Low-temperature solid phase reaction preparation of silicon nitride nano-material

A solid-phase reaction, silicon nitride technology, applied in the direction of polycrystalline material growth, self-solid, chemical instruments and methods, etc., can solve the problems of repeated difficulties, difficult to apply industrial production, high reaction pressure, etc. Effects requiring low toughness, environmental and equipment conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

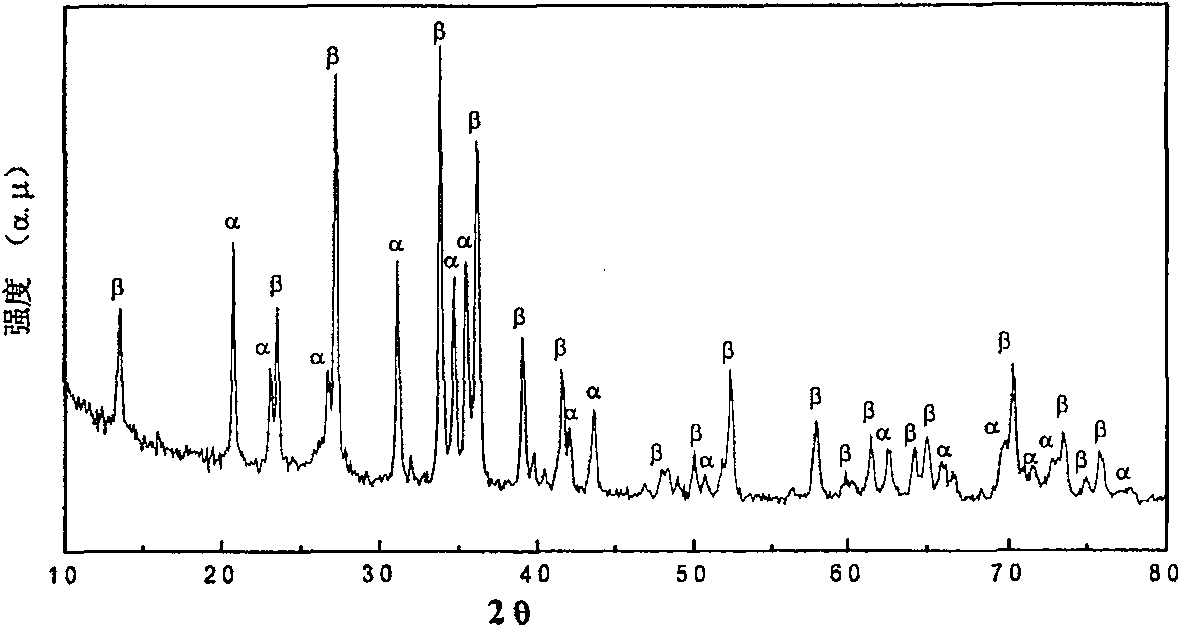

[0024] Example 1: Low temperature synthesis of silicon nitride nanomaterials

[0025] Take 0.8g of silicon powder, 3g of powdered thiosemicarbazide, 3g of sodium azide and 2g of iodine, mix them evenly, put them into a 20mL special stainless steel reaction kettle, seal them and place them in an electric heating constant temperature blast drying oven, and place them in an electric heating constant temperature blast drying oven. ℃ (furnace temperature is controlled at ± 5 ℃) and react for 12 hours; after heating is stopped, the reaction kettle is naturally cooled to room temperature; the kettle is opened, the obtained product is washed with acid and water to neutral pH, centrifuged, and then the obtained product is subjected to hydrogen The mixed solution of hydrofluoric acid and nitric acid (the volume ratio of hydrofluoric acid and nitric acid is 1:3) was washed to remove elemental silicon; vacuum-dried at 50° C. for 6 hours to finally obtain a gray-white powder product.

[00...

