Device for assisting solid solution heat treatment of metal component through pulse current

A technology of solution heat treatment and auxiliary metal, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of not considering the insulation between metal components and the high temperature furnace body, the high temperature furnace cannot be used directly, and the residual stress is low. , to achieve the effect of good solid solution effect, simple and convenient pulling and plugging, and low residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

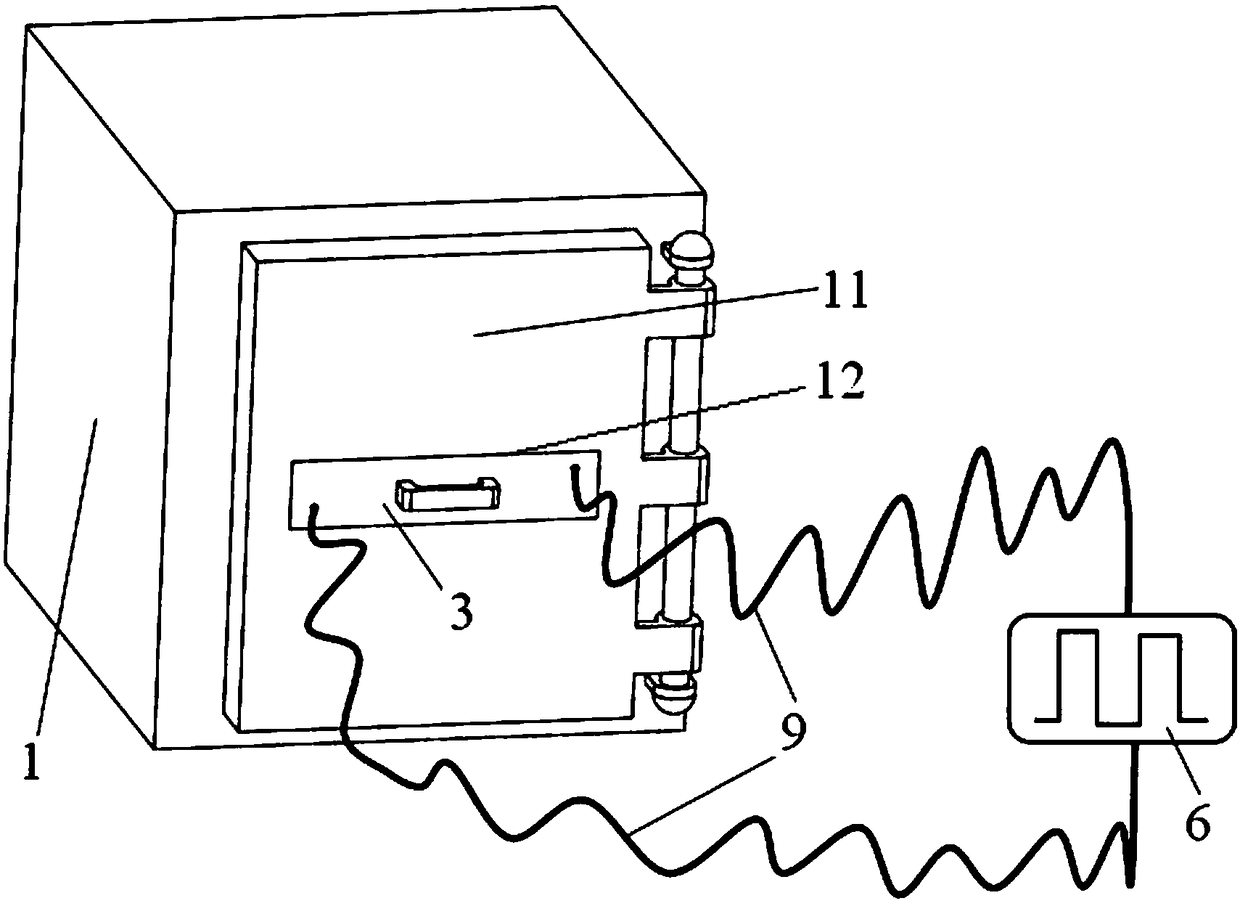

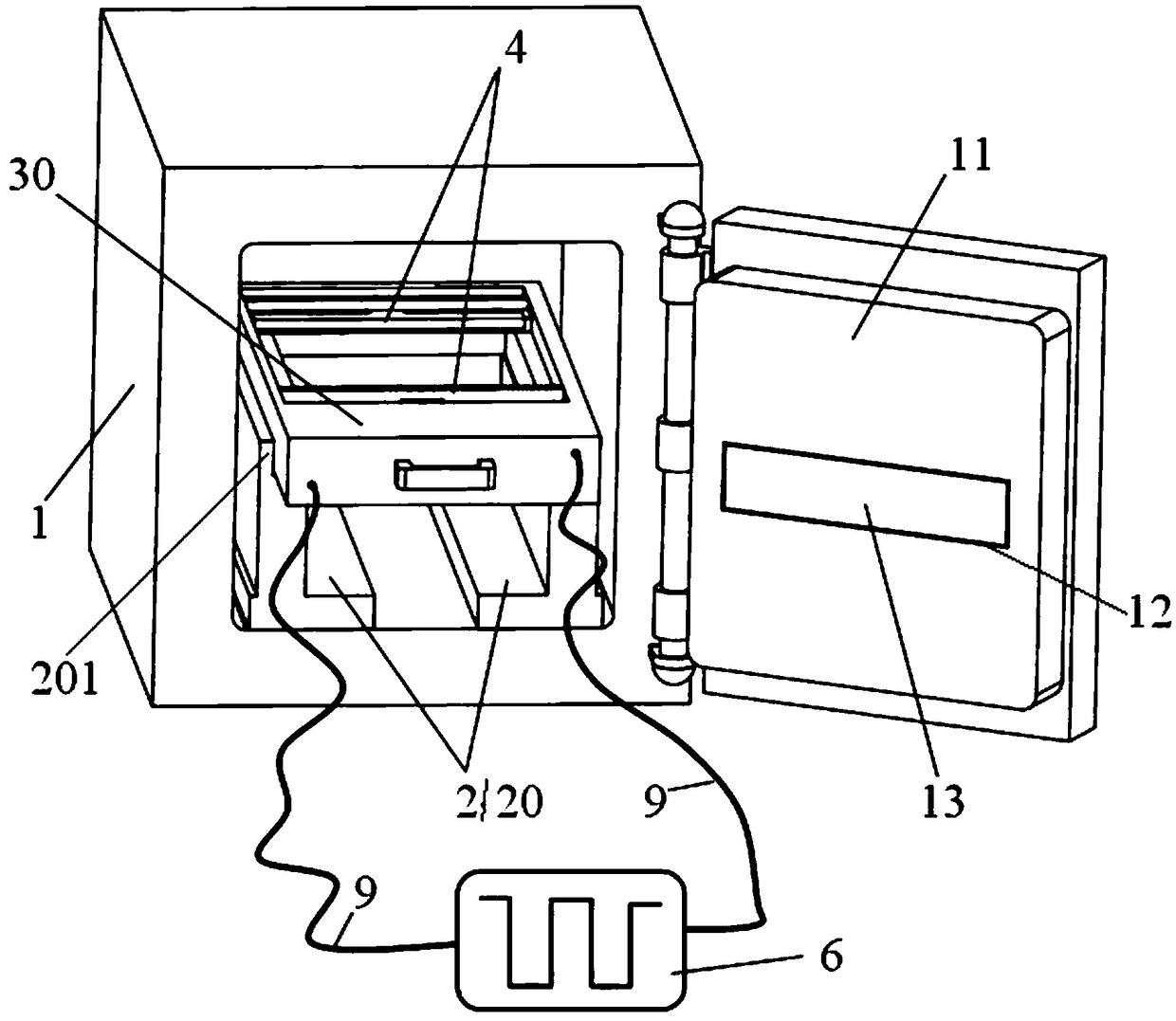

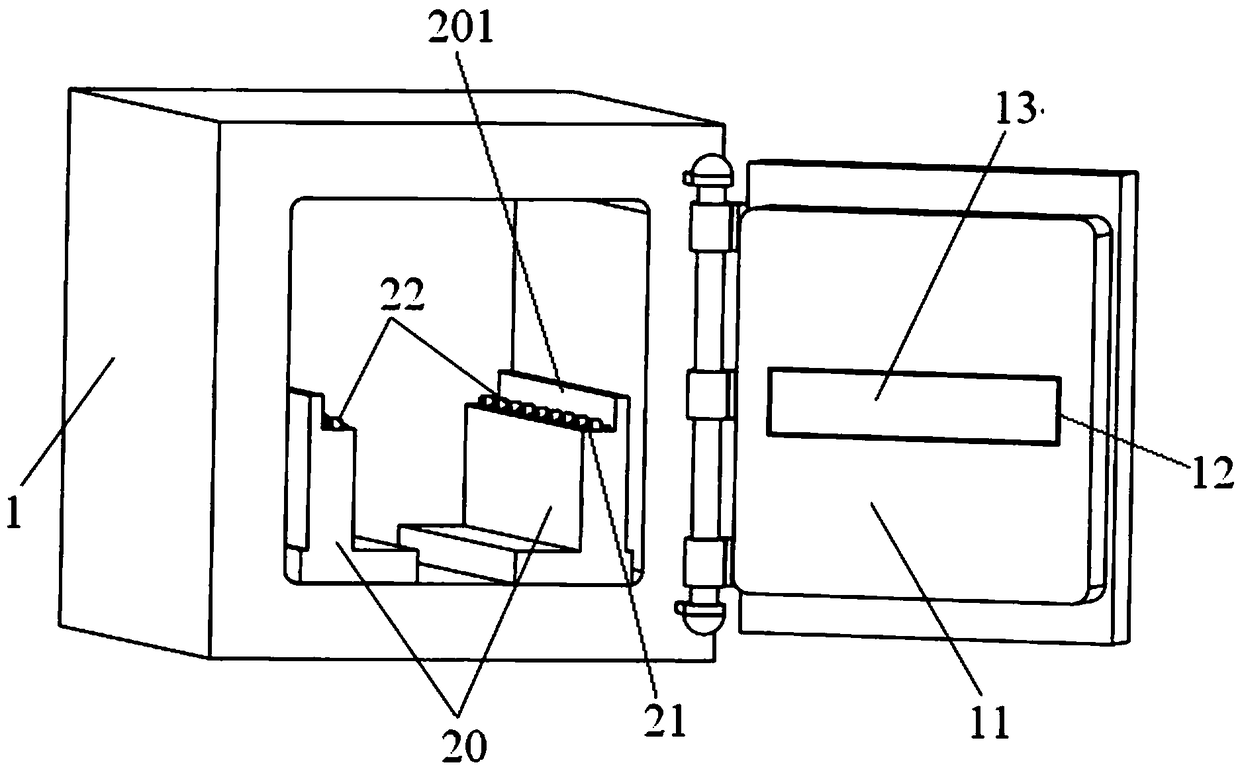

[0035] see Figure 1 to Figure 9 , a device for pulse current-assisted solution heat treatment of metal components, comprising a high-temperature solution furnace 1, a support 2 and a carrier, the bracket is arranged in the hearth of the high-temperature solution furnace, the carrier is used to carry metal components, and the carrier Including the frame 30 and the insulating rod 4, the central area of the frame is set as a hollow structure, the inner side walls of a pair of parallel frame sides of the frame are respectively provided with convex edges 31 whose top surface is lower than the top surface of the frame bar, and the insulating rods are arranged in parallel in the frame The two ends of the insulating rods are respectively supported by two protrud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com