Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Has the ability to restore" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for decoloring burned waste water by using zero-valent iron/ultrasonic wave synergistic reaction

InactiveCN101234812AImprove biodegradabilityEasy to handleWater/sewage treatment with mechanical oscillationsWater/sewage treatment by reductionUltrasound - actionReaction temperature

The invention relates to environmental chemistry, in particular to a method for decolorizing coking wastewater by using synergetic effect of zero-valent iron / ultrasonic waves, which specifically comprises the following steps: wastewater and zero-valent iron chips / powders are added into a reactor; the pH value of the wastewater is adjusted to be 1 to 6; then stirring is carried out under the effect of the ultrasonic waves with the power of 150 to 200W; the reaction is lasted for 30 to 60 minutes; the wastewater is decolorized and COD is removed. During the process, the use amount of zero-valent iron in each liter of wastewater is 2 to 500g, and the reaction temperature is 10 to 80 DEG C. By applying the method for decolorizing coking wastewater by using synergetic effect of zero-valent iron / ultrasonic waves, the chromaticity of the coking wastewater can drop from 1,500 times to 140 times, and the removal efficiency can reach over 90 percent; in addition, after the synergetic effect of the zero-valent iron and ultrasonic waves, the removal efficiency of COD in the coking wastewater is higher than the efficiency under the signal effect of the zero-valent iron and the ultrasonic waves. The obtained BOD5 / COD is increased from 0.08 to 0.36, and the biodegradability of the wastewater is also increased remarkably.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Cosmetics based on nitric oxide

ActiveCN101028229AAvoid infectionImprove local immunityCosmetic preparationsToilet preparationsOrganic acidChemical reaction

A novel cosmetic based on No for promoting the metabolism of skin and beautifying skin is composed of nitrogen component (nitrite or concentrated vegetative liquid extract rich in nitrite) and acid component (organic or inorganic acid), which can take part in chemical reaction to release No.

Owner:北京富丽华德生物医药科技股份有限公司

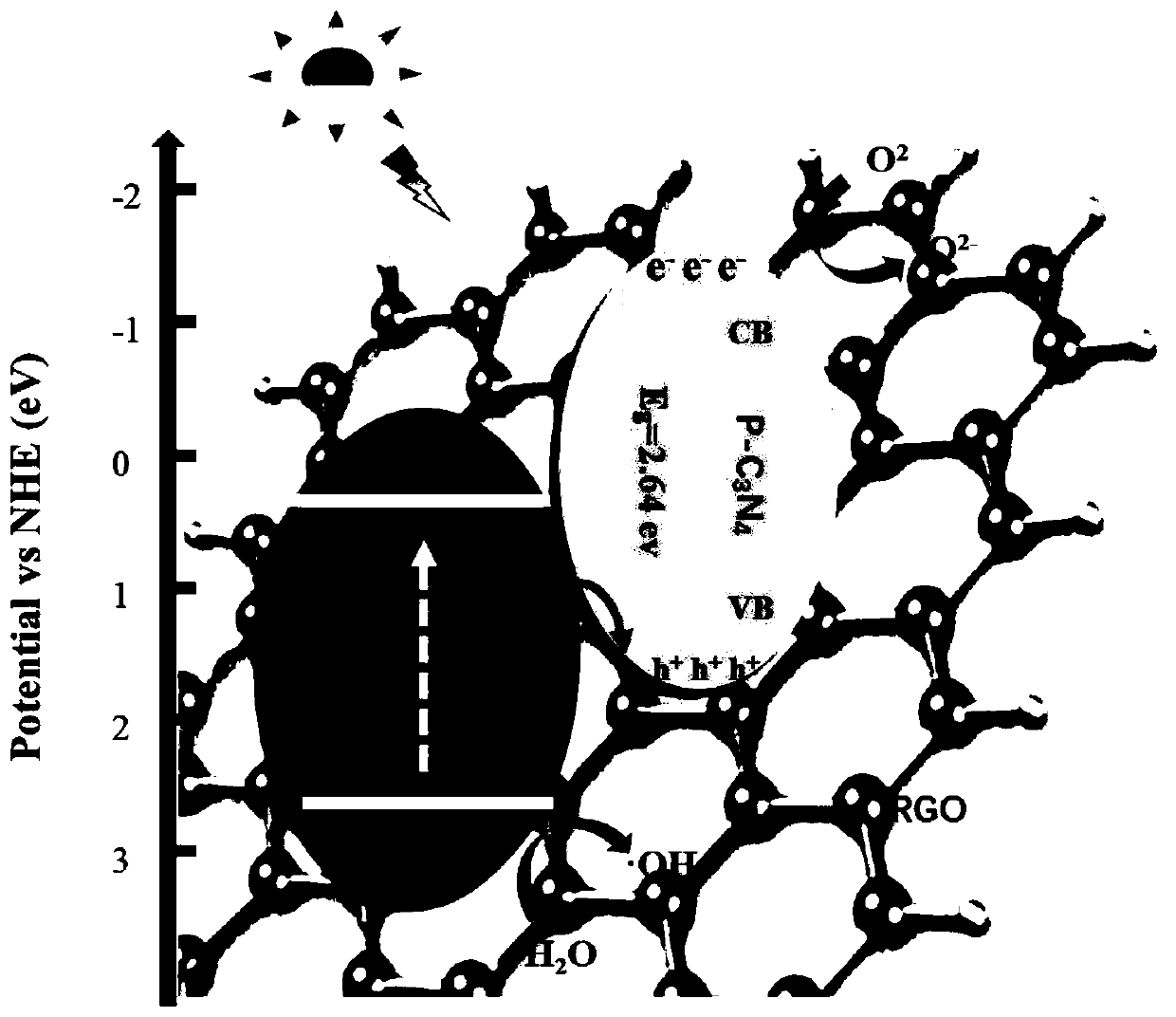

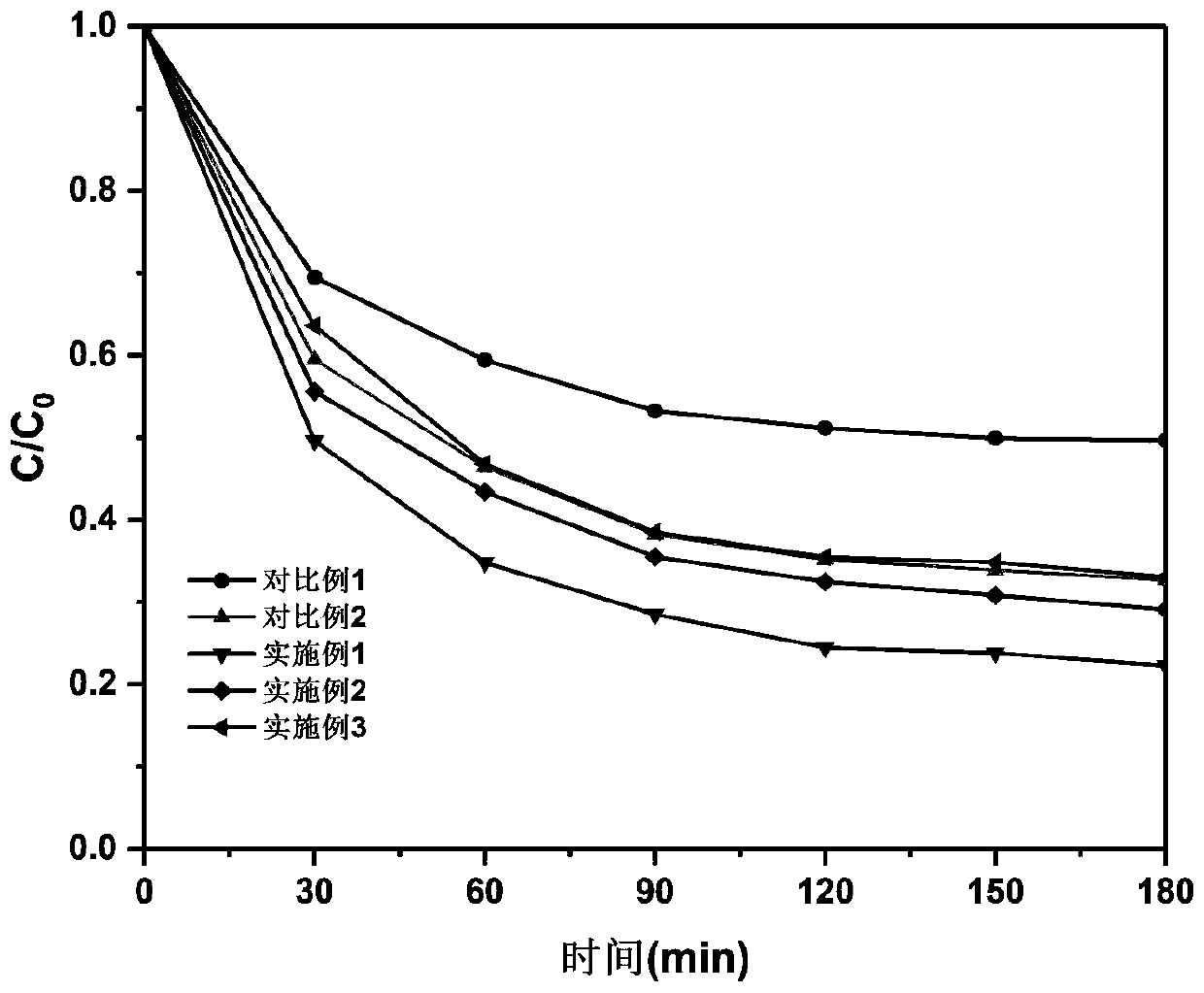

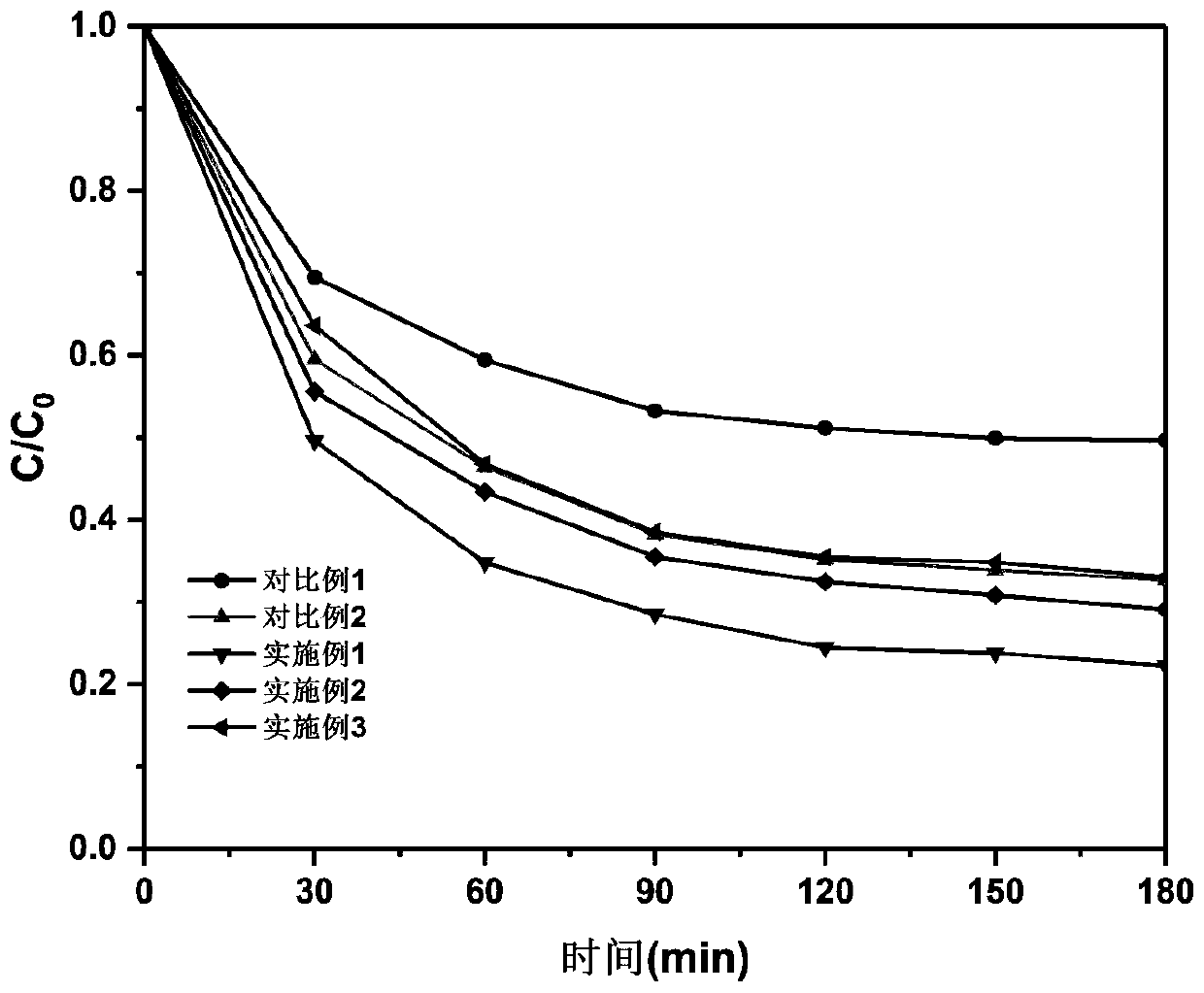

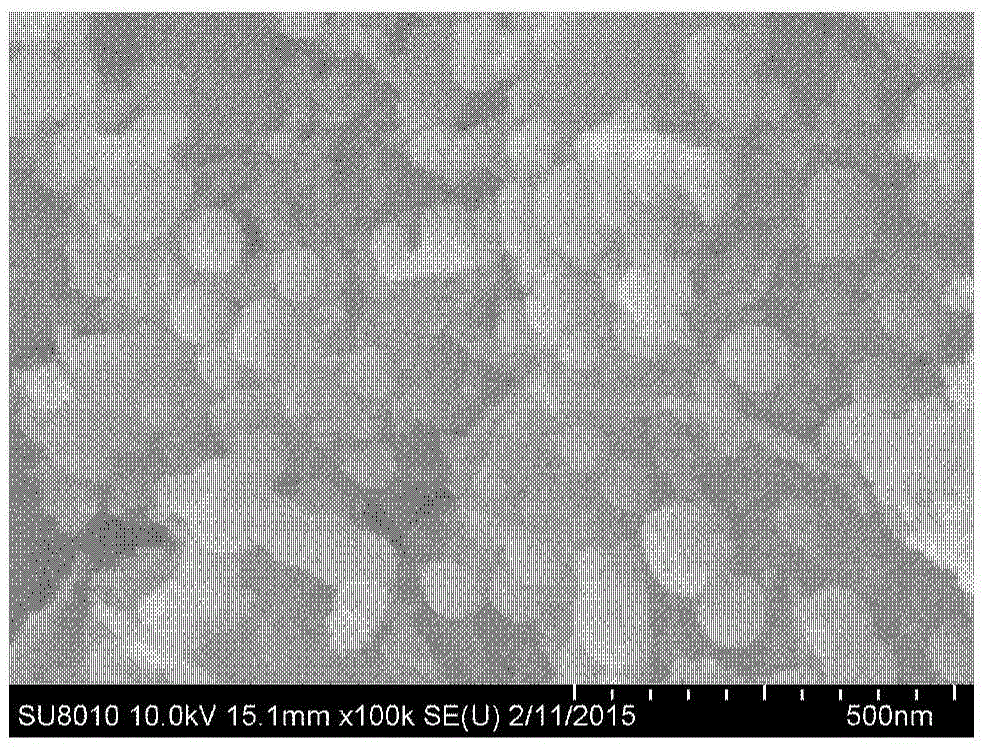

Visible light catalytic material and preparation method and application thereof

ActiveCN111167496AOxidizing abilityConductiveNitrogen compoundsWater/sewage treatment by irradiationPtru catalystBismuth vanadate

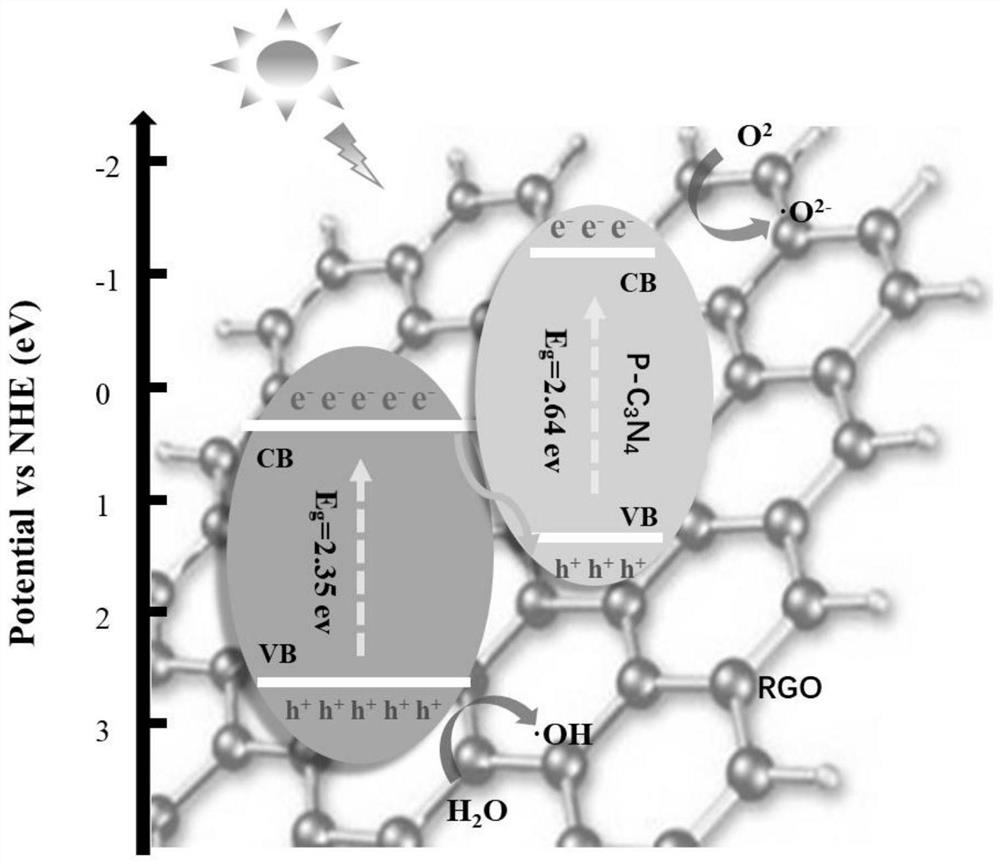

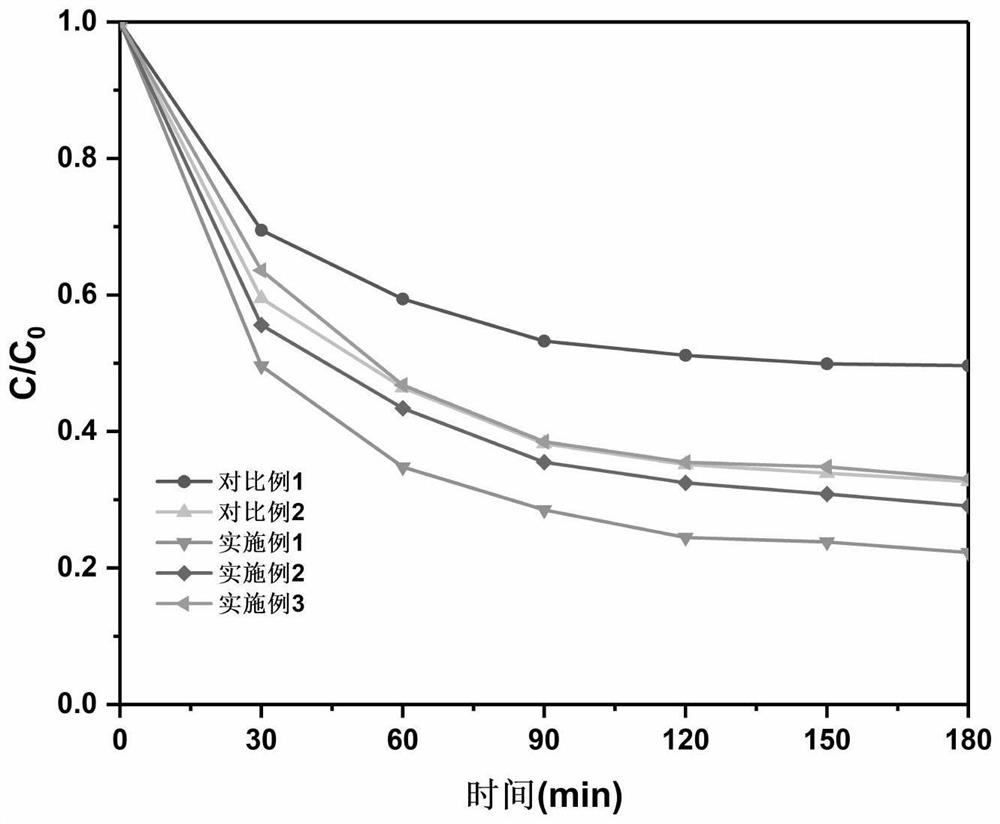

The invention provides a visible light catalytic material and a preparation method and application thereof, which belong to the technical field of catalysts. The visible light catalytic material provided by the invention comprises a carrier and active components loaded on the surface of the carrier, wherein the carrier is conductive ceramic; the active components are P-C3N4, graphene oxide and bismuth vanadate; the conductive ceramic is prepared from the following raw materials: graphene, aluminum oxide and zinc oxide. P-C3N4 and BiVO4 in the visible light catalytic material provided by the invention can be excited by visible light to generate photo-induced electrons and holes; electrons with reducibility on BiVO4 can be transferred to P-C3N4 and are compounded with holes with oxidability,and RGO can be used as an electron transfer medium to enhance the process. The visible light catalytic material provided by the invention has excellent visible light catalytic efficiency and recoveryefficiency by adopting active components with specificcompositions and a carrier for cooperative use.

