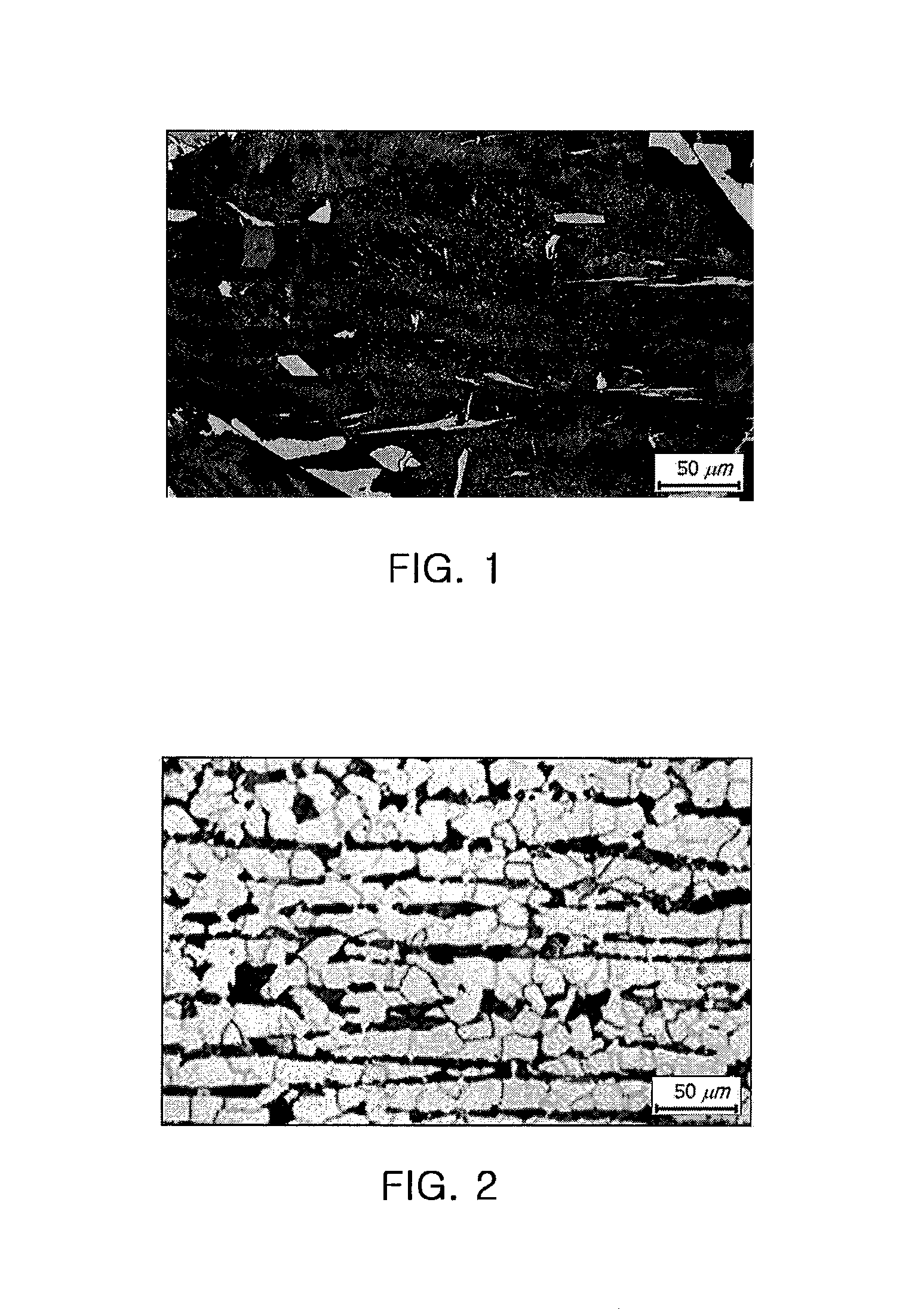

Dissimilar steel welding method

The invention belongs to the technical field of dissimilar steel welding, and particularly relates to a welding method for X1NiCrMoCu25-20-5 and X2CrNiMoCuN25-6-3 dissimilar steel plates or tubes with thicknesses or wall thicknesses smaller than 5 mm. In order to solve the problems that embrittlement and heat cracks of a welding joint easily appear during welding of X1NiCrMoCu25-20-5 and X2CrNiMoCuN25-6-3, the invention discloses a welding method for welding X1NiCrMoCu25-20-5 and X2CrNiMoCuN25-6-3 dissimilar steel. The method comprises the following steps: step S1, performing groove processing and welding assembly on to-be-welded X1NiCrMoCu25-20-5 and X2CrNiMoCuN25-6-3 dissimilar steel base materials; and step 2, performing welding operation on the to-be-welded X1NiCrMoCu25-20-5 and X2CrNiMoCuN25-6-3 dissimilar steel base materials, wherein the welding parameter comprises a welding current value of 35-80 A. Parameters in a welding operation process are selected and controlled, so that welding on X1NiCrMoCu25-20-5 and X2CrNiMoCuN25-6-3 dissimilar steel is realized; and moreover, the welding joint with excellent welding performances is obtained.

