Preparation method of C/C-SIC ceramic composite material

A technology of silicon carbide ceramics and composite materials, applied in ceramic products, applications, household appliances, etc., can solve the problems of restricting the engineering application of C/C-SiC composite materials, long preparation cycle, and high brittleness of ceramics, so as to shorten production Increased cycle time, increased density, and reduced brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

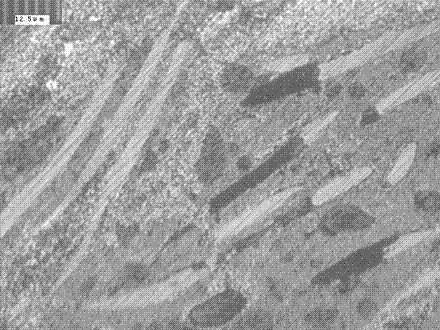

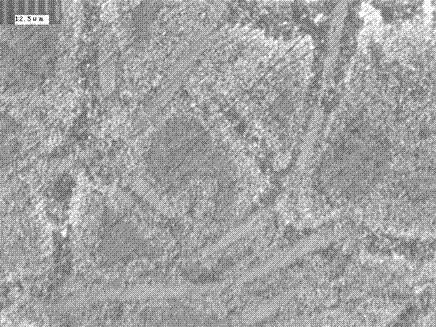

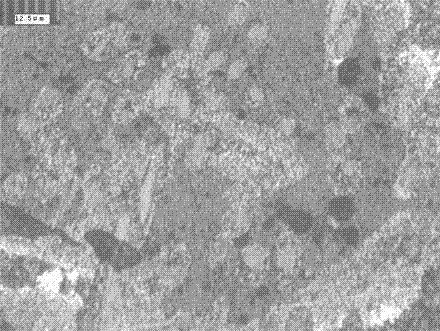

Image

Examples

Embodiment 1

[0032] Weigh the raw materials in the following proportions: 960 grams of phenolic resin, 120 grams of absolute ethanol, and 120 grams of acetone, then add 643 grams of micron-sized silicon carbide (SiC) powder, mix evenly by ball milling (conventional method), and use it as an impregnating slurry .

[0033] Produced according to the following process:

[0034] (1) Carbon coating: First, commercially available (thickness 6mm or 10mm) PAN-based flat carbon felt is used as a reinforcement, and the carbon coating is prepared by isothermal CVD process (conventional process in the industry). The deposition temperature is 900 ° C, -0.098 Under MPa vacuum conditions, use high-purity nitrogen with a flow rate of 20ml / min as the diluent gas and propylene with a flow rate of 200ml / min as the pyrolysis carbon gas source, and then under the protection of high-purity argon, the temperature rises to 1100°C for deposition. Obtaining a PAN-based flat carbon felt with a pyrolytic carbon coati...

Embodiment 2

[0044] Weigh the raw materials in the following proportions: 960 grams of phenolic resin, 120 grams of absolute ethanol and 120 grams of acetone, then add 982 grams of micron-sized silicon carbide (SiC) powder, and mix evenly by ball milling.

[0045] The preparation process is the same as in Example 1, and the product density is 2.52g / cm 3 ; The open porosity is 1.96%, and the three-point bending strength reaches 198MPa.

Embodiment 3

[0047] Weigh the raw materials in the following proportions: 960 grams of phenolic resin solution, 120 grams of anhydrous methanol and 120 grams of acetone, then add 514 grams of micron-sized silicon carbide (SiC) powder, and mix evenly by ball milling.

[0048] The preparation process is the same as in Example 1, and the product density is 2.45g / cm 3 ; The open porosity is 2.91%, and the three-point bending strength reaches 176MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com