Embodiment 2

[0031] Example 2: Low-Temperature Synthesis of β-Phase Silicon Nitride Nanorods

[0032] Take 0.8g of silicon powder, 5g of powdered thiosemicarbazide, 3g of sodium azide and 1g of aluminum powder, mix them evenly, put them into a 20mL special stainless steel reaction kettle, seal and place them in an electric heating constant temperature blast drying oven, and place them in an electric heating constant temperature blast drying oven. 170°C (furnace temperature is controlled at ±5°C) for 10 hours; after heating is stopped, the reaction kettle is naturally cooled to room temperature; the kettle is opened, the obtained product is washed with acid and water to neutral pH, centrifuged, and then the obtained product is subjected to The mixed solution of hydrofluoric acid and nitric acid (the volume ratio of hydrofluoric acid and nitric acid is 1:3) was washed to remove elemental silicon; vacuum-dried at 50° C. for 6 hours, and finally a gray-white powder product was obtained.

[003...

Embodiment 3

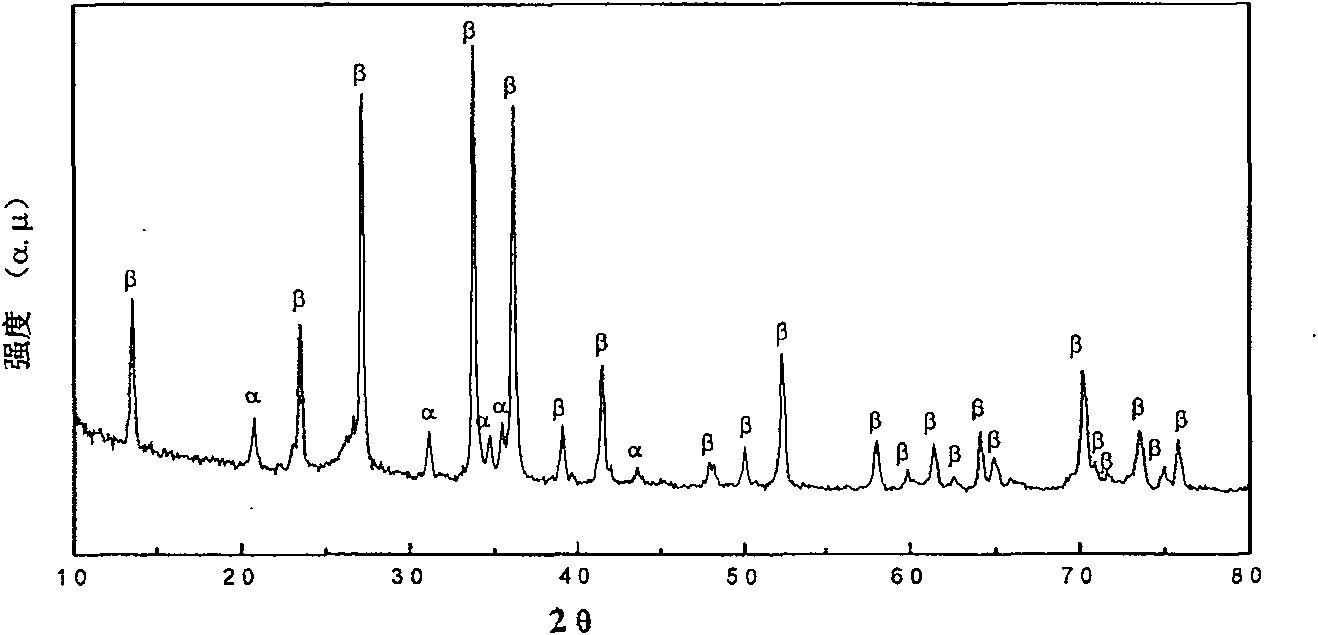

[0037] Example 3: Low temperature synthesis of silicon nitride nanomaterials

[0038] Take 0.8g of silicon powder, 4g of powdered thiosemicarbazide and 3g of sodium azide, mix them evenly, put them into a 20mL special stainless steel reaction kettle, seal and place them in an electric heating constant temperature blast drying oven, at 170 ℃ (furnace temperature) Controlled at ±5°C) and reacted for 10 hours; after heating was stopped, the reaction kettle was naturally cooled to room temperature; the kettle was opened, the resulting product was washed with acid and water to pH neutrality, centrifuged, and then the resulting product was subjected to hydrofluoric acid and nitric acid The mixed solution (the volume ratio of hydrofluoric acid and nitric acid is 1:3) was washed to remove elemental silicon; vacuum-dried at 50° C. for 6 hours, and finally a gray-white powder product was obtained.

[0039] image 3 X-ray diffraction spectrum (XRD) of the product prepared with silicon p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com