Owner:CHINA NUCLEAR IND 23 CONSTR

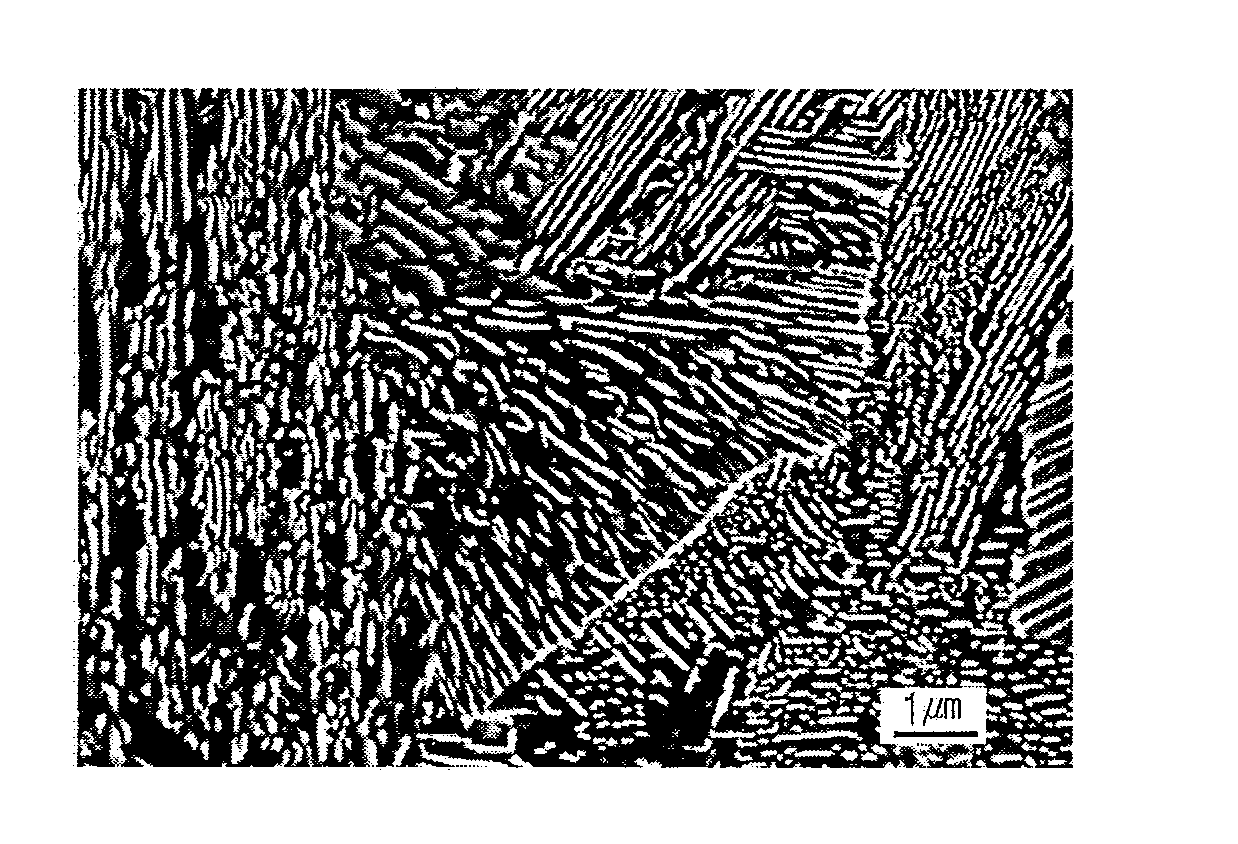

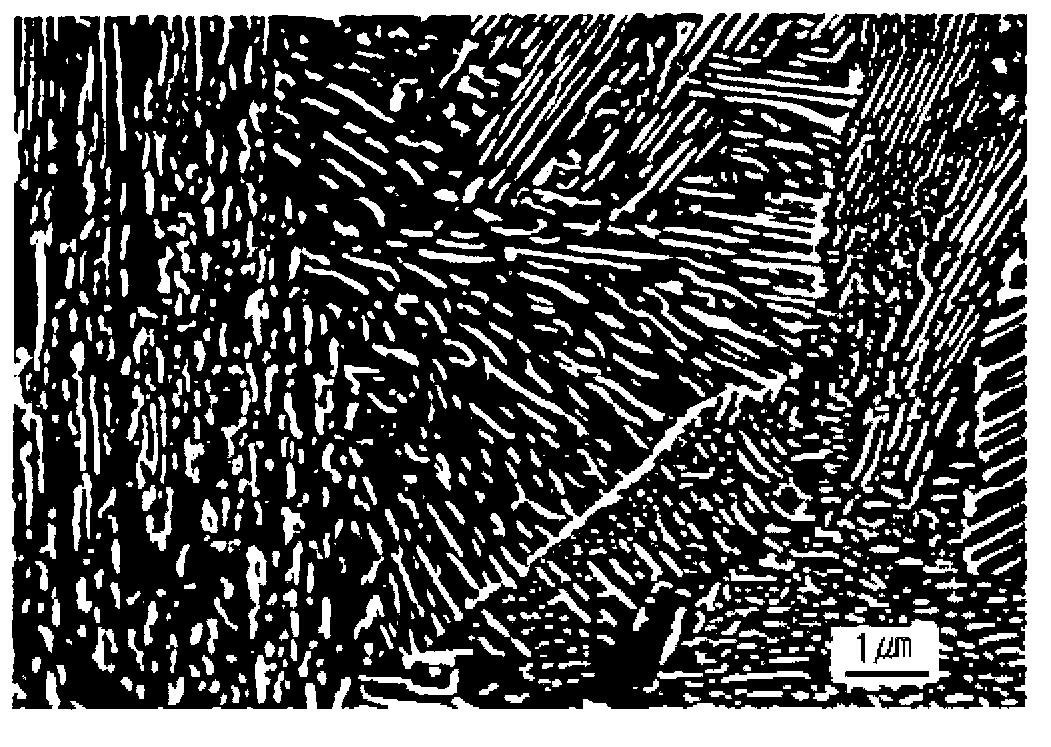

High-toughness cold-drawn non-heat-treated wire rod, and method for manufacturing same

ActiveUS9394580B2Improve toughnessHigh toughness and goodFurnace typesHeat treatment furnacesWire rodSulfur

Provided is a wire rod for use in mechanical structure connections, vehicle components, or the like, and more particularly, to a wire rod which has superior toughness without being subjected to a heat treatment, and the strength of which is ensured through a cold-drawing process. Tot his end, provided are a high-toughness cold-drawn non-heat-treated wire rod and a method for manufacturing the same, wherein the wire rod comprises in % by weight: 0.2 to 0.3% of carbon (C), 0.1 to 0.2% of silicon (Si), 2.5 to 4.0% of manganese (Mn), 0.035% or less (but not 0%) of phosphorus (P), 0.04% or less (but not 0%) of sulfur (S), the remainder being iron (Fe) and unavoidable impurities.

