Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Good solid solution effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

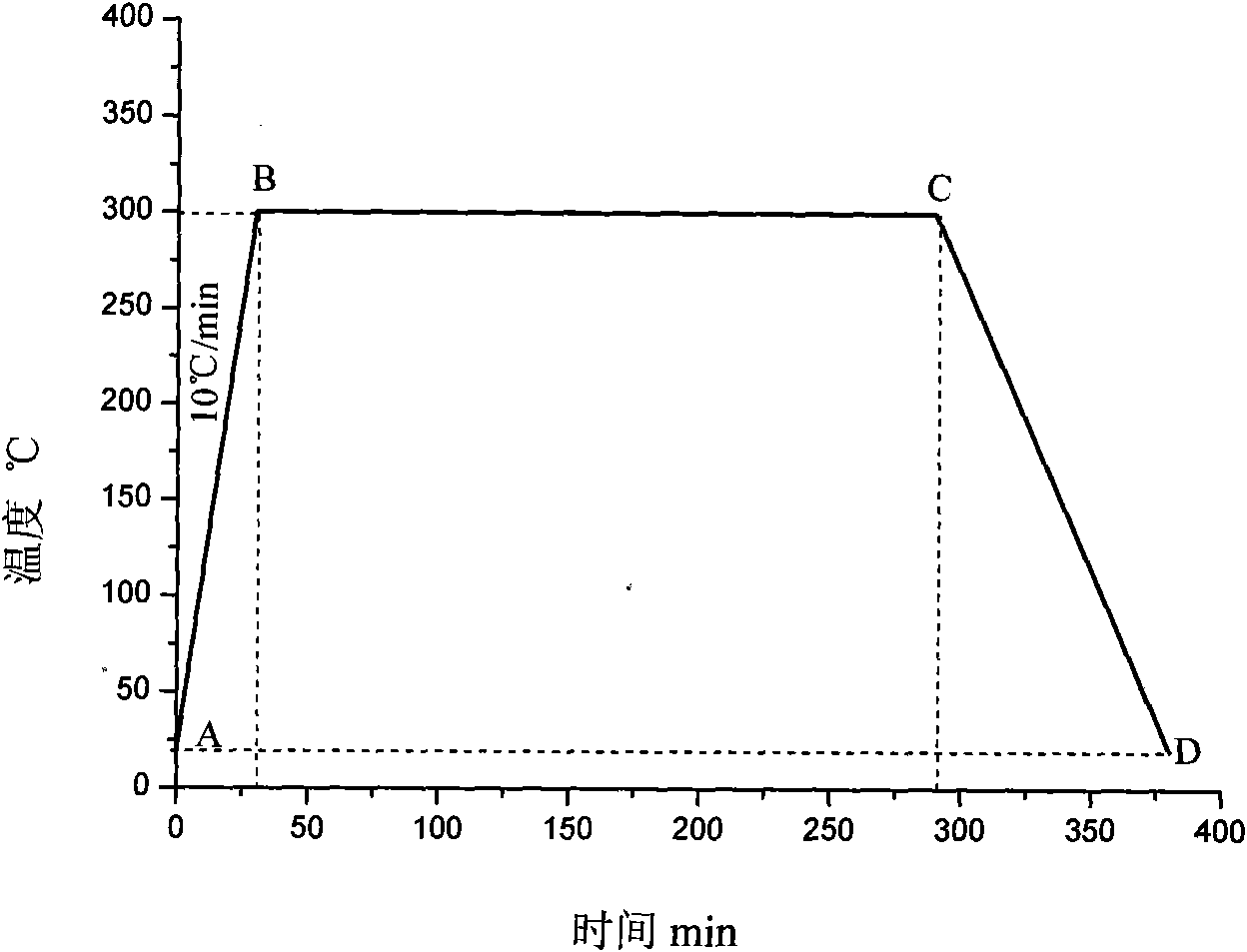

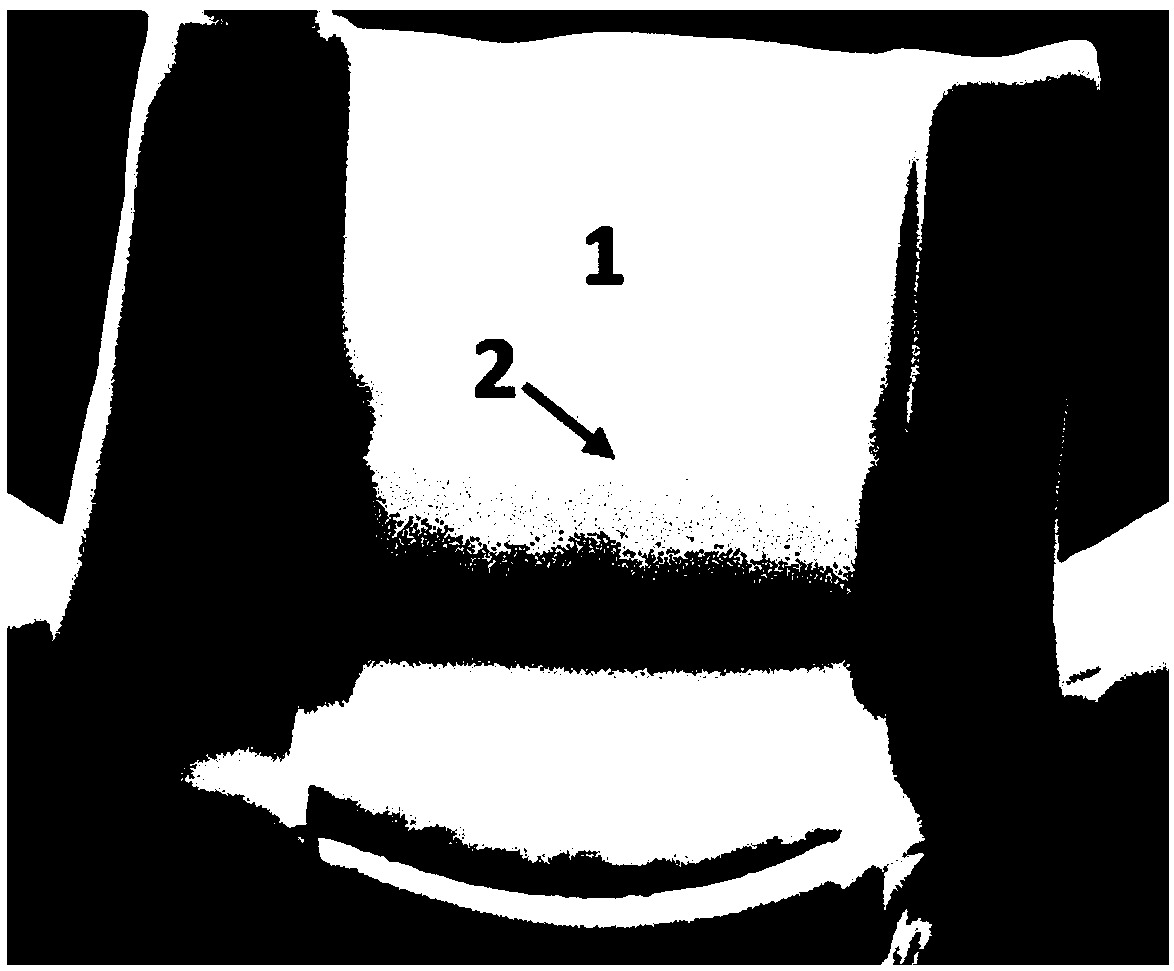

Preparation method of chromium-aluminum-nitrogen film by closed field unbalanced magnetron sputtering

InactiveCN101575696AImprove mechanical propertiesHigh hardnessVacuum evaporation coatingSputtering coatingAluminum IonShielding gas

The invention relates to a preparation method of a chromium-aluminum-nitrogen film by closed field unbalanced magnetron sputtering, which comprises the following steps: a chromium-tungsten-manganese steel plate is taken as a basal body, chromium and aluminum as a target source of metal ion, nitrogen gas as reactant gas, and argon gas as ion bombardment gas and protection gas; in a vacuum sputtering furnace, in a closed magnetic field state, in the argon gas and at the temperature of 300 DEG C, the surface of the chromium-tungsten-manganese steel plate is sputtered with chromium ion, aluminum ion and nitrogen ion and the chromium-aluminum-nitrogen hard film is formed on the surface of the steel plate, and then the low temperature tempering and alloying solid solution are conducted, thus greatly improving mechanical property, hardness, intensity, abrasive resistance and erosion resistance of the surface of the chromium-tungsten-manganese steel plate. The mechanical property of the chromium-tungsten-manganese steel plate can be improved by 466% compared with that of hardened steel plates. The preparation method has short process flow, precise technique, accurate and detailed measurement values, the film with thickness of 4,600nm, and the alloy layer with good solid solution effect and being not easy to peel off, thus being the ideal treatment method for strengthening and hardening the surface of alloy tool steel.

Owner:TAIYUAN UNIV OF TECH

Aluminium foil for electrolytic capacitor low-voltage anode use and producing method thereof

InactiveCN1975949AHigh mechanical strengthIncrease surface areaElectrolytic capacitorsElectrolysisLow voltage

A method for preparing AI foil used on low voltage positive electrode of electrolytic capacitor uses weight compositions with 99.980-99.993% of AI, 15-50ppm of Si, 15-50ppm of Fe, 20-60ppm of Cu, 10-15ppm trace amount element of Mg + Mn +Zn +Ga, impurities and allowance as materials to prepare AI foil used on low voltage positive electrode of electrolytic capacitor.

Owner:RUYUAN DONGYANG UACJ PRECISION FOIL CO LTD

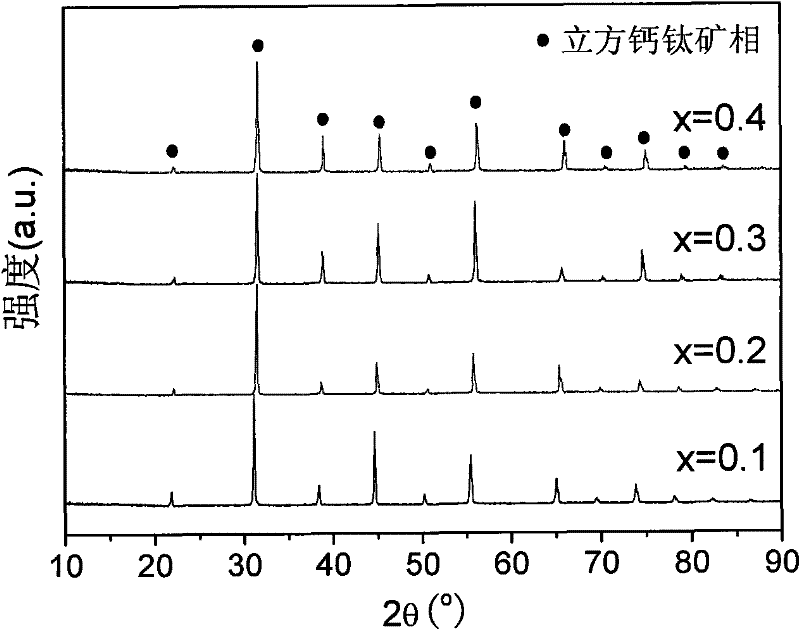

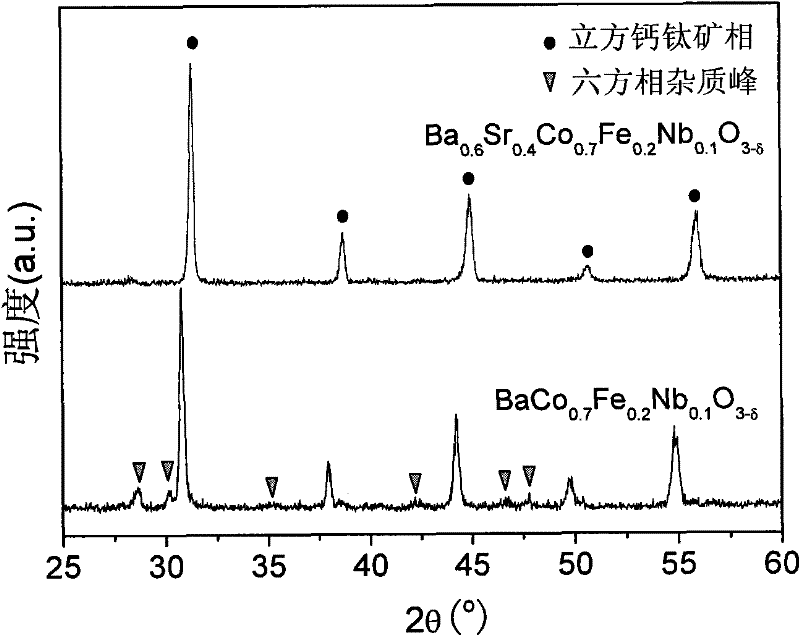

Method for improving structural stability of BaCo0.7Fe0.2Nb0.1O3-Delta oxygen permeation membrane material

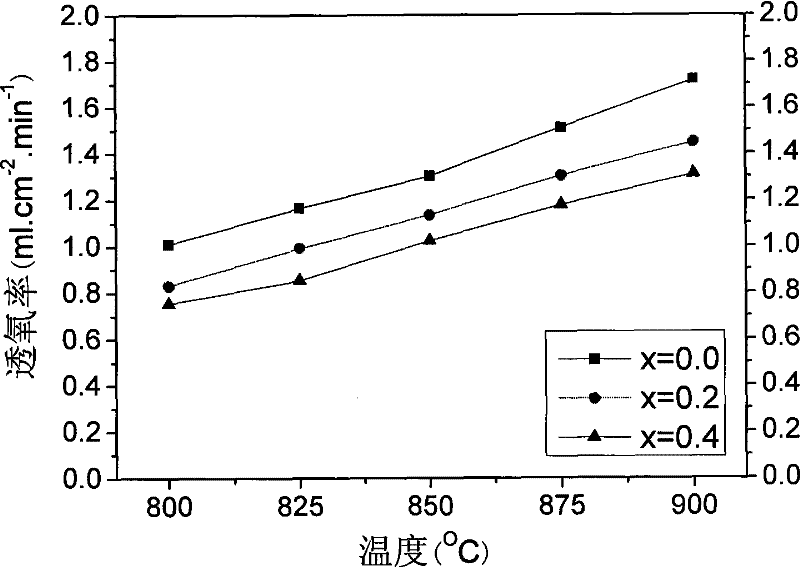

InactiveCN101575210AImprove resistance to reductionGood solid solution effectSemi-permeable membranesHydrogenSr elementConcentration gradient

The invention relates to a method for improving the structural stability of a BaCo0.7Fe0.2Nb0.1O3-Delta oxygen permeation membrane material, which belongs to the technical field of oxygen permeation membranes. The method is characterized in that Sr element is doped into the BaCo0.7Fe0.2Nb0.1O3-Delta base material with a perovskite structure, and the obtained oxygen permeation membrane material has a chemical formula of Ba1-xSrxCo0.7Fe0.2Nb0.1O3-Delta, wherein x is equal to 0.05-0.4. The oxygen permeation membrane material provided by the method remarkably improves the phase structure stability of the BaCo0.7Fe0.2Nb0.1O3-Delta base material under the condition of high temperature and low oxygen partial pressure, and the improved oxygen permeation membrane material can be applied within wider oxygen partial pressure range and under larger oxygen concentration gradient.