Owner:NANKAI UNIV

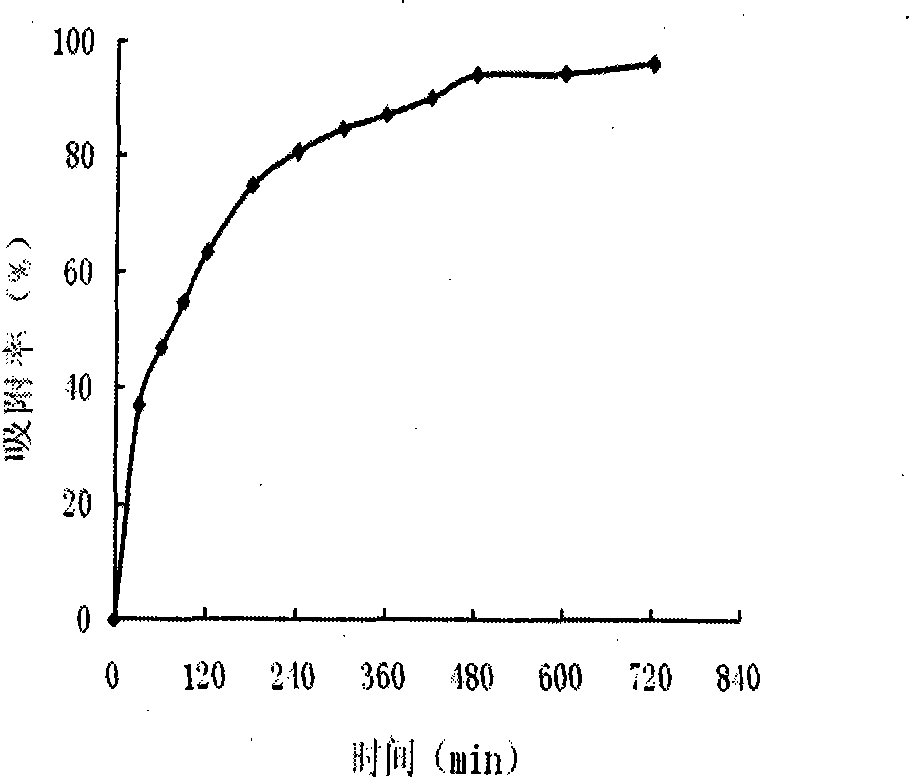

Hangjin 2# soil loaded nano-zero valent iron adsorption material, preparation method and application

InactiveCN105148831AImprove resource utilizationImprove self-worthOther chemical processesWater/sewage treatment by ion-exchangeNitrogenOxygen

The invention relates to a Hangjin 2# soil loaded nano-zero valent iron adsorption material, wherein the mass ratio of nano-zero valent iron to Hangjin 2# soil is 1:4-5. The preparation method employs Hangjin 2# soil as the carrier to load nano-zero valent iron, and the steps include: 1) dissolving an iron-containing oxide in an ethanol solution to obtain a mixed solution; 2) adding Hangjin 2# soil into the mixed solution of step 1, and controlling the mass ratio of nano-zero valent iron to Hangjin 2# soil at 1:4-5; 3) introducing nitrogen into the product of step 2, conducting stirring to remove oxygen; 4) adding a reducing agent into the product of step 3 to reduce the iron-containing oxide into nano-zero valent iron, and uniformly dispersing the nano-zero valent iron on the surface of the carrier material Hangjin 2# soil; and 5) subjecting the product obtained in step 4 to solid-liquid separation, and performing vacuum drying on the solid, thus obtaining the Hangjin 2# soil loaded nano-zero valent iron adsorption material. The adsorption material provided by the invention has higher reaction activity and reduction effectiveness, and has good application value in actual water pollution control and restoration projects.

Owner:BEIJING VOCATIONAL COLLEGE OF AGRI +1

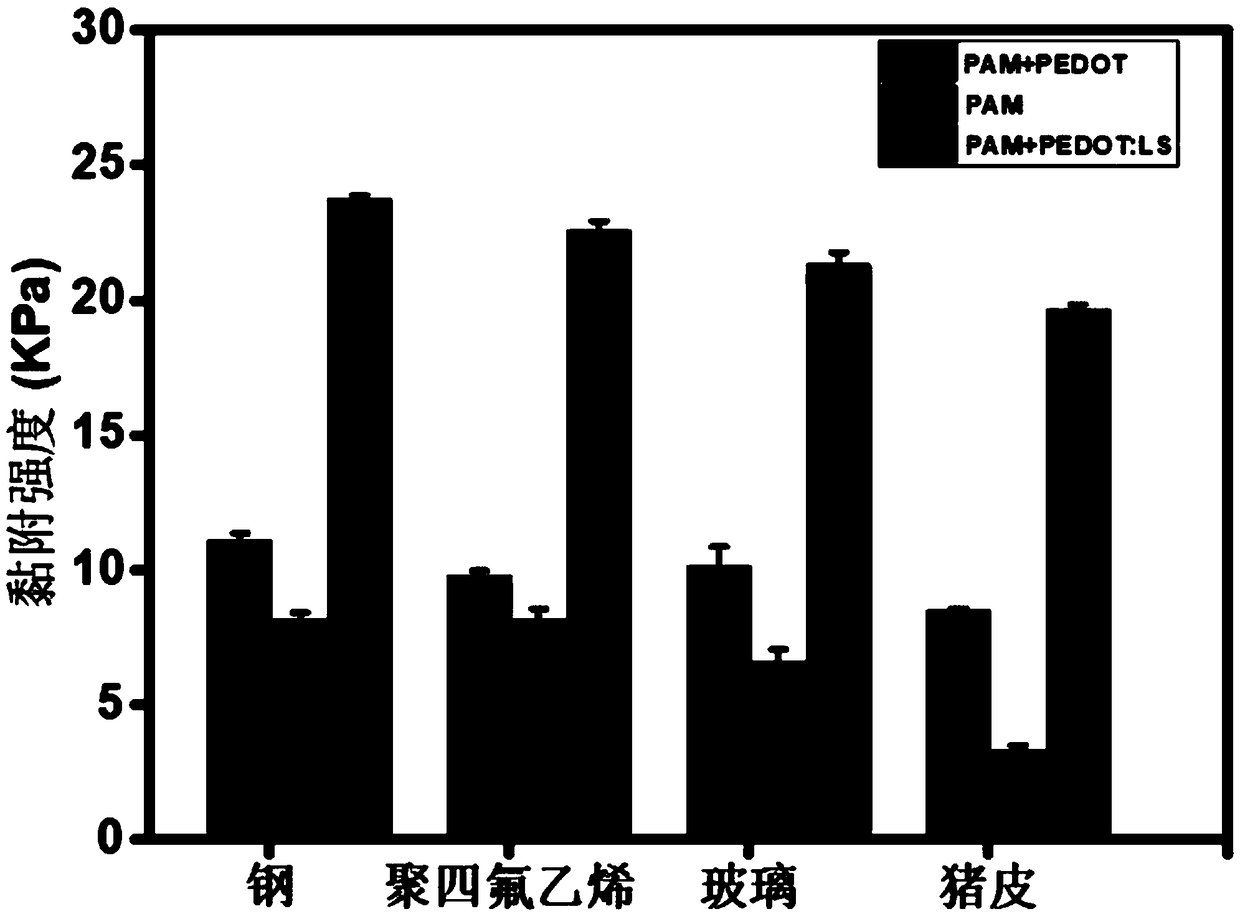

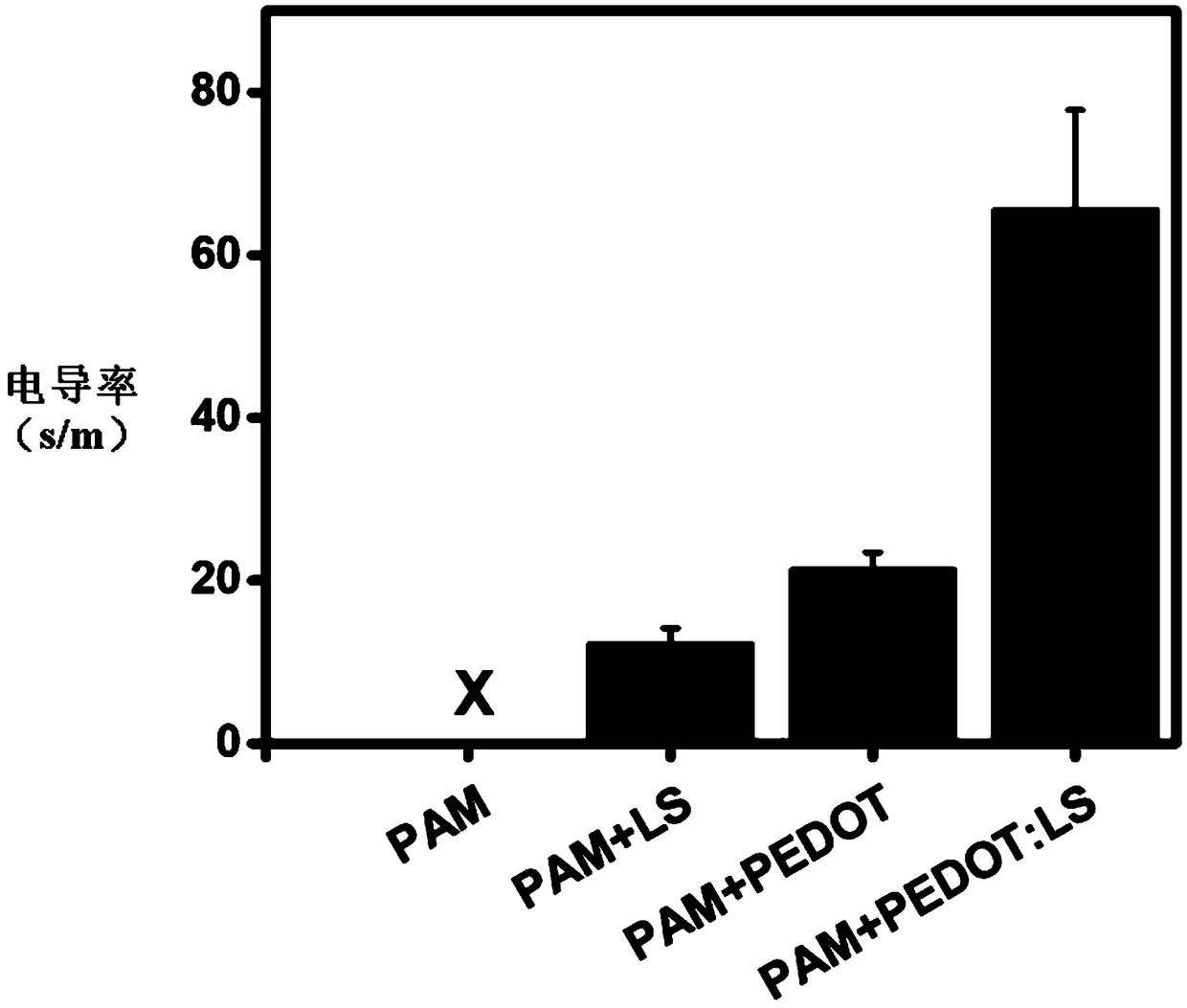

Method for preparing tissue repair adhesion conductive hydrogel

InactiveCN109456444AGood biocompatibilityWide variety of sourcesSurgical adhesivesPharmaceutical delivery mechanismTissue repairBiocompatibility Testing

The invention discloses a method for preparing tissue repair adhesion conductive hydrogel. The method includes carrying out sulfonation modification on lignin to allow the lignin to obtain hydrophilicsulfonic acid groups; polymerizing oxidation 3,4-ethylene thiophene dioxide monomers and simultaneously preparing poly-3,4-ethylene thiophene dioxide / lignin sulfonate complexes; doping the complex particles in hydrogel to obtain the tissue repair adhesion conductive hydrogel. The method has the advantages that the lignin with large quantities of abundant phenolic hydroxy functional groups is doped in the hydrogel, mutual effects can be realized by the phenolic hydroxy functional groups and the surfaces of objects, and accordingly the tissue repair adhesion conductive hydrogel is excellent inadhesion performance; the dispersibility of poly-3,4-ethylene thiophene dioxide can be improved by the sulfonated lignin, accordingly, poly-3,4-ethylene thiophene dioxide polymer particles are small and can be uniformly dispersed in hydrogel matrixes, and the tissue repair adhesion conductive hydrogel is good in conductivity; the tissue repair adhesion conductive hydrogel is good in biocompatibility.

Owner:SOUTHWEST JIAOTONG UNIV

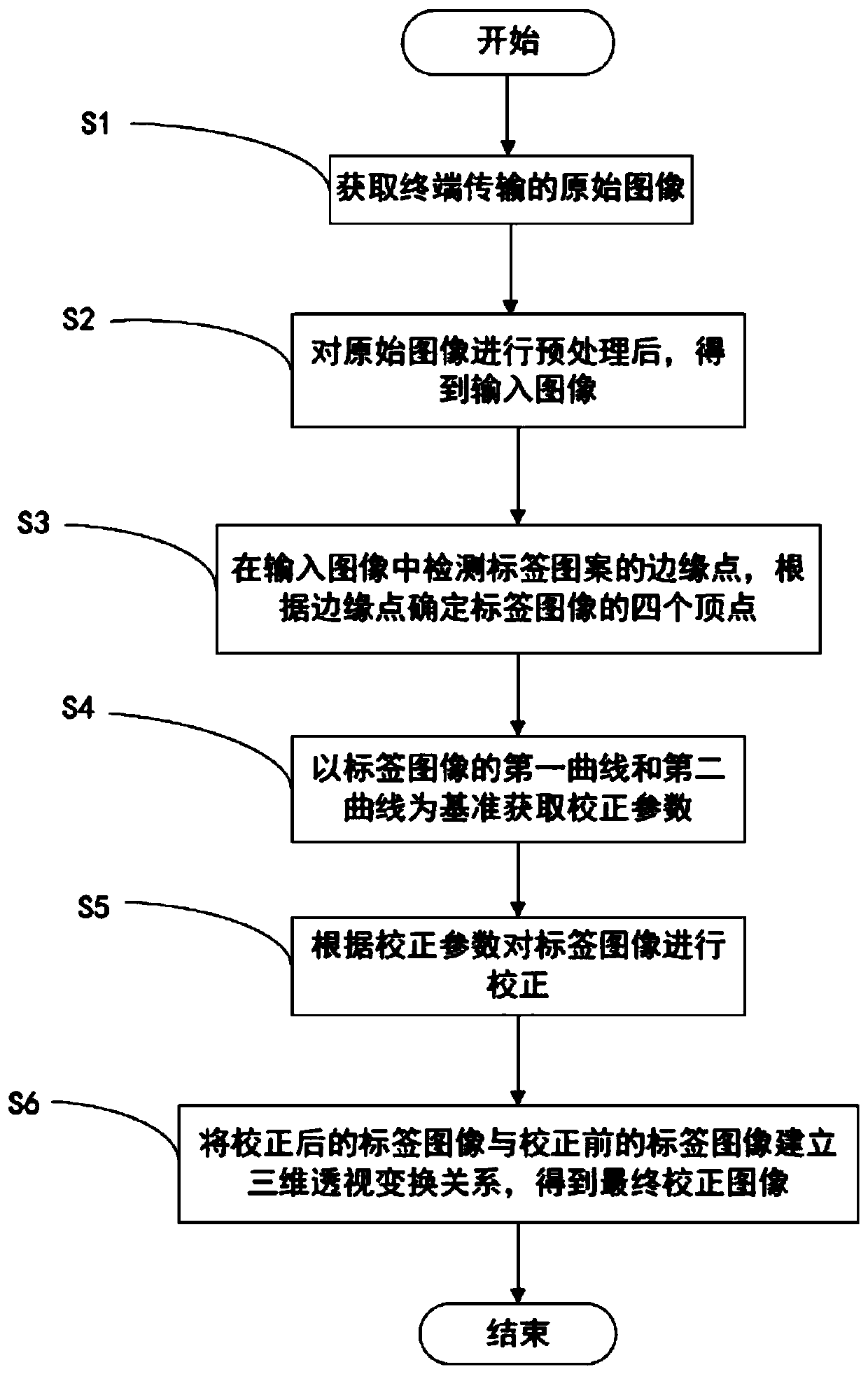

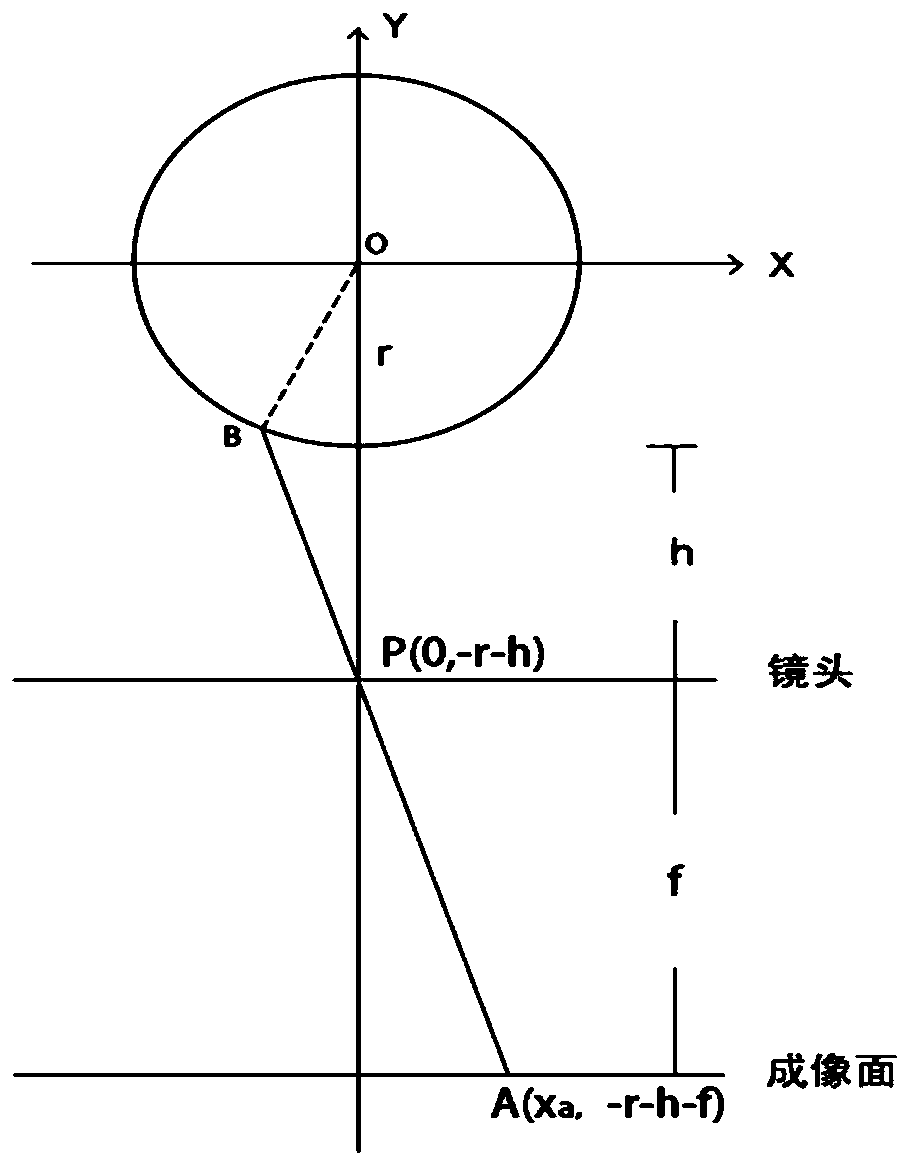

A cylindrical image correction method and system

ActiveCN109949249AImprove experienceHas the ability to restoreImage enhancementImage analysisImage correctionPerspective transformation

The invention discloses a cylindrical image correction method and system. The method comprises the steps of obtaining an original image transmitted by a terminal, preprocessing the original image; obtaining an input image, detecting edge points of the label pattern in the input image; determining four vertexes of the label image according to the edge points, obtaining correction parameters are obtained with the first curve and the second curve of the label image as the reference, correcting the label image according to the correction parameters, establishing a three-dimensional perspective transformation relation between the corrected label image and the label image before correction, and obtaining a final correction image. The system comprises an image preprocessing module, a positioningmodule and a correction module, and is used for realizing the cylindrical image correction method. According to the correction method provided by the invention, the specified characteristics on the cylindrical pattern can be identified, accurate positioning and image correction are completed, the method is accurate and rapid, the method has a certain degree of restoration capability on a distortedimage, and an application scene is not limited to a plane any more.