Owner:POHANG IRON & STEEL CO LTD

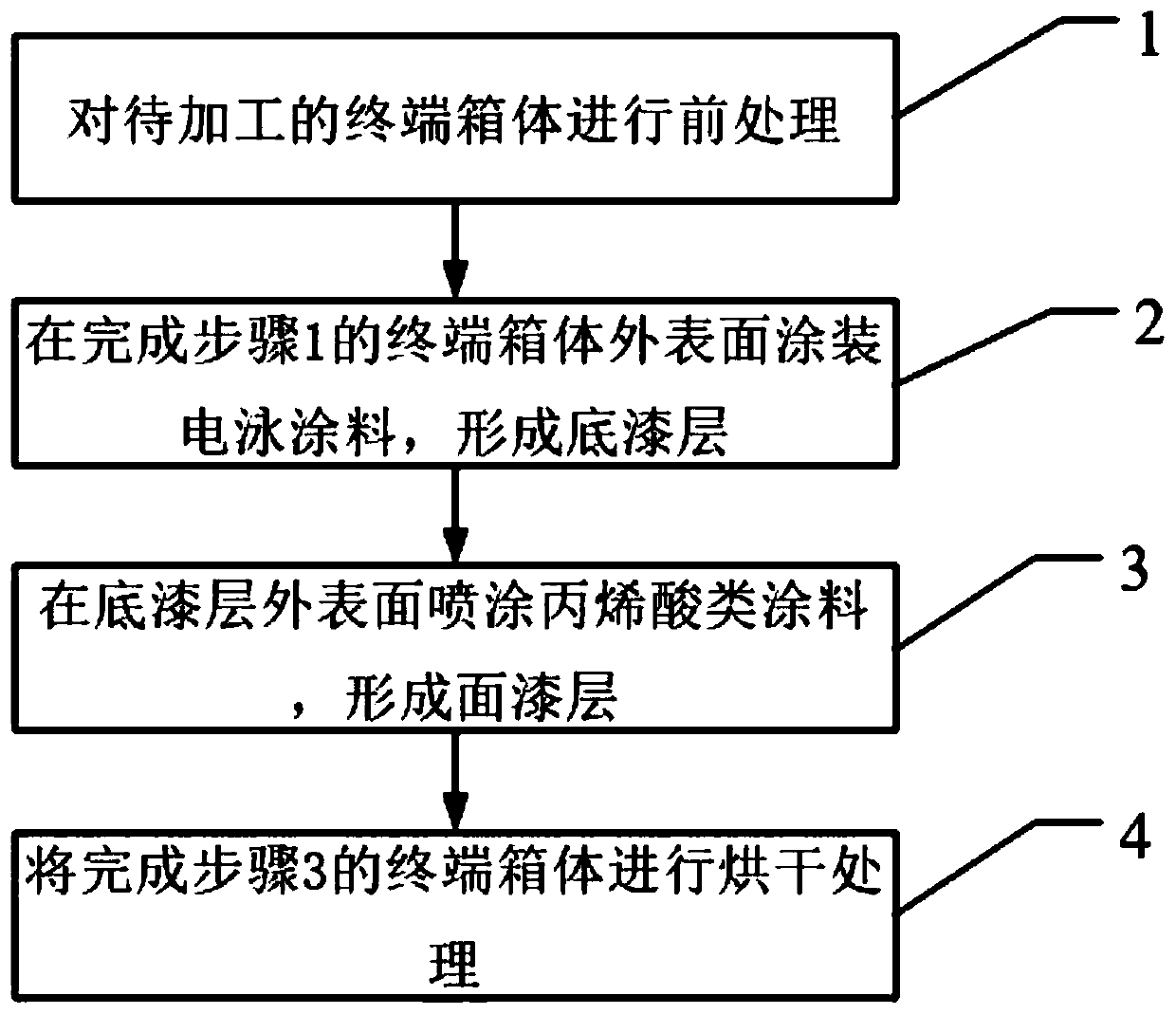

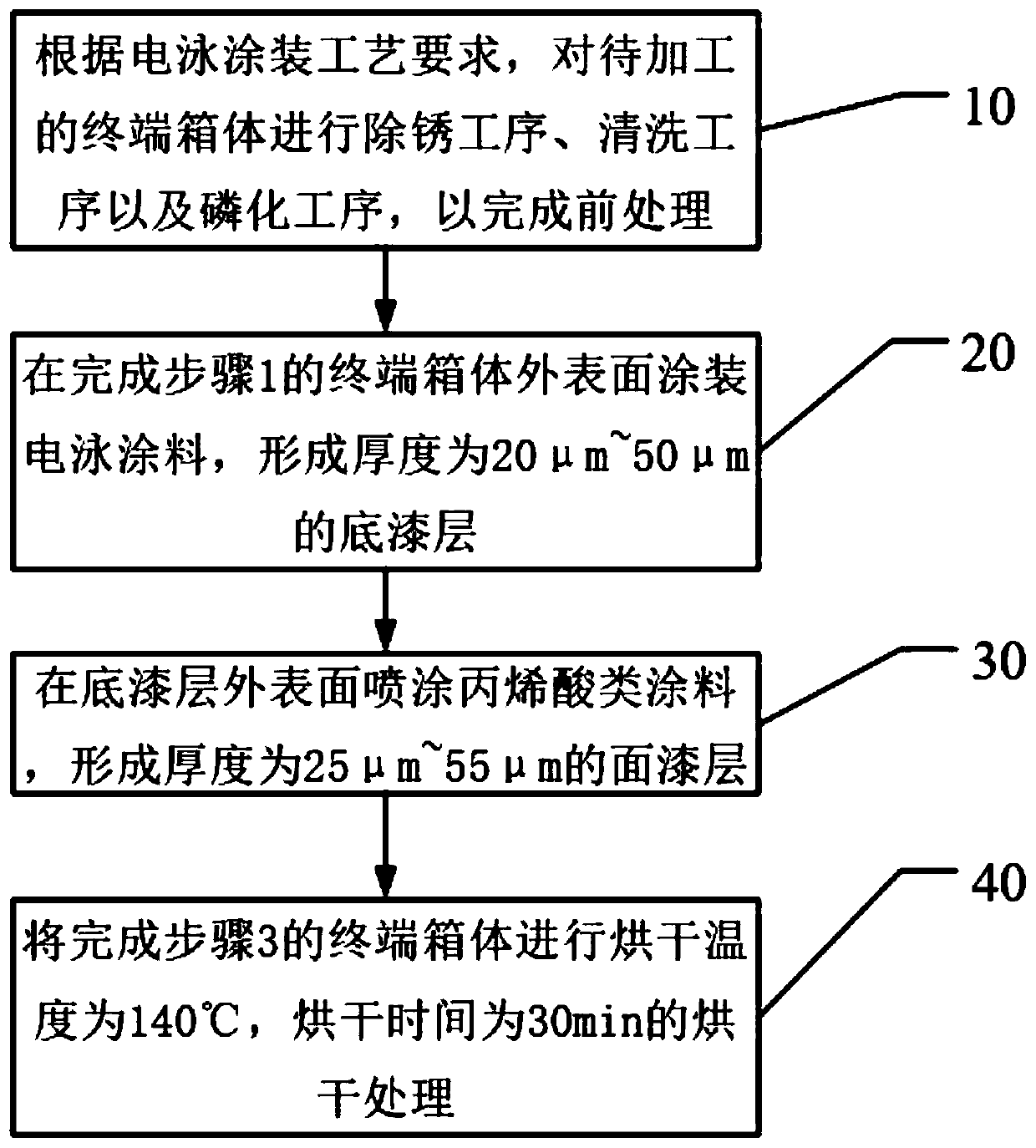

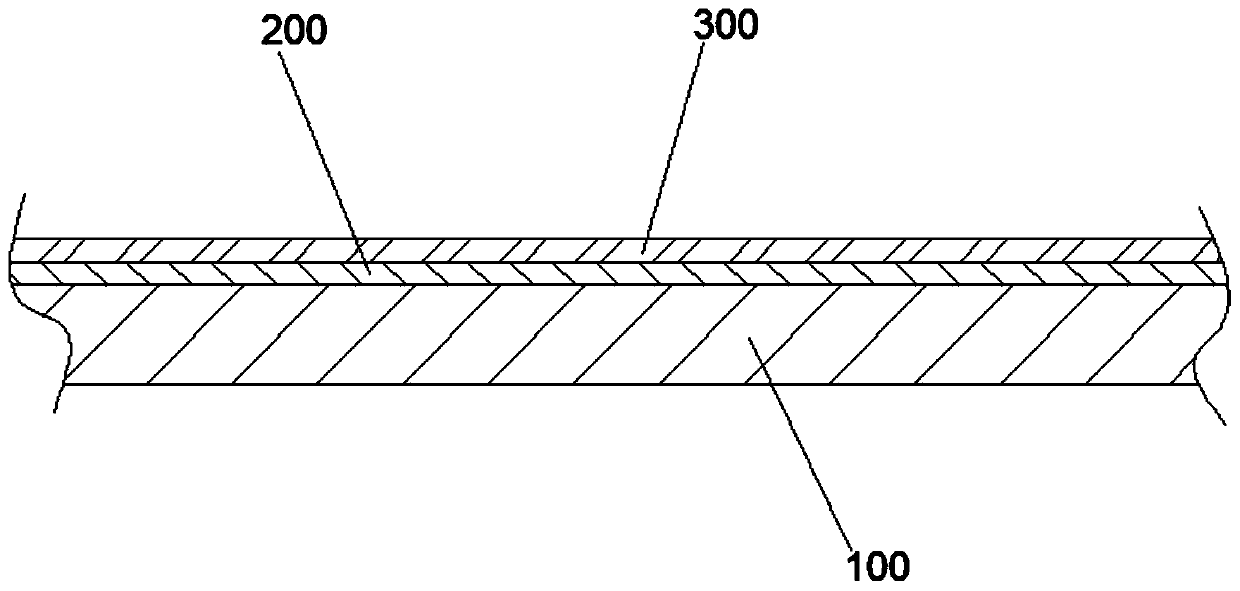

Termination box anti-corrosion processing technology and termination box

InactiveCN111036522AStrong toleranceImproves UV resistanceSubstation/switching arrangement detailsPretreated surfacesElectrophoresesWeather resistance

The invention discloses a termination box anti-corrosion processing technology and a termination box. The termination box anti-corrosion processing technology comprises the steps of carrying out pretreatment on a termination box body to be processed; coating an electrophoretic paint on the outer surface of the termination box body so as to form a primer layer; spray-coating an acrylic coating on the outer surface of the primer layer so as to form a finish paint layer; and drying the termination box body. The whole process flow is non-pollution, the utilization rate is high, the termination boxcan have better anti-corrosion and weather-proof performances, the service life of the termination box is effectively prolonged, and a terminal control device is ensured to normally work stably for along time. The invention further discloses the termination box with better anti-corrosion and weather-proof performance, so that the service life is effectively prolonged, and the terminal control device is ensured to normally work stably for a long time.

Owner:GUANGDONG POWER GRID CO LTD +1

Low-temperature solid phase reaction preparation of silicon nitride nano-material

InactiveCN100560813CLow reaction temperaturePhase controllablePolycrystalline material growthFrom solid stateNeutral phSolid reaction

The invention discloses a method for preparing silicon nitride nanometer material at low temperature by using solid-state reaction. : 0.171-0.256 mixed evenly, sealed in an autoclave, and reacted at 60±5°C for 12±0.5 hours; or silicon powder, powdered thiosemicarbazide, sodium azide and aluminum powder in a molar ratio of 0.386-0.926:0.716 -1.193:1:0.804 mixed evenly, sealed in an autoclave, and reacted at 170±5°C for 10±0.5 hours; or silicon powder, powdered thiosemicarbazide, sodium azide molar ratio 0.386-0.926:0.716-1.193 : 1 mixed evenly, sealed in an autoclave, and reacted at 170±5°C for 10±0.5 hours; the product was washed with acid and water until the pH was neutral, centrifuged and dried, and then washed with mixed acid to remove elemental silicon to obtain silicon nitride nanomaterials. The reaction temperature of the method of the invention is low, the obtained product has good appearance and uniform diameter of nanorods, and is suitable for large-scale industrial production.

