Anti-fog PC board and preparation method thereof

A technology of PC board and anti-fog layer, which is applied in the direction of coating, etc., can solve the problems of not meeting the actual needs, affecting the service life, and the surface is not anti-fog, so as to achieve good anti-fog, improve the sealing performance, and strengthen the anti-UV ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The preparation method of the hydrophobic titanium dioxide in the anti-fog layer 13 is as follows:

[0047] Add an alcoholic aqueous solution containing an aminosilane coupling agent to the titanium dioxide, stir for 45 minutes, then wash with water; then use a fluorine-containing silane coupling agent to treat for 1.5-2 hours, and dry to obtain hydrophobic titanium dioxide.

[0048] The anti-fog PC board of the invention has good hydrophobicity, blister resistance and alcohol wiping resistance.

[0049] The hydrophobic titanium dioxide of the present invention is a specially modified filler with good hydrophobicity; the organosilicon acrylic polymer emulsion contains a highly hydrophobic organosilicon structure, and the organosilicon structure is hydrolyzed in the anti-fog layer to strengthen The stability of the anti-fog layer; after the anti-fog layer raw materials in the present invention are blended, the hydrophobic titanium dioxide and the organic silicon acrylic ...

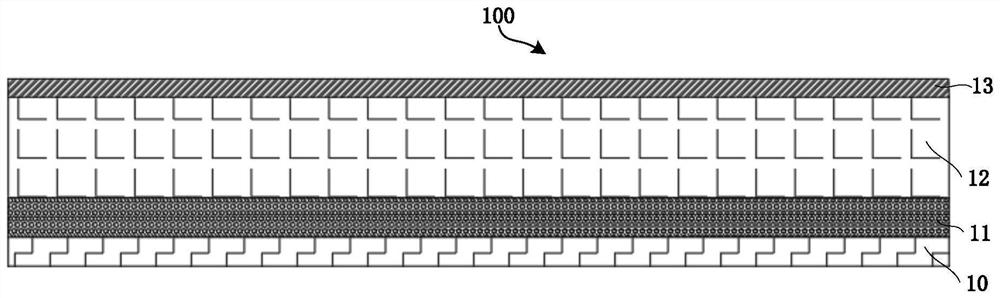

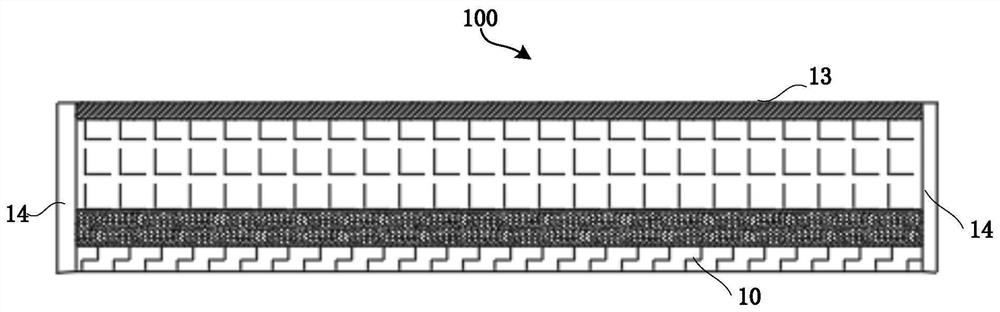

Embodiment 1

[0062] An anti-fog PC board, the anti-fog layer 13 is composed of the following raw materials in parts by weight:

[0063]

[0064] Base 10 is made of the following raw materials in parts by weight:

[0065] 100 parts by weight of polycarbonate;

[0066] 15 parts by weight of organic montmorillonite;

[0067] Antioxidant 1 part by weight.

[0068] The adhesive layer 11 is a latex layer.

[0069] The reinforcement layer 12 is made of the following raw materials in parts by weight:

[0070]

[0071]

[0072] The anti-fog liquid in the anti-fog layer 13 can be prepared in the following manner:

[0073] Mix 1 part by weight of potassium chloride, 2 parts by weight of magnesium sulfate, 2 parts of polyethylene glycol, 0.2 parts by weight of sodium ethylenediamine tetraacetate and 20 parts by weight of deionized water to obtain a mixed solution 1; then mix 2 parts by weight of lecithin 1.5 parts by weight of nano silicon dioxide and 12 parts by weight of ethanol are mi...

Embodiment 2

[0077] An anti-fog PC board, the anti-fog layer 13 is composed of the following raw materials in parts by weight:

[0078]

[0079] Base 10 is made of the following raw materials in parts by weight:

[0080] 130 parts by weight of polycarbonate;

[0081] 20 parts by weight of organic montmorillonite;

[0082] Antioxidant 2 parts by weight.

[0083] The adhesive layer 11 is a latex layer.

[0084] The reinforcement layer 12 is made of the following raw materials in parts by weight:

[0085]

[0086] The anti-fog liquid in the anti-fog layer 13 can be prepared in the following manner:

[0087] 3 parts by weight of potassium chloride, 3 parts by weight of magnesium sulfate, 3 parts of polyethylene glycol, 0.4 parts by weight of sodium edetate and 30 parts by weight of deionized water are mixed to obtain a mixed solution 1; then 5 parts by weight of lecithin part, 2.5 parts by weight of nano silicon dioxide, and 13 parts by weight of ethanol are mixed to obtain mixed li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com