Owner:UNIV OF SCI & TECH BEIJING

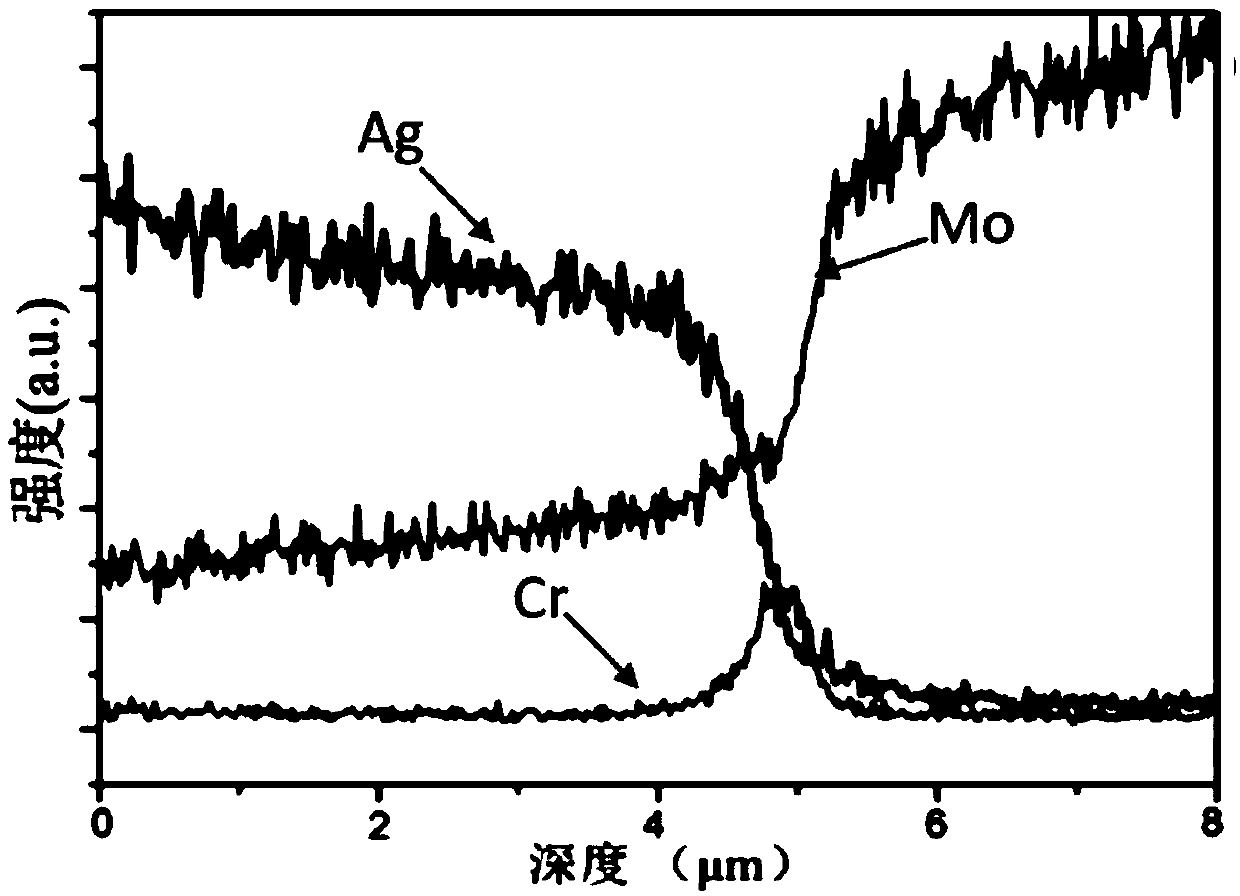

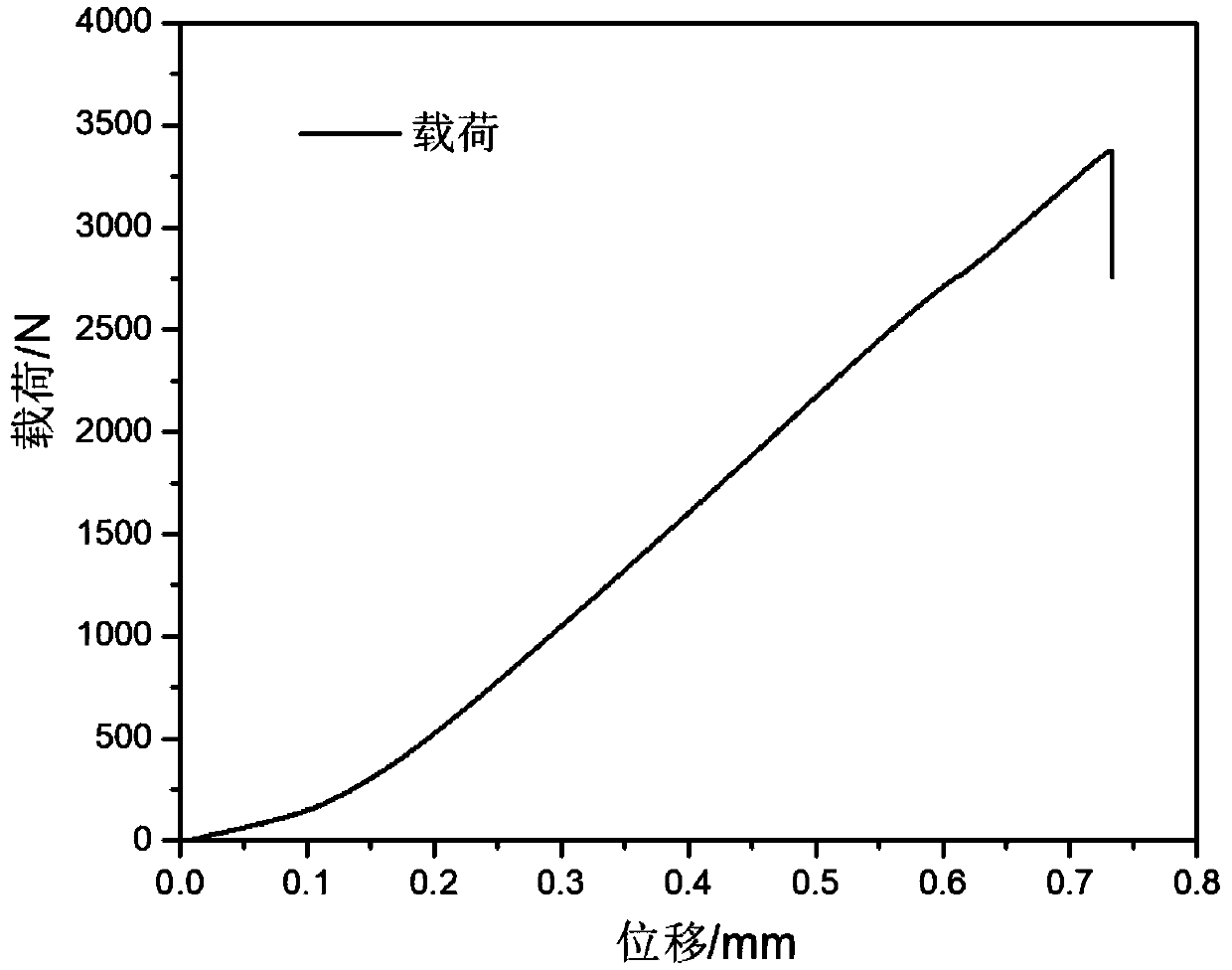

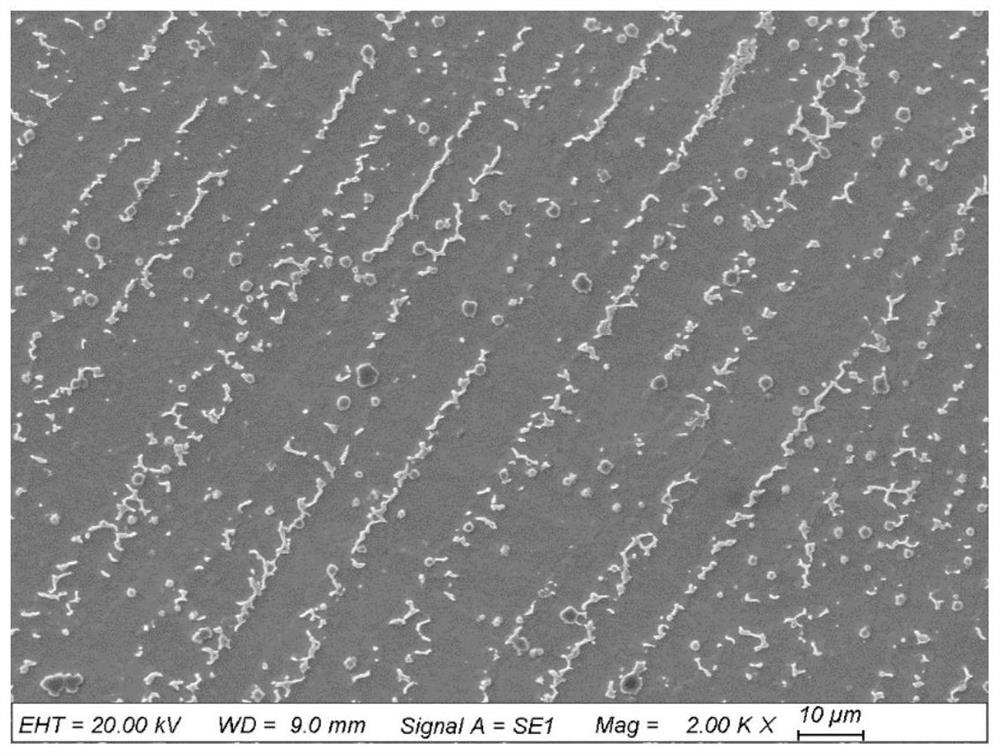

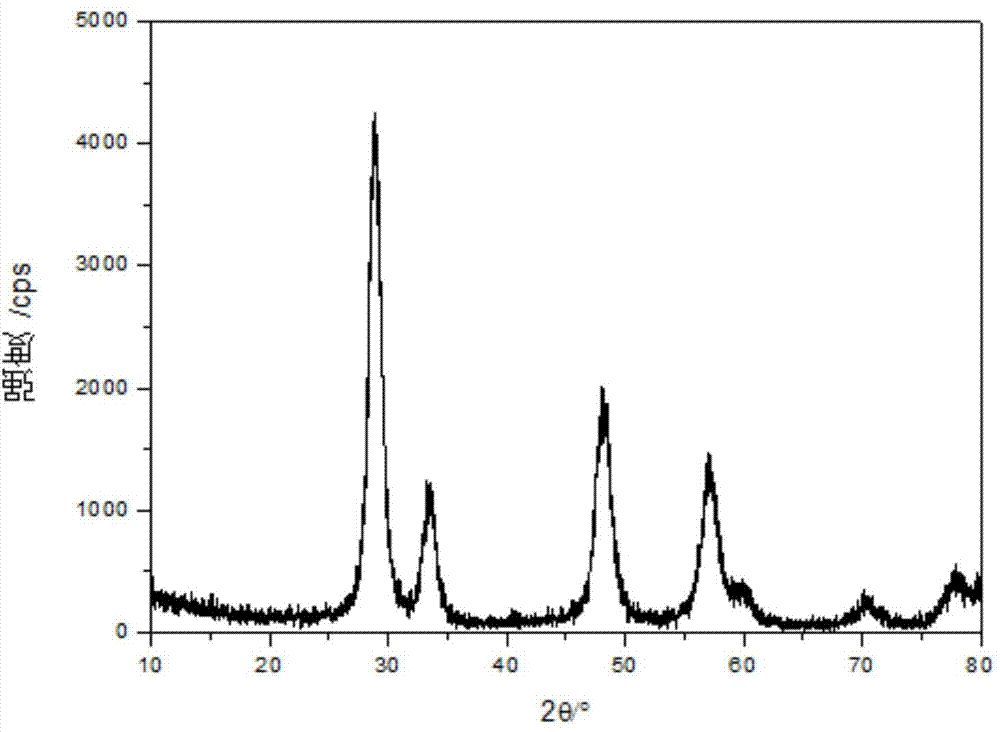

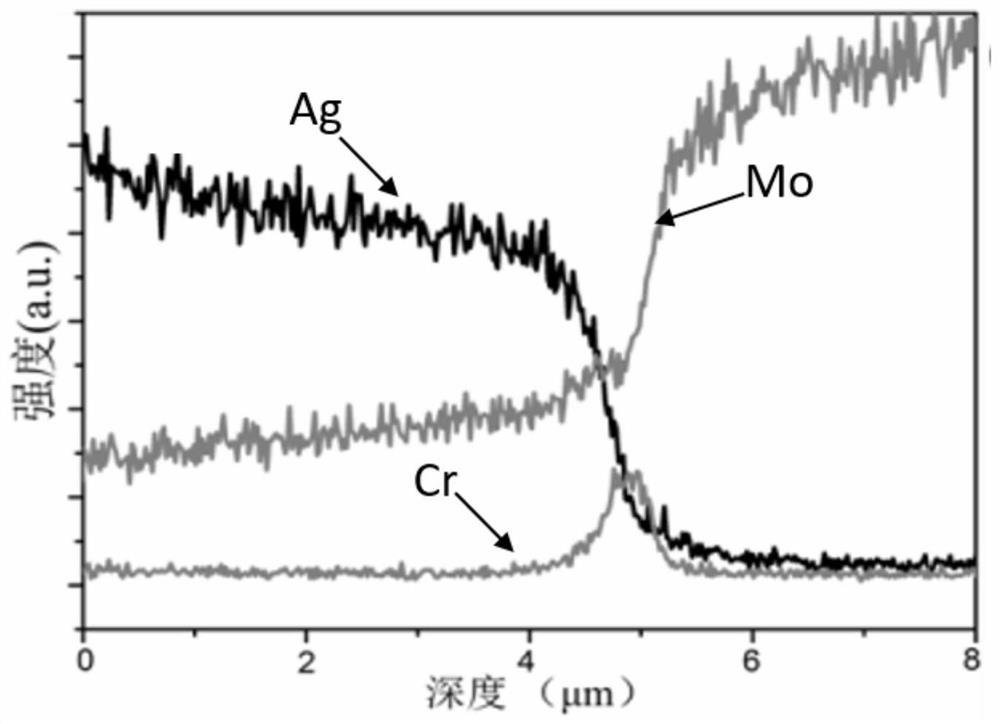

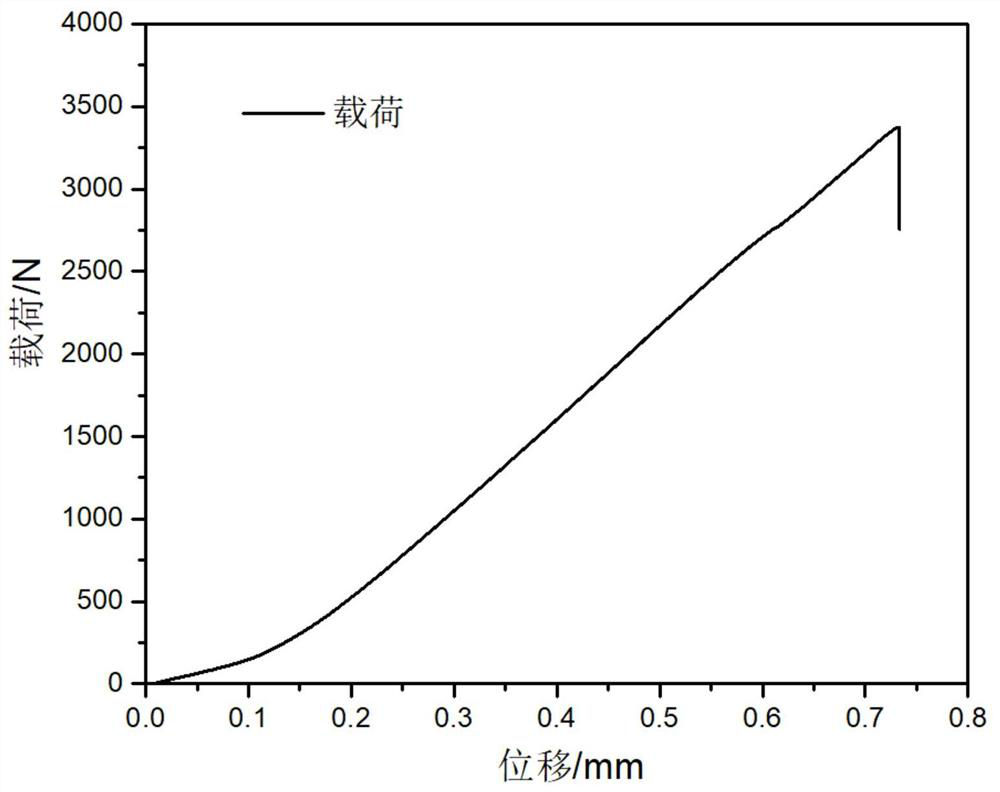

Molybdenum-silver laminar composite material and preparation method and application thereof

ActiveCN110872692AAlleviate thermal expansion coefficient differencesGood solid solution effectVacuum evaporation coatingSputtering coatingThermal fatigueOxidation resistant

The invention discloses a molybdenum-silver laminar composite material and a preparation method and application of the molybdenum-silver laminar composite material. The preparation method includes thesteps that at least a molybdenum base material and a metal target having good solid solubility with molybdenum are placed in a vacuum environment, and a metal intermediate layer is formed on the surface of the molybdenum base material through deposition with a direct-current magnetron sputtering method; at least the molybdenum base material with the metal intermediate layer formed on the surfaceand the metal silver target are placed in a vacuum environment, and a silver layer is formed on the surface of the metal intermediate layer through deposition with the direct-current magnetron sputtering method; and an obtained molybdenum base material-metal intermediate layer-silver layer composite structure is annealed, so that metal elements constituting the metal intermediate layer are continuously diffused into the molybdenum base material and the silver layer. By means of the preparation method, the silver / metal intermediate layer / molybdenum laminar composite material can be successfullyprepared, and the preparation method is environmentally friendly, high in process stability and capable of realizing large-scale production; and besides, the obtained molybdenum-silver laminar composite material is high in density, excellent in bonding strength and excellent in oxidative corrosion resistance and thermal fatigue resistance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

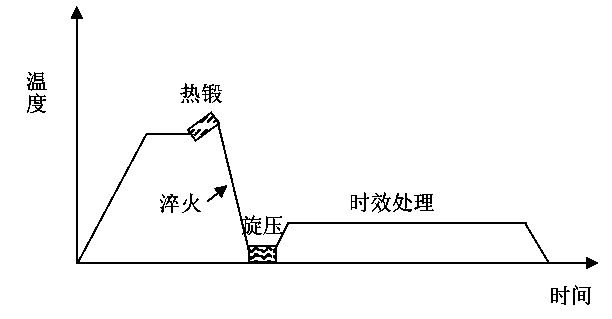

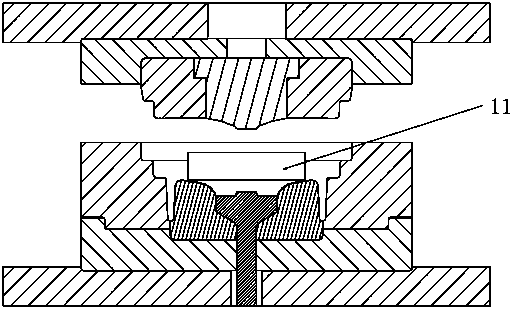

Manufacturing method of Al-Mg-Si alloy hub

The invention discloses a manufacturing method of an Al-Mg-Si alloy hub. The manufacturing method of the Al-Mg-Si alloy hub comprises the following steps of 1 manufacturing an Al-Mg-Si alloy hot rolled plate into a wafer-shaped blank; 2 pre-heating the wafer-shaped blank to 450 DEG C-500 DEG C; 3 performing hot forging on the wafer-shaped blank at the temperature of 450 DEG C-500 DEG C to form a disc-shaped blank; 4 performing quenching treatment on the disc-shaped blank subjected to the hot forging; 5 performing powerful spinning on the disc-shaped blank subjected to the quenching treatment through a spinning machine to form a hollow rotating body hub blank; 6 putting the hub blank formed through spinning into an aging furnace to be heated to 120 DEG C-220 DEG C and keeping the temperature for 2-8 hours; 7 performing machining and surface treatment. The manufacturing method can improve the aluminum hub strength, keep good plasticity, achieve energy consumption and achieve the purposes of reducing the energy consumption and improving the production efficiency.

Owner:ZHEJIANG GKO IND CO LTD

Diamond film based on nanoparticle modification and preparation method thereof

InactiveCN112647056AEasy to cleanImprove adhesionVacuum evaporation coatingSputtering coatingFilm baseMetallic materials

The invention discloses a diamond film based on nanoparticle modification and a preparation method thereof. According to the diamond film based on nanoparticle modification, a silicon-based material, a metal material or a composite material is taken as a substrate, and metal Ni is sputtered on the upper surface of the substrate to serve as a transition layer; the flow of hydrogen, argon and methane gas, the gas pressure, the substrate temperature and the deposition time are reasonably optimized on the surface of the transition layer through a chemical vapor deposition method, so that the adhesive force on the film substrate is enhanced; and finally, the surface of the prepared diamond film is subjected to chemical corrosion, and coated with nano titanium dioxide particles so that the hydrophobic property and the self-cleaning property of the surface of the diamond film can be improved. The prepared diamond film can be widely applied to the fields of machinery, tools and molds, cutters, automobiles, electronics, optics, and decorative appearance protection, such as watch shells, jewelry accessories and mobile phone shells.

