Visible light catalytic material and preparation method and application thereof

A catalytic material, visible light technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. low rate issues

- Summary

- Abstract

- Description

- Claims

- Application Information

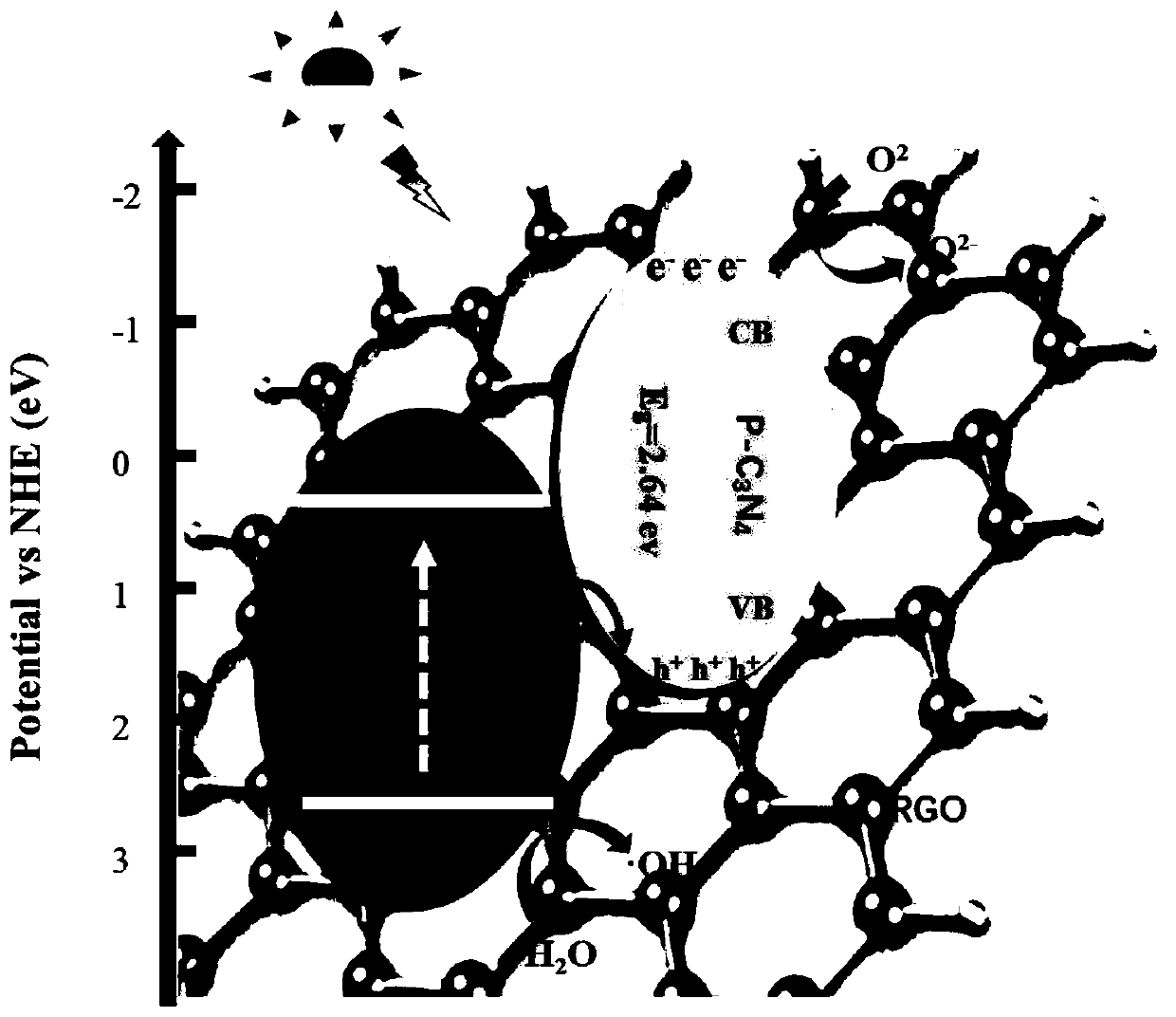

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In the present invention, the preparation method of the conductive ceramic preferably includes the following steps: mixing graphene, aluminum oxide and zinc oxide, followed by crushing, tablet molding and sintering to obtain the conductive ceramic.

[0028] In the present invention, the crushing is preferably ball milling, more preferably wet milling; the solvent used in the wet milling is preferably ethanol; the ball-to-material ratio is preferably 2:1. In the present invention, the usage ratio of described graphene, aluminum oxide, zinc oxide is preferably 1g:(8~9)g:(1~2)g:(500~600)mL, more preferably 1g:(8.5 ~9) g: (1.5 ~ 2) g: (500 ~ 550) mL, most preferably 1 g: 9 g: 2 g: 500 mL. In the present invention, the wet grinding time is preferably 3-5 hours, more preferably 4 hours.

[0029] After the crushing is completed, the present invention preferably further includes drying the obtained powder; the drying temperature is preferably 110-130°C, more preferably 120°C; ...