Owner:SHANDONG UNIV

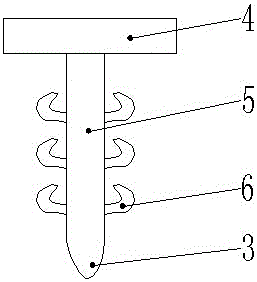

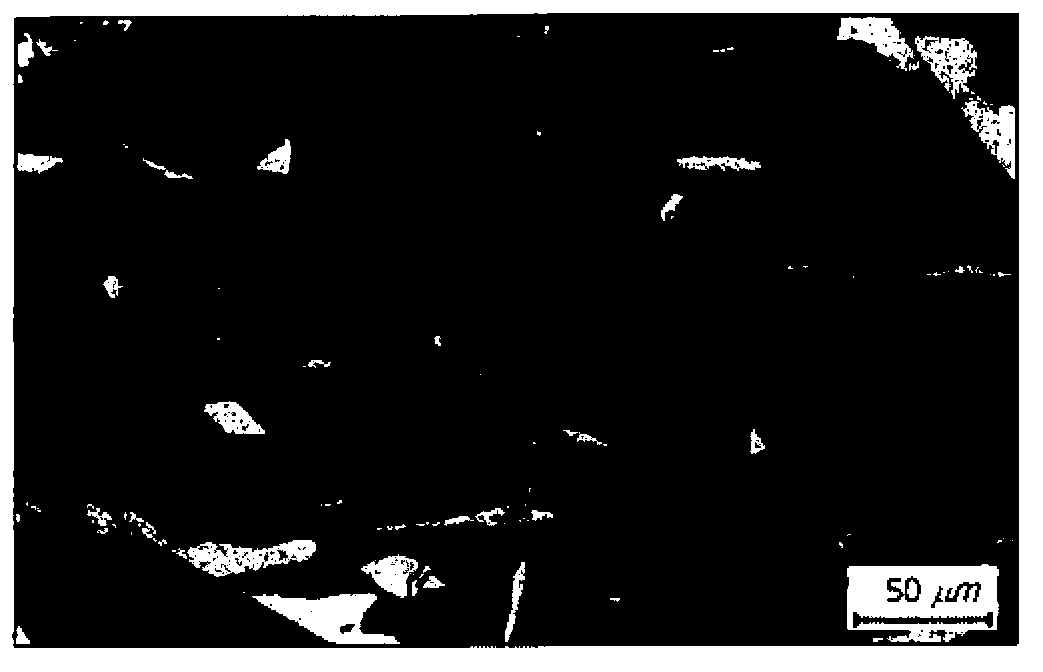

Wear-resisting colored sand floor

The invention belongs to the technical field of floors and in particular relates to a wear-resisting colored sand floor. According to the specific technical scheme, the wear-resisting colored sand floor comprises a foundation layer arranged on the bottommost layer and a concrete layer laid on the top of the foundation layer, wherein a plurality of embedded parts are uniformly distributed in the foundation layer; the embedded parts comprise top plates; vertical rods are fixed at the bottom of the top plates; a plurality of locking hooks are arranged on the outer walls of the vertical rods; open ends of the locking hook heads are arranged upwards; the top plates are fixed in the concrete layer; an unsaturated polyester layer is laid on the top of the concrete layer; an epoxy resin leveling layer is laid on the top of the unsaturated polyester layer; the top of the epoxy resin leveling layer is coated with an anticorrosive coating; the top of the anticorrosive coating is coated with a wear-resistant layer; the top of the wear-resistant layer is coated with an epoxy resin colored sand layer. The floor has the physical properties such as load resistance, water resistance, wear resistance, impact resistance, pollution resistance, high weather resistance and the like, has a flat surface, is bright and easy to clean, repair and maintain, does not produce cracks or raise dust and can meet the requirements of vast owners.