Owner:SHANGHAI ZHENGSHI TECH CO LTD

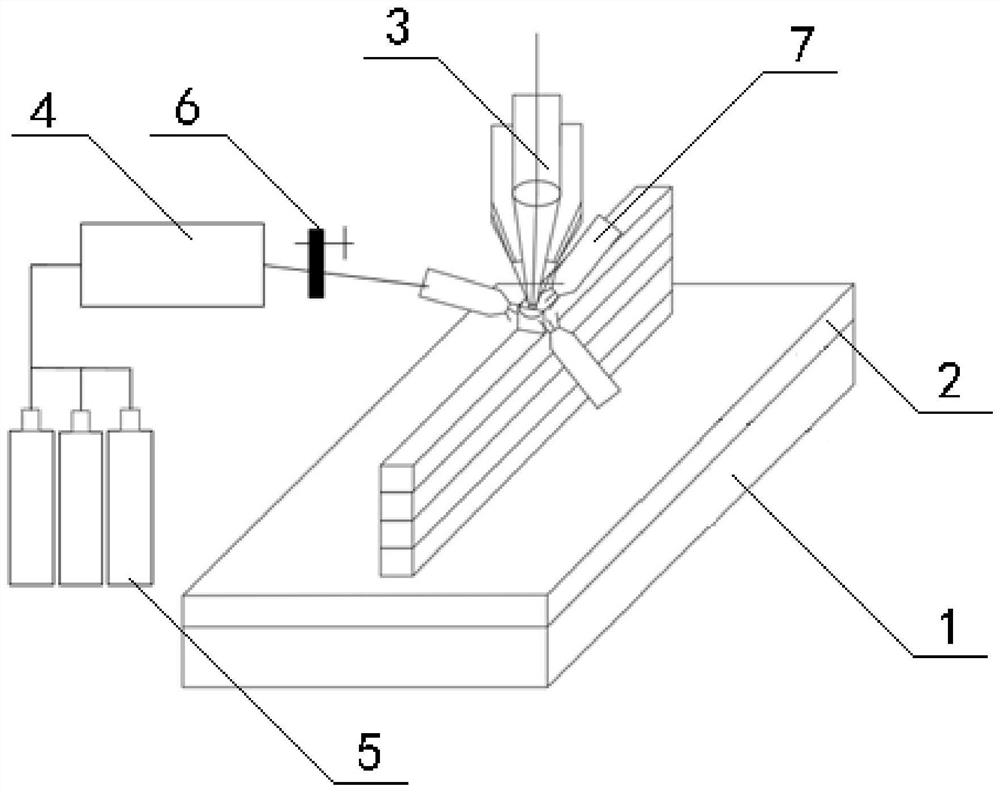

Method for inhibiting Laves phase precipitation in nickel-based alloy laser additive manufacturing process

PendingCN113579249AIncreasing front temperature gradientSpeed up the solidificationAdditive manufacturing apparatusIncreasing energy efficiencyErbium lasersRemanufacturing

The invention discloses a method for inhibiting Laves phase precipitation in a nickel-based alloy laser additive manufacturing process. The method specifically comprises the following steps that a base material is placed on a workbench with a cooling device, a synchronous inhibiting device is well installed, a semiconductor laser and a boiling type powder feeder are started to start cladding of metal powder, meanwhile, three chilling copper pipes of the synchronous inhibiting device are used for chilling the edge of a molten pool, after machining is completed, a sample is scanned, and the cross section structure condition of the sample is observed. According to the method, in the laser additive manufacturing or remanufacturing process of the nickel-based superalloy, a chilling source is added around the liquid molten pool, redistribution of a temperature field in the molten pool can be achieved, the front edge temperature gradient of a solid-liquid interface is increased, the solidification speed of the molten pool is increased, gathering of segregation elements such as Nb, Al and Ti among dendritic crystals is effectively reduced, and a guarantee is provided for precipitation of a strengthening phase in the subsequent aging treatment process.

Owner:ZHEJIANG UNIV OF TECH

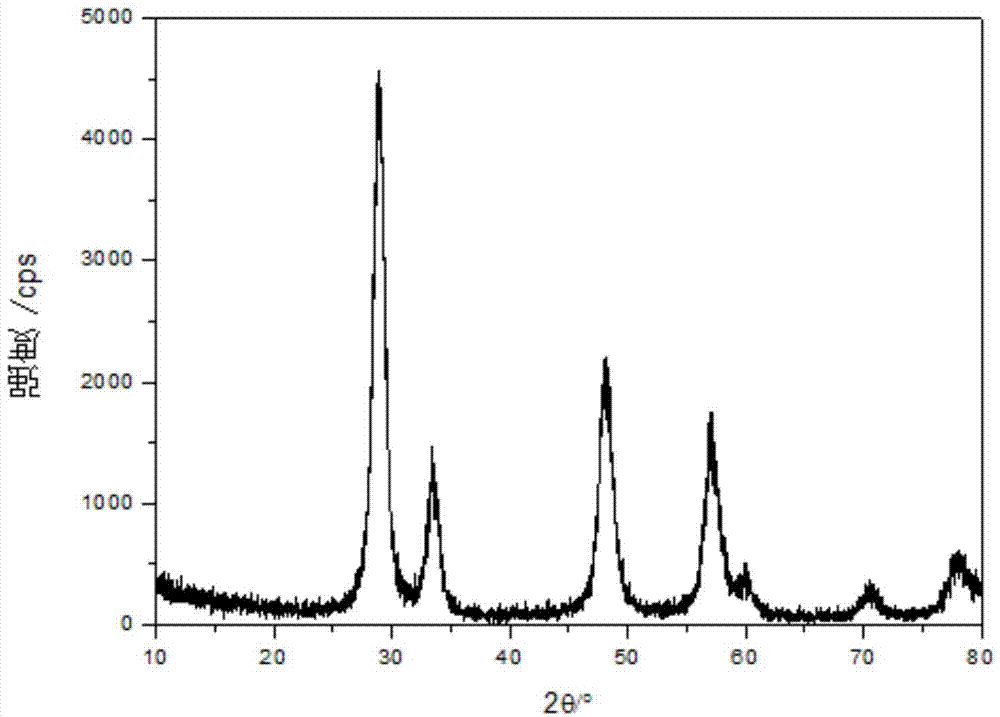

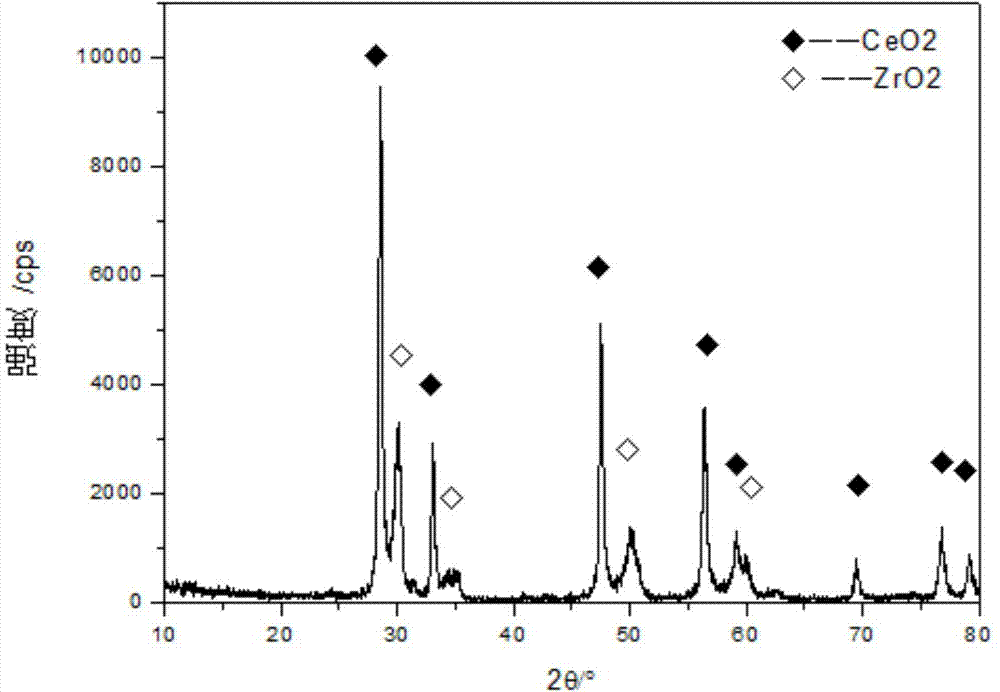

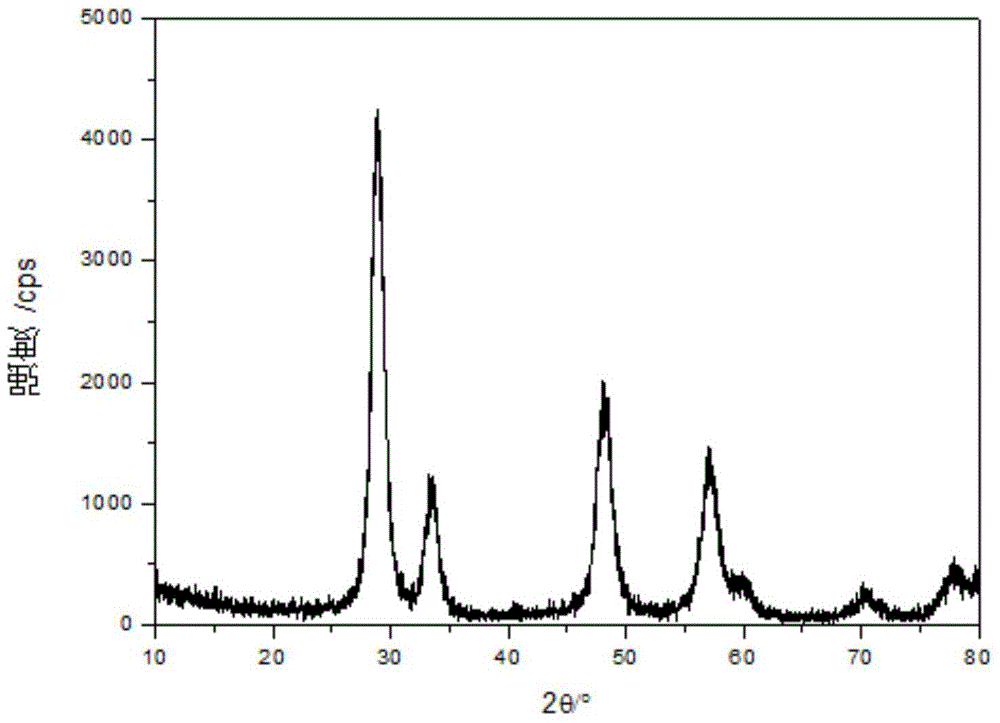

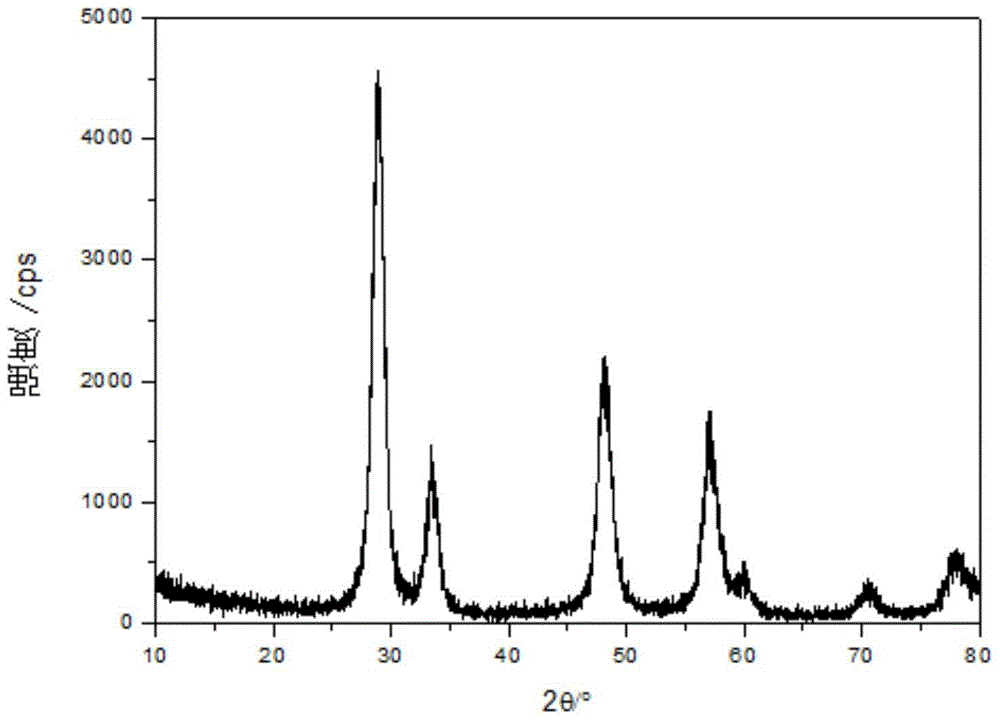

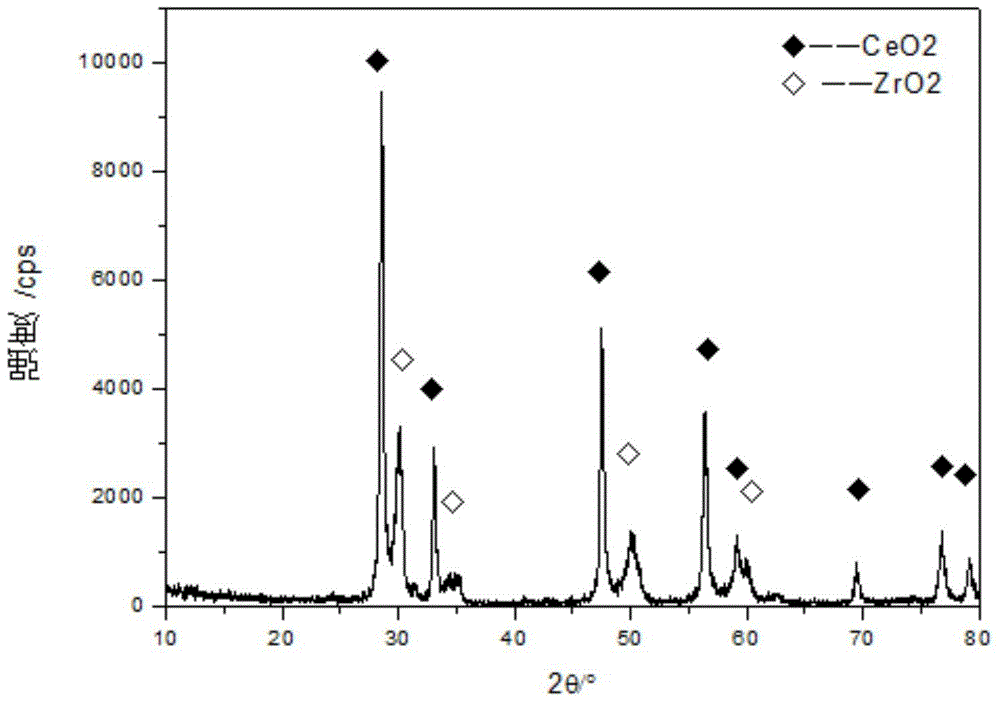

Preparation method of cerium-zirconium based solid solution

ActiveCN104492414AUniform particle sizeLarge particle sizeMetal/metal-oxides/metal-hydroxide catalystsCeriumBULK ACTIVE INGREDIENT

The invention discloses a preparation method of a cerium-zirconium based solid solution. The preparation method comprises the following sequential steps: (1) preparation of Ce<4+>; (2) preparation of active ingredient solution; (3) precipitation reaction; (4) surface modification; (5) roasting. The Ce<4+> is prepared firstly and then mixed with other rare earth ions and positively quadrivalent zirconium ions to obtain a mixed metal nitrate solution; as the mixed metal nitrate solution contains an organic complexing agent, the precipitation speed in the precipitation reaction process is controlled by virtue of complexing coordination of the organic complexing agent and the rare earth and zirconium ions, so that a precursor uniform and stable in particle size is obtained; the surface treatment is performed on the precipitate precursor by use of polyacrylic acid, and therefore, the agglomeration problem of particles in the roasting process is solved, and the pore diameter and the pore volume of the roasted product are increased, and consequently, the cerium-zirconium based solid solution catalytic material excellent in heat stability is obtained. The preparation method is suitable for the preparation of the solid solutions.

