Acid-modified white ash compound basic lead phosphate auxiliary and preparation method thereof

A technology of lead phosphite additives and white soot, which is applied in the field of acidification modified white soot compound salt-based lead phosphite additives and its preparation, which can solve the problems of large fluctuations in phase composition, difficult processing methods, complex soot components, etc. Problems, to achieve the effect of good product performance, avoid poisoning, wide source of raw materials and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

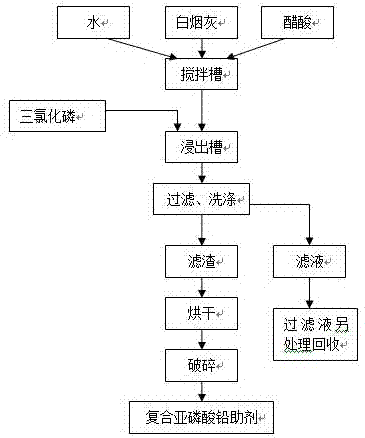

Method used

Image

Examples

Embodiment 1

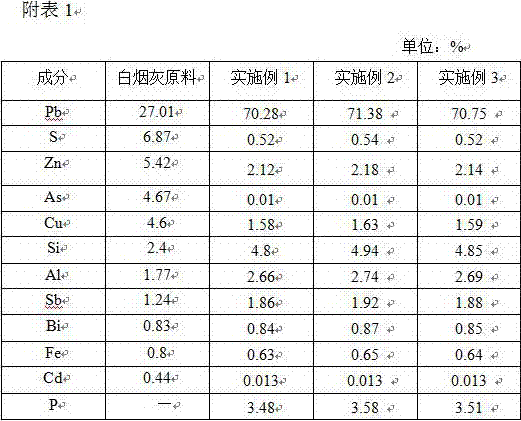

[0022] (1) Raw materials for the test: The copper smelting product of the copper smelting plant of the Baiyin Nonferrous Metals Group Co., Ltd. was used as the raw material for electro-recovery comprehensive soot (white soot). The composition of the white soot is shown in Table 1.

[0023] (2) Preparation method:

[0024] a. Add water, white soot and glacial acetic acid into the acid-resistant leaching tank in sequence according to the solid-to-liquid ratio of 1:3:0.005, start stirring at a speed of 120r / min, and stir to form a slurry;

[0025] b. Weigh phosphorus trichloride with 20% of the mass of white soot, and then slowly drop it into the above slurry under stirring, the dropping time is 60min, and the stirring speed is 120r / min; the dropping process and the leaching process must be ventilated Good, to prevent the generation of arsine or phosphine.

[0026] c. After adding phosphorus trichloride, heat to 50°C and continue the leaching reaction for 5 hours.

[0027] d. A...

Embodiment 2

[0031] (1) Raw materials for the test: The copper smelting product of the copper smelting plant of the Baiyin Nonferrous Metals Group Co., Ltd. was used as the raw material for electro-recovery comprehensive soot (white soot). The composition of the white soot is shown in Table 1.

[0032] (2) Preparation method:

[0033] a. Add water, white soot and glacial acetic acid into the acid-resistant leaching tank in sequence according to the solid-to-liquid ratio of 1:5:0.02, start stirring at a speed of 90r / min, and stir to form a slurry;

[0034] b. Weigh phosphorus trichloride with 40% mass of white soot, and then slowly drop it into the above slurry under stirring, the dropping time is 30min, and the stirring speed is 90r / min; the dropping process and leaching process must be ventilated Good, to prevent the generation of arsine or phosphine.

[0035] c. After adding phosphorus trichloride, heat to 50°C and continue the leaching reaction for 2 hours.

[0036] d. After the leach...

Embodiment 3

[0040] (1) Raw materials for the test: The copper smelting product of the copper smelting plant of the Baiyin Nonferrous Metals Group Co., Ltd. was used as the raw material for electro-recovery comprehensive soot (white soot). The composition of the white soot is shown in Table 1.

[0041] (2) Preparation method:

[0042] a. Add water, white soot and glacial acetic acid into the acid-resistant leaching tank in sequence according to the solid-to-liquid ratio of 1:4:0.01, start stirring at a speed of 120r / min, and stir to form a slurry;

[0043] b. Weigh phosphorus trichloride with 30% of the mass of white soot, and then slowly drop it into the above slurry under stirring, the dropping time is 45min, and the stirring speed is 120r / min; the dropping process and the leaching process must be ventilated Good, to prevent the generation of arsine or phosphine.

[0044] c. After adding phosphorus trichloride, heat to 70°C and continue the leaching reaction for 4 hours.

[0045] d. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com