Owner:SHANGHAI FENGBANF BUILDING MATERIAL TECH CO LTD

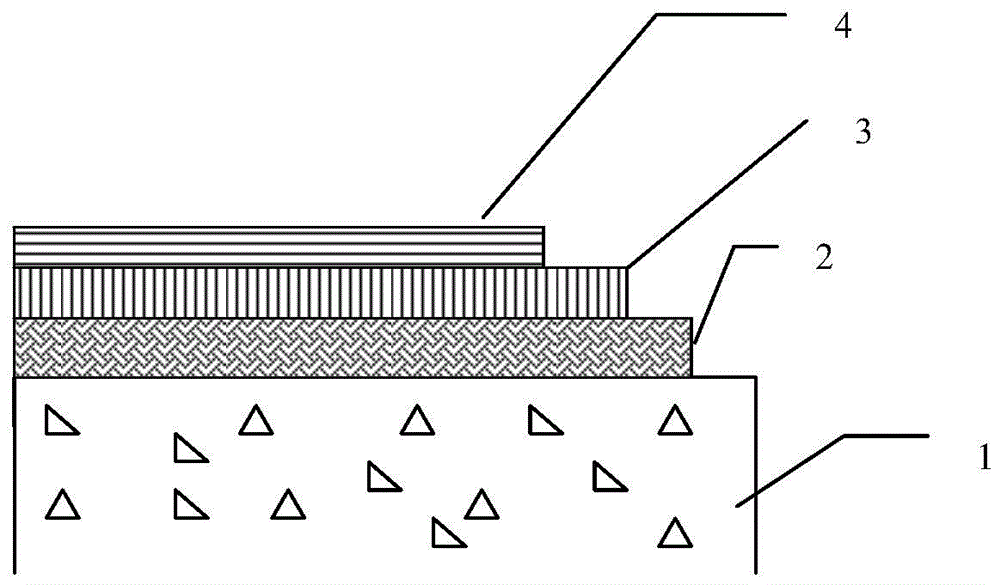

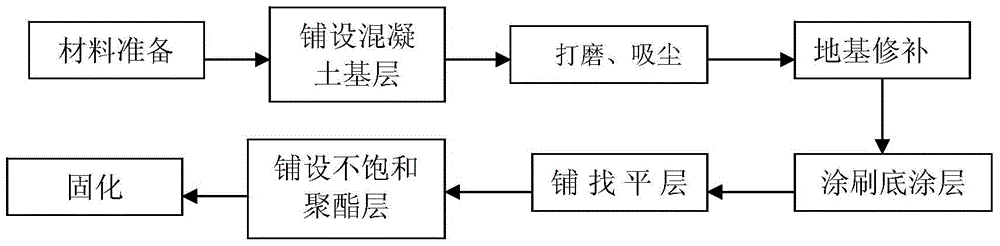

A method for preparing colored sand self-leveling floor

The invention relates to the technical field of floors, and discloses a color sand self-leveling floor which comprises a concrete basic layer, an epoxy resin priming coating, an epoxy resin leveling layer and an unsaturated polyester layer, wherein the epoxy resin priming coating, the epoxy resin leveling layer and the unsaturated polyester layer are sequentially laid on the concrete basic layer from bottom to top. The oxy resin priming coating is formed by mixing epoxy resin and curing agents, the epoxy resin leveling layer is formed by mixing epoxy resin and color sand, and the unsaturated polyester layer is formed by mixing unsaturated polyester and the color sand. The color sand self-leveling floor has the excellent physical characteristics of being high in toughness, resistant to load, waterproof, resistant to abrasion, high in impact resistance, pollution resistance and weather resistance and the like, besides, the surface of the floor is smooth and bright, cracks are not generated, dust does not accumulate, and the floor is easy to clean and maintain.