Owner:DANDE IMAGE MASTER CO LTD ZHUHAI

Preparation method and application of anti-oxidation Venerupis philippinarum enzymatic extract

InactiveCN102846665AImprove cleanlinessGood workmanshipAntinoxious agentsMolluscs material medical ingredientsVenerupis philippinarumChemistry

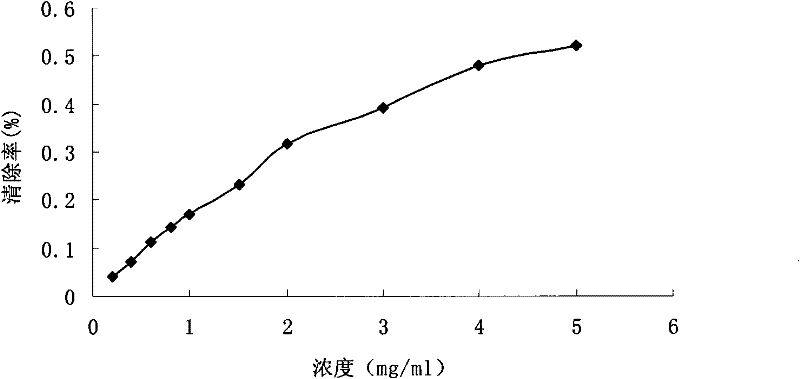

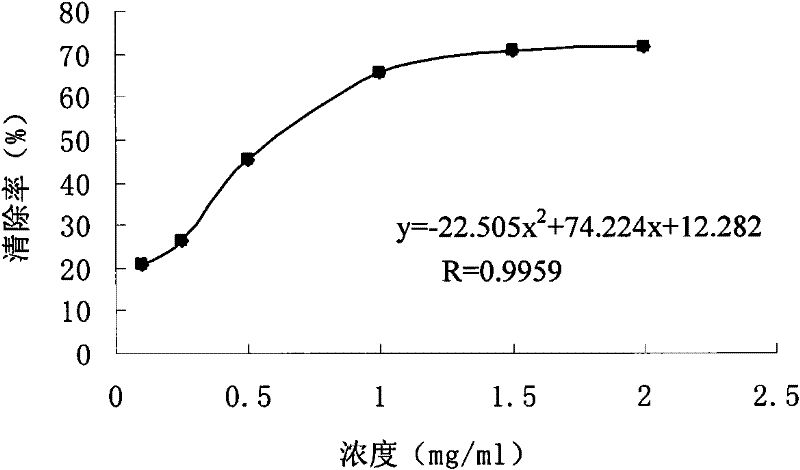

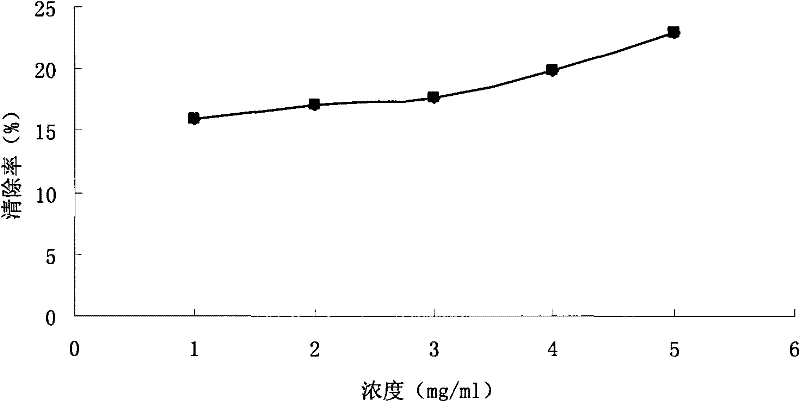

A preparation method of anti-oxidation Venerupis philippinarum enzymatic extract includes preparing sample by cleaning Venerupis philippinarum, shelling to obtain meat, homogenizing, and adding deionized water at the ratio of material to liquid of 1:2-1:3; and regulating pH to 6.8-7.3, adding papain 1500-2000 u / g, performing enzymolysis at 42-47 degrees for 2-4 h, inactivating at 90-95 degrees, centrifuging, and collecting supernatant to obtain enzymolysis product. The invention also discloses an application of enzymatic extract in oxidation resistance activity. Compared with prior art, the invention obtains a perfect process via control on pH value, enzyme amount, temperature and enzymolysis time, and has perfect effect of removing a plurality of free radicals.

Owner:ZHEJIANG OCEAN UNIV

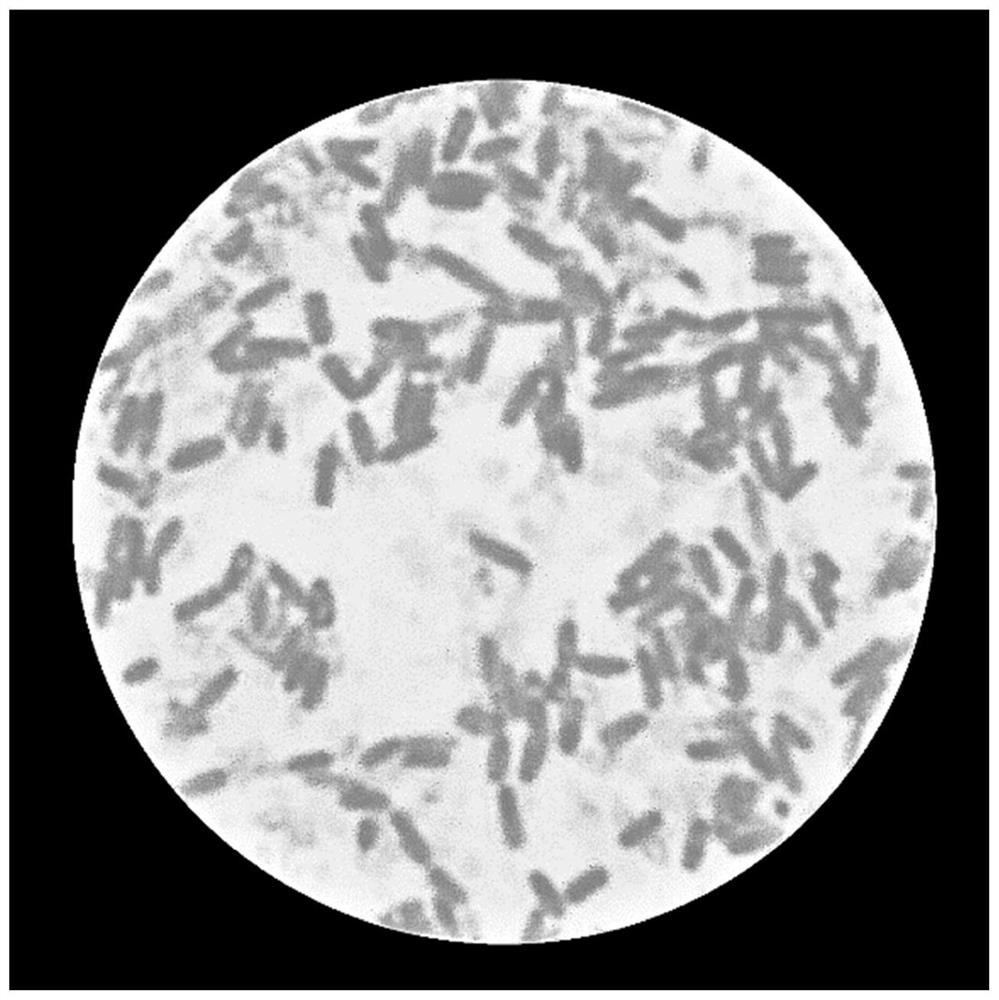

Lactobacillus gasseri with hypoglycemic capacity and application of lactobacillus gasseri

PendingCN114292766AHas the ability to restoreImprove securityBacteriaMetabolism disorderBiotechnologyDipeptidyl peptidase

The invention relates to a Lactobacillus gasseri strain CKCC 1913 and application thereof, the strain is preserved in the General Microbiological Culture Collection Center of the China Committee for Culture Collection of Microorganisms on August 23, 2021, and the preservation number is CGMCC No.23175. The Lactobacillus gasseri strain CKCC 1913 has the advantages that the Lactobacillus gasseri strain CKCC 1913 can be used for preparing the lactobacillus gasseri strain CKCC 1913; a bacterial suspension, a cell metabolite and a cell content of the lactobacillus gasseri CKCC 1913 have a very good inhibition effect on the activity of dipeptidyl peptidase-4 and alpha-glucosidase, have antioxidant activity and can be used for preparing hypoglycemic drugs and antioxidant products. In addition, the strain CKCC 1913 has high gastrointestinal fluid tolerance and good gastric mucosa protein adhesion capacity, the viable count of CKCC 1913 single-strain fermented milk in the 21-day storage period is basically kept unchanged, and the acidity change is lower than 20 DEG T. Comprehensive research results show that the strain CKCC 1913 can be used as probiotics for reducing blood sugar and increasing the viable count of fermented milk products in the shelf life, and has huge application value.