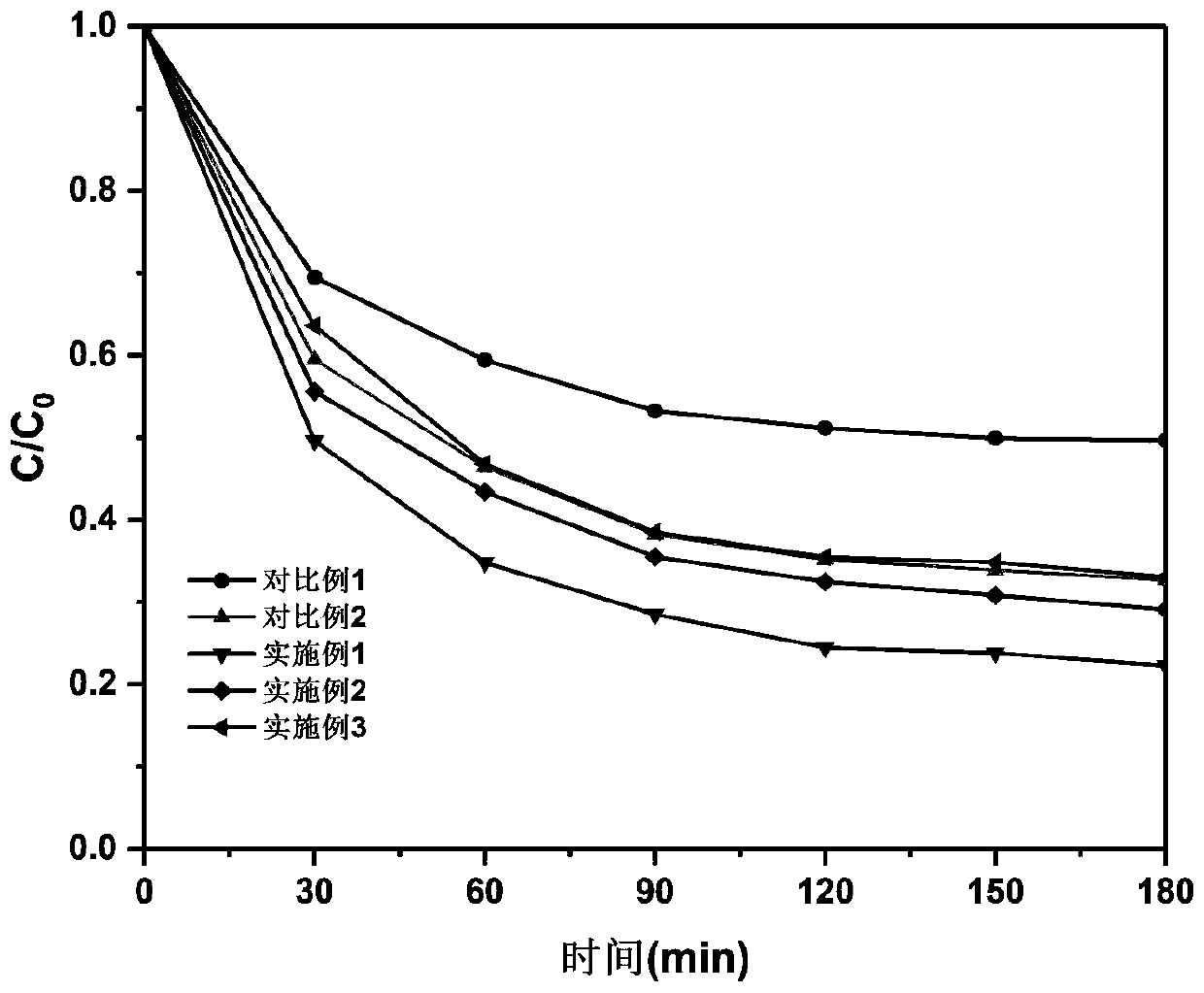

Embodiment 1

[0066] Disperse melamine (3g) in deionized water (20mL), add ammonium dihydrogen phosphate (0.35g) to the resulting suspension and mix ultrasonically for 30min, then stir and react at room temperature (25°C) for 12h, then place in an oven Dry at 100°C for 6h, put it in a crucible with a lid, heat up to 550°C at a rate of 2.5°C / min, bake for 4h, cool to room temperature, and get P-C 3 N 4 ;

[0067] Graphene oxide (5 mg) and deionized water (20 mL) were ultrasonically mixed for 1 h, and P-C 3 N 4 (0.75g) and ultrasonically mixed for 0.5h, stirred at room temperature for 12h, and then dried in an oven at 100°C for 6h to obtain P-C 3 N 4 / GO;

[0068] Bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 (2mmol) was dissolved in glacial acetic acid (5mL) to obtain an acetic acid solution of bismuth nitrate, and P-C 3 N 4 / GO (0.2g), ammonium metavanadate (NH 4 VO 4 , 2mmol) and 30mL of deionized ultrasonic mixing for 30min to obtain a suspension, under the condition of a stirring speed ...

Embodiment 2

[0072] Disperse melamine (3g) in deionized water (20mL), add ammonium dihydrogen phosphate (0.35g) to the resulting suspension and mix ultrasonically for 30min, then stir and react at room temperature (25°C) for 12h, then place in an oven Dry at 100°C for 6h, put it in a crucible with a lid, heat up to 550°C at a rate of 2.5°C / min, bake for 4h, cool to room temperature, and get P-C 3 N 4 ;

[0073] Graphene oxide (5 mg) and deionized water (20 mL) were ultrasonically mixed for 1 h, and P-C 3 N 4 (0.75g) and ultrasonically mixed for 0.5h, stirred at room temperature for 12h, and then dried in an oven at 100°C for 6h to obtain P-C 3 N 4 / GO;

[0074] Bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O, 1.5mmol) was dissolved in glacial acetic acid (5mL) to obtain an acetic acid solution of bismuth nitrate, and P-C 3 N 4 / GO (0.2g), ammonium metavanadate (NH 4 VO 4 , 1.5mmol) and 30mL of deionized ultrasonic mixing for 30min to obtain a suspension, under the stirring speed condition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com