Preparation method of chromium-aluminum-nitrogen film by closed field unbalanced magnetron sputtering

A magnetron sputtering and chrome-aluminum-nitrogen technology, applied in sputtering coating, ion implantation coating, metal material coating process, etc., can solve the problems of unbalanced film thickness and unstable technical parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0097] The present invention will be further described below in conjunction with accompanying drawing:

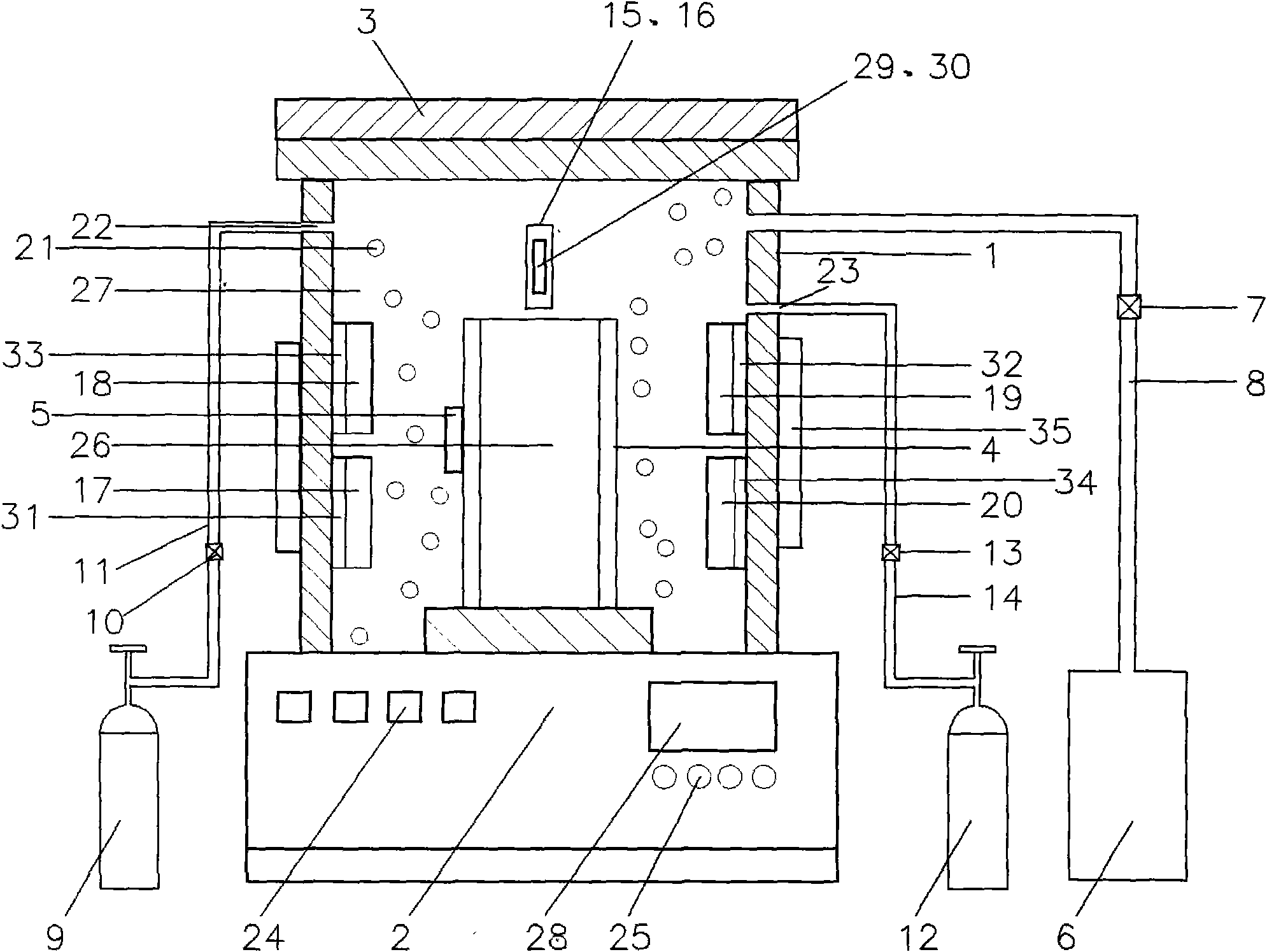

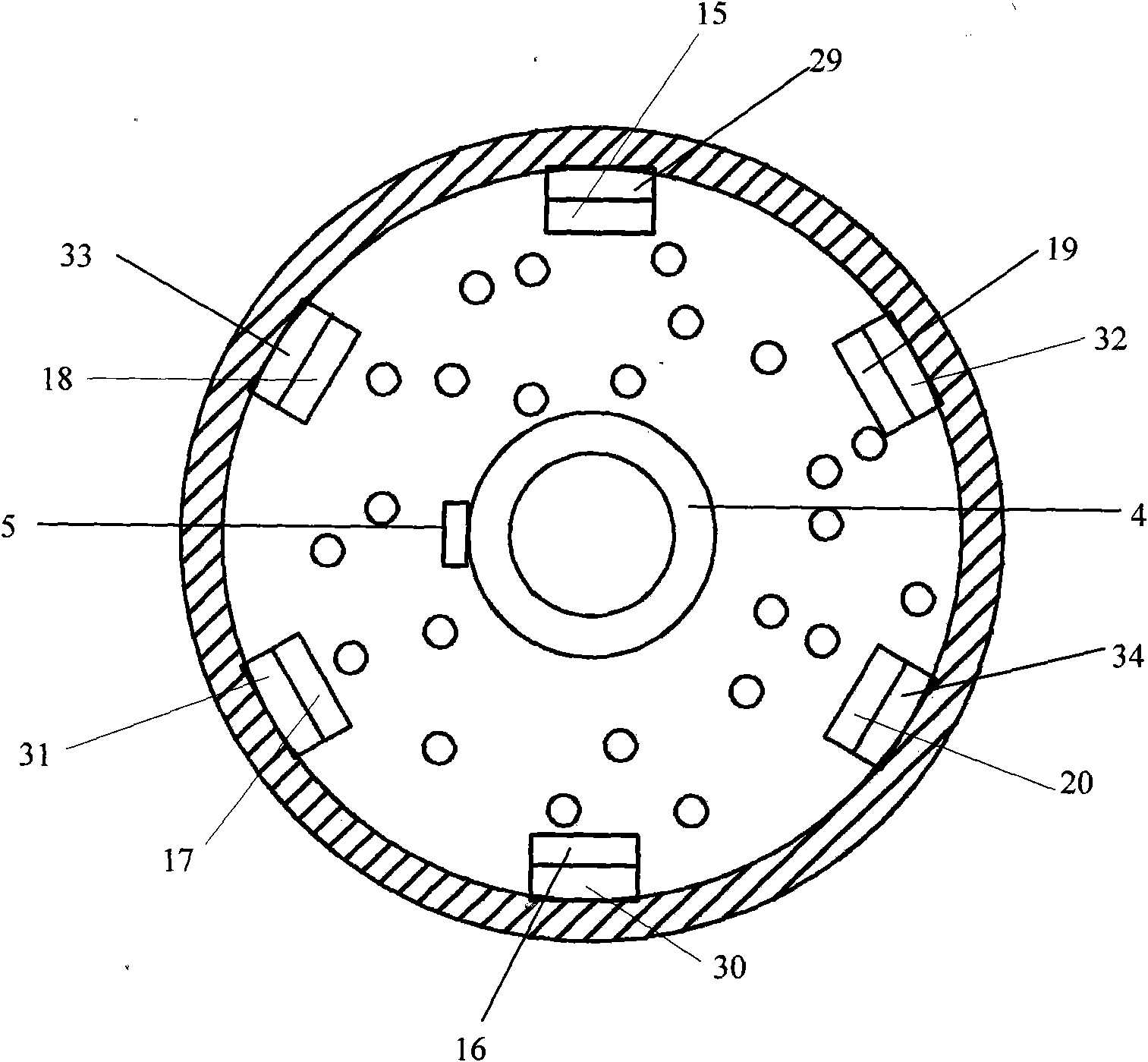

[0098] figure 1 As shown in the figure, it is a state diagram for preparing chrome-aluminum-nitrogen hard film in a magnetron sputtering furnace. The position of each part should be correct, the installation should be firm, and the operation and use should be convenient.