Owner:GREENS BIOENG SHENZHEN

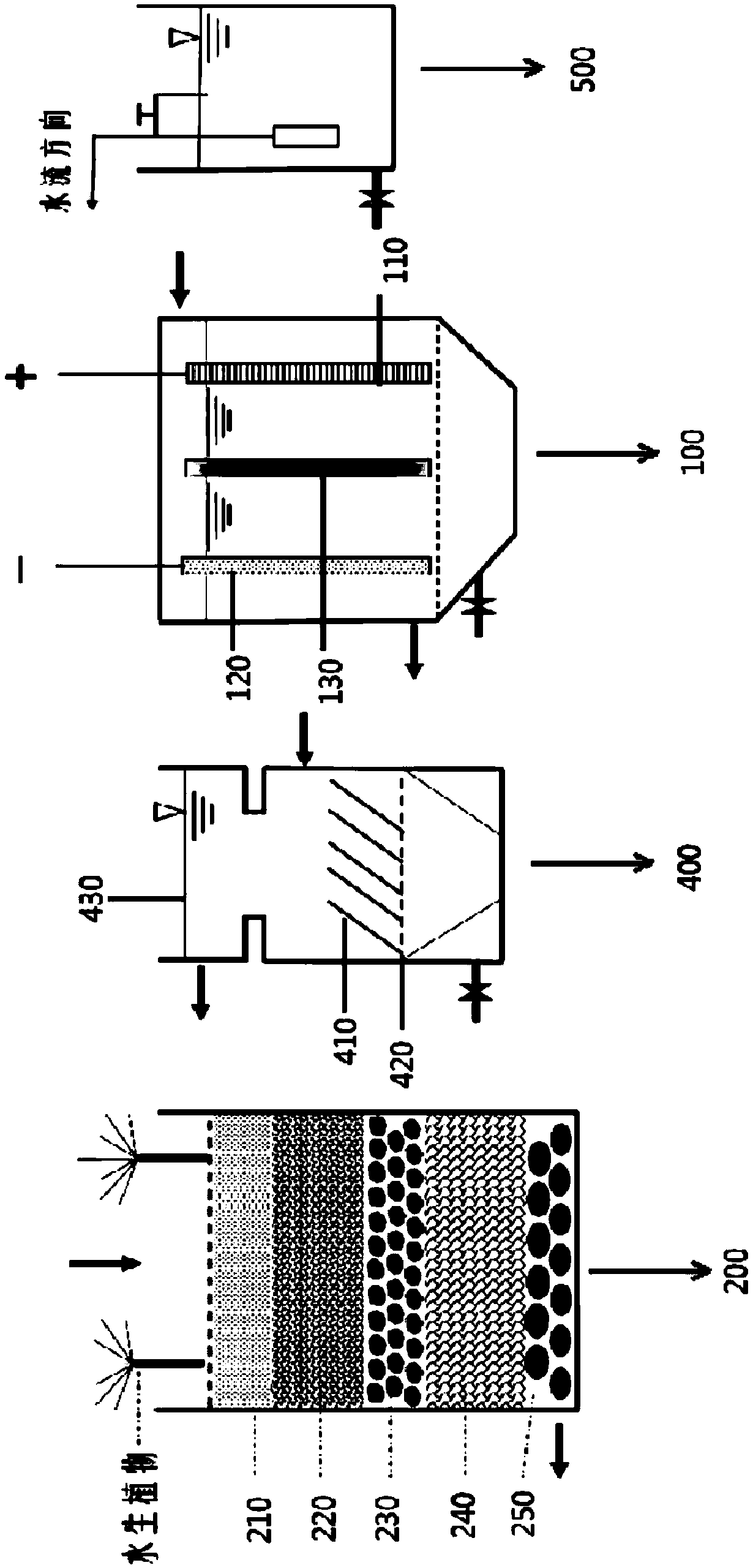

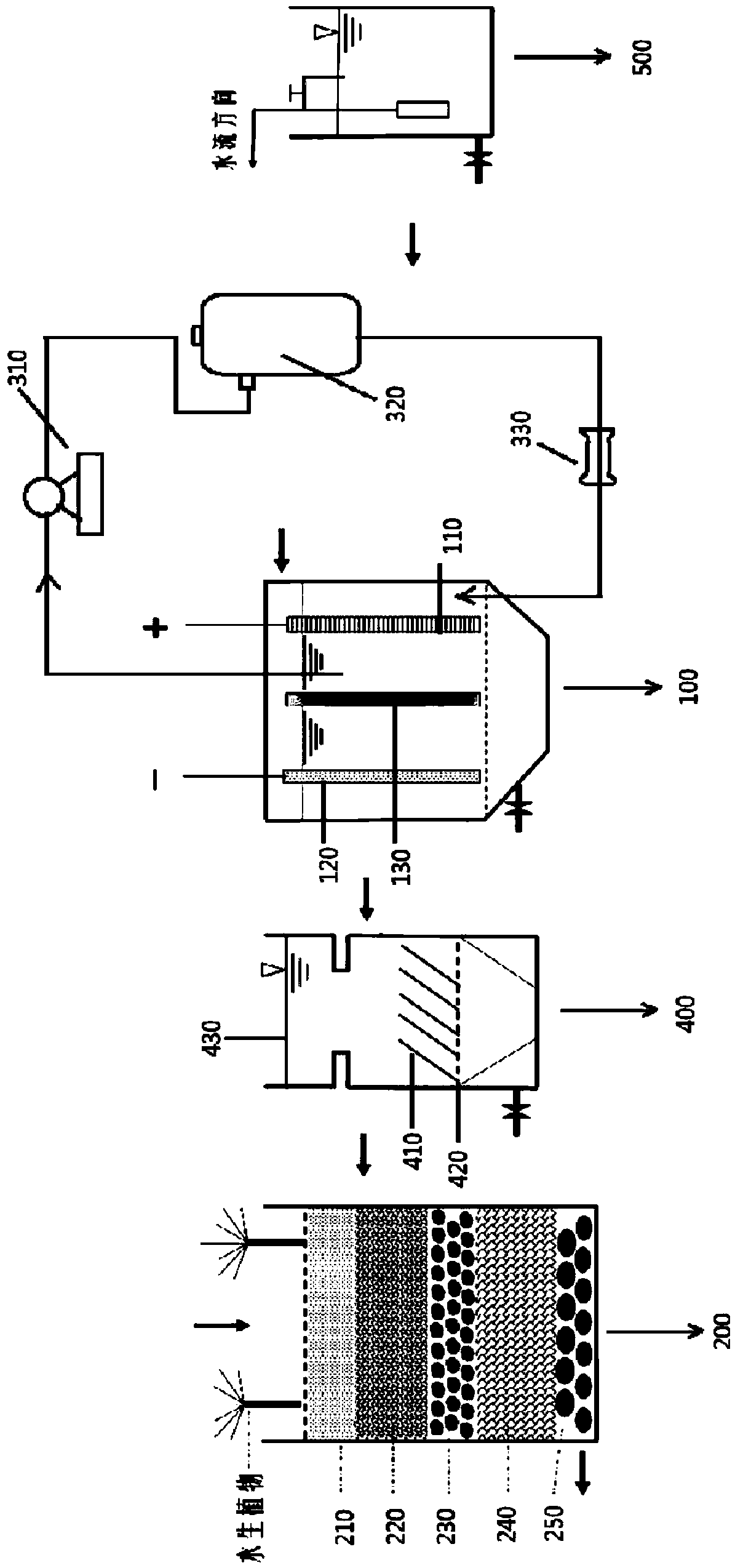

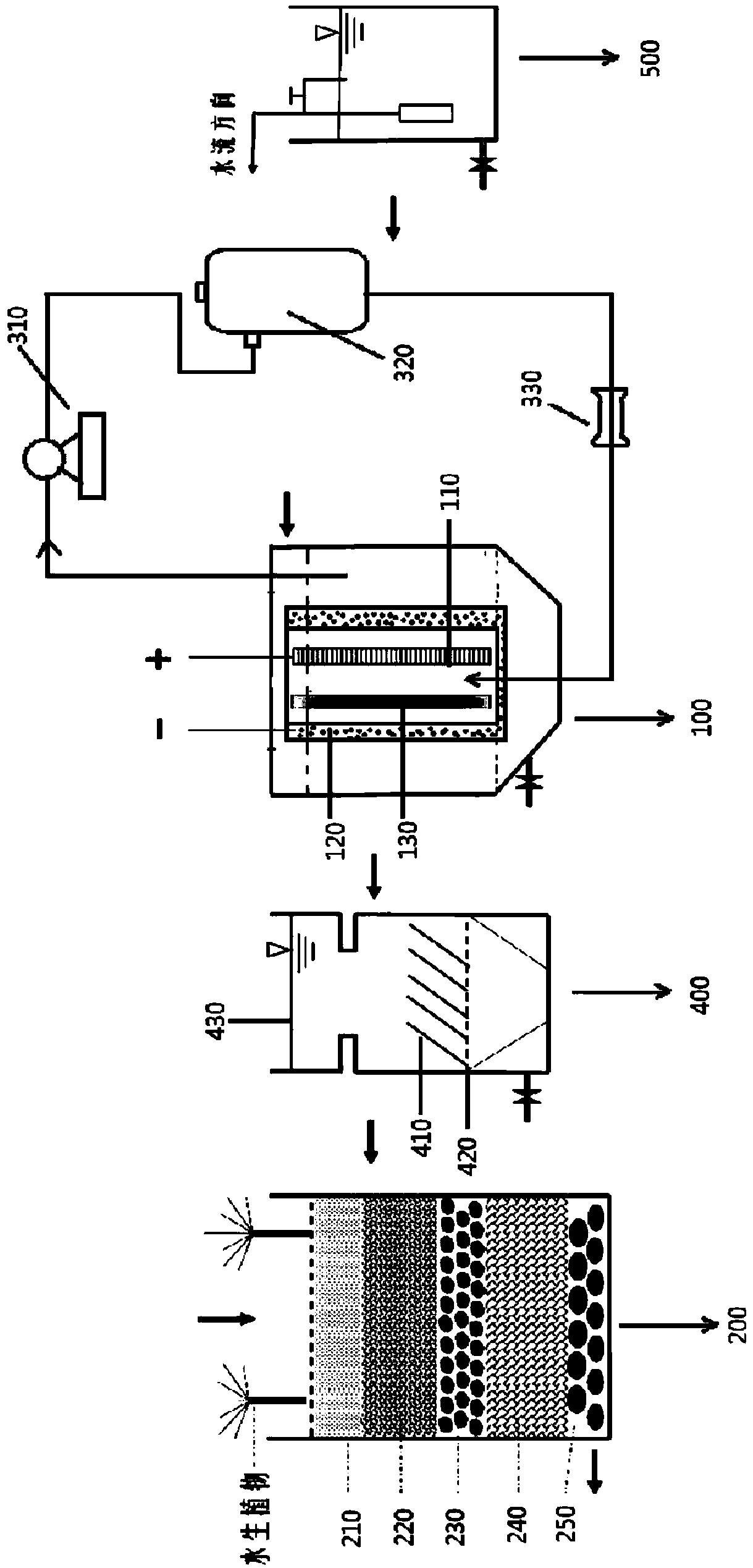

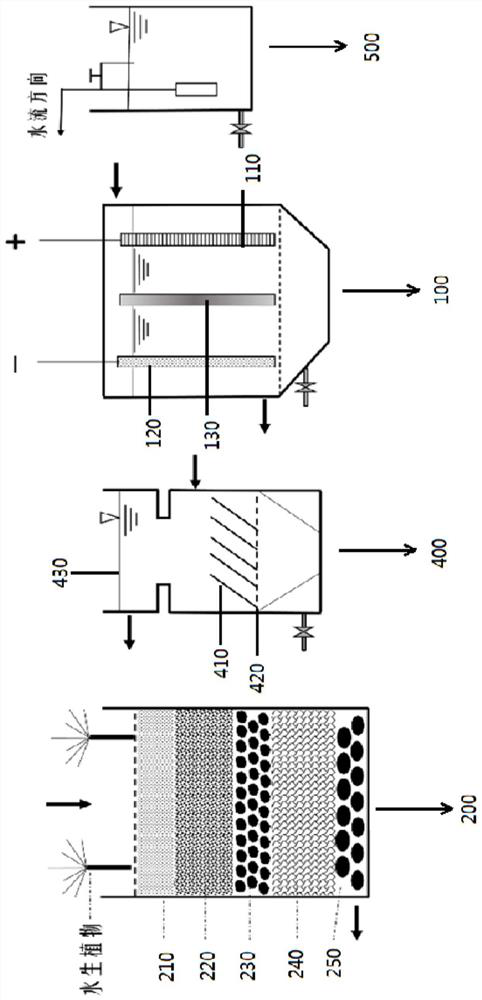

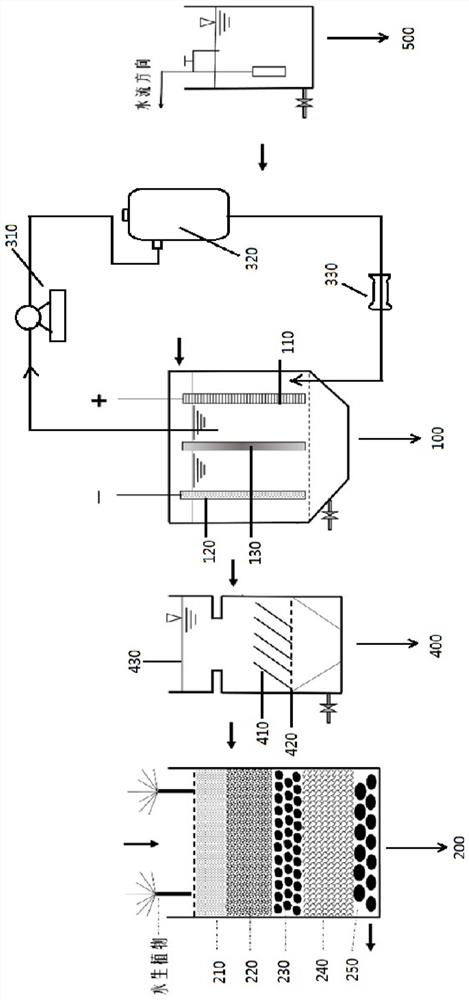

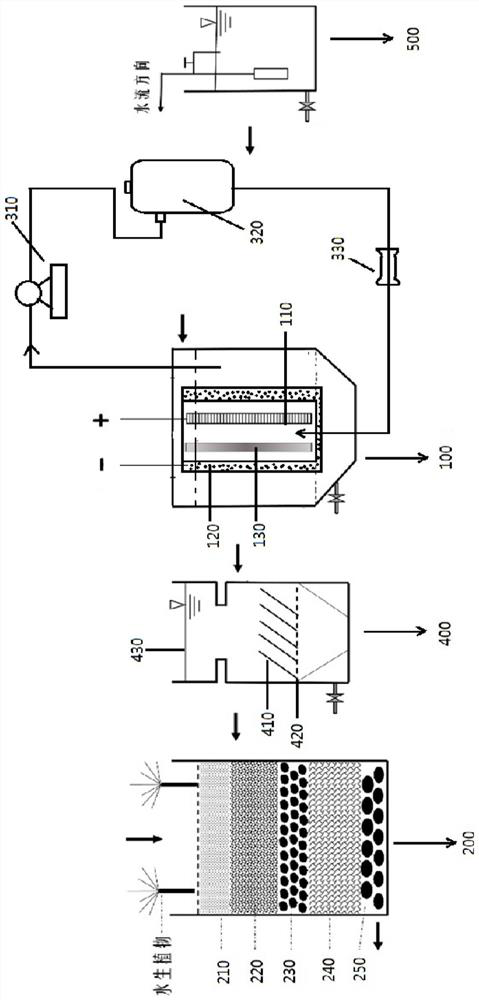

Method and system for deeply treating leachate

ActiveCN109205928AImprove adsorption performanceHigh shock load resistanceGas treatmentWater contaminantsVolatile organic compoundChemistry

The invention discloses a method and a system for deeply treating leachate, the method comprises the following steps: introducing the leachate to be treated into an electrolytic tank (100) to carry out electrochemical treatment; carrying out solid-liquid separation on a flocculation turbid liquid subjected to the electrochemical treatment, amd discharging a flocculated precipitate / suspended substance; and introducing discharged water after the solid-liquid separation into a wetland purification device (200), degrading or removing leachate pollutants through a paved packing layer, and finally discharging water; and preferably, the method further comprises the step of removing volatile organic compounds and a malodorous gas of the leachate. According to the method and the system disclosing by the invention, by electric oxidation, electric flocculation and wetland deep treatment, the leachate pollutants can be effectively reduced or removed, atmospheric pollution induced by the leachate can even be eliminated through an eodorization system, effective management and disposal of the leachate are realized, and the method and the system ensure that the leachate does not influence human health in human activities.

Owner:何小松 +2

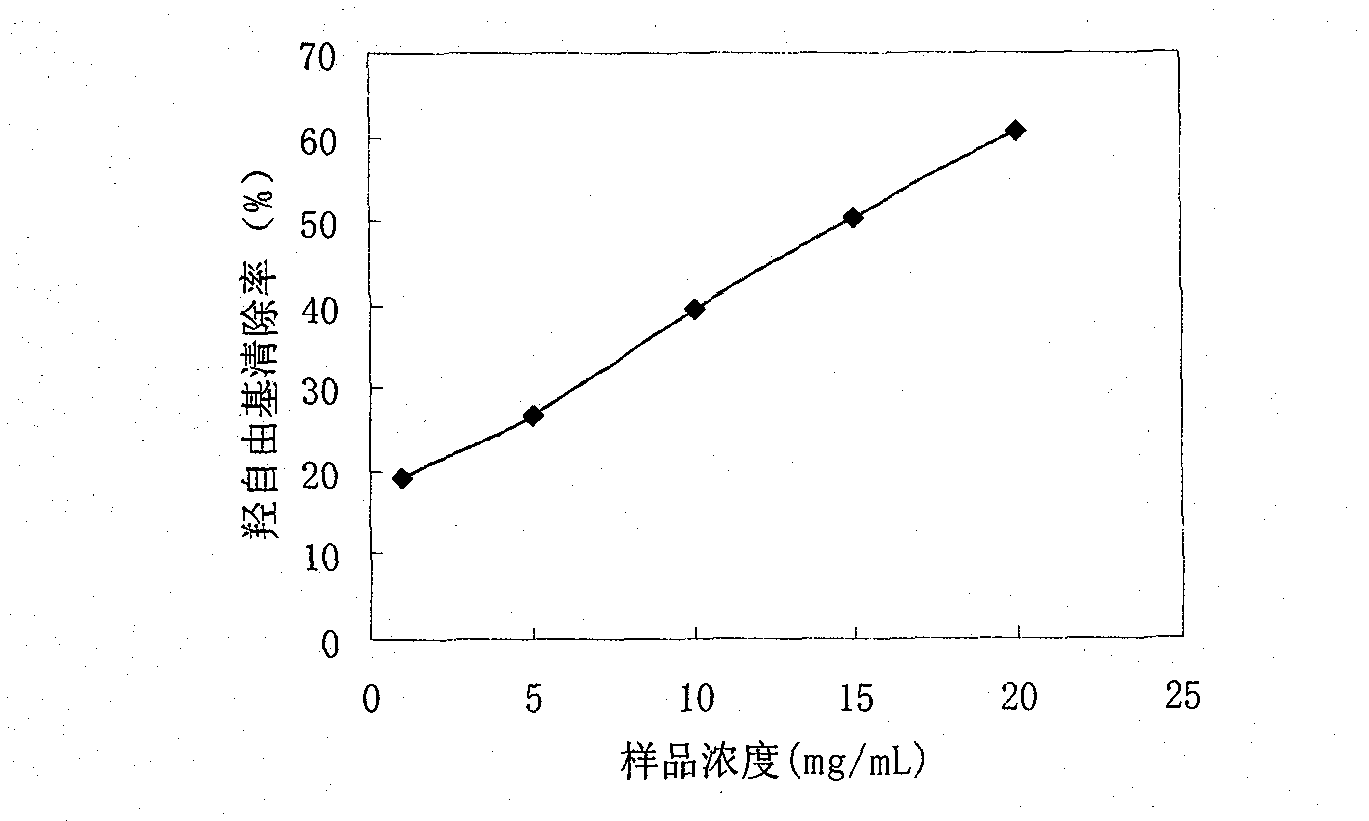

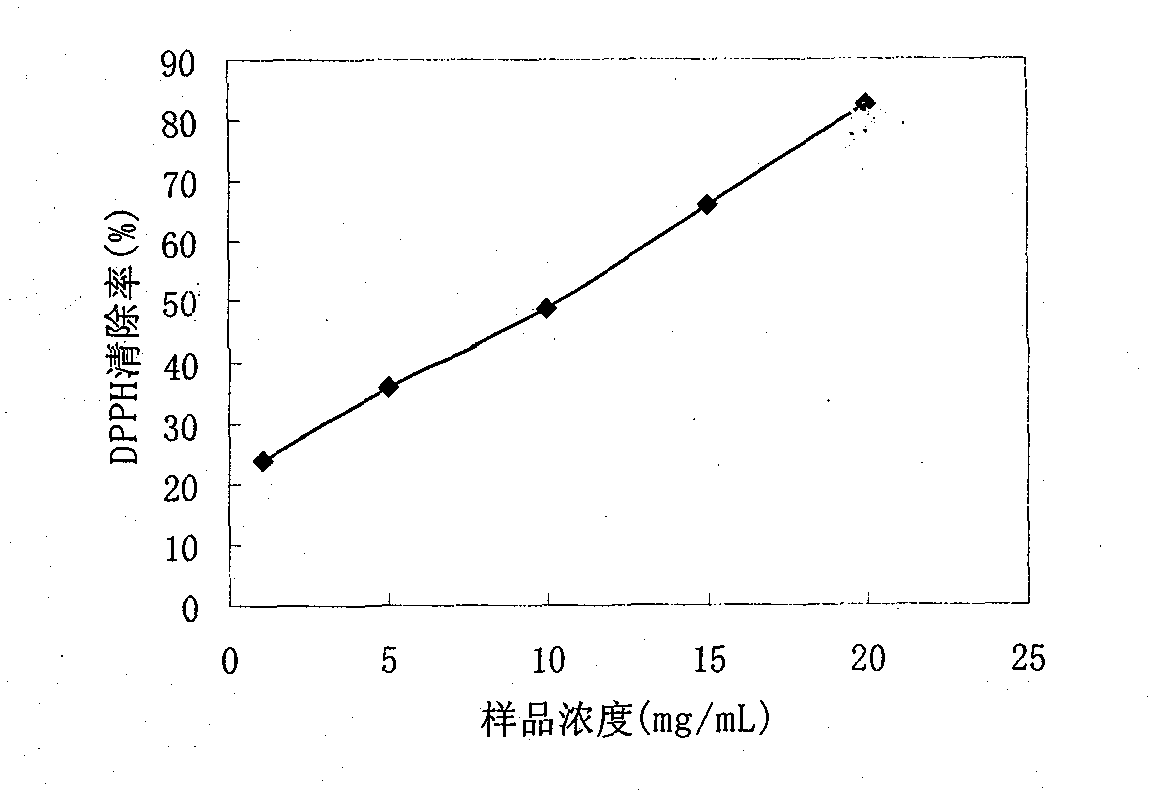

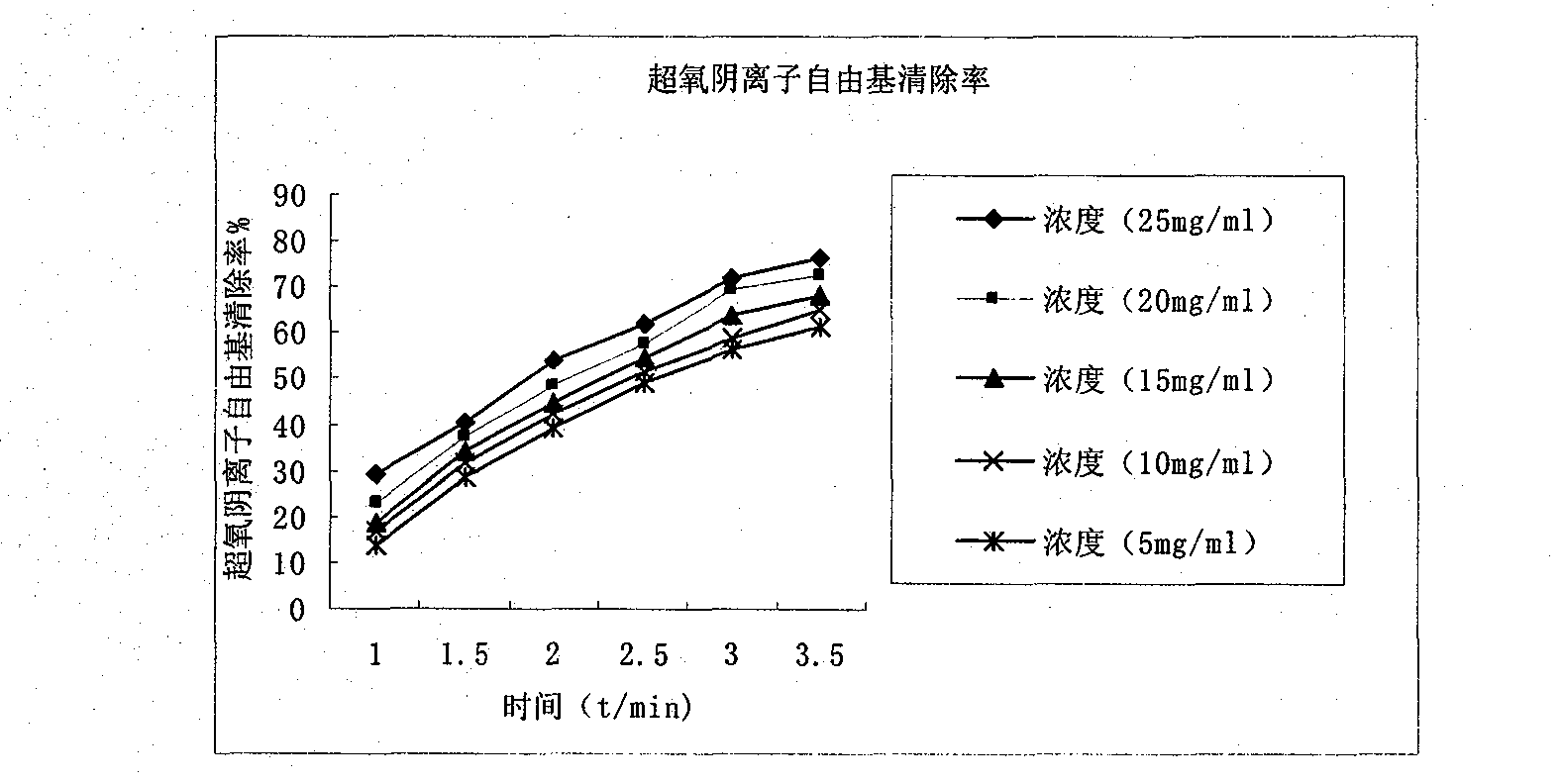

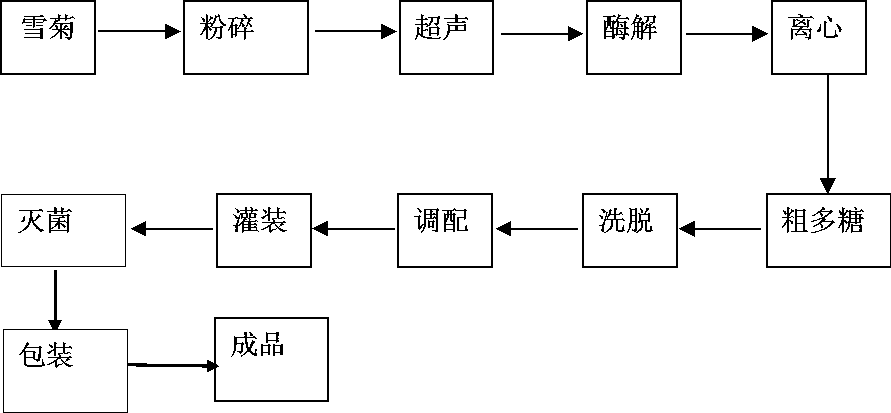

Coreopsis tinctoria flower polysaccharide oral liquid and production method thereof

ActiveCN104042622AGood decolorization effectImprove recycling ratesAntibacterial agentsOrganic active ingredientsBiotechnologyPectinase

The invention discloses a method for preparing coreopsis tinctoria flower polysaccharide oral liquid. The method comprises the following steps: mixing the raw material coreopsis tinctoria flower powder with water uniformly at a massic volume ratio of 1:30; after carrying out thermostatic waterbath, carrying out ultrasonic treatment, wherein the temperature for ultrasonic treatment is 55DEG C, the time for ultrasonic treatment is 15minutes, and the power is 160w; carrying out enzymolysis on the coreopsis tinctoria flower solution, wherein the dosage of cellulase for enzymolysis is 1%, the dosage of pectinase is 1%, the dosage of papain is 1.5%, the enzymatic time is 3 hours, and the temperature is 55DEG C; deactivating the enzyme and centrifuging to obtain supernate, and carrying out chromatography by use of a polyamide column; blending the effluent liquid with distilled water, wherein the weight / volume ratio of the effluent liquid and distilled water is 1:0.8; bottling the blended solution, sterilizing, and packaging so as to obtain the coreopsis tinctoria flower polysaccharide oral liquid. The oral liquid has obvious antibacterial activity, can be used for clearing and reducing free radical 1,1-diphenyl-2-picrylbydrazyl (DPPH) and hydroxyl radical, has the effect of improving the organism immunity sharply, and has extensive application value.