Owner:方复(上海)新材料科技有限公司

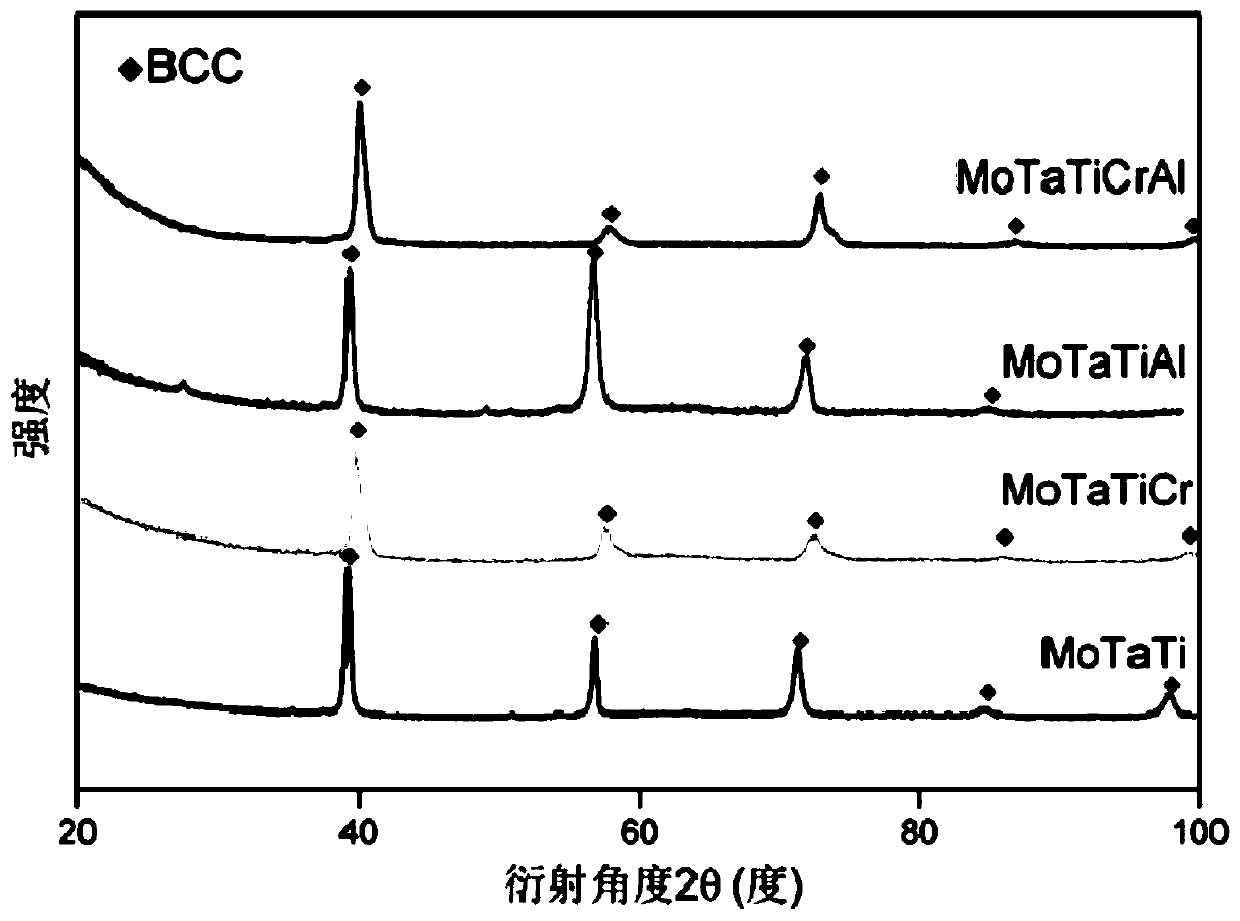

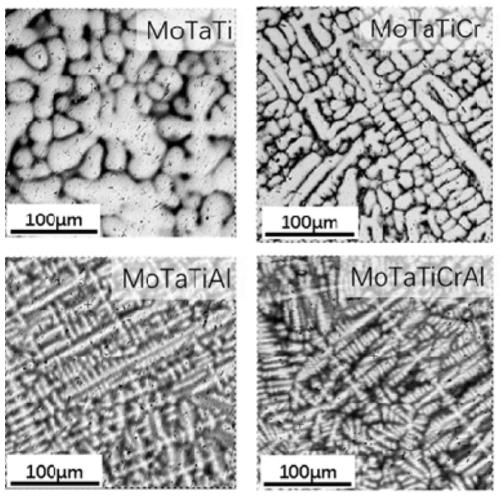

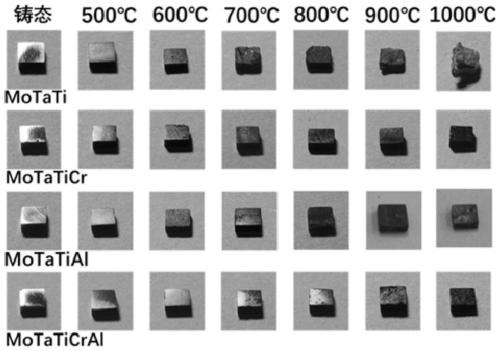

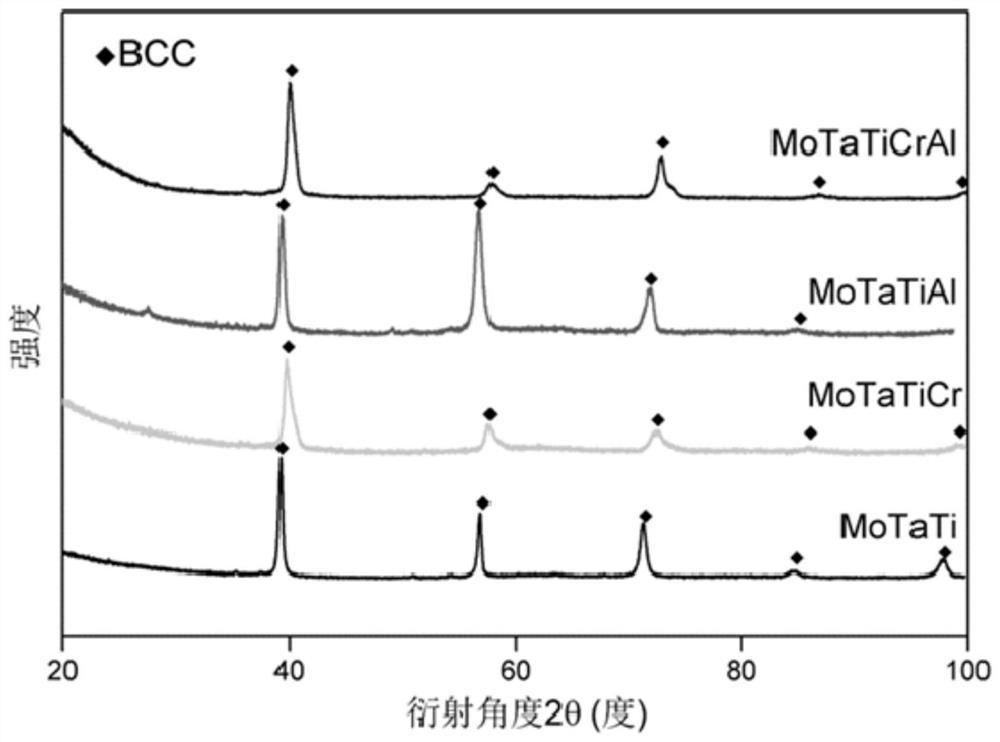

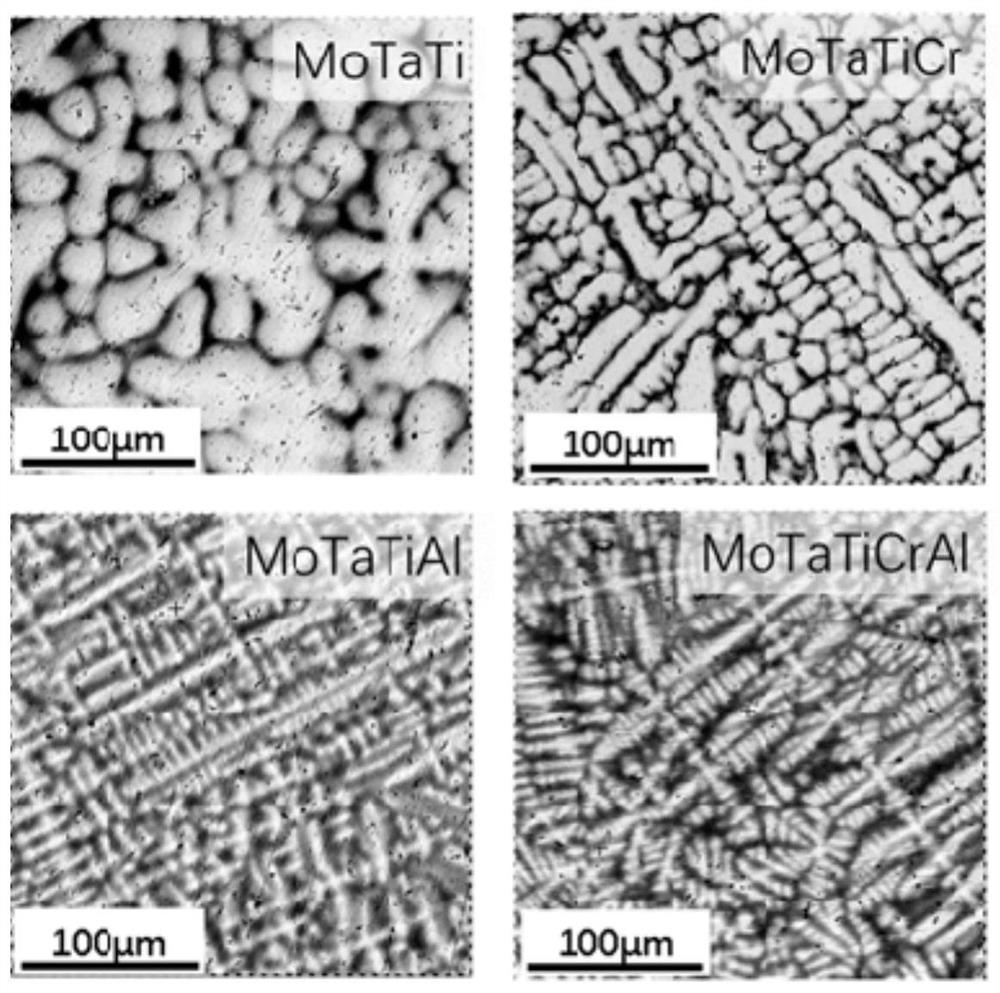

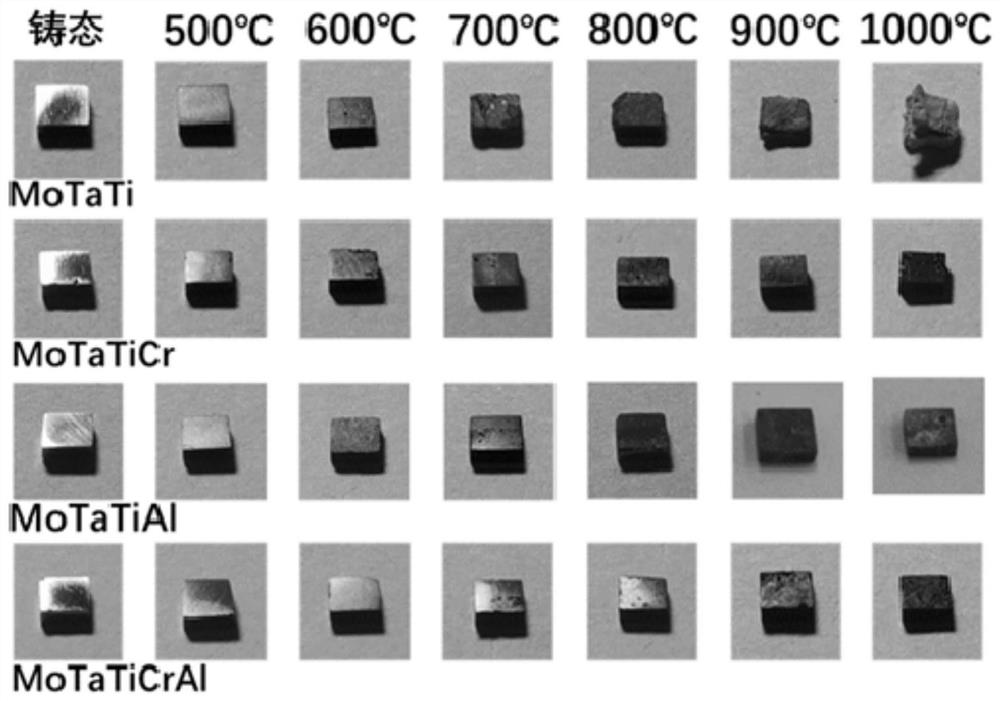

Medium-high-entropy alloy material and preparation method and application thereof

ActiveCN111304512ASolve the problem that it is difficult to smelt the bulk raw materials evenlyEasy to prepareHigh entropy alloysHeat stability

The invention provides a medium-high-entropy alloy material. The medium-high-entropy alloy material is a solid solution alloy of a single-phase body-centered cubic structure, and the medium-high-entropy alloy material at least comprises Mo, Ta and Ti elements. The invention further provides a preparation method and an application of the medium-high-entropy alloy material. The refractory medium-high-entropy alloy has good thermal stability, good high-temperature oxidation resistance, relatively high hardness and wear resistance and good solid solution capability. According to the medium-high-entropy alloy material, the innovative preparation method of powder briquetting and arc melting is adopted, the difficult problem that the melting point difference between the alloy components is too large, the normal arc melting is difficult to melt the bulk raw materials uniformly is solved, and a simple and feasible preparation method for the alloy material with large melting point difference isprovided.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