Owner:BEIJING NOVALON IND SURFACES

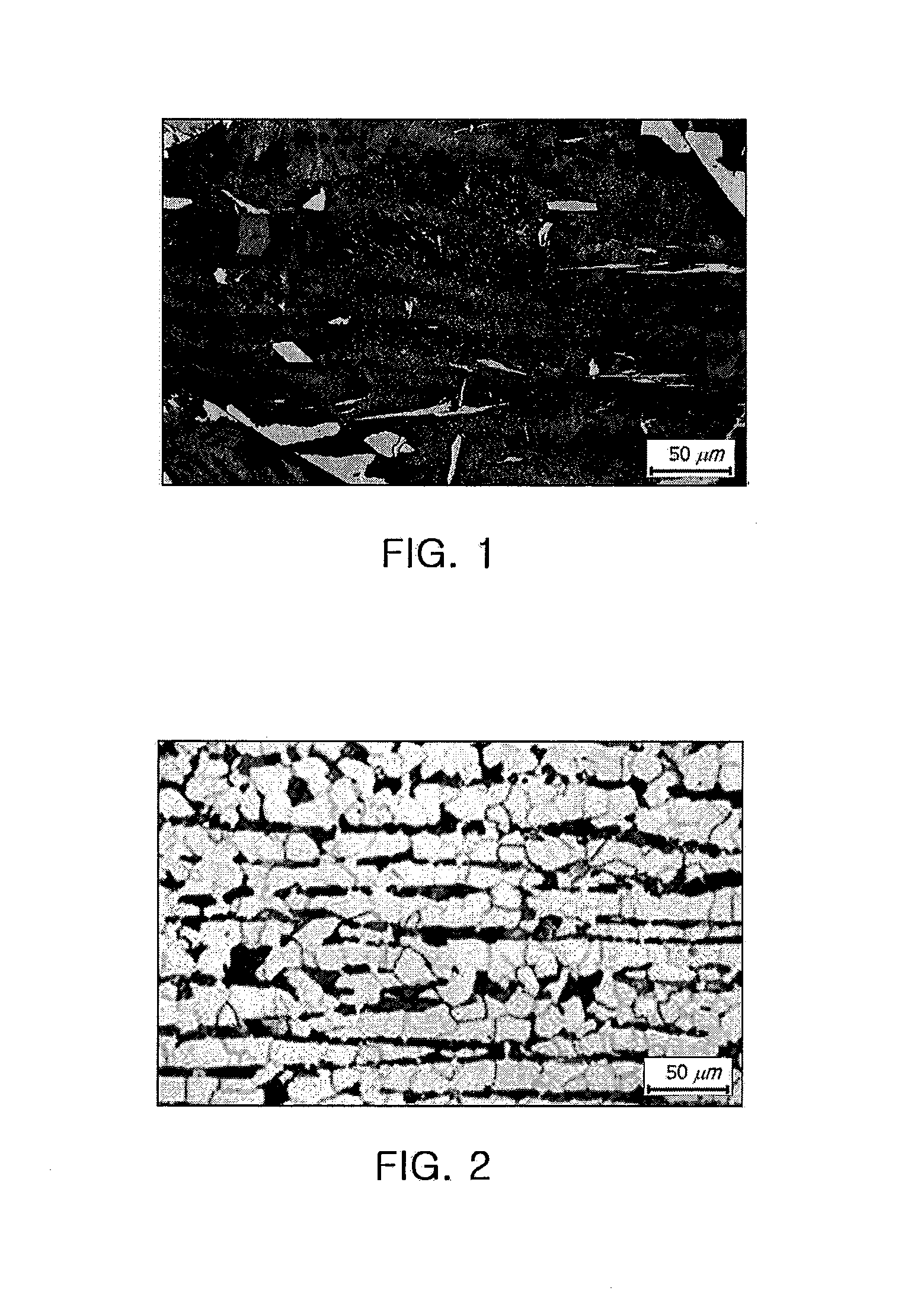

High-toughness cold-drawn non-heat-treated wire rod, and method for manufacturing same

InactiveCN103210106AEfficient manufacturingHigh toughness and goodFurnace typesHeat treatment furnacesWire rodUltimate tensile strength

The present invention relates to a wire rod for use in mechanical structure connections, vehicle components, or the like, and more particularly, to a wire rod which has superior toughness without being subjected to a heat treatment, and the strength of which is ensured through a cold-drawing process. To this end, provided are a high-toughness cold-drawn non-heat-treated wire rod and a method for manufacturing same, wherein the wire rod comprises 0.2 to 0.3% of C, 0.1 to 0.2% of Si, 2.5 to 4.0% of Mn, 0.035% or less (but not 0%) of P, 0.04% or less (but not 0%) of S, the remainder being Fe and unavoidable impurities.

Owner:POHANG IRON & STEEL CO LTD

Tungsten-based plasma facing material and preparation method thereof

The invention discloses a tungsten-based plasma facing material and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing tungsten powder and tungsten fiber by a powder mixing method which does not damage the tungsten fiber; and sintering to prepare a bulk fiber toughened tungsten-based material by a hot isostatic pressing process. The tungsten powder is one of pure tungsten powder, tungsten-rhenium alloy powder, and tungsten powder doped with carbide and oxide; and the tungsten fiber is a pure tungsten wire, a tungsten-rhenium alloy wire or the like. The tungsten-based plasma facing material has the advantages of high thermal conductivity, high melting point temperature, low sputtering yield, low hydrogen isotope retention and low vapor pressure, as well as low cost and greater toughness.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Water-resistant interior wall decorating coating

InactiveCN105505157AMaintain stabilityDurablePolyether coatingsLignin material coatingsCelluloseFiber