Owner:URUMQI SHENGMING HELI HIGH TECH

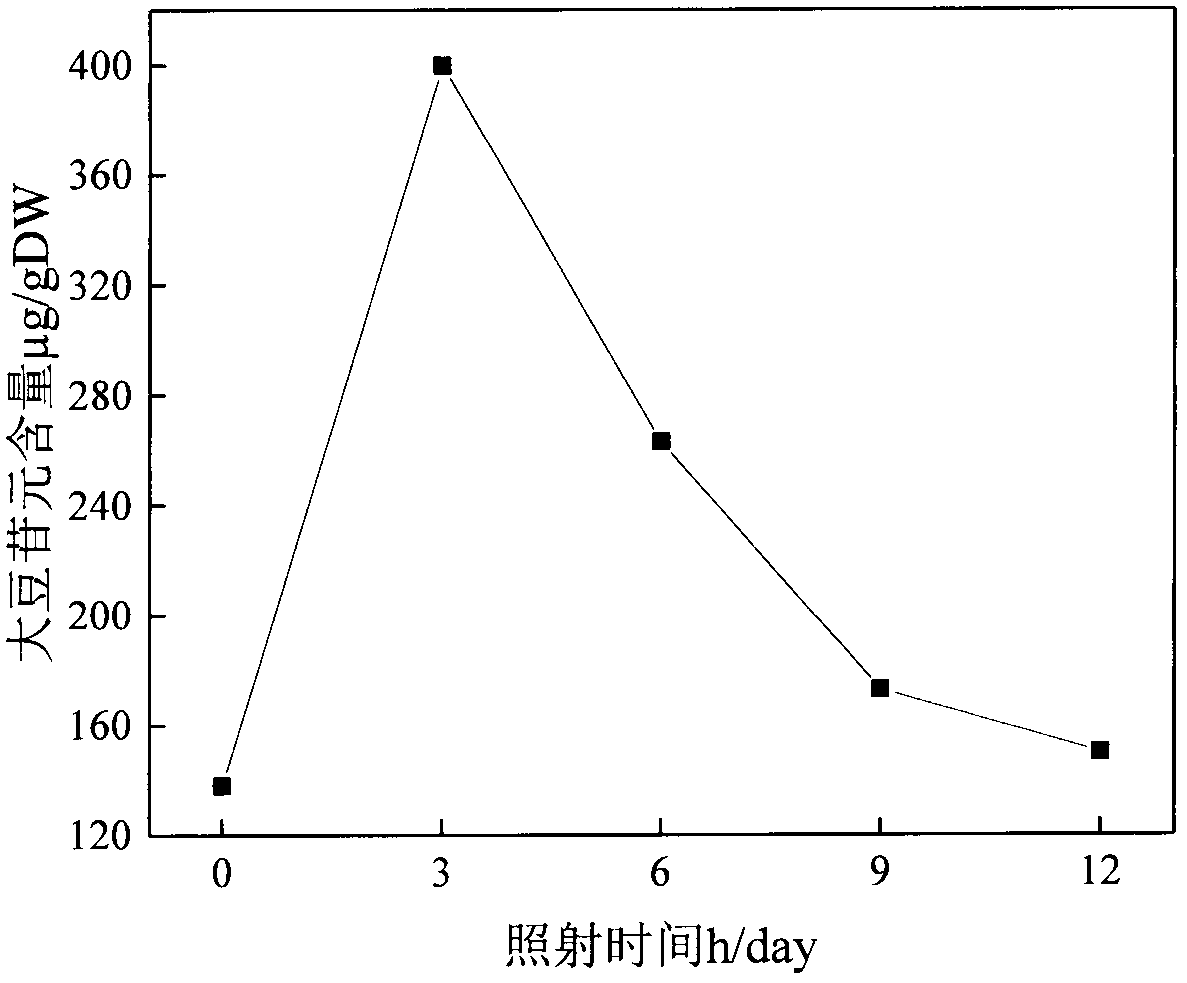

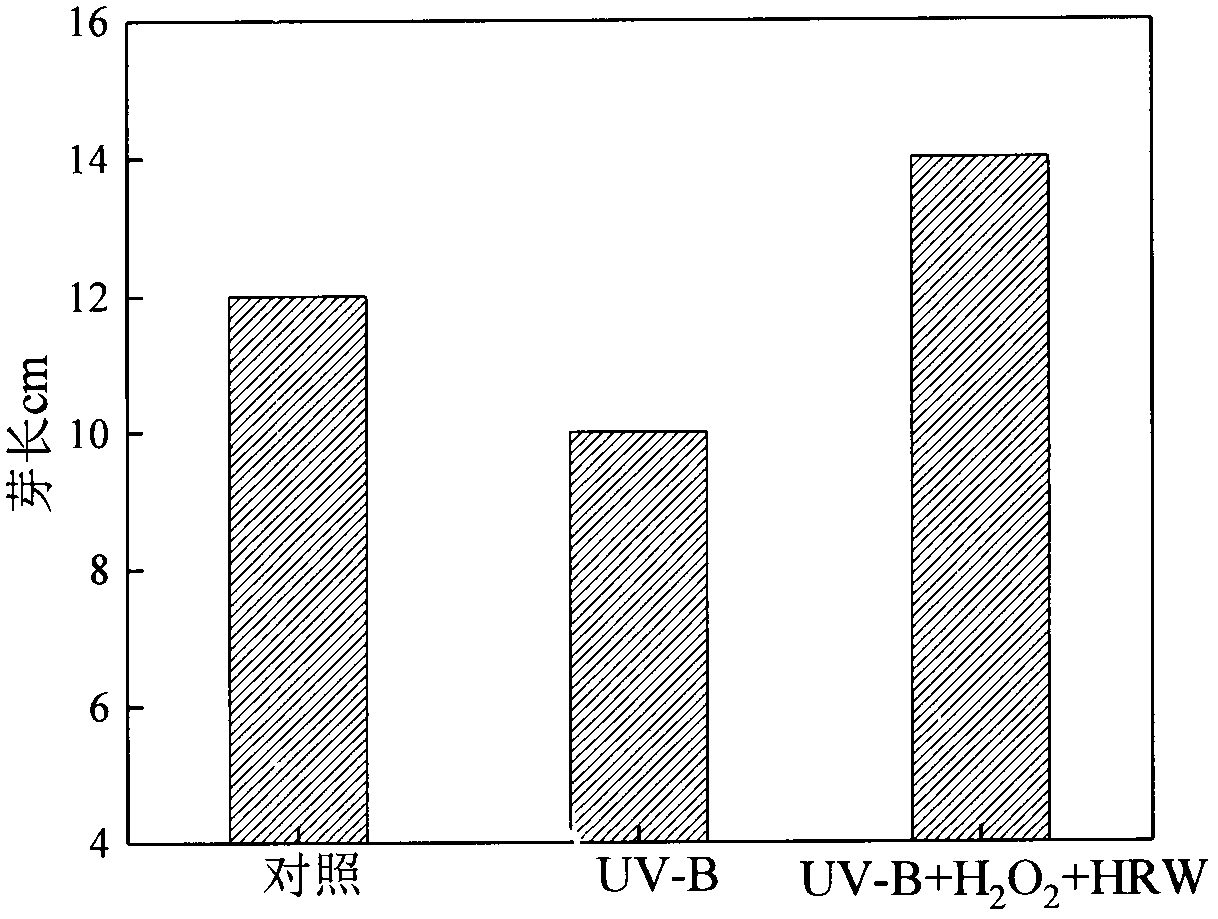

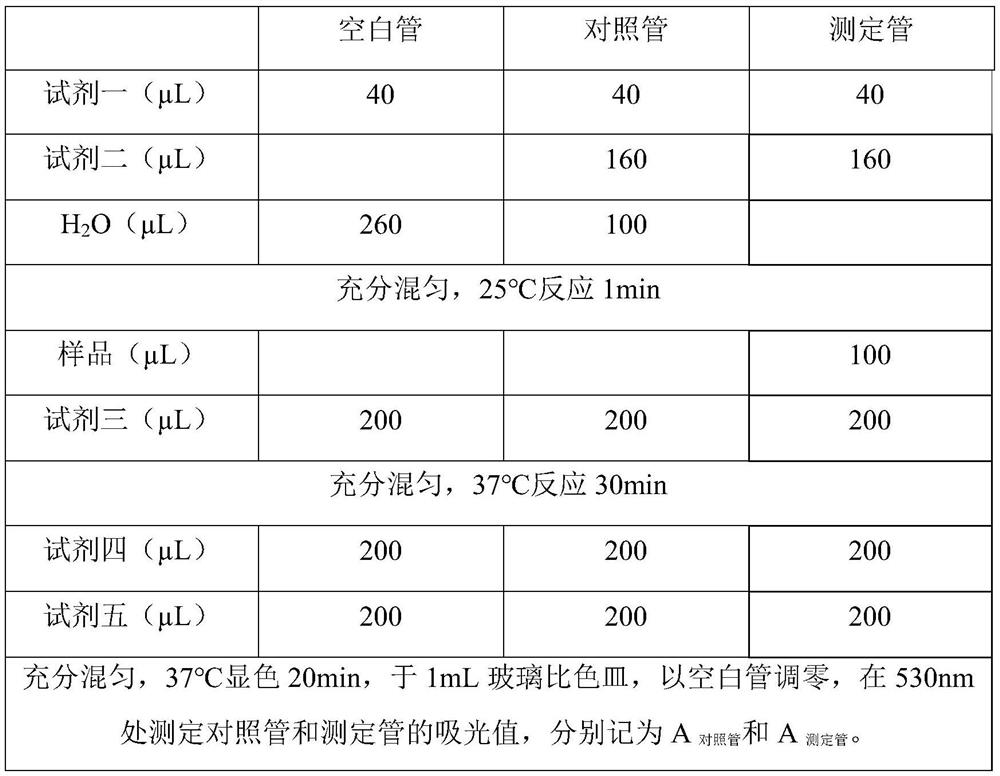

Method of enriching daidzein with soybean sprouts

The invention relates to a method of enriching daidzein with soybean sprouts and belongs to the technical field of food production. The method is characterized in that physiologically active bean seeds are used as a raw material, the raw material is disinfected with sodium hypochlorite, the disinfected material is soaked in hydrogen perioxide solution, the soaked material is paced in a sprouting plate of a medium-wave ultraviolet (UV-B) radiation device, and a hydrogen-rich solution is sprayed to the material under UV-B intermittent radiation to allow sprouting; the content of daidzein in soybean sprouts reaches 139-400 mu g / g DW. The method herein has the advantages of good operational convenience, short production period, low cost, good safety and zero pollution, and large-scale production of soybean sprouts with rich daidzein is facilitated.

Owner:NANJING AGRICULTURAL UNIVERSITY

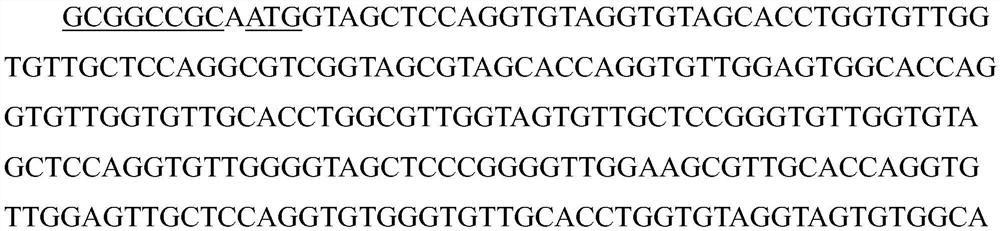

Long-acting recombinant elastin expressed by saccharomyces cerevisiae and application of the long-acting recombinant elastin in cosmetics

PendingCN113061179AHas antioxidant activityHas the ability to restoreCosmetic preparationsConnective tissue peptidesBiochemistryNucleotide sequencing

The invention discloses a long-acting recombinant elastin expressed by saccharomyces cerevisiae and application of the long-acting recombinant elastin in cosmetics. The nucleotide sequence of the long-acting recombinant elastin is shown as Seq ID NO.1. The nucleotide sequence of the long-acting recombinant elastin is obtained by optimizing an original sequence of natural elastin through a yeast codon, and is mainly obtained by artificially designing a key hexapeptide repetitive sequence GVGVAP. The long-acting recombinant elastin provided by the invention has good biocompatibility, antioxidant activity and reducing ability. Compared with the elastin extracted from animal tissues and variants, the long-acting recombinant elastin has the advantages of solubility, no virus hidden danger and low rejection reaction. Compared with the elastin extracted from animal tissues and variants, the long-acting recombinant elastin provided by the invention has the advantages of solubility, no virus hidden danger and low rejection reaction.

Owner:WUHU YINGTE FEIER BIOLOGICAL PROD IND RES INST CO LTD

A method and system for advanced treatment of leachate

ActiveCN109205928BControlling Oxidation-Flocculation CapabilityRealize adsorption stabilization treatmentGas treatmentWater contaminantsChemical treatmentFlocculation

The invention discloses a method and system for advanced treatment of leachate. The method comprises the following steps: passing the leachate to be treated into an electrolytic cell (100) for electrochemical treatment; Liquid separation, discharge the flocculated sediment / suspended matter; the effluent after solid-liquid separation is passed into the wetland purification device (200), and the leachate pollutants are degraded or removed through the laid packing layer, and finally the water is effluent; preferably , the method also includes the step of removing volatile organic compounds and malodorous gas in the leachate. In the method and system of the present invention, the pollutant content in the leachate can be effectively reduced or removed through electro-oxidation, electro-flocculation, and wetland advanced treatment, and even the air pollution caused by the leachate can be eliminated through the deodorization system, and the effective treatment of the leachate is realized. Management and disposal to ensure that leachate does not affect human health during human activities.

Owner:何小松 +2

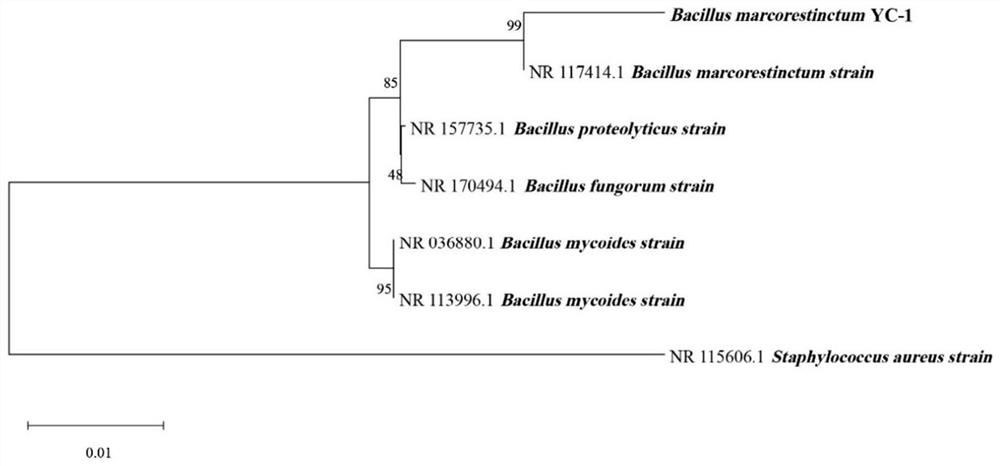

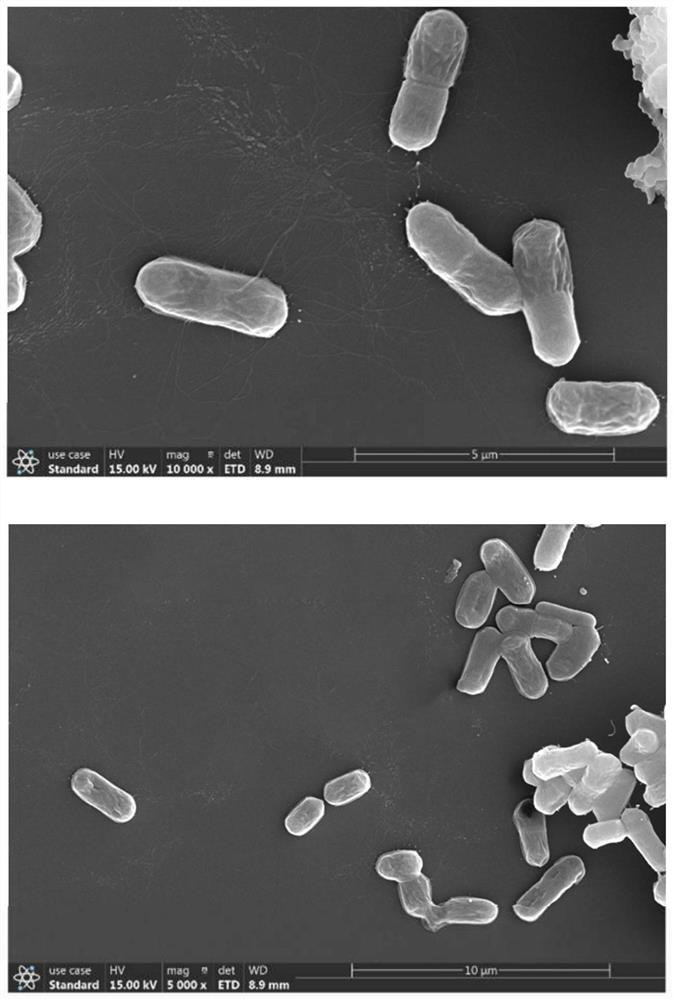

Bacillus martensii and application thereof

ActiveCN114317375AImprove aroma qualityImprove fermentation qualityBacteriaMicroorganism based processesBiotechnologySugar

The invention discloses bacillus martensii and application of the bacillus martensii. The bacillus martensii YC-1 is preserved in the China Center for Type Culture Collection, and the preservation number of the bacillus martensii YC-1 is CCTCC (China Center for Type Culture Collection) No. M 20211678. The bacillus martensii YC-1 provided by the invention is relatively good in activity and relatively fast in growth, has nitrate reducing capacity, and can be applied to fermentation of bean sprouts. The preparation method comprises the following steps: taking fresh leaf mustard as a raw material, scribing, airing, salting, desalting, marking sugar, adding auxiliary materials, and then inoculating the bacillus martensii YC-1 for fermentation, thereby obtaining the fermented bean sprouts. The preparation method comprises the following steps: taking fresh leaf mustard as a raw material, and carrying out slicing, airing, salting, desalting, marking sugar, adding auxiliary materials, and inoculating the bacillus martensii YC-1 for fermentation. According to the method, the fragrance and the fermentation quality of the bean sprouts are improved, bean sprout products with flavor and quality superior to those of naturally-fermented bean sprouts are obtained, the nitrite content of naturally-fermented bean sprouts is reduced, and the safety of the products is improved.

