Method for adsorbing and recovering precious metal palladium by persimmon tannin-containing metal adsorbent

The technology of adsorbent and persimmon tannin is applied in the field of preparation and utilization of natural products, which can solve the problems of inconvenient harvesting and many physiological fruit drop, and achieve the effects of convenient industrial production, low production cost and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0037] Embodiment 2 utilizes persimmon tannin metal adsorbent to adsorb and reclaim noble metal palladium in palladium-containing mixed solution

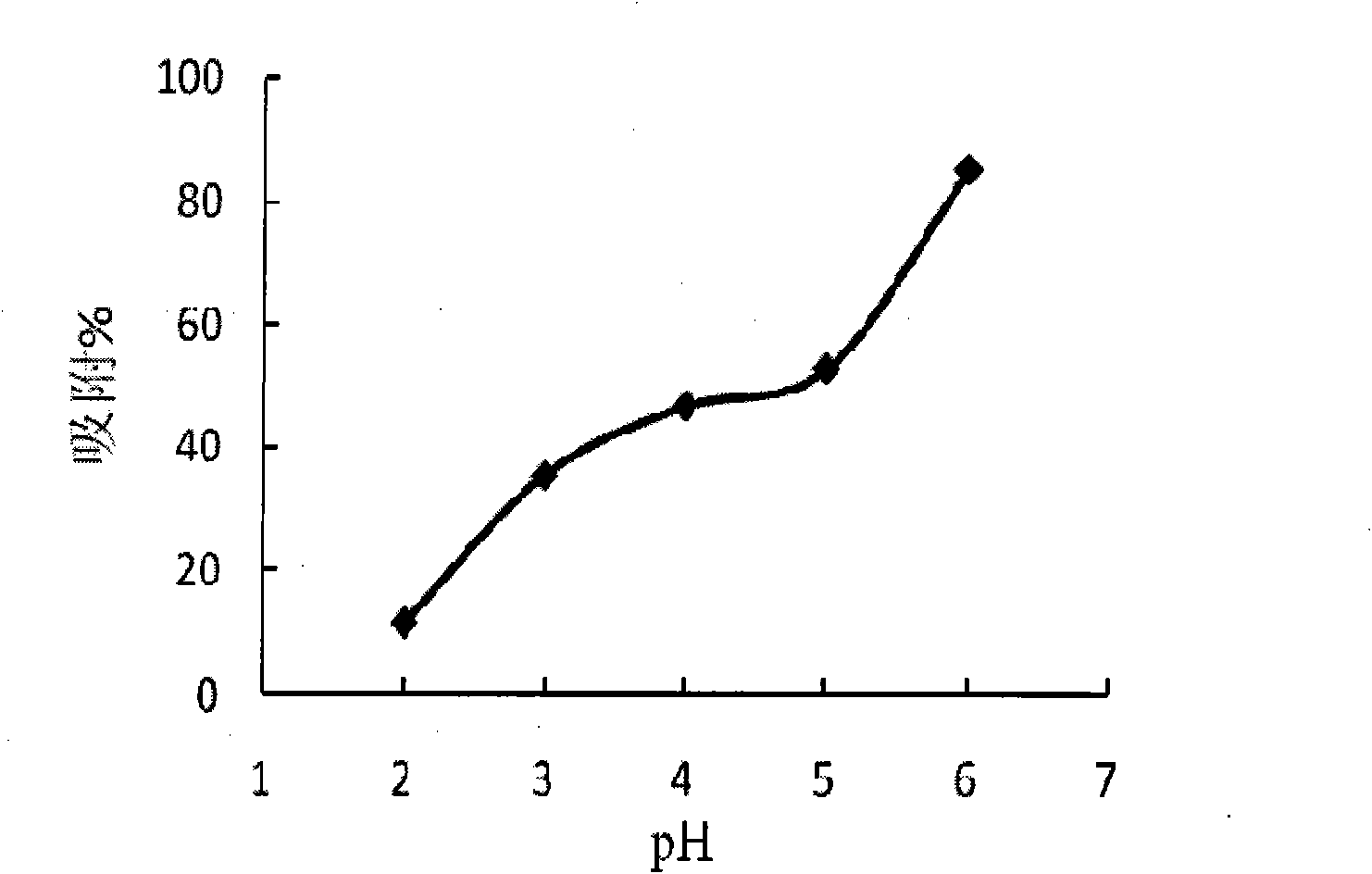

[0038] (1) The pH value of the palladium ion mixed solution is adjusted to 5.0-5.5;

[0039] (2) Metal adsorbent and palladium ion mixed solution are joined in the Erlenmeyer flask by metal adsorbent (mg) / solution (ml) mass volume ratio is 1: 3-5;