The invention discloses a water-resistant interior wall decorating coating, which is prepared from the following raw materials in parts by weight: 8 to 14 parts of thermosetting plastics, 4 to 6 parts of oaklet wood flour, 2 to 4 parts of diatomite, 10 to 16 parts of pachystachys lutea wood flour, 12 to 23 parts of melamine resin, 5 to 8 parts of silicic acid cellucotton, 7 to 12 parts of magnesium hydroxides, 15 to 25 parts of absolute ethyl alcohol, 2 to 5 parts of hydrochloric acid solutions, 4 to 7 parts of acetylacetone, 1 to 2 parts of emulsion powder, 6 to 14 parts of inorganic thickening agents, 25 to 35 parts of polyether polyol, 8 to 13 parts of phenolic resin, 3 to 5 parts of aluminum oxides, 1 to 3 parts of stabilizing agents, 1.2 to 2.5 parts of dispersing agents, and 2 to 5 parts of hydroxyethyl cellulose. The water-resistant interior wall decorating coating has the beneficial effects that the water-resistant interior wall decorating coating provided by the invention has stability, durability and environment friendliness, is excellent in wear resistance and high toughness, does not fall and crack easily, and is long in service life.

Owner:王丽萍

A kind of preparation method of boron carbide based cermet composite material

The invention discloses a preparation method of a boron-carbide-based metal ceramic composite material. The method comprises the following steps that (1) the raw materials including, by weight, 76-96.9 parts of boron carbide, 1-5 parts of zirconium oxide, 1-4 parts of yttrium oxide, 1-5 parts of chrome carbide and 0.1-10 parts of cobalt-nickel alloy are weighed; (2) firstly, the boron carbide andchrome carbide are subjected mixed ball milling until the average particle size is 10-50 microns; a spray drying tower is used for pelletizing, particles are added into a sintering furnace for sintering for 5-12 hours at 1,400-1,600 DEG C, heat preservation is conducted for 1-3 hours, and after cooling is conducted, ball milling is conducted again until the average particle size is 15-30 microns,so that a sintering material is obtained. The prepared boron-carbide-based metal ceramic composite material has good isotropy, structure uniformity, thermal conductivity, oxidation resistance and high-temperature creep resistance.

Owner:NINGBO DONGLIAN MECHANICAL SEAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com