Owner:SICHUAN UNIV

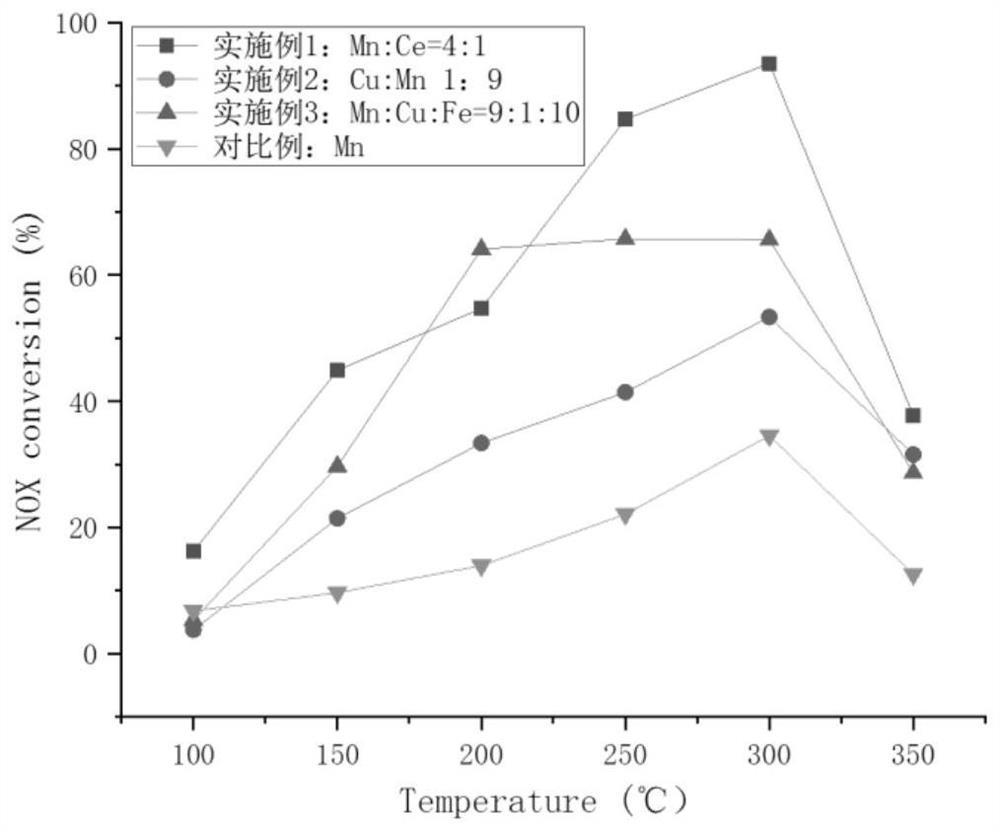

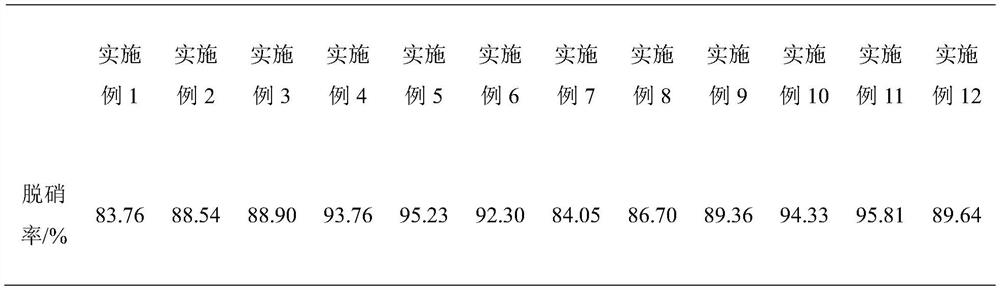

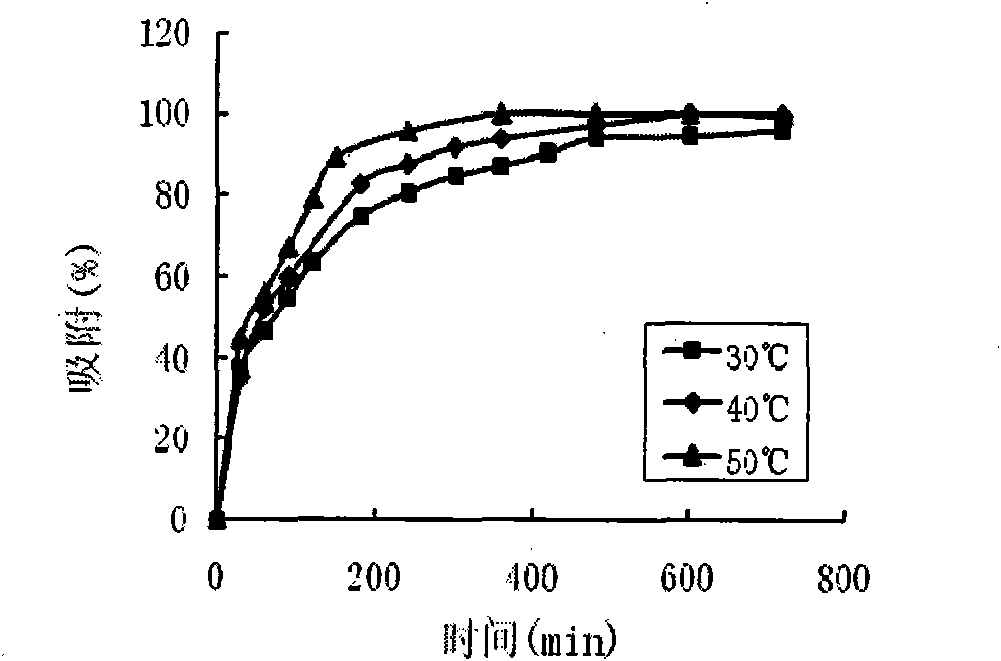

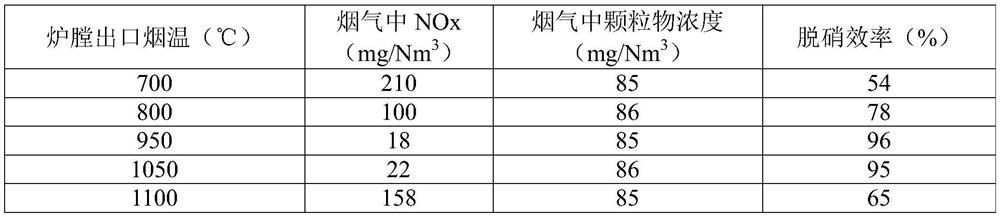

A kind of co-scr denitrification catalyst and its preparation method and application

ActiveCN111229212BHas the ability to restoreImprove the toxic effectGas treatmentHeterogenous catalyst chemical elementsNickel saltIron salts

Owner:SHANDONG UNIV

Preparation method for buckwheat bran polysaccharide-containing antioxidative diet bread

InactiveCN107333840AHas the ability to restoreWith weight loss functionDough treatmentModified nutritive productsFiltrationFermentation

The invention discloses a preparation method for buckwheat bran polysaccharide-containing antioxidative diet bread. The preparation method is characterized by comprising the following steps: crushing and sieving buckwheat bran, adding ethanol for degreasing treatment, performing suction filtration and precipitation drying, adding hot water for impregnation, performing suction filtration, evaporating and condensing supernatant under reduced pressure, adding ethanol, and performing precipitation to obtain buckwheat bran polysaccharide; purifying, crushing, extruding and modifying corn flour to obtain modified corn flour; drying and crushing cornhusks, and performing extrusion treatment to obtain high-quality corn dietary fibers; mixing buckwheat flour, high-gluten flour and the materials obtained in a and b, adding yeast powder, white granulated sugar, shortening, water, a tea extract, a hydrophilic colloid and an enzyme preparation, and performing dough preparation, rounding, forming, fermentation, baking, cooling and packaging.

Owner:张永霞

Method for flue gas denitration with iron-carbon composite material as SNCR additive

ActiveCN113385008APromote low temperature denitrificationImprove SNCR denitrification rateGas treatmentDispersed particle separationEnvironmental chemistryCarbon composites

The invention discloses a method for applying a composite material containing iron and carbon as SNCR additive to an SNCR technology, belonging to the technical field of flue gas pollutant control. The method comprises the following steps: firstly, fully mixing 70%-75% of carbon, 15%-18% of Fe3O4 and 10%-12% of FeOOH, conducting calcining for 2 hours by using inert gas at a temperature of 200-300 DEG C to prepare the iron-carbon composite material, conducting cooling, performing drying for 24 hours at a temperature of 110 DEG C, carrying out granulating, screening particles with particle sizes in a range of 20-60 meshes, and sealing and storing the particles; and then removing NOx by using the iron-carbon composite material as the SNCR additive under the conditions that a temperature is 750-1000 DEG C, an oxygen concentration is 2 vol.% and a molar ratio of an NH3 concentration to an NO concentration is 0.5-1. According to the invention, CO and FeOOH generated by carbon in an anoxic environment can provide SNCR with active groups OH and H required by a reaction at low temperature and promote C and NH3 to generate a new reducing agent HCNO; and when the temperature reaches the oxidation temperature of Fe3O4, NO is adsorbed by active sites on the surface of Fe3O4, so reduction of NO to generate N2 is promoted. The iron-carbon composite material is adopted as the additive for SNCR denitration, and existing equipment of a factory does not need to be transformed, so investment cost is low, operation is easy, an SNCR denitration temperature window can be reduced, and meanwhile, a denitration rate can be increased.

Owner:BEIJING UNIV OF TECH

Preparation process of antioxidant diet bread containing buckwheat bran polysaccharides

InactiveCN107318924AHas the ability to restoreWith weight loss functionDough treatmentModified nutritive productsCooking & bakingRounding

The invention discloses a preparation process of an antioxidant diet bread containing buckwheat bran polysaccharides. The preparation method is characterized by comprising the steps of crushing and screening buckwheat bran, adding in ethanol for degreasing treatment, performing processes of suction filtration, precipitation, filtering, hot water soaking, suction filtering, supernatant reduced-pressure evaporation and concentration and ethanol precipitation to obtain the buckwheat bran polysaccharides; performing treatments of impurity removal, crushing and extrusion modification on corn flour to obtain modified corn flour; performing treatments of drying, crushing and extrusion on corn bran to obtain high-quality corn dietary fiber; mixing buckwheat flour, high-gluten flour and the raw materials obtained in the steps above, then adding in yeast powder, white sugar, shortening, water, tea extract, hydrophilic colloid and enzymic preparations, preparing dough and performing processes of rounding, shaping, fermentation, baking, cooling and packaging.

Owner:HEFEI HUIHUIDOU FOOD CO LTD

Seaweed fiber functional dressing and its application, seaweed fiber functional dressing

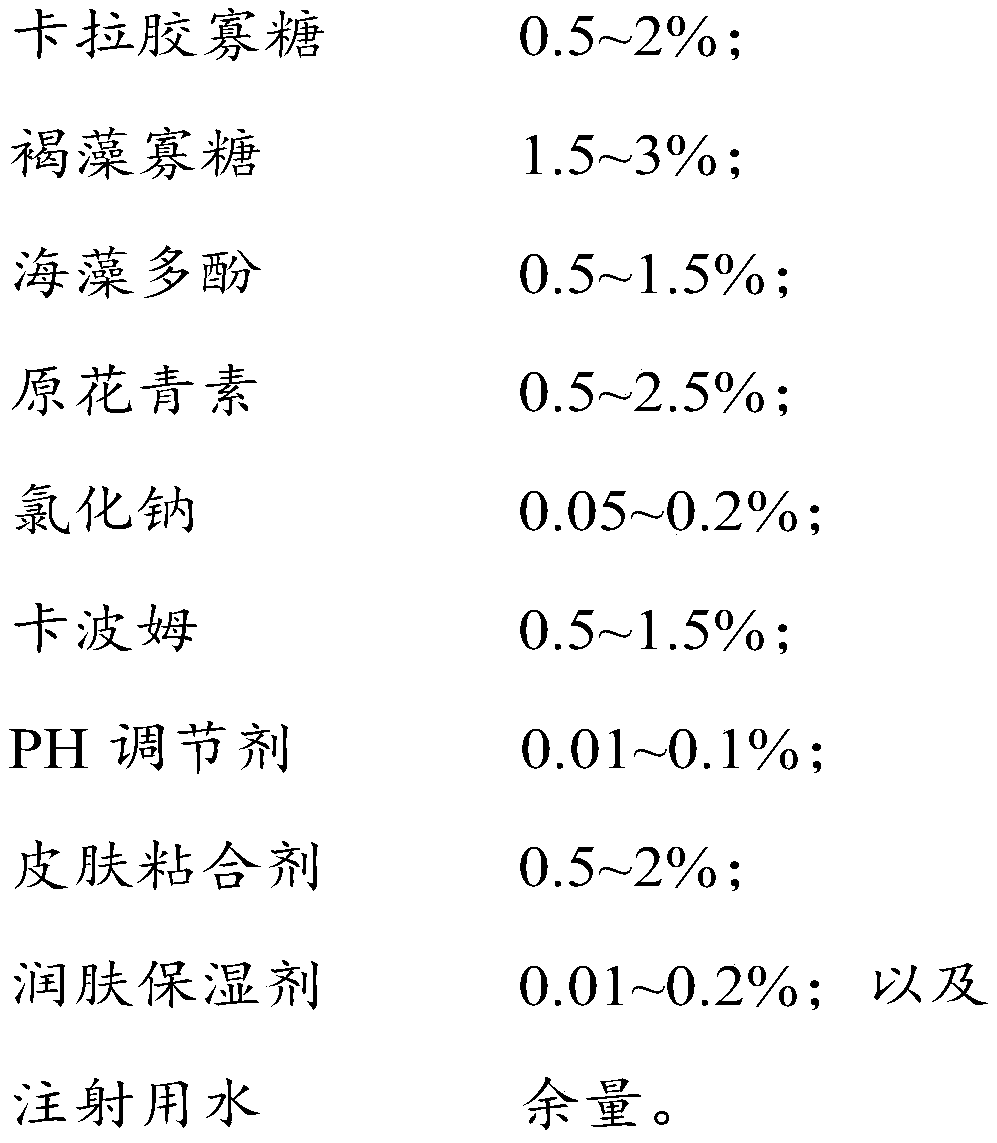

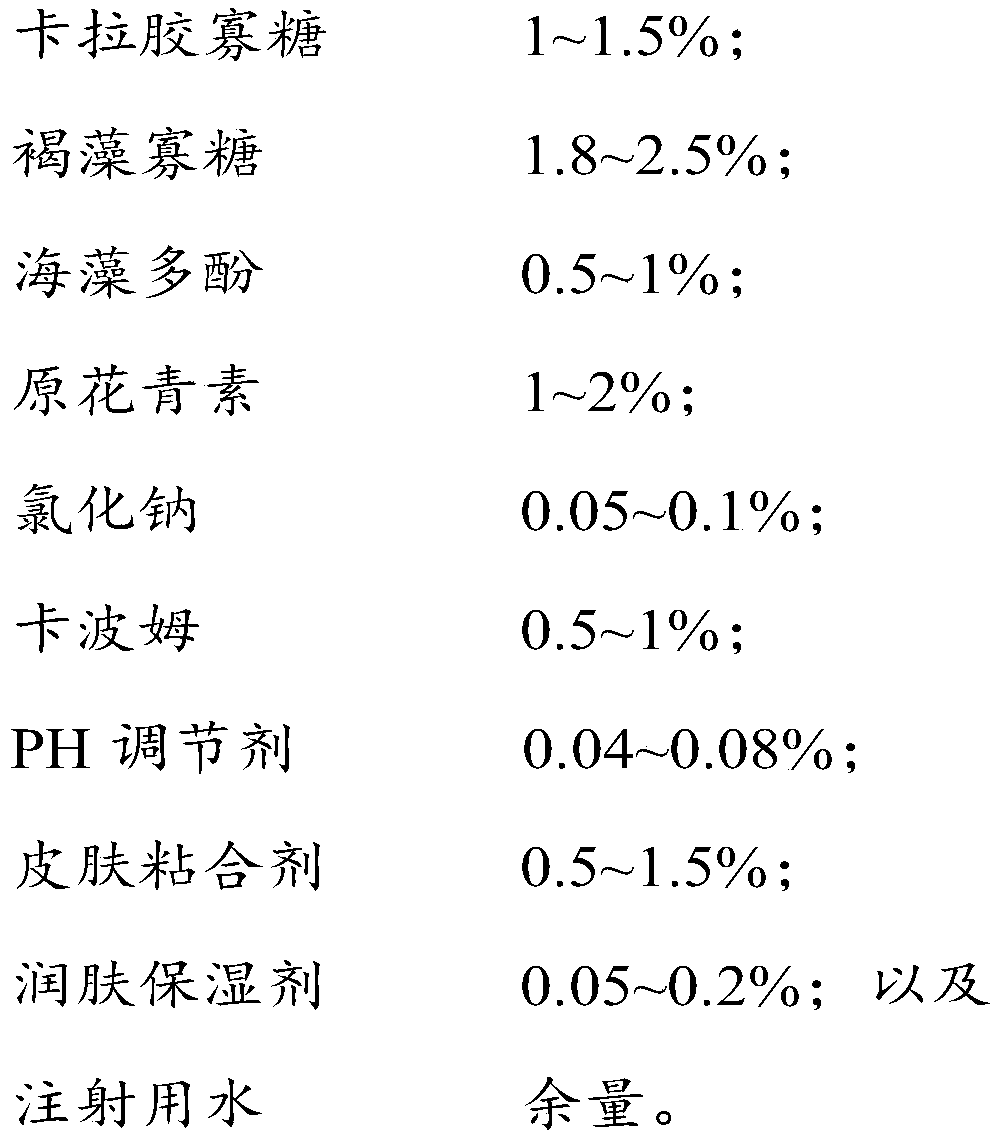

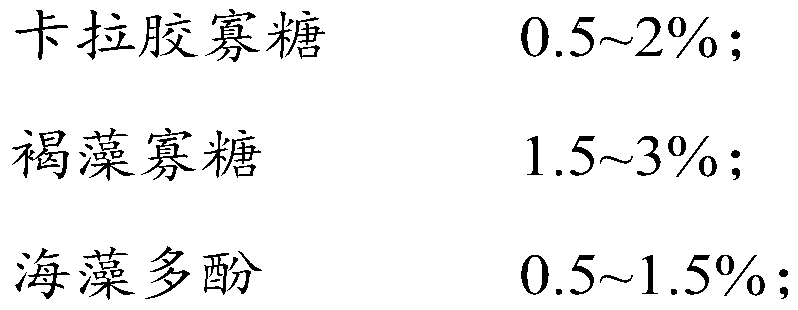

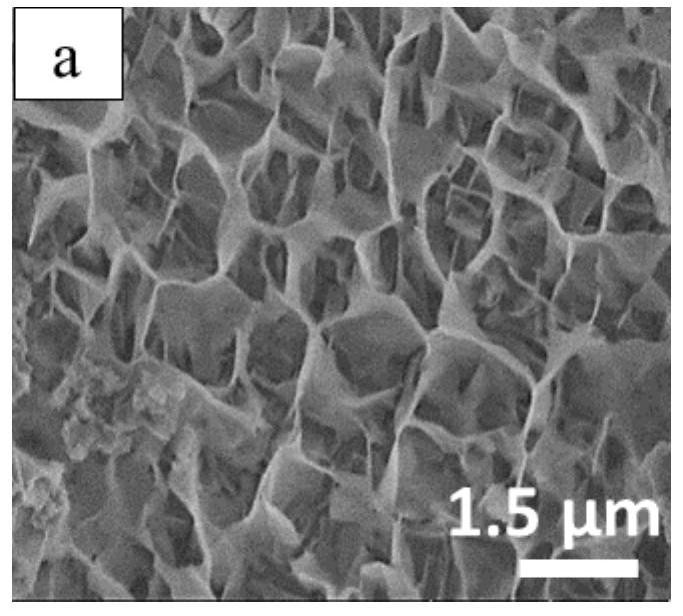

The invention provides an alginate fiber functional dressing, application of the alginate fiber functional dressing and an alginate fiber functional dressing plaster and relates to the field of medical materials. The alginate fiber functional dressing is prepared from the flowing raw materials in percentage by mass, 0.5 to 2 percent of oligocarrageenan, 1.5 to 3 percent of alginate-derived oligosaccharide, 0.5 to 1.5 percent of algae polyphenol, 0.5 to 2.5 percent of procyanidine, 0.05 to 0.2 percent of sodium chloride, 0.5 to 1.5 percent of Carbomer, 0.01 to 0.1 percent of PH conditioning agent, 0.5 to 2 percent of skin adhesive, 0.01 to 0.2 percent of skin-moistening moisturizer, and the balance of water for injection. The alginate fiber functional dressing plaster comprises a dressing surface layer onto which the alginate fiber functional dressing is absorbed. The alginate fiber functional dressing can be used to effectively repair and heal a skin injury, and the wound healing time is shortened. Furthermore, the invention provides the application of the alginate fiber functional dressing to repairing and healing the skin injury.

