Preparation method of 6111-T7 state aluminum alloy plate

An aluminum alloy sheet and aluminum alloy technology, applied in the direction of improving process efficiency, can solve the problems of inability to meet the strength requirements of structural parts, insufficient corrosion resistance performance state analysis, product defects, etc., to achieve good solid solution effect, optimize solid solution, etc. The effect of dissolution system and stable mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

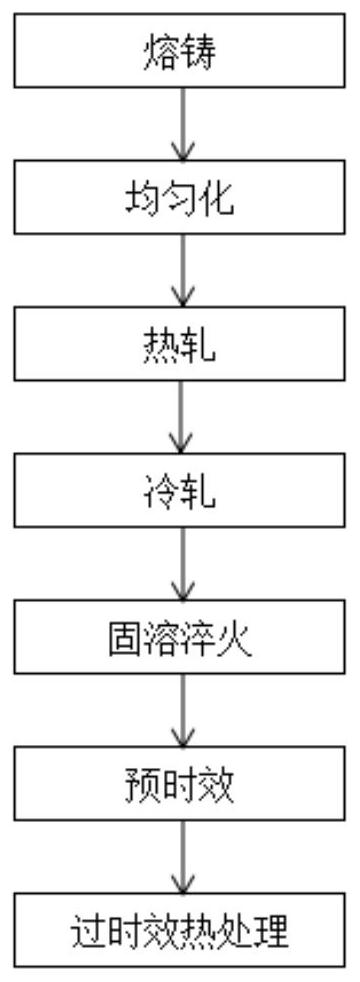

[0037] see figure 1 , which is a preparation method of a 6111-T7 state aluminum alloy sheet, comprising the following steps:

[0038] A. Batching: The aluminum alloy raw materials for preparing 6111 aluminum alloy are batched according to weight percentage, namely Si: 0.6-1.0%, Fe: 0.2-0.4%, Cu: 0.6-0.8%, Mn: 0.2-0.4%, Mg: 0.6-0.8%, Cr: 0.10%, Zn: 0.10%, single impurity≤0.05%, total≤0.15%, and the balance is Al.

[0039] B. Melting and casting: The prepared aluminum alloy raw materials are placed in a melting furnace and smelted into a liquid aluminum alloy. After refining, slag removal, filtration, and online refinement, the liquid aluminum alloy is cast into an aluminum alloy ingot.

[0040] C. Homogenization heat treatment: The aluminum alloy ingot is sawed and milled, the sawn and milled ingot is placed in a homogenization furnace for homogenization heat treatment, and the aluminum alloy ingot is heated to 550-560 ℃ for 6-12h .

[0041] D. Hot rolling: Directly hot-roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com