Manufacturing method of Al-Mg-Si alloy hub

A technology of al-mg-si and manufacturing method, which is applied in the field of wheel hub manufacturing, can solve the problems of low production efficiency, complex process, high energy consumption, etc., and achieve the effects of reducing energy consumption, simplifying process and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

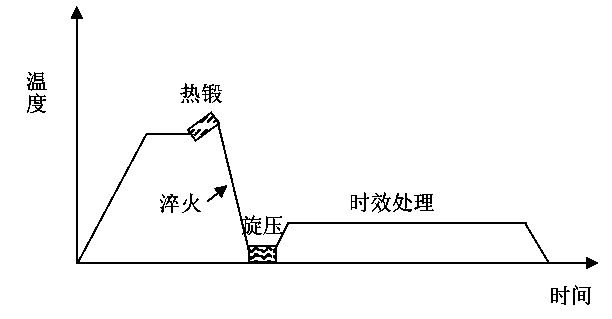

[0061] Punching the 6061 aluminum alloy hot-rolled plate into a disc-shaped blank with a size of Φ350×65mm;

[0062]Preheat the disc-shaped blank to 490°C;

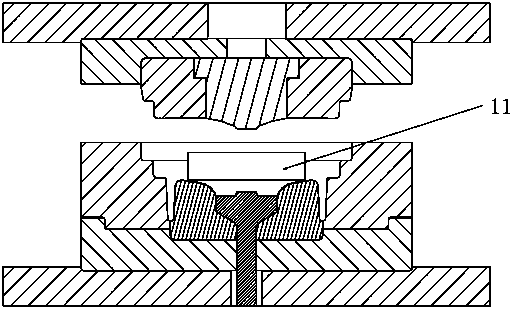

[0063] Before the forging work, preheat the forging die to 480°C, separate the upper die from the lower die, spray lubricant on the working surface of the forging die, put the preheated disc-shaped blank into the forging die, and use the forging press Forging at a speed of 20mm / s once to make a disc-shaped blank, so that the wheel hub is initially formed into a disc shape; immediately put it into water for quenching after forging;

[0064] Put the quenched disc-shaped blank into the spinning machine for strong spinning to form a hollow rotating body hub blank; then put the hub blank into an aging furnace and heat it to 175°C and keep it warm for 8 hours; finally, machine the hub blank and follow up the surface processing to obtain automotive aluminum alloy wheel products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com