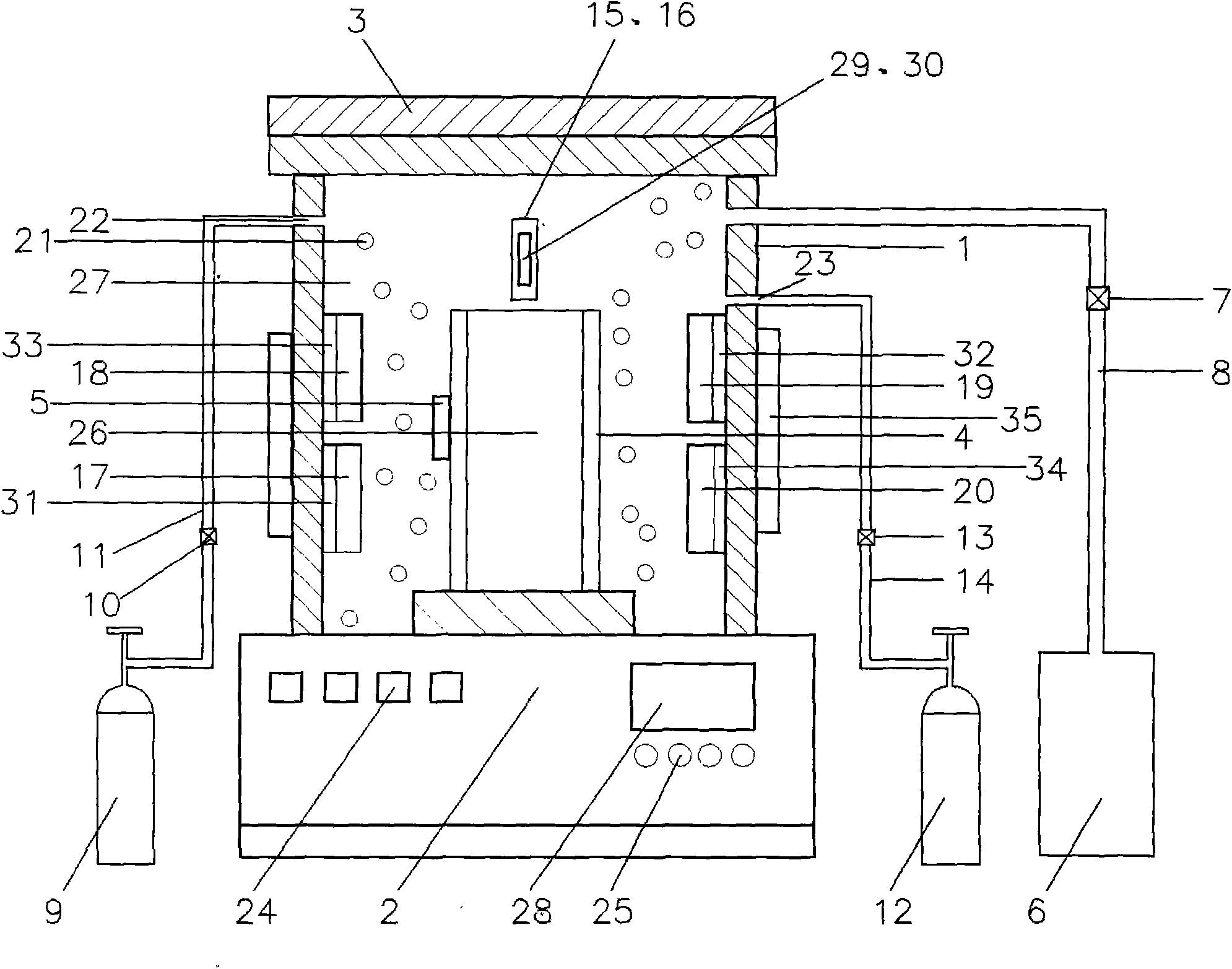

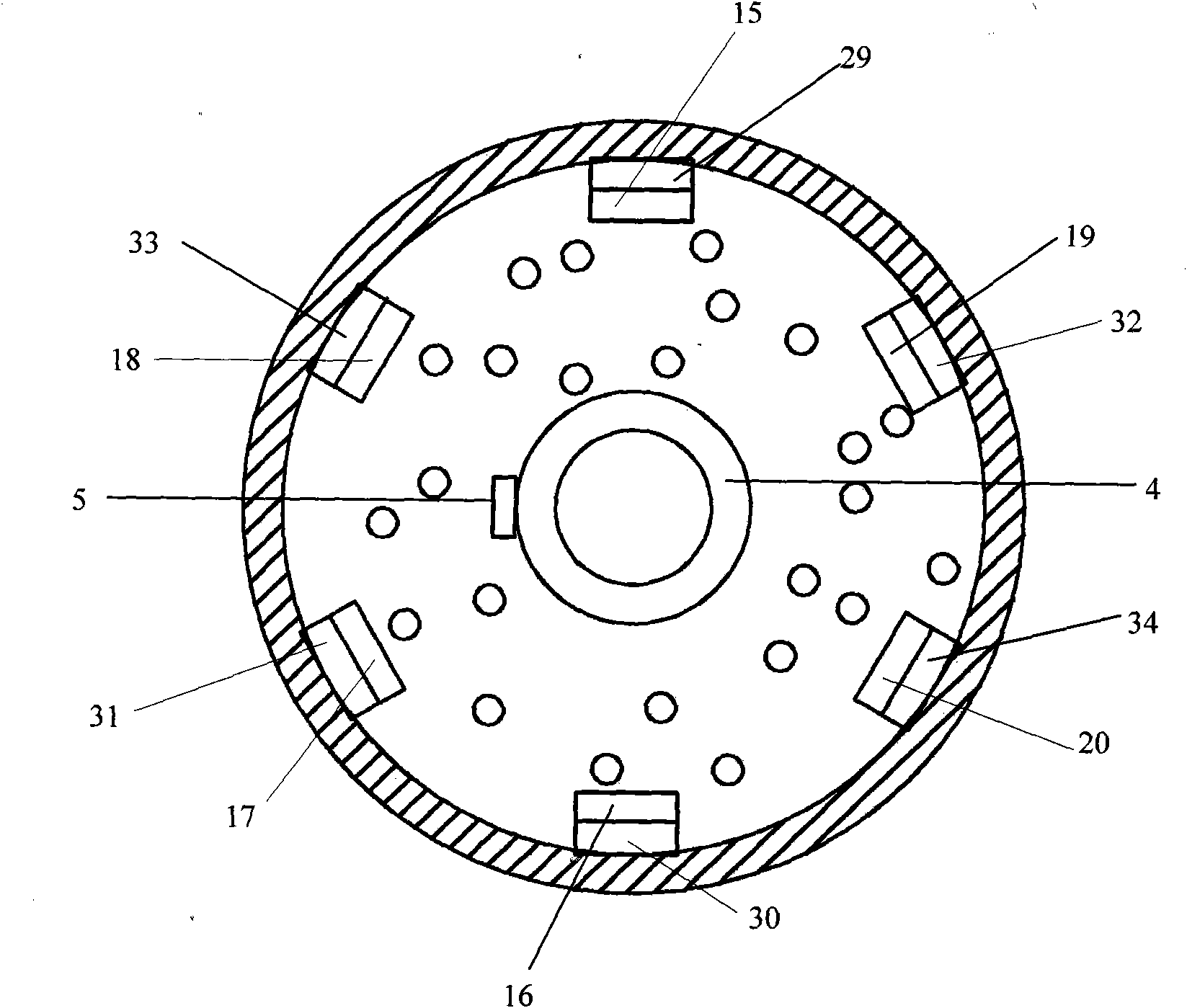

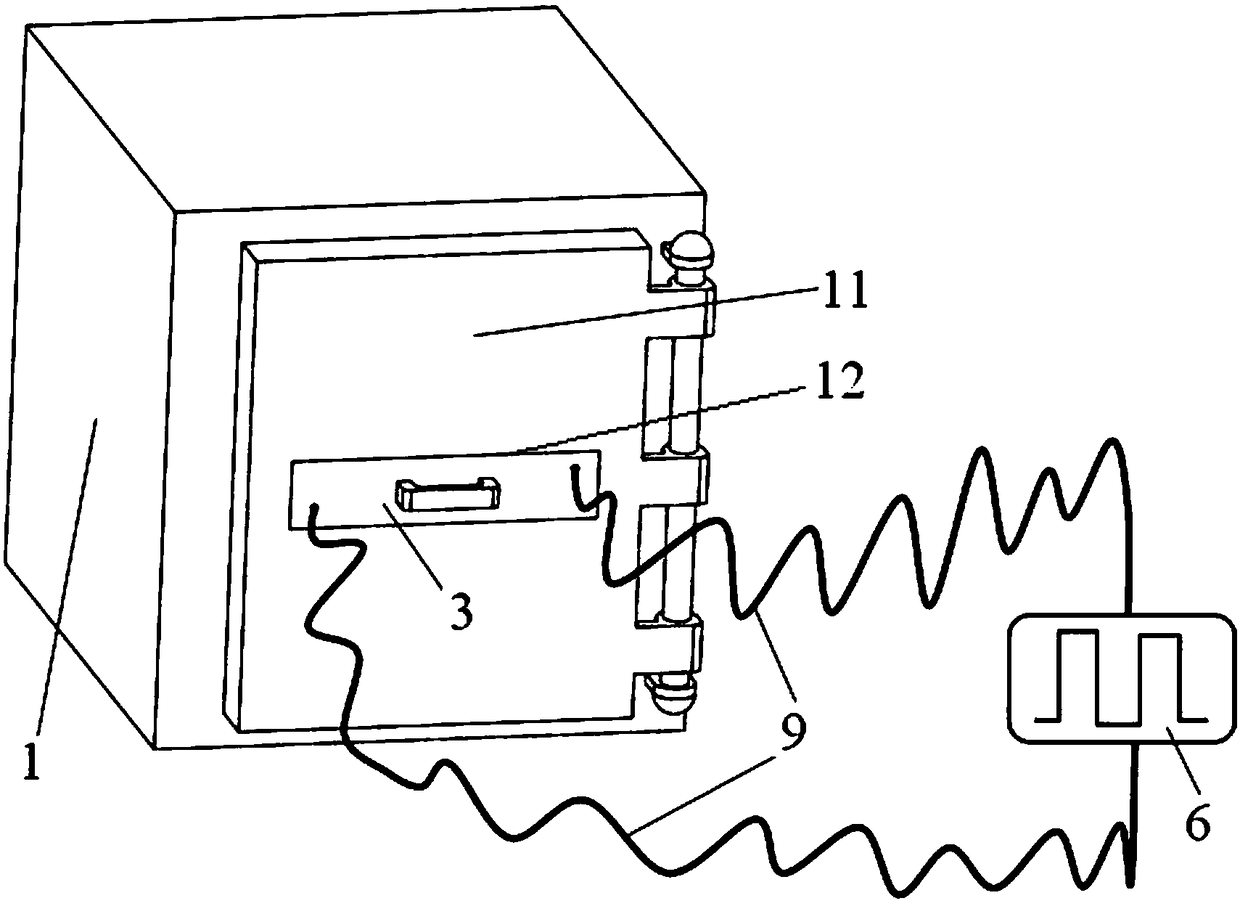

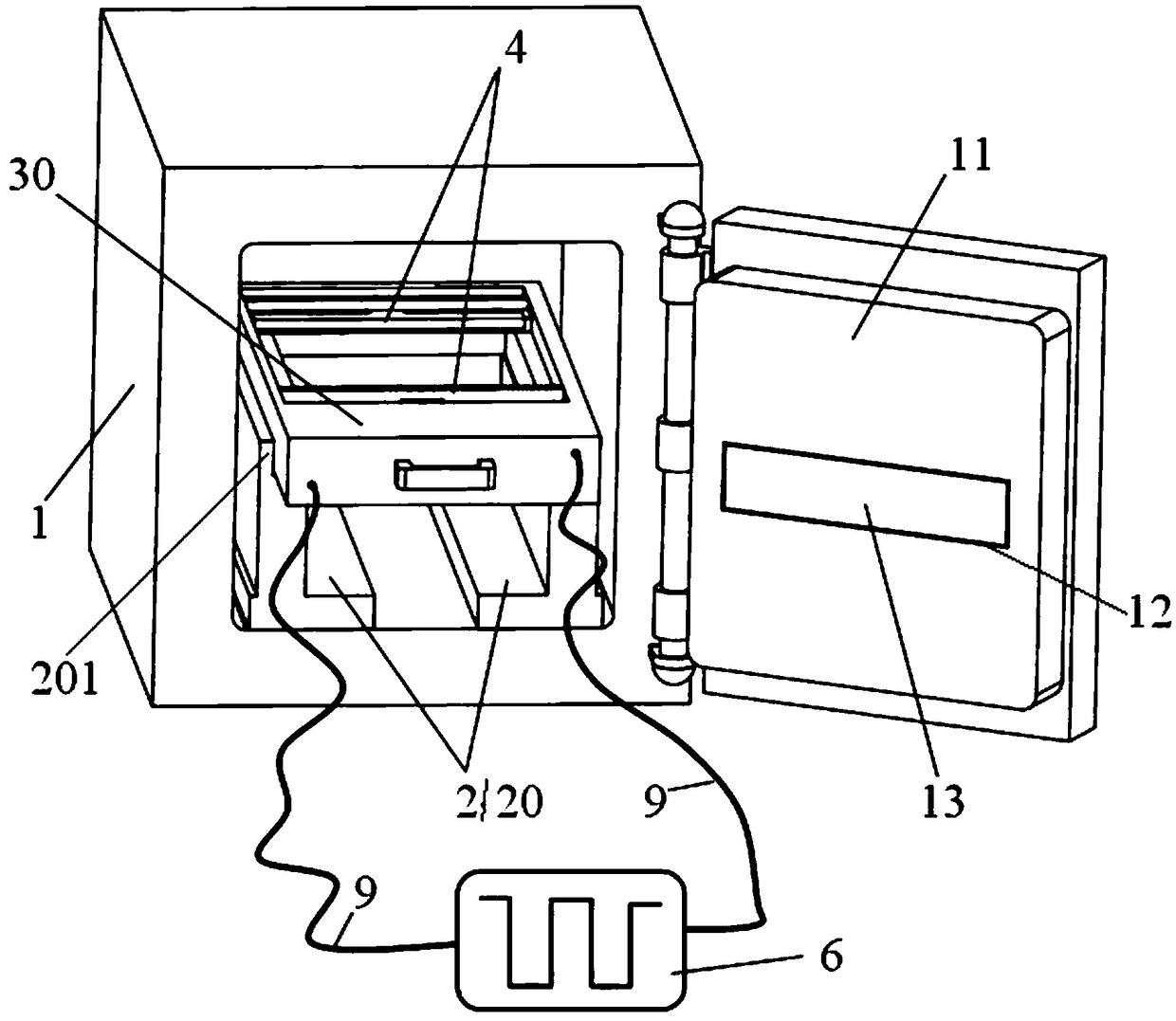

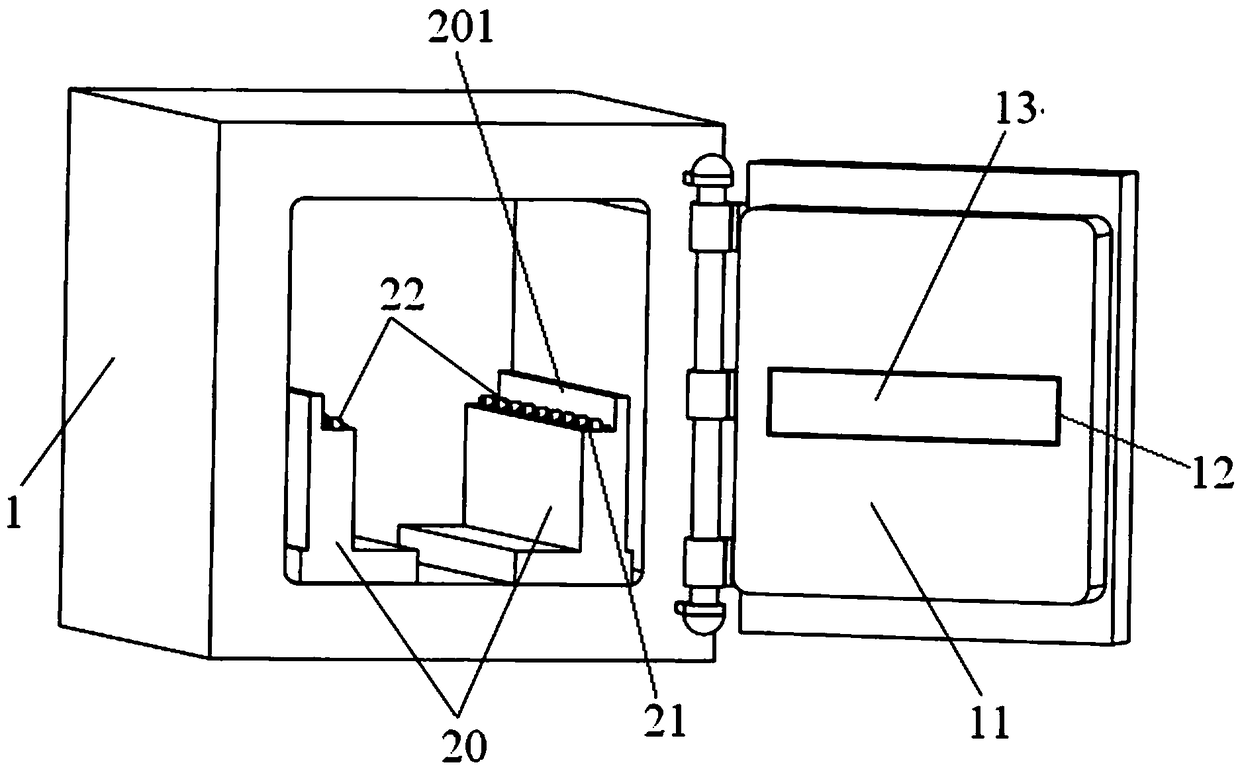

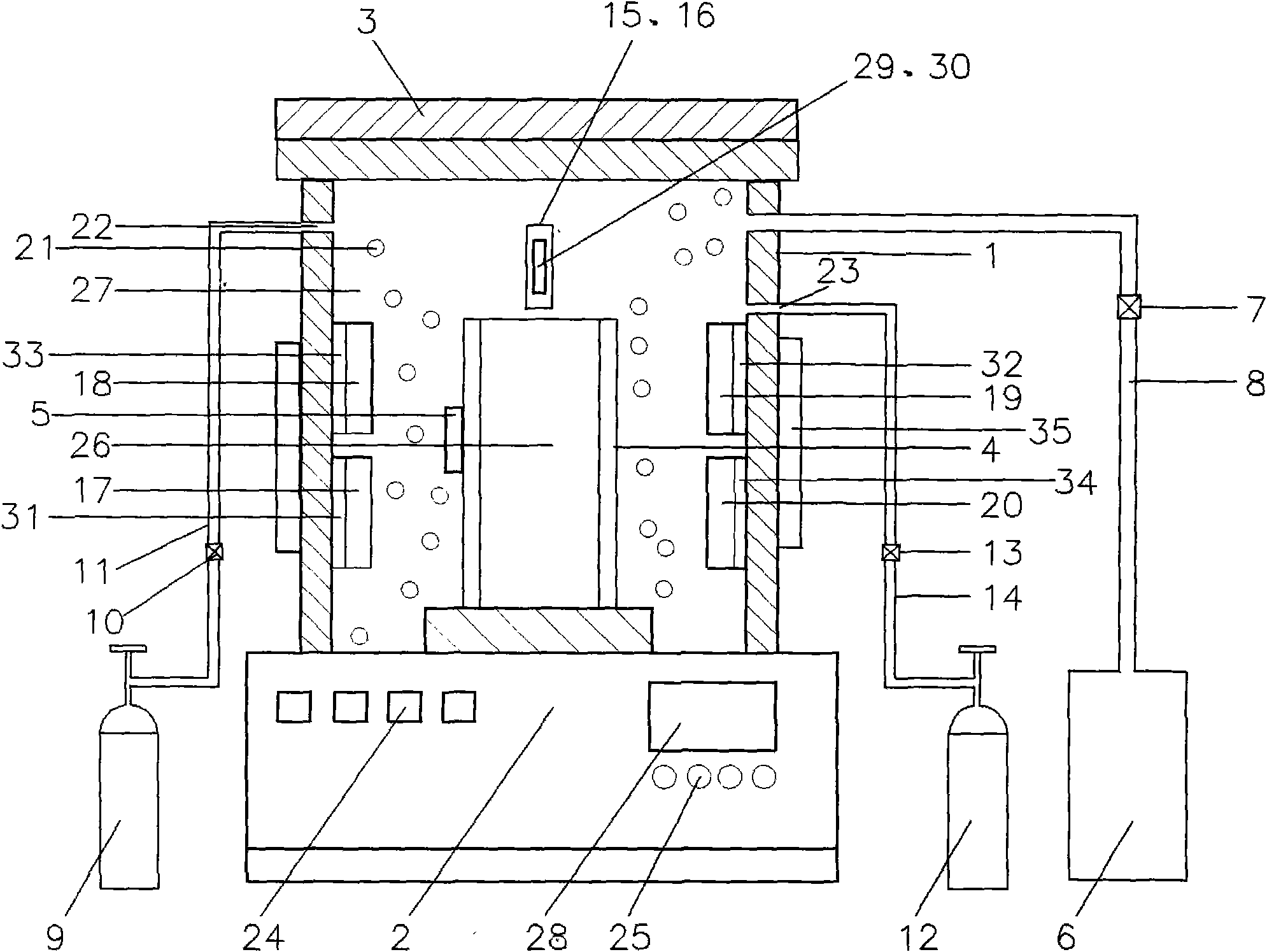

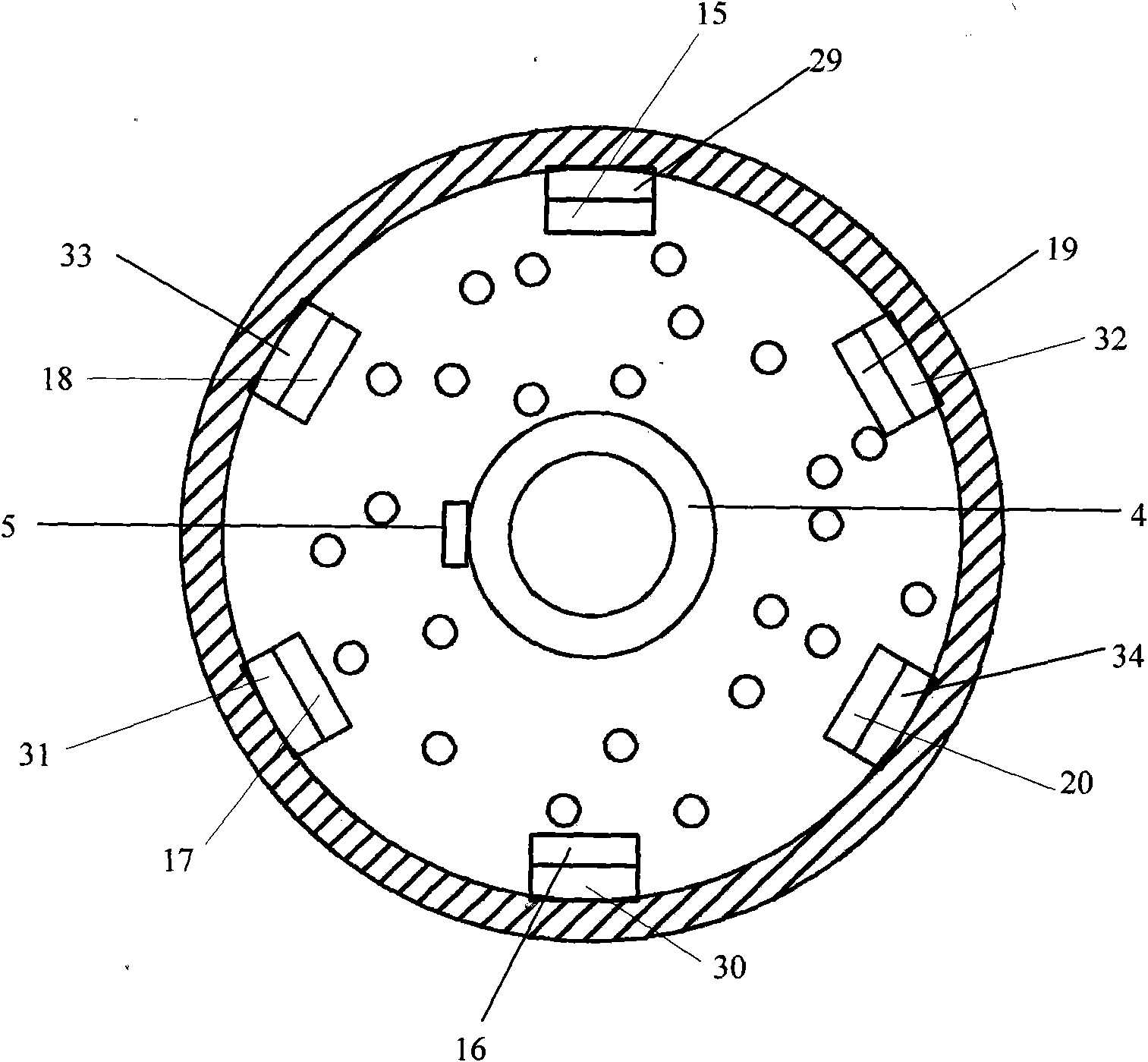

Device for assisting solid solution heat treatment of metal component through pulse current

ActiveCN108103296AEvenly heatedImprove solubilityFurnace typesProcess efficiency improvementLap jointEngineering

The invention provides a device for assisting solid solution heat treatment of a metal component through pulse current. The device comprises a support and a bearing frame. The support is arranged in ahearth of a high-temperature solid solution furnace. The bearing frame comprises a frame and insulation rods. The center area of the frame is set to be of a hollow structure, and protruding edges with the top faces lower than the top faces of frame strips are arranged on the inner side walls of a pair of parallel frame edges of the frame. Conductive blocks are fixed to the top faces of the insulation rods. The two conductive blocks are connected with two poles of a pulse power source correspondingly. The two ends of the metal component are in lap joint to the conductive blocks corresponding to the two insulation rods, and the positions of the two insulation rods can be moved on the protruding edges. A pulse current loop is formed by the pulse power source, a wire, the conductive blocks and the metal component for studying the influences of the pulse current on a material microstructure in the metal component solid solution heat treatment process and whether dissolving of indissolvablesolute atoms can be promoted or not; and the device is simple, convenient and reliable to use, cost is low, and the test reliability and accuracy are improved.