Owner:ARNOKANG NINGXIA BIOTECH

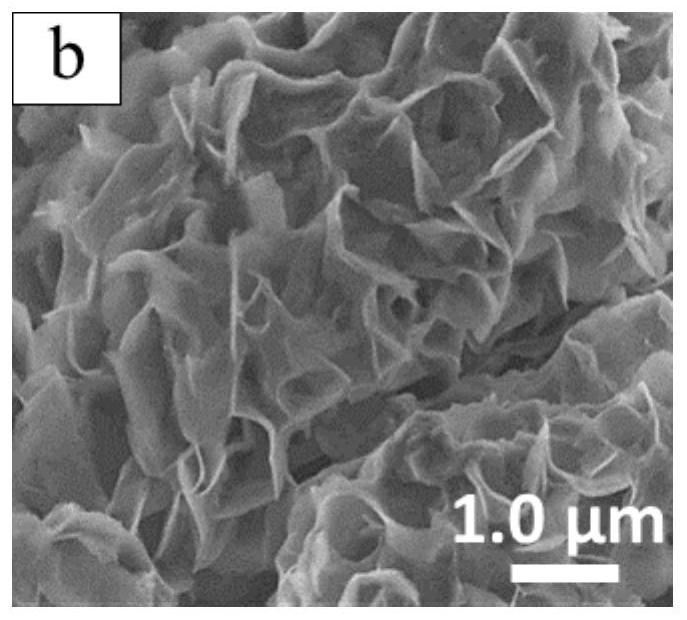

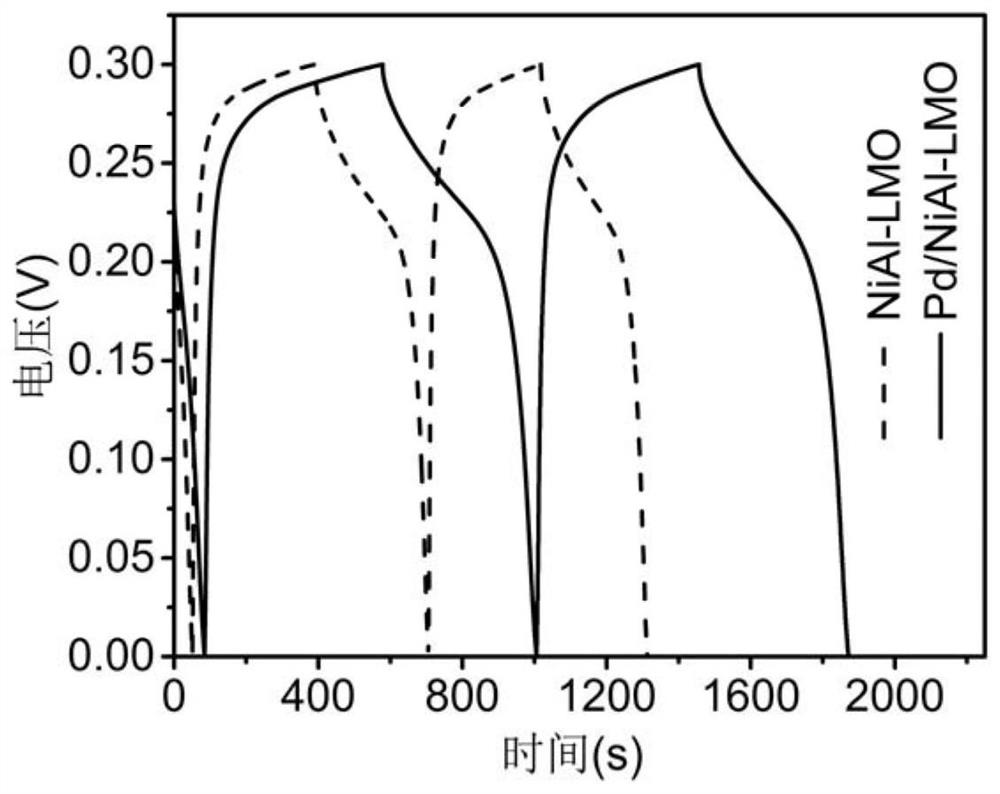

A kind of pd/nial metal oxide film electrode and its preparation method and application

ActiveCN107459115BIncrease capacitanceImprove performanceWater contaminantsDispersed particle separationCapacitanceCapacitive deionization

The invention provides a Pd / NiAl metal oxide film electrode as well as a preparation method and application thereof. According to the Pd / NiAl metal oxide film electrode provided by the invention, the mass of Pd accounts for 1 percent to 10 percent of the mass of the Pd / NiAl metal oxide film electrode. According to the Pd / NiAl metal oxide film electrode provided by the invention, Ni, Al and Pd are deposited on foam nickel through in-situ hydrothermal reaction to obtain Pd / NiAl-LMO membrane electrode materials with different Pd deposition amounts. According to the Pd / NiAl metal oxide film electrode, the prepared Pd / NiAl-LMO membrane electrode can be used as a capacitive deionization electrode; when being used as a positive electrode, the Pd / NiAl-LMO membrane electrode can be used for adsorbing acid group ions in water in a charging process; when the Pd / NiAl-LMO membrane electrode is used as a negative electrode, the acid group ions are converted into a harmless product under the catalysis effect of Pd atoms in a discharging process; meanwhile, the electrode is regenerated and concentrated wastewater of acid salt is not generated in a capacitive deionization process.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

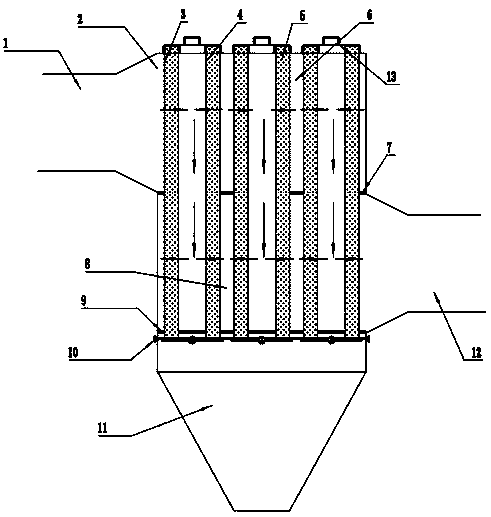

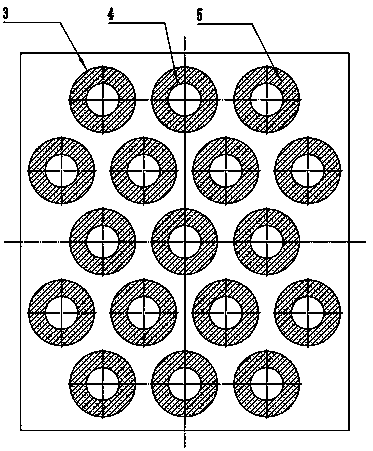

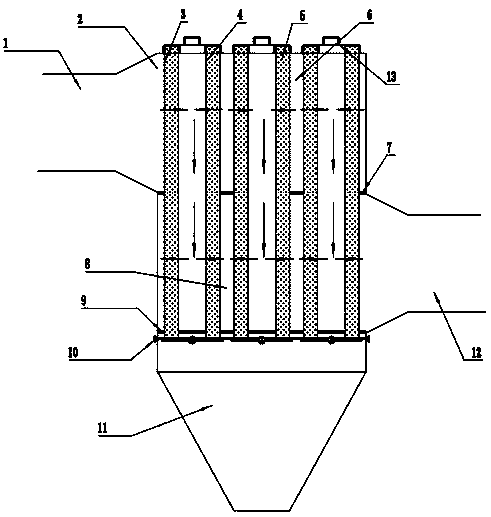

Double-flow-direction active coke adsorption type desulfurization and denitration device

PendingCN109966861AImprove pore structureImprove thermal stabilityGas treatmentDispersed particle separationBaghouseEngineering

The invention relates to a double-flow-direction active coke adsorption type desulfurization and denitration device. The device comprises an adsorption tower, adsorption outer cylinders, adsorption inner cylinders, a middle isolation plate and a lower isolation plate, wherein a plurality of vertically arranged adsorption outer cylinders with holes are arranged in the adsorption tower; the adsorption inner cylinders with holes are arranged in the adsorption outer cylinders; the middle part of the adsorption tower is provided with the middle isolation plate with holes; the middle isolation plateis fixedly connected with the adsorption outer cylinder; the adsorption tower is sequentially divided into an upper air chamber and a lower air chamber from top to bottom; the upper air chamber of the adsorption tower is connected with a flue gas inlet; and the lower air chamber of the adsorption tower is connected with a flue gas outlet. The two air chambers are communicated only through the adsorption cylinders, so that the double purification of the flue gas from outside to inside and from inside to outside can be realized, and the utilization rate of the device is effectively improved. The device is positioned behind equipment such as a boiler, a sintering machine and the like, and is positioned in front of or behind a bag-type dust remover or an electrostatic dust remover, can be used for a dry desulfurization and denitration process, is suitable for a wet desulfurization and denitration process, and is an independent process of flue gas desulfurization and denitration treatment.

Owner:山东中玻节能环保发展有限公司

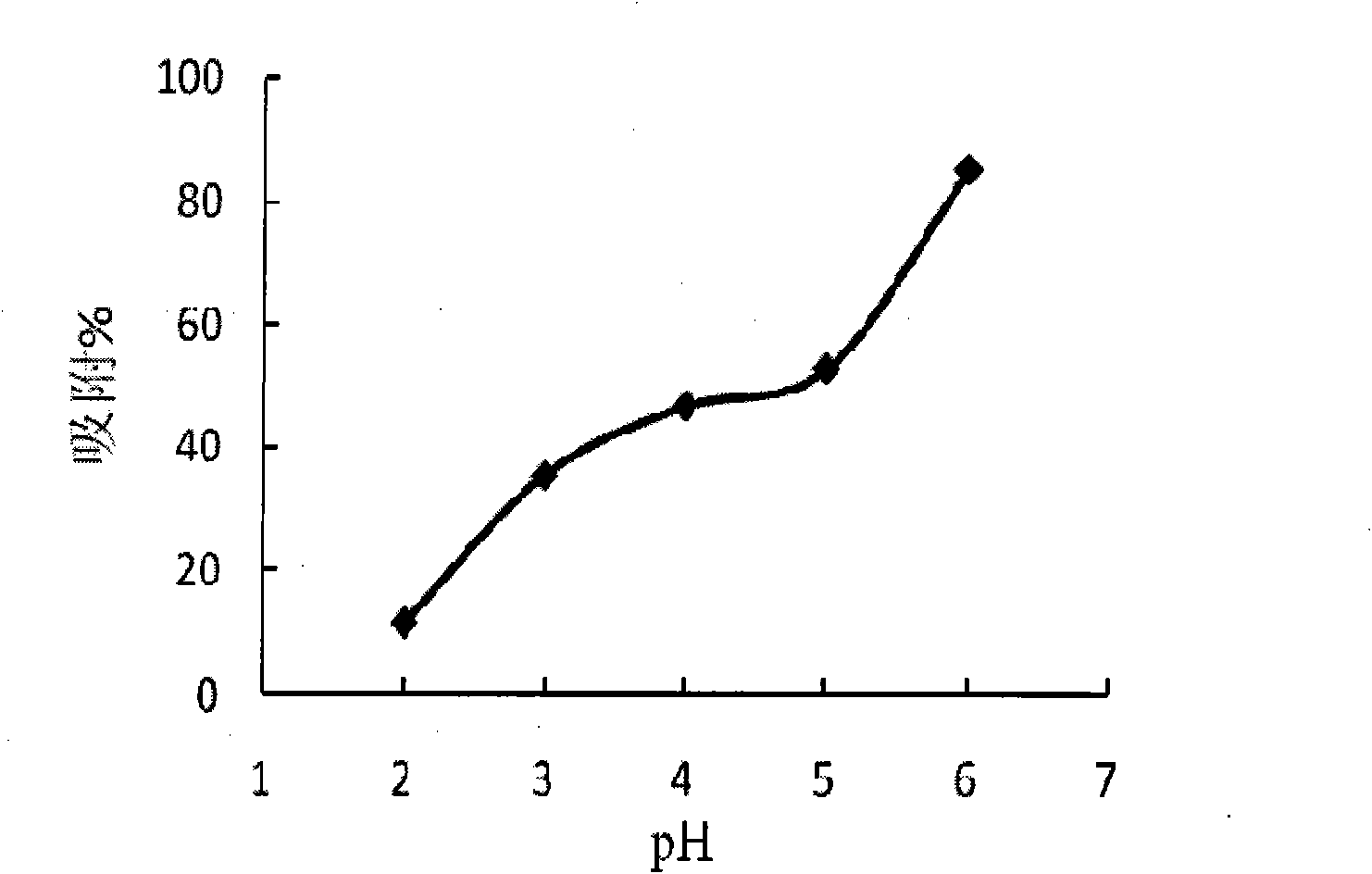

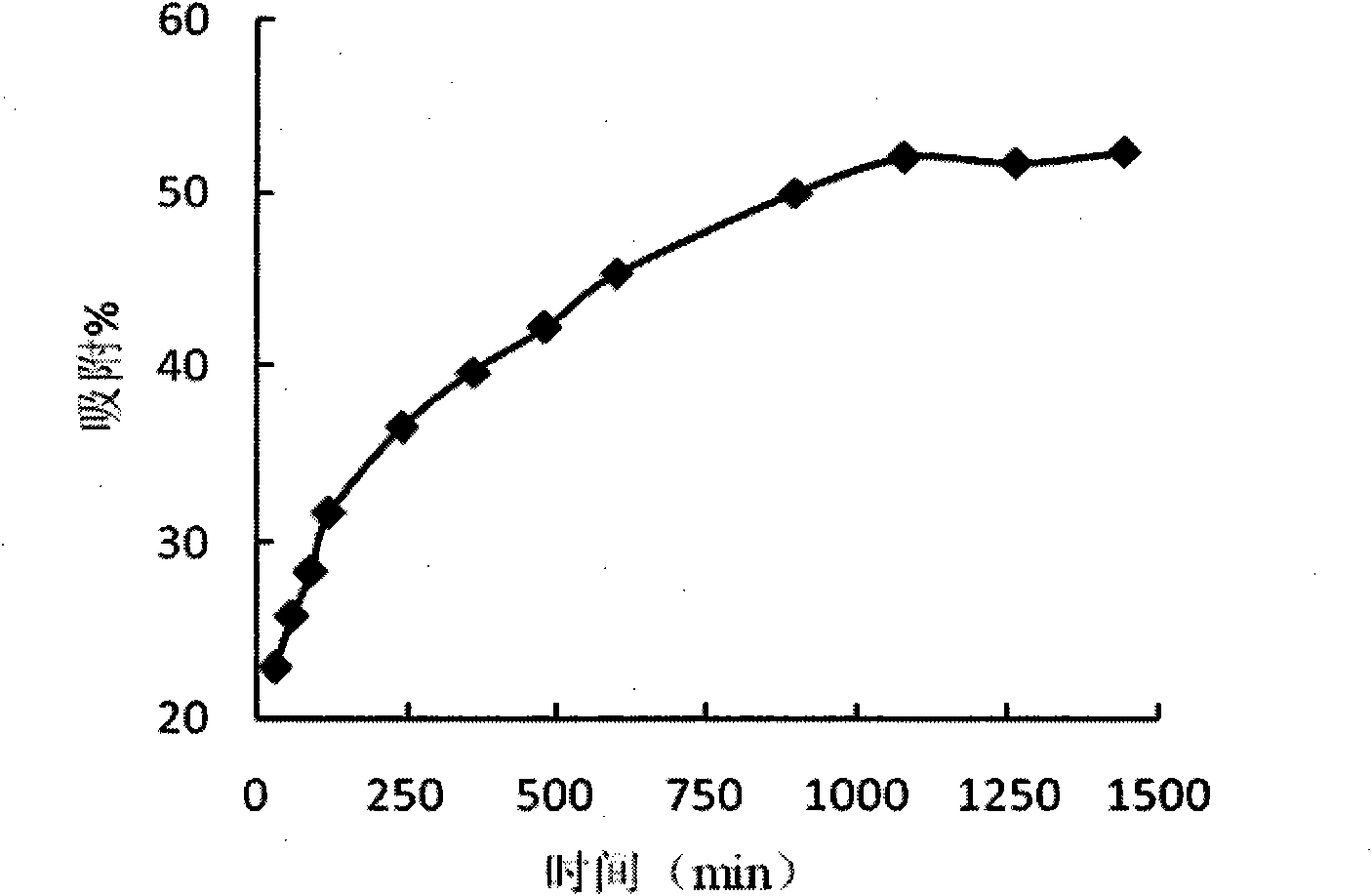

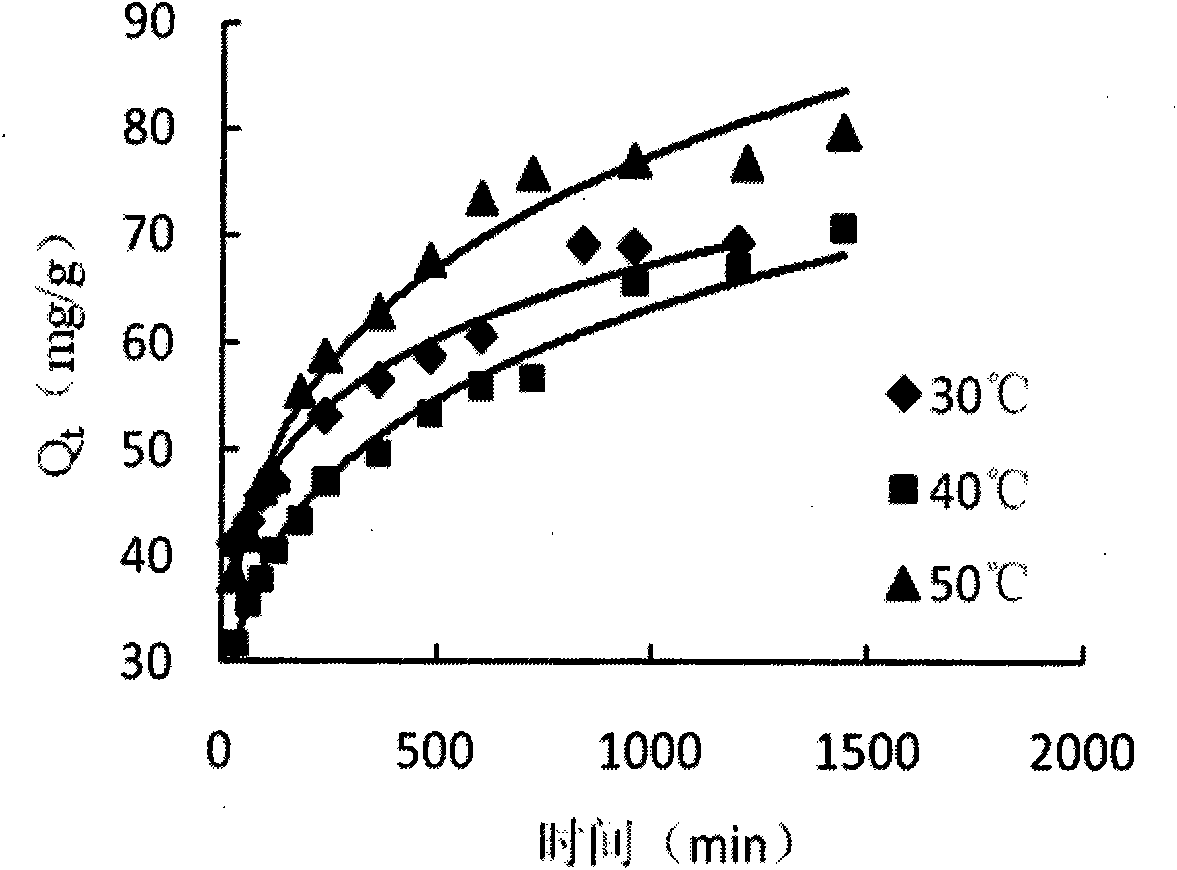

Method for adsorbing and recovering precious metal palladium by persimmon tannin-containing metal adsorbent

InactiveCN102614836BHigh ability to adsorb palladium ionsReduce manufacturing costIon-exchange process apparatusOther chemical processesNatural productFiltration

Owner:HUAZHONG AGRI UNIV

A kind of visible light catalytic material and its preparation method and application

ActiveCN111167496BOxidizing abilityConductiveNitrogen compoundsWater/sewage treatment by irradiationPtru catalystBismuth vanadate

The invention provides a visible light catalytic material and its preparation method and application, belonging to the technical field of catalysts. The visible light catalytic material provided by the present invention includes a carrier and an active component loaded on the surface of the carrier; the carrier is a conductive ceramic; the active component is P-C 3 N 4 , graphene oxide and bismuth vanadate; the raw materials for the preparation of the conductive ceramics include graphene, aluminum oxide and zinc oxide. P-C in the visible photocatalytic material provided by the invention 3 N 4 and BiVO 4 Both can be excited by visible light to generate photogenerated electrons and holes, BiVO 4 The reducing electrons on the P‑C will be transferred to the 3 N 4 On, and recombining with its oxidative holes, RGO can act as an electron transport medium to enhance the above process. The present invention adopts active components of a specific composition and a carrier to be used together, and the provided visible light catalytic material has excellent visible light catalytic efficiency and recovery efficiency.