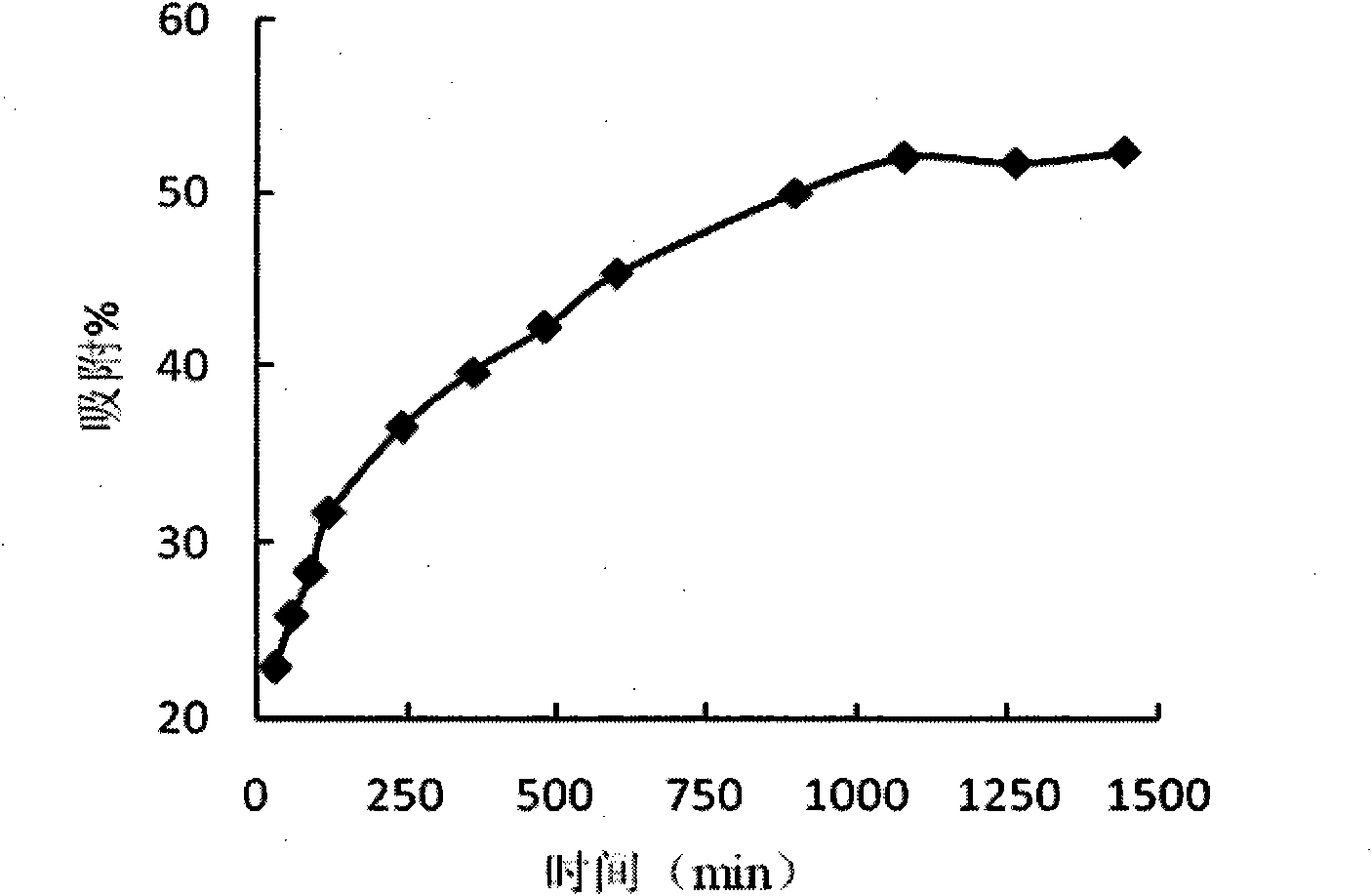

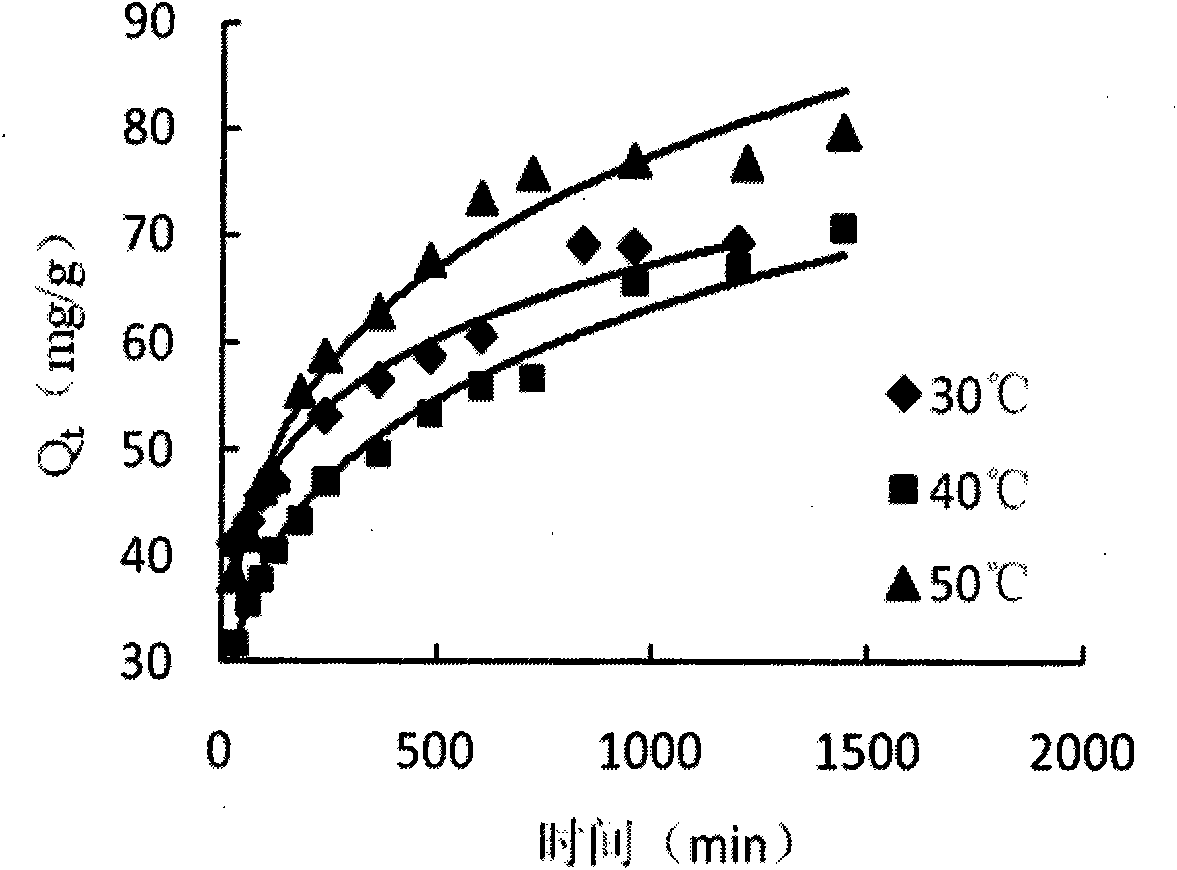

[0040] (4) Seal the triangular flask with a sealing film, put it into a shaker with a pre-set temperature of 20-50°C and a rotating speed of 100-200rpm for oscillating adsorption; and

[0041] (5) After adsorption for 12-24h, filter, and the palladium ion in the palladium ion mixed solution can be completely adsorbed by the metal adsorbent of the present invention;

[0042] (6) Burning the mixture of the metal adsorbent having adsorbed palladium ions in step (5) with a flame until the impurities in the metal adsorbent are all burnt out to obtain high-purity palladium.

Embodiment 3

[0043] Embodiment 3 Utilizes persimmon tannin metal adsorbent to adsorb and reclaim noble metal palladium in palladium-containing mixed solution

[0044] (1) The pH value of the mixed ion solution (see Table 1) containing the different concentrations of palladium ions is adjusted to 4-6;

[0045] (2) metal adsorbent (mg) / palladium ion mixed solution (ml) mass volume ratio of the present invention is 1: 3-51: 3-5 joins in the Erlenmeyer flask;

[0046] (3) Seal the triangular flask with a sealing film, put it into a shaker with a pre-set temperature of 30-50° C. and a rotating speed of 100-200 rpm, and oscillate for adsorption; and