Owner:CENT SOUTH UNIV

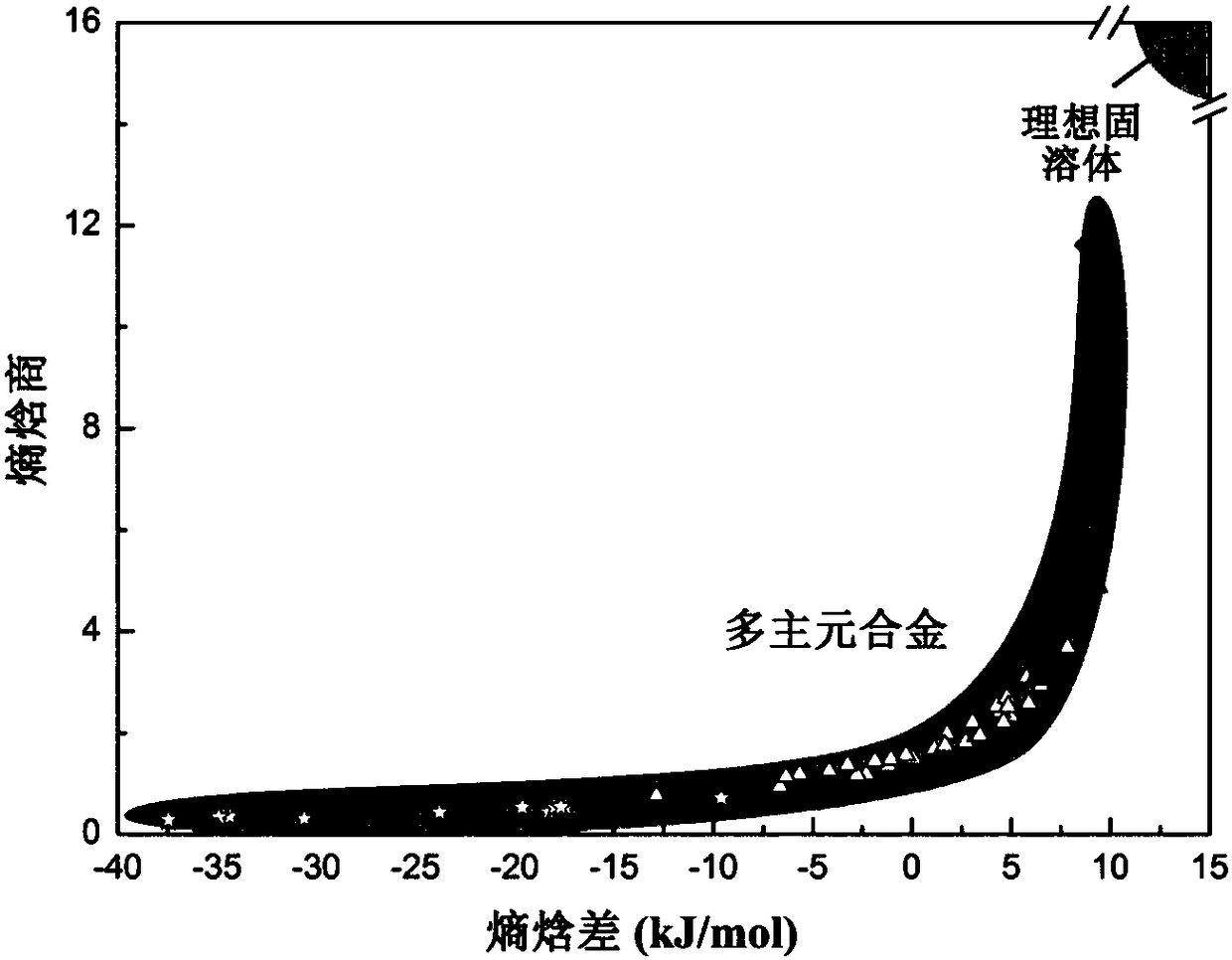

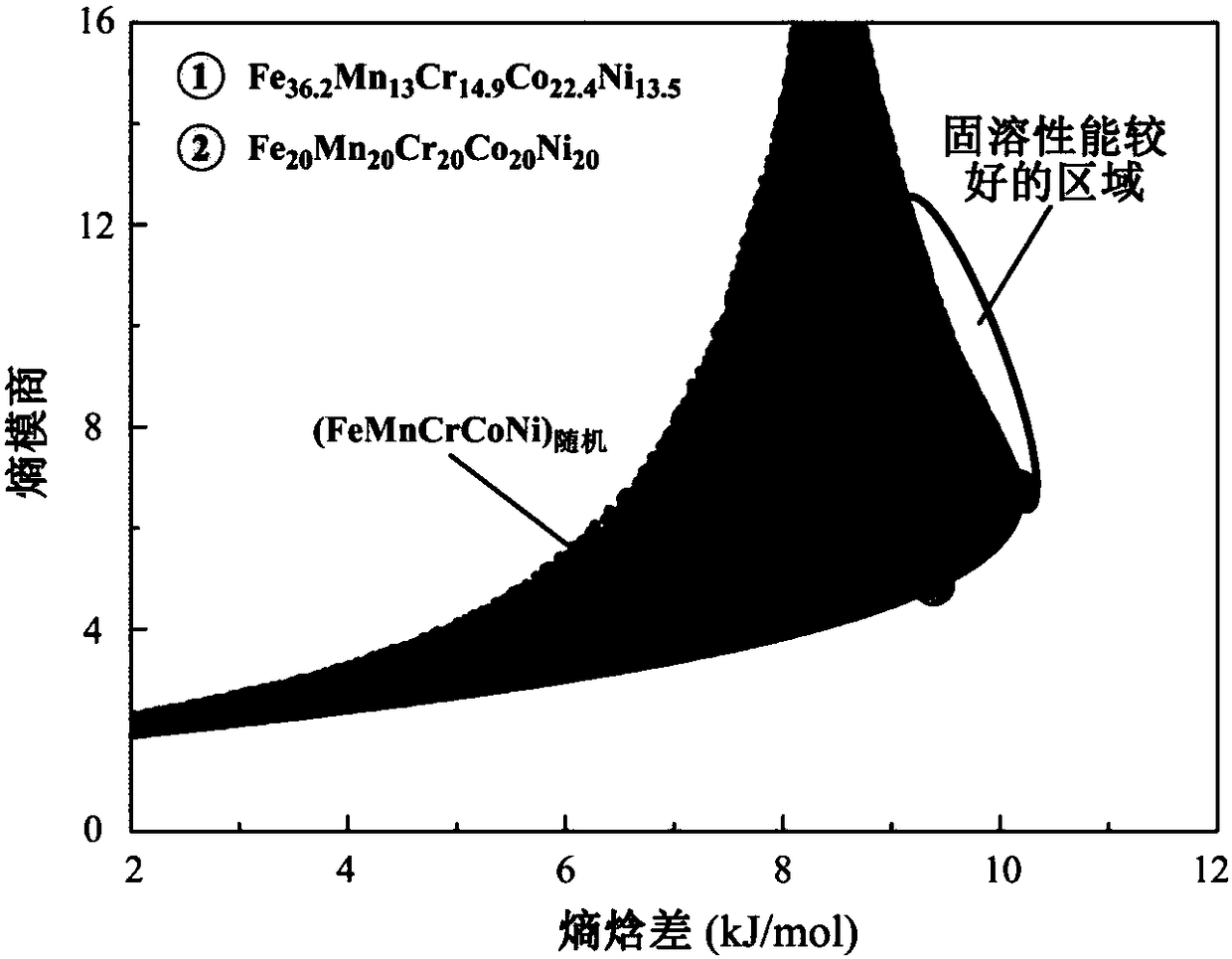

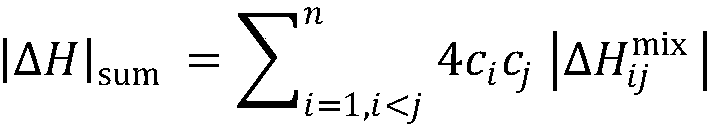

High-solid-solubility multi-principal-component alloy screening method

ActiveCN108182340AReduce R&D costs and cyclesGood solid solution effectCheminformatics data warehousingCheminformatics programming languagesDesign technologySolid solubility

The invention belongs to the technical field of alloy material design, and particularly relates to a high-solid-solubility multi-principal-component alloy screening method. According to the high-solid-solubility multi-principal-component alloy screening method, components of multi-principal-component alloy are designed from the atomic level according to requirements of the multi-principal-component alloy. The high-solid-solubility multi-principal-component alloy screening method is a double-parameter screening method based on the two thermodynamic parameters, namely entropy enthalpy quotient and entropy enthalpy difference. According to the rapid screening method, Monte Carlo random sampling is used for generating millions of kinds of alloy in any component proportion, and the thermodynamic parameters, namely entropy enthalpy quotient and entropy enthalpy difference, are used for evaluating the solid solution formation capacity of the alloy, so that the multi-principal-component alloyexcellent in solid solubility is screened out from millions of kinds of alloy.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