Owner:NANKAI UNIV

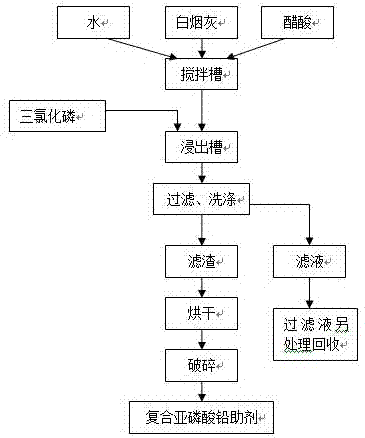

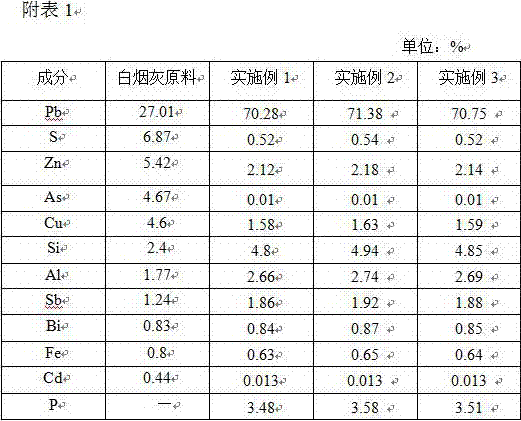

Acid-modified white ash compound basic lead phosphate auxiliary and preparation method thereof

InactiveCN107987313AEnhanced UV resistanceRaw materials are widely sourced and cheapIonIndustrial waste

The invention discloses an acid-modified white ash compound basic lead phosphate auxiliary. White ash which is produced in a copper smelting process and is collected by virtue of an electrical dust precipitation process and phosphorus trichloride are adopted as raw materials, reaction is carried out under the catalytic action of glacial acetic acid for removing soluble metal ions, insoluble metalions are modified to generate precipitates, and filtering and drying are carried out, so that the acid-modified white ash compound basic lead phosphate auxiliary is obtained. The acid-modified white ash compound basic lead phosphate auxiliary disclosed by the invention has the advantages that industrial waste slag is adopted as a raw material, the raw material is extensive in source and low in price; and a preparation method of the acid-modified white ash compound basic lead phosphate auxiliary is simple and reasonable in operation, poisoning caused by lead dust during production and use is avoided, and product performance is good, so that the acid-modified white ash compound basic lead phosphate auxiliary is applicable to industrial production.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

A kind of adsorption material, preparation method and application of Hangjin soil 2# soil loaded nano-zero valent iron

InactiveCN105148831BImprove resource utilizationImprove self-worthOther chemical processesWater/sewage treatment by ion-exchangeNitrogen gasOxygen

An adsorption material for Hangjin 2# soil loaded with nanometer zero-valent iron, wherein the mass ratio of nanometer zerovalent iron to Hangjin 2# soil is 1:4‑5. The preparation method uses Hangjin 2# soil as the carrier to load nanometer zero-valent iron. The steps are as follows: 1) dissolving iron-containing oxides in ethanol solution to obtain a mixed solution; 2) adding Hangjin 2 to the mixed solution in step 1 #soil, nanometer zero valent iron and Hang Jin 2# soil mass ratio are 1:4-5; 3) pass into nitrogen in the product of step 2, stir and remove oxygen; 4) add reducing agent to the product of step 3, will Iron-containing oxides are reduced to nanometer zero-valent iron, and evenly dispersed on the surface of the carrier material Hangjin 2# soil; 5) The product obtained in step 4 is subjected to solid-liquid separation, and the solid is vacuum-dried to obtain Hangjin soil 2# soil-loaded nanometer zero-valent iron Adsorbent material for iron. The adsorption material of the invention has higher reactivity and reduction effectiveness, and has good application value in actual water pollution control and repair projects.

Owner:BEIJING VOCATIONAL COLLEGE OF AGRI +1

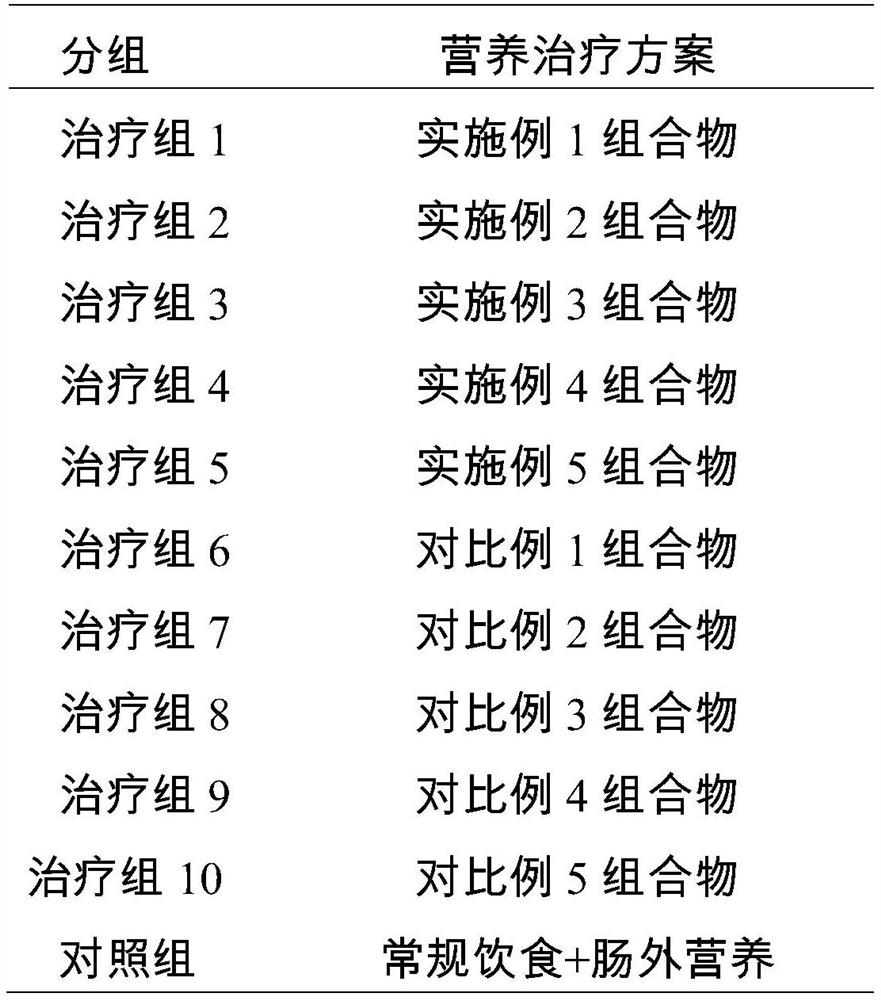

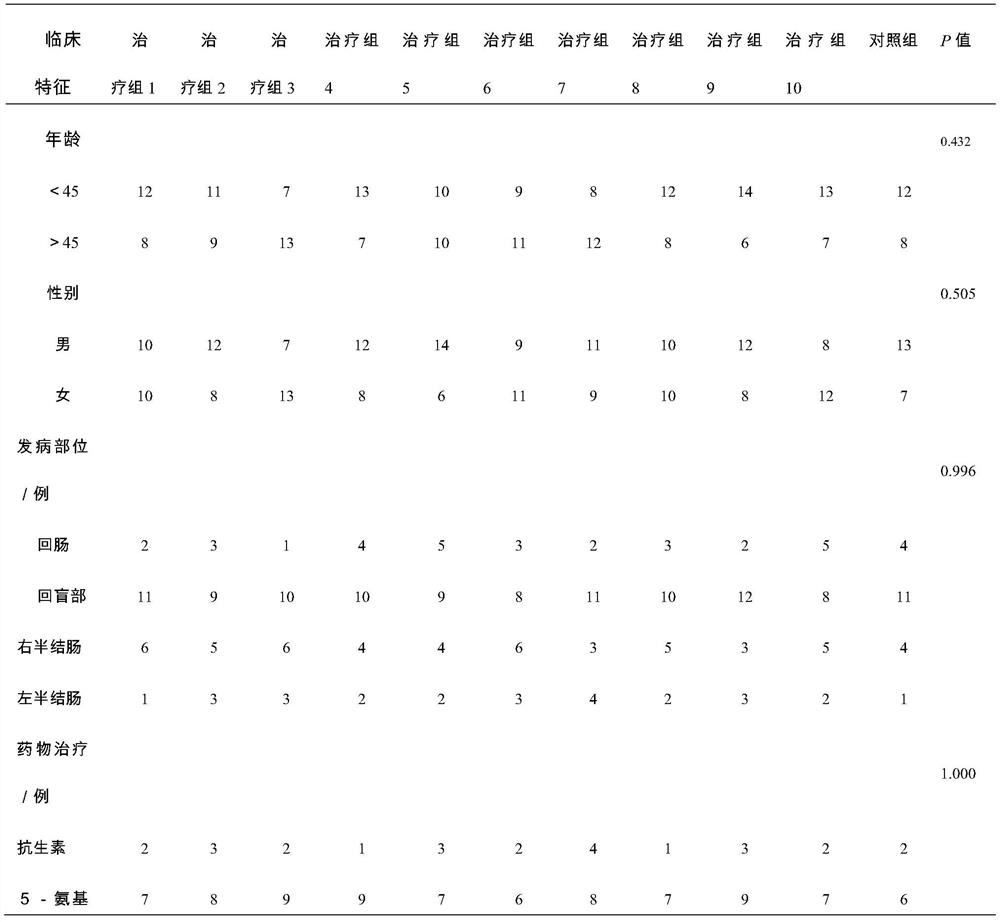

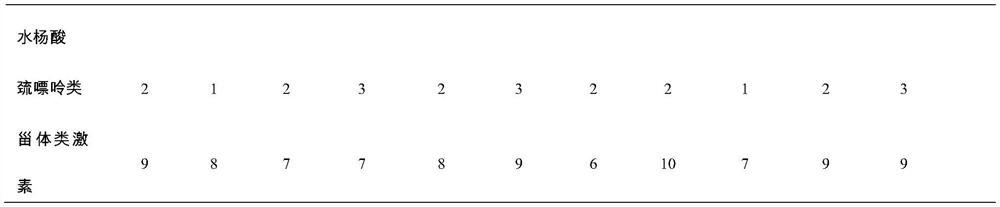

Full-nutrient dietary composition suitable for Crohn disease and preparation method thereof

ActiveCN113679038APromote absorptionAntioxidantSugar food ingredientsVitamin food ingredientsArginineNutrition

The invention discloses a full-nutrient dietary composition suitable for the Crohn disease and a preparation method thereof. The full-nutrient dietary composition comprises the following components: glucose, hemsleya amabilis polysaccharide, a whey protein hydrolysate small molecule peptide, leucine, isoleucine, valine, glycine, histidine, milk fat, medium chain triglyceride, corn oil, n-3 unsaturated fatty acid, choline, taurine, hemsleya amabilis polyphenol, curcumin, vitamin A, vitamin D, vitamin E, vitamin C, potassium, magnesium, calcium, phosphorus, zinc, selenium, iron, glutamine, arginine, nicotinic acid, pantothenic acid, vitamin B1, vitamin B2, vitamin B6, vitamin B12, folic acid, iodine, vitamin K1 and biotin. According to the invention, the small molecule peptide is selected, so that the intestinal burden can be relieved, diarrhea can be relieved; and meanwhile, various antioxidant nutrients are added to synergistically take an antioxidant multiplication effect, so that the postoperative oxidative stress reaction is reduced, and the risk of postoperative infection and complications of a patient suffering from the Crohn disease is reduced.

Owner:THE FIRST AFFILIATED HOSPITAL OF MEDICAL COLLEGE OF XIAN JIAOTONG UNIV

Green rust-polydimethyldiallylammonium chloride in-situ composite coagulant and its preparation method and application

ActiveCN111908579BOxidizingHas the ability to restoreWater/sewage treatment by flocculation/precipitationEngineeringSewage treatment

The invention relates to green rust-polydimethyldiallylammonium chloride in-situ composite coagulant and its preparation method and application, comprising the following steps: under stirring, Fe(II)-containing solution and dimethyl diene After the propylammonium chloride is mixed evenly, flush into nitrogen, then heat, adjust the pH value to 7, add the initiator solution, keep warm and continue the reaction. Add lye, seal and age at room temperature to get the green rust-polydimethyldiallylammonium chloride in-situ composite coagulant; dimethyldiallylammonium chloride contains Fe(II) The mass concentration in the solution is 100-300g / L; the addition amount of the initiator is 0.2-0.8% of the mass of dimethyl diallyl ammonium chloride. The in-situ composite coagulant prepared by controlling the partial oxidation of Fe(II) to Fe(III) in the in-situ synthesis process of the present invention is used for sewage treatment with a turbidity reduction rate of 95% or more, and the coagulation effect is good.

Owner:CHANGZHOU QINGLIU WATER TREATMENT AGENT +1

Preparation method of corydalis ochotensis total alkaloid

InactiveCN101829195BImprove memory functionHas the ability to restoreNervous disorderPlant ingredientsAlkaloidMacroporous resin

The invention relates to a corydalis ochotensis total alkaloid and a preparation method and a medicinal application thereof. The corydalis ochotensis total alkaloid is prepared by the following methods: grinding corydalis ochotensis into coarse powder; adding sulfuric acid solution with a concentration of 0.1-5% for soaking the coarse powder; then carrying out extraction by the sulfuric acid solution with a concentration of 0.1-5% by means of percolation; adjusting pH value of percolation liquid to 5-8 by NaOH solution; applying macroporous resin, eluting the percolation liquid by NaOH solution with a concentration of 1-10% until effluent liquid becomes almost colorless; washing the percolation liquid until the pH value of the percolation liquid ranges from 7 to 9; eluting the percolationliquid by ethanol with a concentration of 40% until the effluent liquid becomes colorless; eluting the percolation liquid by ethanol with a concentration of 80-95% until no alkaloid reactions occurs;and finally recovering ethanol by eluent and drying.The invention also relates to the application of the corydalis ochotensis total alkaloid in preparing medicine for improving memory function and treating senile dementia.Being a common medicinal material in Changbaishan Mount in China, the corydalis ochotensis is in existence in large quantities; therefore development of such a medicinal material is of positive significance.

Owner:JILIN UNIV

Method for adsorbing and recovering precious metal gold by persimmon tannin-containing metal adsorbent

InactiveCN102614837BHigh ability to adsorb gold ionsHighly selective adsorptionIon-exchange process apparatusOther chemical processesNatural productSorbent

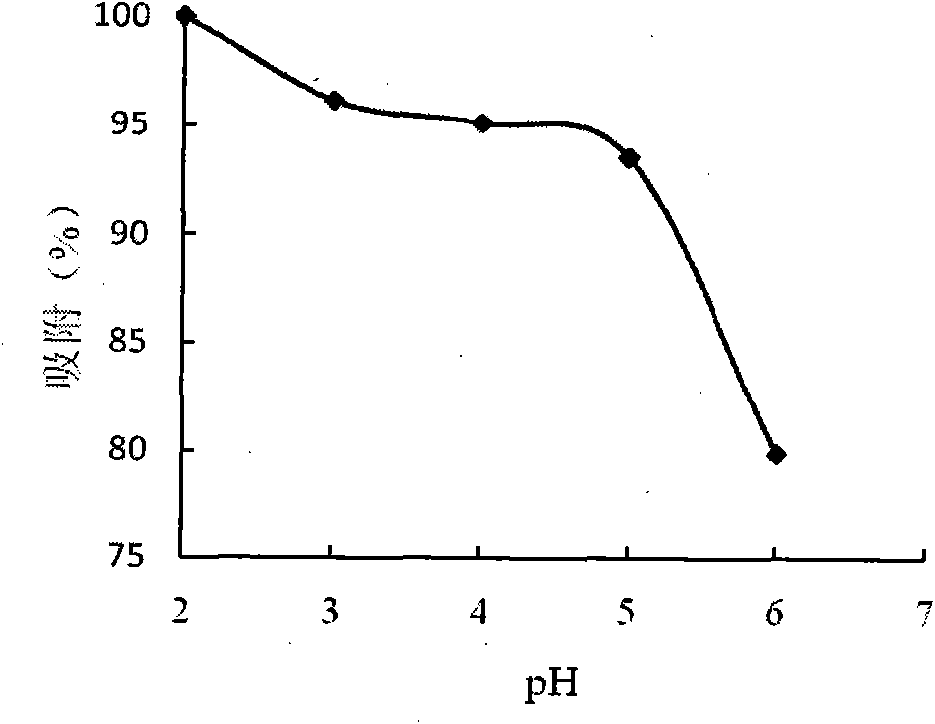

The invention belongs to the technical field of natural product extraction and utilization, and especially relates to a method for adsorbing and recovering a precious metal gold by a persimmon tannin-containing metal adsorbent. The method can be used for selectively adsorbing and recovering a gold element in a secondary resource and has the characteristics of low cost, large adsorption capacity, good environmental benefits and convenient operation. The method comprises the following steps of 1, weighing a certain amount of a persimmon tannin-containing adsorbent, and adding the weighed persimmon tannin-containing adsorbent into a triangular flask, 2, adding an alloy ion-containing mixed solution having a pH value of 2 to 4 into the triangular flask, wherein the volume of the used alloy ion-containing mixed solution is less than or equal to half of the volume of the triangular flask, 3, sealing an opening of the triangular flask by a sealing film, putting the sealed triangular flask into a shaking table, and carrying out adsorption at a shaking-table rotation rate of 100 to 200rpm at a temperature of 25 to 50 DEG C for 12 to 24h, and 4, carrying out filtration so that gold ions in the alloy ion-containing mixed solution are adsorbed by the persimmon tannin-containing adsorbent. The method also can be used for adsorbing and recovering a precious metal gold by a chromatographic column.

Owner:HUAZHONG AGRI UNIV

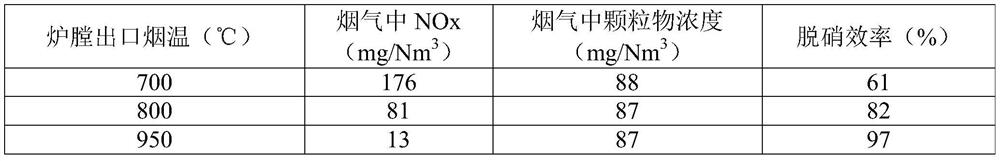

A kind of flue gas sncr denitrification agent and preparation method thereof

ActiveCN111974186BHas the ability to restoreImprove adsorption capacityDispersed particle separationActivated carbonNitrogen oxides

The present invention provides a flue gas SNCR denitrification agent and a preparation method thereof, which, calculated in parts by mass, include 80-95 parts of a reducing agent, 1-5 parts of activated carbon and 0.01-0.2 parts of a hydrogen storage metal, and the hydrogen storage metal is Pre-hydrogenation treatment, the preparation method includes: mixing hydrogen storage metal with activated carbon and then mixing with reducing agent, thereby obtaining flue gas SNCR denitration agent. The flue gas SNCR denitrification agent of the invention has a wider effective reaction temperature range, and at the same time produces less solid particles after the reaction, has stronger reducing ability to nitrogen oxides, and has a good application prospect.

Owner:南通润启环保服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com