Medium-high-entropy alloy material and preparation method and application thereof

A high-entropy alloy, high-temperature material technology, applied in the field of materials, to achieve the effects of high hardness and wear resistance, low accuracy requirements, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

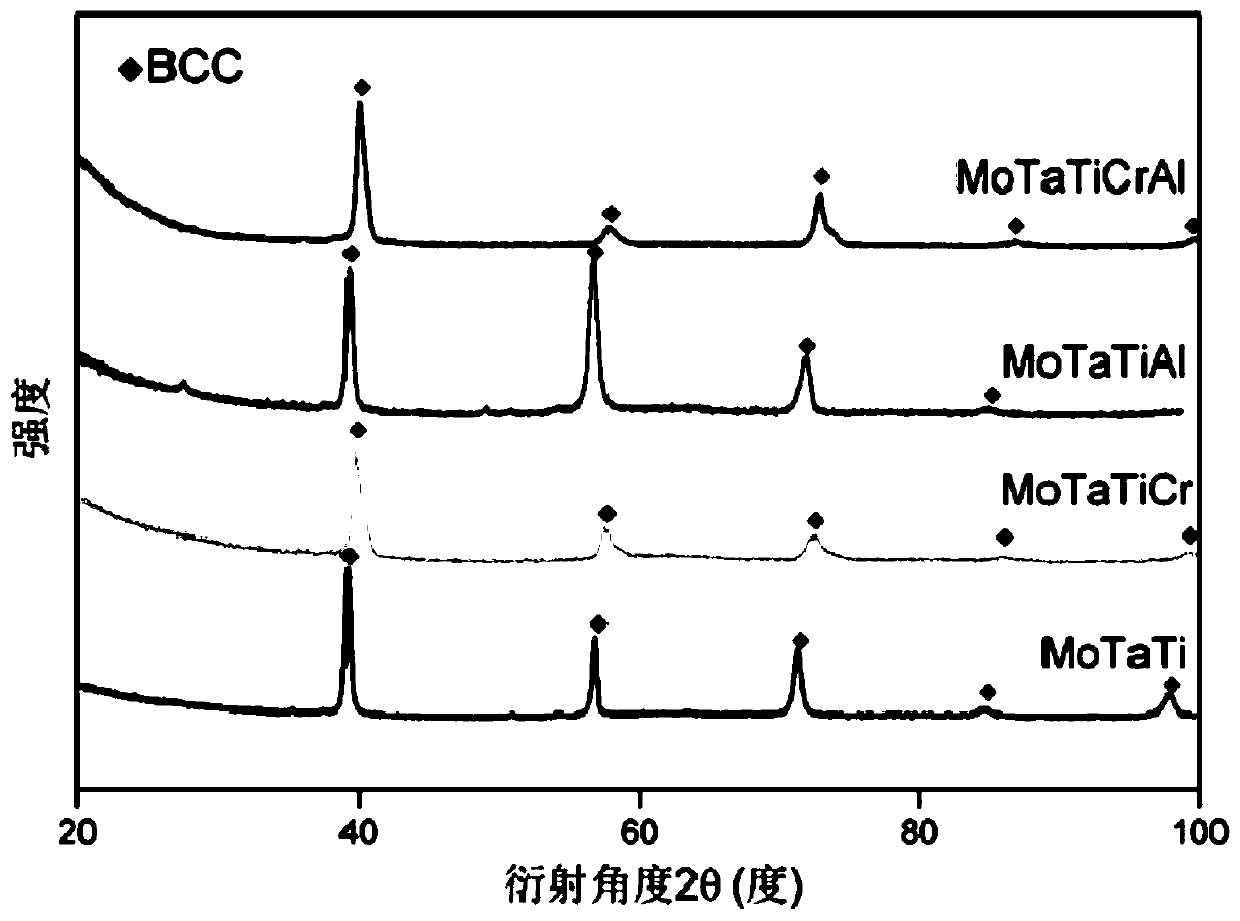

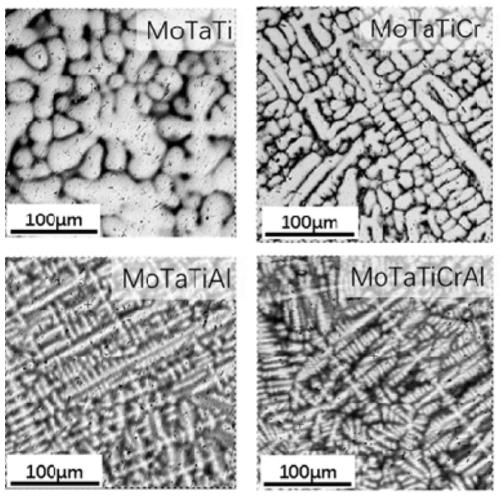

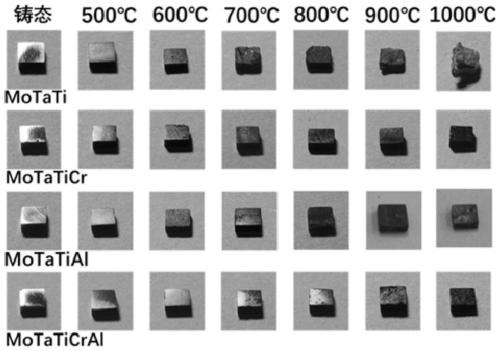

[0077] This example is used to illustrate the preparation method of MoTaTi alloy.

[0078] Preparation of MoTaTi alloy. Use an electronic balance to accurately weigh Mo, Ta, and Ti metal powders with a purity of 99.9%, the total mass is 6 grams, and the molar ratio is 1:1:1. Pour the three metal powders weighed into the same small beaker, Stir with a thin metal rod for 10 minutes (other methods can also be used to stir well), so that it is basically mixed. Pour the mixed powder into a tableting mold, and then use a tablet machine to compress the powder with a pressure of 300 MPa, and release the pressure after holding the pressure for about 2 minutes. The pressed raw material is taken out from the tableting mold. At this time, the powder raw material becomes a cylindrical block with a certain strength and will not be easily broken or scattered. Repeat the above tabletting steps until all powder raw materials are compressed into blocks. Put the finished powder block into an ...

Embodiment 2-3

[0085] This example is used to illustrate the preparation method of MoTaTi alloy.

[0086] Prepare refractory middle entropy alloy Mo according to the method of embodiment 1 35 Ta 35 Ti 30 and Mo 30 Ta 30 Ti 40 , the difference is only in the adjustment of the ratio of raw materials. Its lattice structure, alloy structure, microhardness and high temperature oxidation behavior are shown in Table 1.

Embodiment 4

[0088] This example is used to illustrate the preparation method of MoTaTiCr alloy.

[0089] Use an electronic balance to accurately weigh Mo, Ta, Ti, Cr metal powders with a purity of 99.9%. The total mass is 6 grams, and the molar ratio is 1:1:1:1. In a small beaker, stir with a thin metal rod for 10 minutes (other methods can also be used to stir evenly), so that it is basically mixed evenly. Pour the mixed powder into a tableting mold, and then use a tablet machine to compress the powder with a pressure of 300 MPa, and release the pressure after holding the pressure for about 2 minutes. The compressed raw material is taken out from the tableting die, and the powder raw material becomes a cylindrical block at this time. Repeat the above tabletting steps until all the powder raw materials are compressed into blocks. Put the finished powder block into an electric arc furnace with titanium adsorption and argon atmosphere, and melt it with a current of 260 amps, smelting 4 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com