A kind of pd/nial metal oxide film electrode and its preparation method and application

A technology of oxide film and membrane electrode, which is applied in the field of water treatment, can solve problems such as the follow-up treatment of acid radical ions, and achieve the best effect, simple preparation method, and large specific capacitance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

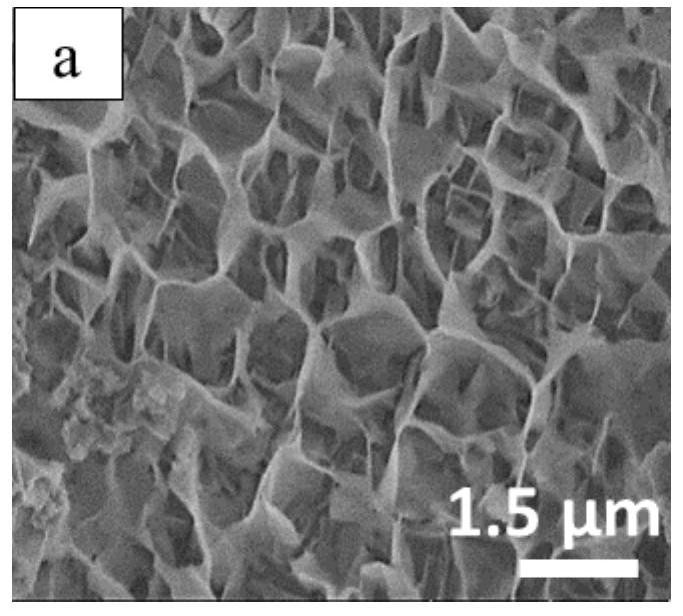

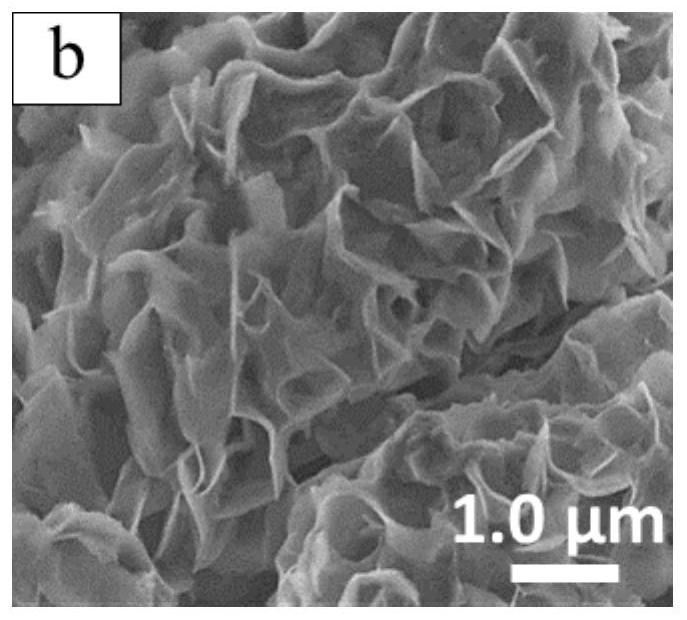

[0042] The Pd / NiAl-LMO membrane electrode and NiAl-LMO membrane electrode of this embodiment are prepared by the following method:

[0043] Configure 1.2mol / L NiCl 2 , 0.4mol / L AlCl 3 Mixture A (one group added PdCl 2 , a group without PdCl 2 ), and configure a certain concentration of NaOH, Na 2 CO 3 For mixed solution B, add an appropriate amount of mixed solution B solution to 100ml mixed solution A solution, and adjust the pH of mixed solution A to 9.5-10.5. Add the pH-adjusted mixed solution into a 100ml reaction kettle, put a piece of pretreated nickel foam, and put the reaction kettle in an oven at 100°C for 10 hours. After the reaction kettle was cooled to room temperature, the reacted nickel foam was dried in an oven at 60°C for 12 hours, and then the electrode was calcined in a tube furnace at 500°C for 4 hours, and heated under H 2 The Pd / NiAl-LMO membrane electrode and the NiAl-LMO membrane electrode can be obtained by calcining at 250°C for 3h in air atmosph...