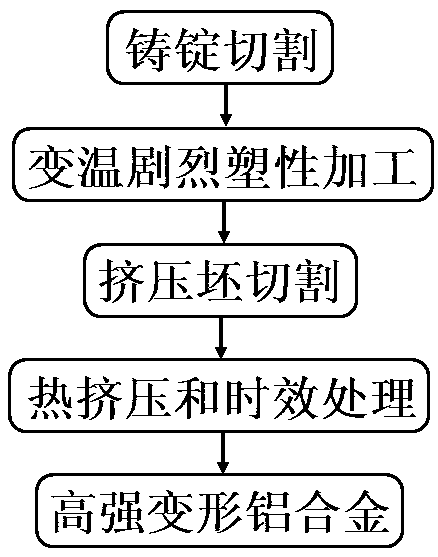

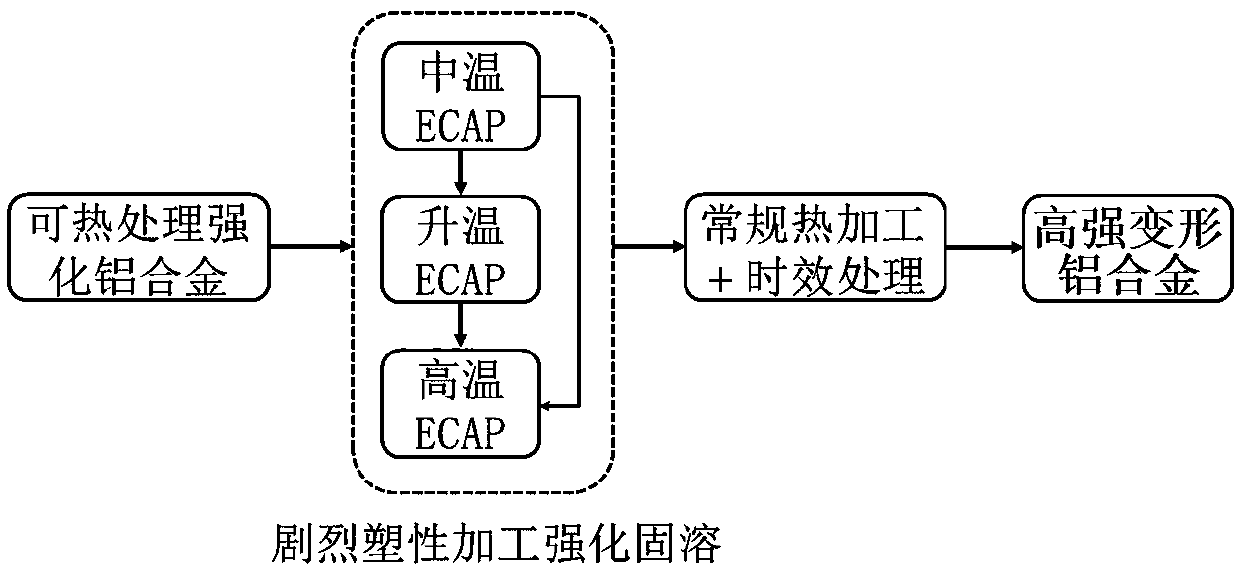

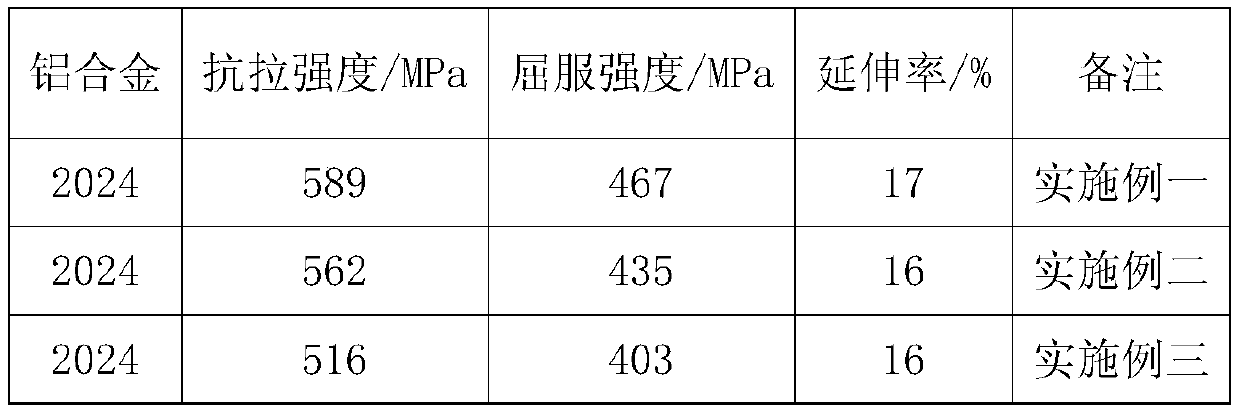

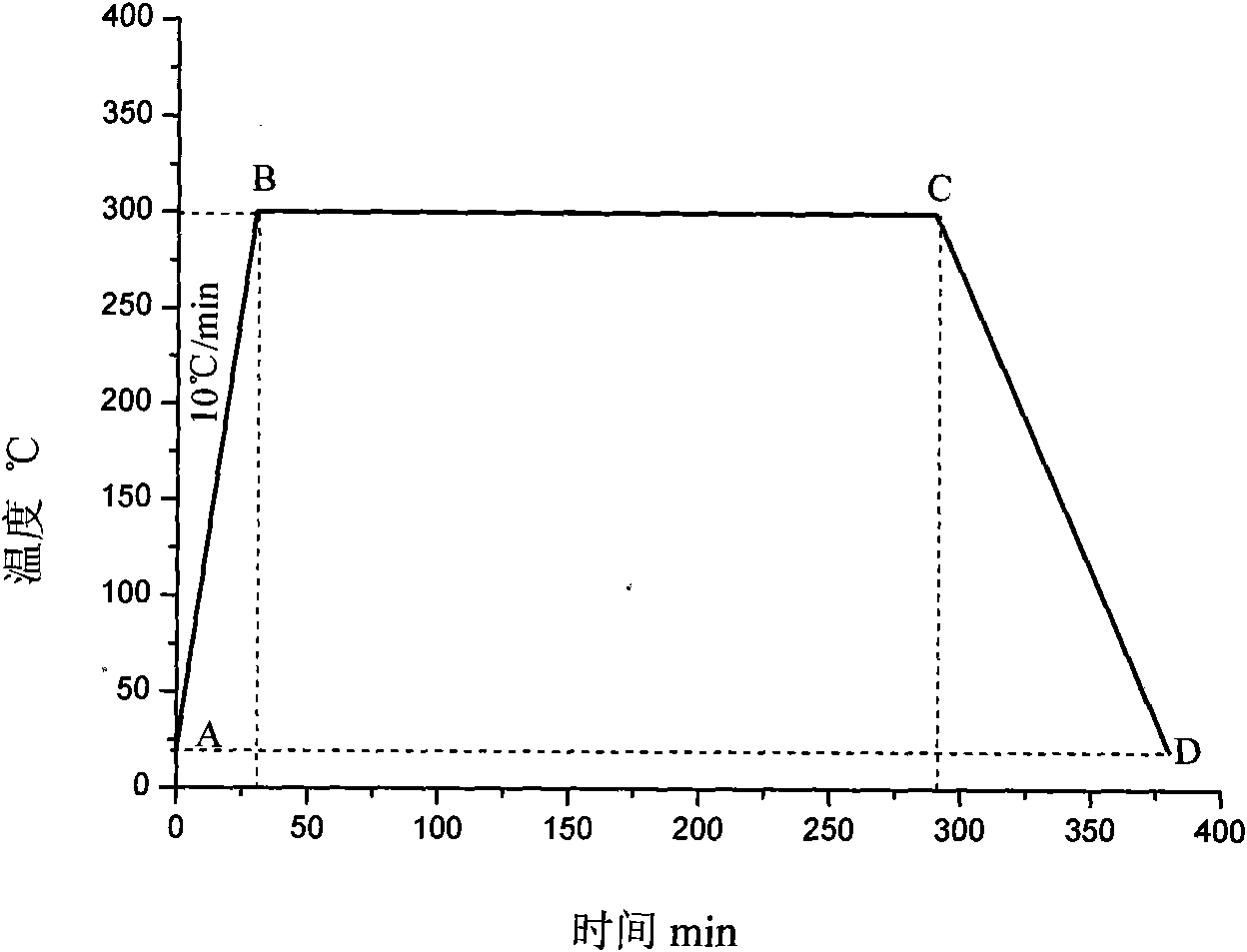

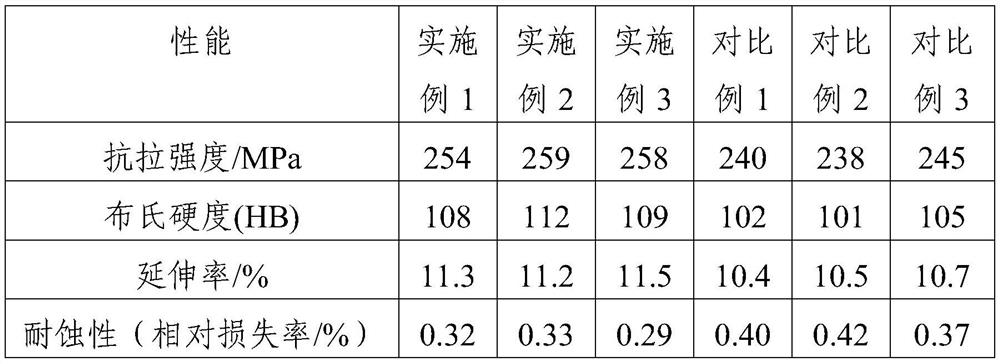

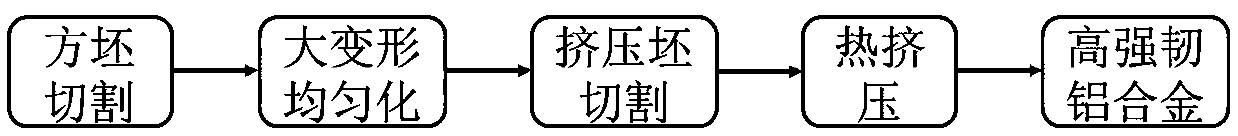

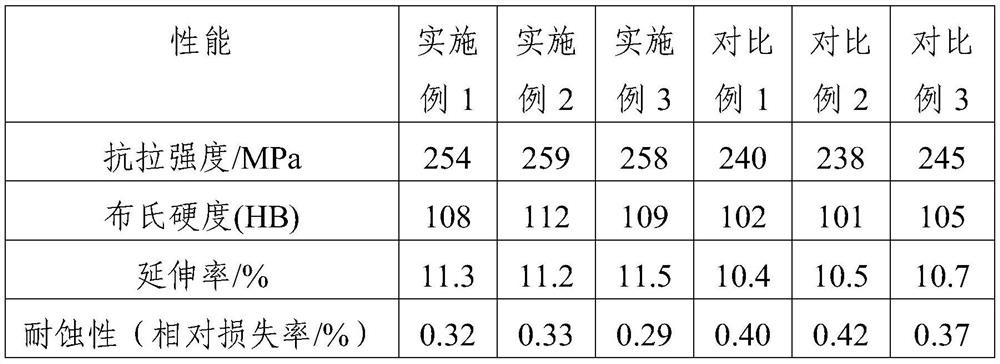

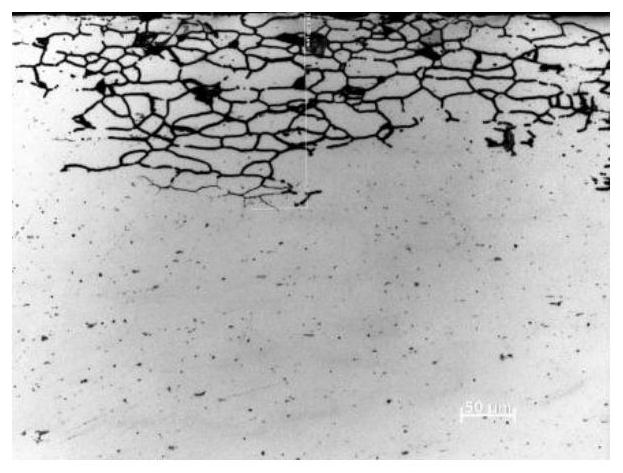

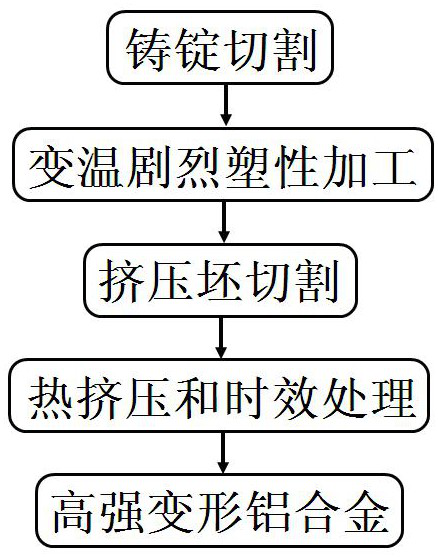

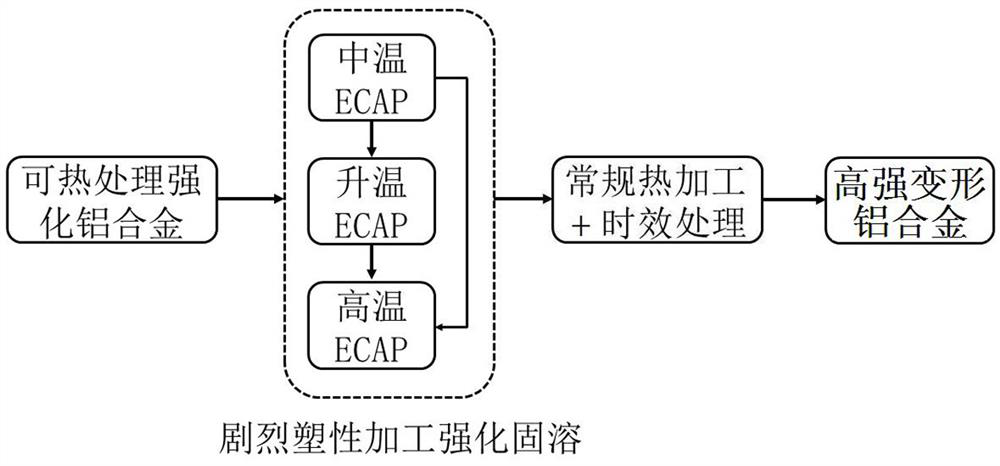

Method for preparing high-strength wrought aluminum alloy based on severe plastic deformation

The invention discloses a method for preparing a high-strength wrought aluminum alloy based on severe plastic deformation. The method comprises the following steps that A, a blank is cut out from an aluminum alloy cast ingot; B, the blank is put into a rotary die equal channel angular pressing die, equal channel angular pressing processing is continuously carried out by adopting multi-temperaturestages of step-by-step temperature rise, strengthened solid solution treatment is realized by using a severe plastic deformation technology, and after completion, water quenching treatment is carriedout so as to obtain a supersaturated solid solution block extrusion billet; and C, an alloy bar with the length direction parallel to the equal-channel angular pressing direction is cut out, and conventional hot extrusion processing and aging treatment are carried out on the alloy bar so as to obtain the high-strength wrought aluminum alloy. According to the method, strengthened solid solution treatment is realized through staged severe plastic deformation of step-by-step temperature rise, a second phase is effectively promoted to dissolve, a single-phase solid solution alloy with fine grain size, high density defects and high supersaturation degree is obtained, then uniform precipitation of a nano precipitation phase is promoted through hot working and aging treatment, and the high-strength wrought aluminum alloy is obtained.

Owner:江苏江南创佳型材有限公司

Anti-abrasion non-magnetic stainless steel wire special for washing screen and preparation method thereof

The invention provides an anti-abrasion non-magnetic stainless steel wire special for a washing screen and a preparation method thereof. The anti-abrasion non-magnetic stainless steel wire comprises the components of, by mass, 0.06-0.15% of C, 0.5-1.0% of Si, 6.0-17.0% of Mn, 0.040% of P, 0.03% of S, 17-23.5% of Cr, 1.3-13% of Ni, 0.15-2.5% of Mo, 0.3-1.5% of Cu, 0.15-0.6% of Ti, 0.15-0.75% of N and the balance Fe. According to the anti-abrasion non-magnetic stainless steel wire, through reasonable proportion and a machining technology, a product is good in abrasion resistance, low in magneticconductivity, excellent in weldability, good in machining ductility, high in cost performance and long in service life and meets all requirements, and the anti-abrasion non-magnetic stainless steel wire is a novel special super anti-abrasion stainless steel wire urgently needed by the washing industry.

Owner:江苏大屯矿业设备有限公司 +1

Preparation method of chromium-aluminum-nitrogen film by closed field unbalanced magnetron sputtering

InactiveCN101575696BImprove mechanical propertiesHigh hardnessVacuum evaporation coatingSputtering coatingAluminum IonShielding gas

The invention relates to a preparation method of a chromium-aluminum-nitrogen film by closed field unbalanced magnetron sputtering, which comprises the following steps: a chromium-tungsten-manganese steel plate is taken as a basal body, chromium and aluminum as a target source of metal ion, nitrogen gas as reactant gas, and argon gas as ion bombardment gas and protection gas; in a vacuum sputtering furnace, in a closed magnetic field state, in the argon gas and at the temperature of 300 DEG C, the surface of the chromium-tungsten-manganese steel plate is sputtered with chromium ion, aluminum ion and nitrogen ion and the chromium-aluminum-nitrogen hard film is formed on the surface of the steel plate, and then the low temperature tempering and alloying solid solution are conducted, thus greatly improving mechanical property, hardness, intensity, abrasive resistance and erosion resistance of the surface of the chromium-tungsten-manganese steel plate. The mechanical property of the chromium-tungsten-manganese steel plate can be improved by 466% compared with that of hardened steel plates. The preparation method has short process flow, precise technique, accurate and detailed measurement values, the film with thickness of 4,600nm, and the alloy layer with good solid solution effect and being not easy to peel off, thus being the ideal treatment method for strengthening and hardeningthe surface of alloy tool steel.

Owner:TAIYUAN UNIV OF TECH

Heat treatment process for machining aluminum alloy extruded profile

The invention provides a heat treatment process for machining an aluminum alloy extruded profile. The heat treatment process comprises the following steps of (1), performing homogenization heat treatment to a 6063 aluminum alloy ingot; performing heat treatment to and extruding the aluminum alloy ingot, an extrusion die and an extrusion container of an extruder; (2), performing quenching treatmentand tempering treatment to the obtained 6063 aluminum alloy extruded profile; (3), performing five-stage aging heat treatment to the aluminum alloy extruded profile, wherein the first-stage aging heat treatment is performed at 425 DEG C-450 DEG C for 2-3 h, and water cooling is adopted; the second-stage aging heat treatment is performed at 320 DEG C-340 DEG C for 4-6 h, and air cooling is adopted; the third-stage aging heat treatment is performed at 245 DEG C-265 DEG C for 5-8 h, and air cooling is adopted; the fourth-stage aging heat treatment is performed at 180 DEG C-215 DEG C for 5-8 hours, and furnace cooling is adopted; and the fifth-stage aging heat treatment is performed at 125 DEG C-135 DEG C for 5-8 hours, and furnace cooling is adopted; The 6063 aluminum alloy extruded profilemachined with the heat treatment process is high in strength, hardness and corrosion resistance.

Owner:苏州意友金属材料有限公司

Preparation method of aging-free high-strength and high-ductility aluminum alloy based on large deformation homogenization

The invention discloses a preparation method of an aging-free high-strength and high-ductility aluminum alloy based on large deformation homogenization. The production method comprises the following steps of A, cutting 7XXX-series aluminum alloy cast ingots to obtain blanks; B, conducting continuous equal-channel angular pressing machining on the blanks at the solution temperature to realize largedeformation homogenization and obtaining supersaturated solid solution block extrusion blanks; C, cutting the block extrusion blanks into alloy bars of which the length direction is parallel to the equal-channel angular pressing direction; and D, conducting hot extrusion processing on the alloy bars to obtain the aging-free high-strength and high-ductility aluminum alloy based on large deformation homogenization. Through the preparation method, the large deformation homogenization effect is achieved through continuous equal-channel angular pressing at the solid solution temperature, the defect density of the homogenized alloy is increased, grains are refined through follow-up hot extrusion, dynamic precipitation of nano precipitated phases is promoted, the aluminum alloy structure with the refined grains and uniform and high-density nano precipitated phases is obtained, and the strength and ductility of the alloy are remarkably improved.

Owner:江苏江南创佳型材有限公司

A kind of method of ito waste target recovery powder preparation ito target material

ActiveCN107129277BHigh sintering activityHigh densityVacuum evaporation coatingSputtering coatingIndiumMaterials science

The invention discloses a method for recycling powder from ITO (indium tin oxide) waste targets for preparing ITO target materials. The method includes adding tin oxide and / or indium oxide powder into gasified recycled ITO powder and distributing the tin oxide and / or the indium oxide powder in the ITO powder; adding water and dispersing agents into mixed powder, carrying out ball-milling on the water, the dispersing agents and the mixed powder to obtain mixtures, then carrying out spray-drying on the mixtures, placing the mixtures in molds, pressurizing the mixtures step by step at stages, compressing the mixtures to obtain initial blanks in such a manner that pressures are kept for certain time after being boosted in each procedure, then boosting the pressures step by step at stages, preparing blanks by means of cold isostatic pressing in such a manner that the pressures are kept for certain time after being boosted in each procedure, carrying out heat-insulation degreasing on the prepared blanks and then burning the blanks in oxygen atmosphere to obtain the ITO target materials. The gasified recycled ITO powder is used as a raw material, the weights of the tin oxide and / or the indium oxide powder are not lower than 5% of the weight of the raw material, and the tin oxide and / or the indium oxide powder are used as sintering activity enhancers. The method has the advantages that the added powder is distributed in the recycled ITO powder, accordingly, the sintering activity of the mixed powder can be integrally improved, and characteristics of the mixed powder in forming and sintering procedures can be changed; the blanks are pressurized step by step at stages in forming procedures and are high in density, and accordingly the relative density of the ITO target materials can reach 99.5% at least.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

High conductivity, heat-resistant aluminum alloy and preparation method thereof

ActiveCN110218918BImprove conductivityImprove heat resistanceConductive materialMetal/alloy conductorsMetallurgyHeat resistance

The invention relates to a high-conductivity, heat-resistant aluminum alloy and a preparation method thereof, belonging to the technical field of aluminum-based alloys, and is made of the following components in mass percentage: 1.5-3.2% Mg, 0.7-2.8% Si, 0.2-0.5% Ni, 0.06-0.25% Co, 0.1-0.2% Zr, 0.1-0.4% Y, the balance is Al and unavoidable impurities with a total content of ≤0.03%. The high-conductivity and heat-resistant aluminum alloy of the invention can remarkably improve its conductivity and heat-resistance, so that it can better meet the requirements of high-voltage power transmission.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +1

A method for improving composite heat treatment of nickel-based alloy pipe

ActiveCN103757644BImprove mechanical propertiesImprove corrosion resistanceSolid state diffusion coatingTreatment fieldAlloy

The invention relates to the heat treatment field of the nickel-based alloy pipes, and in particular relates to a complex heat treatment method capable of improving a nickel-based alloy pipe. The complex heat treatment method comprises early-stage heat treatment and surface treatment, wherein the surface treatment comprises the steps of pretreatment, coating of a co-permeating agent, co-permeation of ions Al-B and the like. The early-stage heat treatment of the complex heat treatment method is capable of obtaining remarkable effect of dispersion strengthening so that the nickel-based alloy pipe can have excellent mechanical properties; Al-B co-permeation is realized by virtue of ion bombardment, and consequently, the heating temperature of the surface heat treatment of the nickel-based alloy pipe is greatly reduced in contrast with that of the co-permeation in the traditional high-temperature furnace and the permeation rate is remarkably increased in contrast with that of the traditional electrolytic method or high-temperature slurry; especially, the method is capable of effectively improving the properties of the nickel-based alloy pipe such as high-temperature creep resistance and corrosion resistance and thus greatly prolonging the service life of the nickel-based alloy pipe.

Owner:CHANGZHOU SHENGTAK SEAMLESS STEEL TUBE

A processing heat treatment process of aluminum alloy extruded profiles

The invention provides a processing heat treatment process for aluminum alloy extruded profiles, comprising the following steps: (1) performing homogenization heat treatment on 6063 aluminum alloy ingot; Carry out heat treatment and extrusion respectively; (2) carry out quenching treatment and tempering treatment to the obtained 6063 aluminum alloy extruded profile; 425‑450°C for 2‑3h, water cooling; second stage aging heat treatment, temperature 320‑340°C, time 4‑6h, air cooling; third stage aging heat treatment, temperature 245‑265°C, time 5-8h, air cooling; the fourth aging heat treatment, the temperature is 180-215℃, the time is 5-8h, cooling with the furnace; the fifth aging heat treatment, the temperature is 125-135℃, the time is 5-8h, with the furnace Cooling: the 6063 aluminum alloy extruded profile processed by the present invention has high strength and hardness, and excellent corrosion resistance.