[0047] (4) after adsorption 12-24h, filter, and palladium ion can be almost completely adsorbed by the metal adsorbent of the present invention when other ion concentrations are very high;

[0048](5) Burning the mixture of the metal adsorbent that has adsorbed palladium ions in step (4) with flame until the impurities in the metal adsorbent are c...

Embodiment 4

[0051] Example 4 Utilize persimmon tannin metal adsorbent to adsorb and recover precious metal palladium in waste mobile phone circuit board solution

[0052] (1) Take 300mL of the waste mobile phone circuit board solution (see Table 2 for ingredients) dissolved in aqua regia and put it into a 500mL beaker (the pH of the waste mobile phone circuit board solution is measured to be 0.8), and use NaOH solution to make the pH of the mixed solution Adjust to 4-6, spare;

[0053] (2) Take 500 mL of deionized water, adjust its pH value to 4-6 with hydrochloric acid solution, and use it as a buffer;

[0054] (3) Take 200mL of the buffer solution of step (2) and soak 11mg of the metal adsorbent prepared by the present invention for 12h;

[0055] (4) Fill the metal adsorbent soaked for 12h into a chromatographic column with an internal diameter of 1cm and a length of 30cm; and

[0056] (5) The flow rate is set to 6mL / h, the sampling time interval is 1h, and the buffer solution of step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com