Embodiment 2

[0048] The Pd / NiAl-LMO membrane electrode and NiAl-LMO membrane electrode of this embodiment are prepared by the following method:

[0049] Configure 1.2mol / L NiCl 2 , 0.4mol / L AlCl 3 Mixture A (one group added PdCl 2 , a group without PdCl 2 ), and configure a certain concentration of NaOH, Na 2 CO 3 For mixed solution B, add an appropriate amount of mixed solution B solution to 100ml mixed solution A solution, and adjust the pH of mixed solution A to 9.5-10.5. Add the pH-adjusted mixed solution into a 100ml reaction kettle, put a piece of pretreated nickel foam, and put the reaction kettle in an oven at 100°C for 10 hours. After the reaction kettle was cooled to room temperature, the reacted nickel foam was dried in an oven at 60°C for 12 hours, and then the electrode was calcined in a tube furnace at 500°C for 4 hours, and heated under H 2 The Pd / NiAl-LMO membrane electrode and the NiAl-LMO membrane electrode can be obtained by calcining at 250°C for 3h in air atmosph...

Embodiment 3

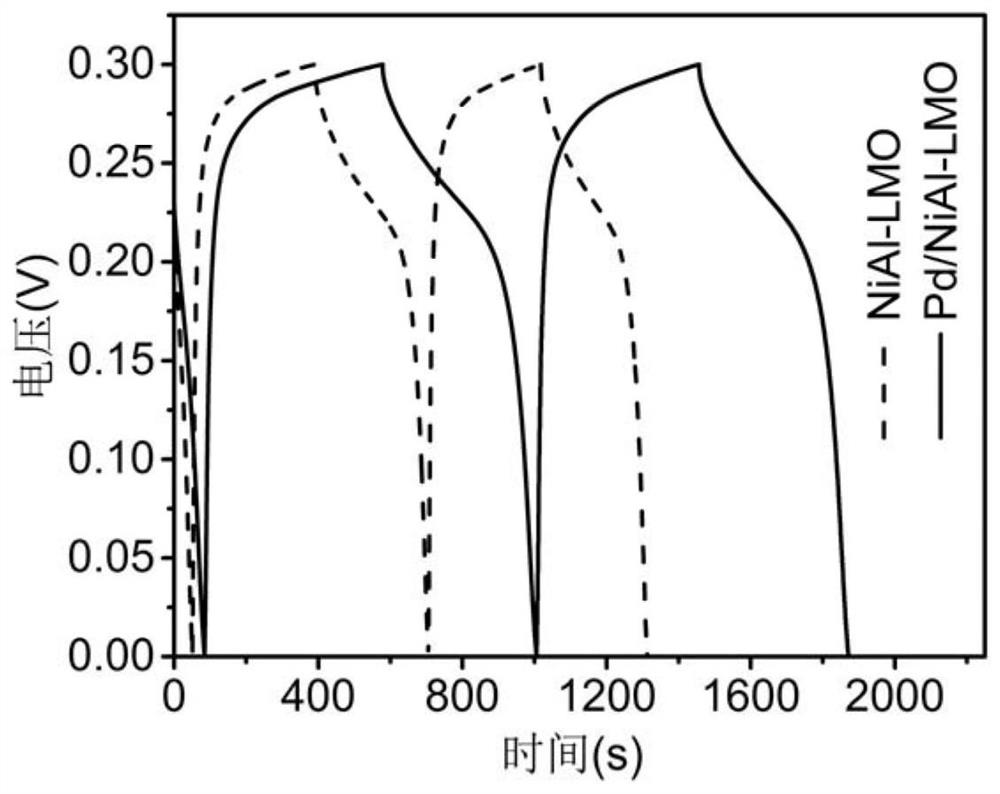

[0052] During the experiment, the NaNO 3 The initial concentration of the solution was set to 0.003mol / L. Using the Pd / NiAl-LMO membrane electrode as the working electrode, the NO 3 - Electrosorption was carried out, and the adsorption reached equilibrium when the adsorption time was 2.5 h. Then, by inverting the cathode and anode, the nitrate ion is electroreduced, and it is converted into harmless nitrogen for removal. Through the speciation analysis of nitrogen-containing ions during the experiment, it can be known that the Pd / NiAl-LMO membrane electrode will NO 3 - Revert to NO first 2 - , NO 2 - further reduced to N 2 removal, the by-product NH 4 + and a very small amount of N 2 O, NO.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com