Owner:苏州意友金属材料有限公司

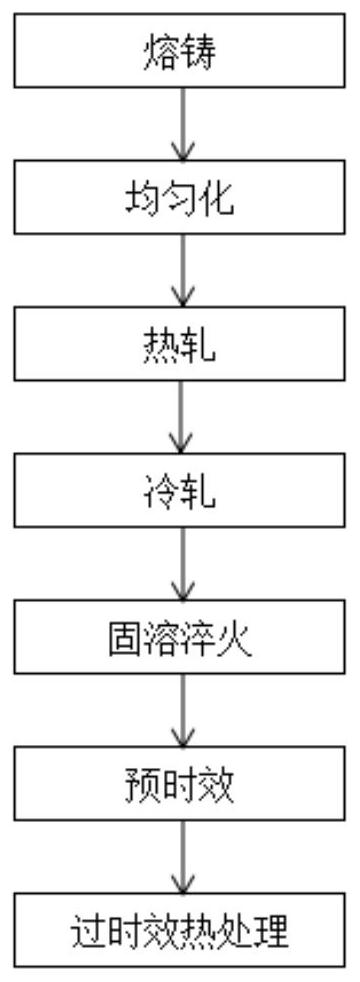

Preparation method of 6111-T7 state aluminum alloy plate

ActiveCN114737070AImprove performanceImprove corrosion resistanceProcess efficiency improvementIngotUltimate tensile strength

The invention relates to a preparation method of a 6111-T7 state aluminum alloy plate, and belongs to the technical field of aluminum alloy material preparation. B, casting; c, homogenizing heat treatment; d, hot rolling is conducted, specifically, the aluminum alloy cast ingot subjected to homogenizing heat treatment is directly subjected to hot rolling to obtain a hot-rolled coil, and the coiling temperature is 310-330 DEG C; e, cold rolling: directly carrying out cold rolling on the hot-rolled coil to obtain an aluminum alloy plate; f, solid solution quenching is conducted, specifically, the aluminum alloy plate is heated to 520-540 DEG C, water quenching is conducted after heat preservation is conducted for 10 S, the temperature of the aluminum alloy plate subjected to water quenching is not higher than 150 DEG C, and air cooling is conducted to 20-25 DEG C; g, pre-aging treatment is conducted, specifically, the aluminum alloy plate is heated to 75-95 DEG C and then coiled, and after coiling is completed, the aluminum alloy plate is naturally cooled to 20-25 DEG C; and H, overaging heat treatment is conducted, specifically, after the aluminum alloy coil is heated to 230 DEG C, heat preservation is conducted for 10-14 h, and the 6111-T7 aluminum alloy plate is obtained. The 6111-T7 aluminum alloy plate prepared through the method has moderate strength and good corrosion resistance, and the application range of the 6111 alloy in the field of automobile structural parts is widened.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

A preparation method of high-strength deformed aluminum alloy based on severe plastic deformation

The invention discloses a method for preparing a high-strength deformed aluminum alloy based on severe plastic deformation. The steps of the method are: A. cutting a green body from an aluminum alloy ingot; In the press die, the equal-channel angular extrusion process is carried out continuously with multi-temperature steps that gradually increase in temperature, and the severe plastic deformation technology is used to achieve enhanced solution treatment, and after the end of the water quenching treatment, a supersaturated solid solution block extrusion billet is obtained; C, cutting The alloy rod whose length direction is parallel to the direction of equal-channel angular extrusion is produced; the alloy rod is subjected to conventional hot extrusion processing and aging treatment to obtain high-strength deformed aluminum alloy. The present invention utilizes stage-by-stage severe plastic deformation of gradual heating to realize enhanced solid solution treatment, effectively promotes the dissolution of the second phase, and obtains a single-phase solid solution alloy with fine grain size, high-density defects, and high supersaturation, and then through thermal processing And aging treatment promotes the uniform precipitation of nano-precipitated phases, and obtains high-strength deformed aluminum alloys.

Owner:江苏江南创佳型材有限公司

Aluminium foil for electrolytic capacitor low-voltage anode and producing method thereof

InactiveCN1975949BReduce manufacturing costLarge area expansion rateElectrolytic capacitorsElectrolysisLow voltage

A method for preparing AI foil used on low voltage positive electrode of electrolytic capacitor uses weight compositions with 99.980-99.993% of AI, 15-50ppm of Si, 15-50ppm of Fe, 20-60ppm of Cu, 10-15ppm trace amount element of Mg + Mn +Zn +Ga, impurities and allowance as materials to prepare AI foil used on low voltage positive electrode of electrolytic capacitor.

Owner:RUYUAN DONGYANG UACJ PRECISION FOIL CO LTD

Preparation method of cerium-zirconium based solid solution

ActiveCN104492414BUniform particle sizeLarge particle sizeMetal/metal-oxides/metal-hydroxide catalystsCeriumBULK ACTIVE INGREDIENT

The invention discloses a preparation method of a cerium-zirconium based solid solution. The preparation method comprises the following sequential steps: (1) preparation of Ce<4+>; (2) preparation of active ingredient solution; (3) precipitation reaction; (4) surface modification; (5) roasting. The Ce<4+> is prepared firstly and then mixed with other rare earth ions and positively quadrivalent zirconium ions to obtain a mixed metal nitrate solution; as the mixed metal nitrate solution contains an organic complexing agent, the precipitation speed in the precipitation reaction process is controlled by virtue of complexing coordination of the organic complexing agent and the rare earth and zirconium ions, so that a precursor uniform and stable in particle size is obtained; the surface treatment is performed on the precipitate precursor by use of polyacrylic acid, and therefore, the agglomeration problem of particles in the roasting process is solved, and the pore diameter and the pore volume of the roasted product are increased, and consequently, the cerium-zirconium based solid solution catalytic material excellent in heat stability is obtained. The preparation method is suitable for the preparation of the solid solutions.

Owner:方复(上海)新材料科技有限公司

A kind of medium and high entropy alloy material, its preparation method and application

ActiveCN111304512BSolve the problem that it is difficult to smelt the bulk raw materials evenlyEasy to prepareHigh entropy alloysHeat stability

The invention provides a medium-high entropy alloy material, the medium-high-entropy alloy material is a solid solution alloy with a single-phase body-centered cubic structure, and the medium-high-entropy alloy material includes at least Mo, Ta, and Ti elements. It also provides its preparation method and application. The refractory medium-high entropy alloy of the invention has good thermal stability, good high temperature oxidation resistance, rather high hardness and wear resistance and good solid solution capacity. The invention adopts the innovative preparation method of powder briquetting + arc melting, which solves the problem that the melting point difference between the alloy components is too large, and it is difficult to melt the bulk raw materials evenly in ordinary arc melting, and provides a simple and easy method for the alloy material with a large melting point difference. Row of preparation means.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

A method for improving the structural stability of baco0.7fe0.2nb0.1o3-δ oxygen permeable membrane material

InactiveCN101575210BImprove resistance to reductionGood solid solution effectHydrogenSemi-permeable membranesPhysical chemistryConcentration gradient

A method for improving the structural stability of a BaCo0.7Fe0.2Nb0.1O3-δ oxygen-permeable membrane material belongs to the technical field of oxygen-permeable membranes. The present invention is characterized in that: BaCo0.7Fe0.2Nb0.1O3-δ base material with perovskite structure is doped with Sr element, and the chemical formula of the obtained oxygen-permeable membrane material is Ba1-xSrxCo0.7Fe0.2Nb0.1O3-δ, Wherein x=0.05~0.4. The oxygen-permeable membrane material provided by the method of the present invention significantly improves the phase structure stability of the BaCo0.7Fe0.2Nb0.1O3-δ matrix material under high temperature and low oxygen partial pressure conditions, so that the improved oxygen-permeable membrane material can be used in a wider range It can be applied in the range of oxygen partial pressure and larger oxygen concentration gradient.

Owner:UNIV OF SCI & TECH BEIJING

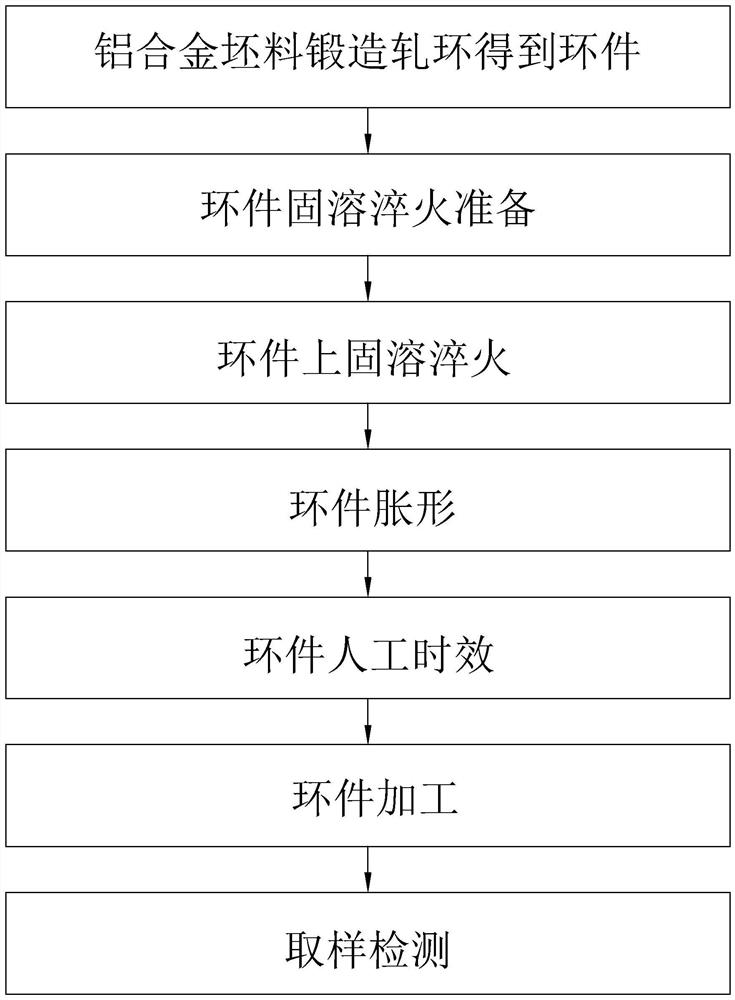

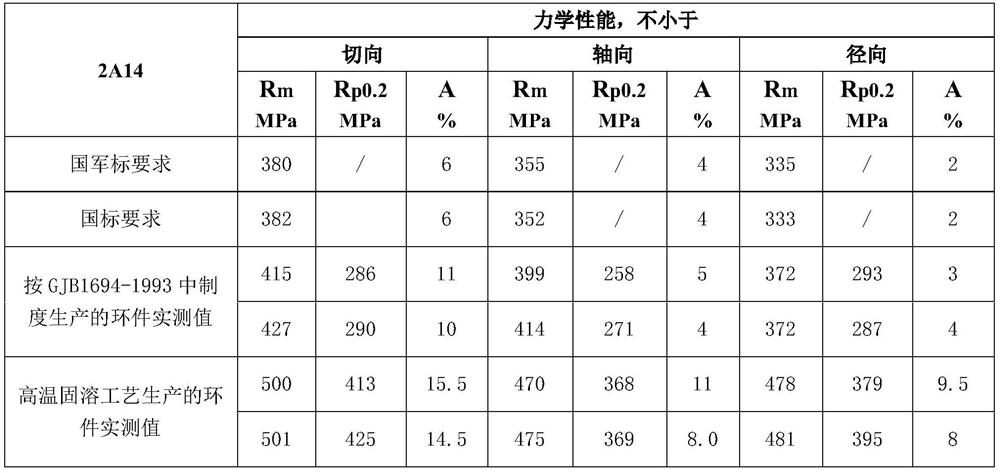

High-temperature solid solution process for 2A14 aluminum alloy ring piece

InactiveCN112708833AImprove solid solution effectAvoid overall overheatingFurnace typesHeat treatment process controlTemperature controlThermocouple device

The invention discloses a high-temperature solid solution process for a 2A14 aluminum alloy ring piece, and belongs to the technical field of heat treatment of aluminum alloy forge pieces. The invention provides the technical scheme that the high-temperature solid solution process for the 2A14 aluminum alloy ring piece is characterized by comprising the following steps of: S1, forging and ring-rolling an aluminum alloy blank to obtain a ring piece; S2, preparing for ring piece solid solution quenching: putting the ring piece into a solid solution furnace, and fixing four external thermocouples on the ring piece; S3, conducting solid solution quenching and real-time temperature control on the ring piece; S4, bulging of the ring piece; S5, conducting artificial aging of the ring part; S6, machining the ring piece; and S7, sampling and inspecting. The high-temperature solid solution process for the 2A14 aluminum alloy ring piece provided by the invention has the advantages that the solid solution effect of the 2A14 product is improved by adopting a high-temperature solid solution system and a process method for controlling the real-time temperature of the product by using the external thermocouples, the product is prevented from being scrapped due to overheating and overburning, and the final mechanical property of the product is improved.

Owner:WUXI PAIKE HEAVY CASTING & FORGING

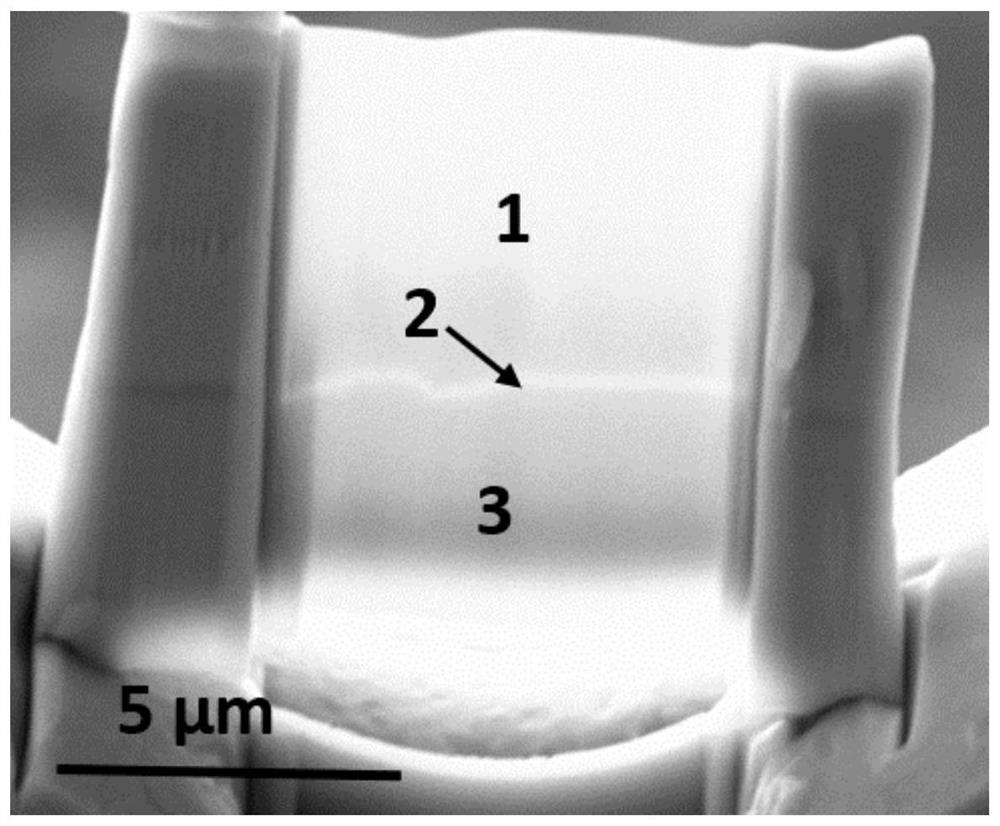

A molybdenum-silver layered composite material, its preparation method and application

ActiveCN110872692BAlleviate thermal expansion coefficient differencesGood solid solution effectVacuum evaporation coatingSputtering coatingOxidation resistantDirect current magnetron sputtering

The invention discloses a molybdenum-silver layered composite material, its preparation method and application. The preparation method comprises: at least placing a molybdenum base material and a metal target having good solid solubility with molybdenum into a vacuum environment, and depositing a metal intermediate layer on the surface of the molybdenum base material by DC magnetron sputtering; at least Putting the molybdenum substrate and the metal silver target material with the metal intermediate layer formed on the surface into a vacuum environment, and depositing a silver layer on the surface of the metal intermediate layer by DC magnetron sputtering; and the obtained molybdenum substrate ‑Metal interlayer‑silver layer composite structure is annealed, so that the metal elements constituting the metal interlayer continuously diffuse into the molybdenum substrate and the silver layer. The present invention can successfully prepare the silver / metal interlayer / molybdenum layered composite material, which is environmentally friendly, has high process stability, and can be produced on a large scale; and the obtained molybdenum-silver layered composite material has high density, excellent bonding strength, and excellent Anti-oxidation corrosion and thermal fatigue resistance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

A production process of nickel-based alloy tubes for high-pressure boilers

The invention relates to a production technology of an alloy tube, in particular to a nickel base alloy tube producing technology for a high-pressure boiler. The nickel base alloy tube producing technology sequentially comprises the steps of centrifugal tube blank casting, tube blank cutting-off, first cold rolling, middle annealing, second cold rolling, finished product heat treatment, physical and chemical inspection, straightening, finishing, eddy current inspection (substituting water pressure tests), tube body detection, ultrasonic flaw detection, mark spraying, packaging, storing and the like. The nickel base alloy tube producing technology is short in production process and capable of greatly reducing the production cycle of the nickel base alloy tube, improving production efficiency and reducing production cost. Moreover, the tube blank is produced in a centrifugal casting mode, so that the material utilization rate is high, and material waste is avoided. The inner surface of the centrifugal casting tube blank is high in roughness degree. An acid washing method is used after centrifugal casting, so that the roughness degree of the inner surface of the centrifugal casting tube blank is reduced. Moreover, two times of deformation are both conducted through cold rolling, so that the hot extrusion process is eliminated, the further arrangement of hot extrusion equipment is eliminated, and production cost is reduced.

Owner:CHANGZHOU SHENGTAK SEAMLESS STEEL TUBE

Flux-cored wire for jaw plate

InactiveCN107116317AHigh strengthImprove toughnessWelding/cutting media/materialsSoldering mediaRare earthSilicon dioxide

The invention discloses a flux-cored wire for a jaw plate. The flux-cored wire comprises a steel-tape sheath and a flux core, wherein the flux core comprises the following raw materials in percentage by weight: 4-6% of graphite, 15-16% of chromium powder, 3-8% of ferromanganese, 2-3% of molybdenum powder, 8-9% of vanadium powder, 3-5% of nickel power, 2-4% of silicon dioxide, 0.5-1% of titanium diboride, 1-2% of titanium dioxide, 4-6% of rare earth, 5-7% of magnalium, 1-3% of fluorite and the balance of iron powder. According to the flux core, through mutual cooperation of all elements, a welding coating is enabled to have high wear resistance as well as high strength and toughness.

Owner:安徽飞弧焊业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com