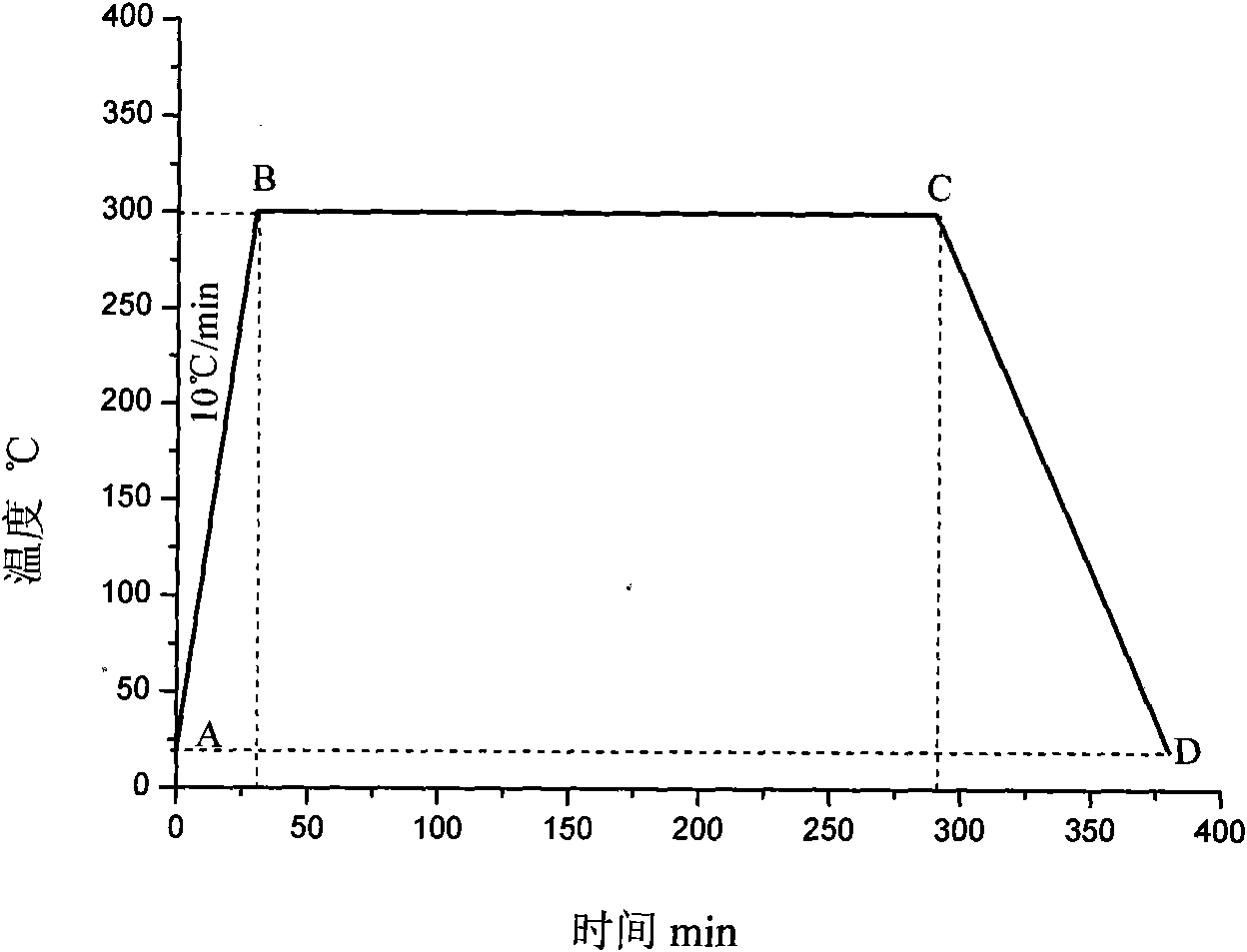

[0099] Argon cylinders, nitrogen cylinders, and vacuum pumps should be reasonably prepared. During coating, the pressure in the furnace chamber should be constant and the gas should be sufficient. The chromium targets and aluminum targets should be arranged symmetrically and equidistantly on the furnace wall. Under the action of a closed unbalanced magnetic field, the argon Ions accelerate the bombardment of the target, so that chromium and aluminum atoms are deposited on the substrate, and react with nitrogen ions to form a hard film of chromium, aluminum and nitrogen. The parameters and temperature are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com