A method for improving the structural stability of baco0.7fe0.2nb0.1o3-δ oxygen permeable membrane material

A material structure, oxygen-permeable membrane technology, applied in semi-permeable membrane separation, chemical instruments and methods, membrane technology, etc., can solve the problems of low mechanical strength, poor structural stability, coarse grains, etc. Structural stability, the effect of improving anti-reduction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Synthesis of Ba by solid phase reaction 0.9 Sr 0.1 co 0.7 Fe 0.2 Nb 0.1 o 3-δ Dense samples. with BaCO 3 , SrCO 3 , CoCH 3 COOH, Fe 2 o 3 , Nb 2 o 5 As a raw material, a mixture is prepared according to the stoichiometric ratio of the elements of each component. The mixture was fully milled in an agate ball mill jar with alcohol as the medium for 10 hours, and then dried in an oven. After the dried mixture is ground and sieved, the powder is pre-fired at 900° C. for 10 hours. The block produced by calcination was ground in an agate mortar, and then placed in a ball mill jar with alcohol as a medium for ball milling for 5 hours, and then put into a drying oven to dry for 10 hours. Grind the dried ingredients evenly, add an appropriate amount of PVA with a concentration of 1.0wt.%, mix evenly, and then press it into a diaphragm and a rectangular strip in a stainless steel abrasive tool with a pressure of 100 MPa. Then the green body was sintered at 1150°C f...

Embodiment 2

[0020] Synthesis of Ba by solid phase reaction 0.6 Sr 0.4 co 0.7 Fe 0.2 Nb 0.1 o 3-δ Dense samples. The synthetic materials and preparation process are as described in Example 1. The main process parameters in the preparation process are: the mixture powder after ball milling, drying, grinding and sieving is pre-fired at 1000°C for 10 hours; the green body after pressing is sintered at 1225°C for 10 hours to obtain a dense sample ; The heating and cooling rates of the sample in the high temperature furnace are both 3°C / min.

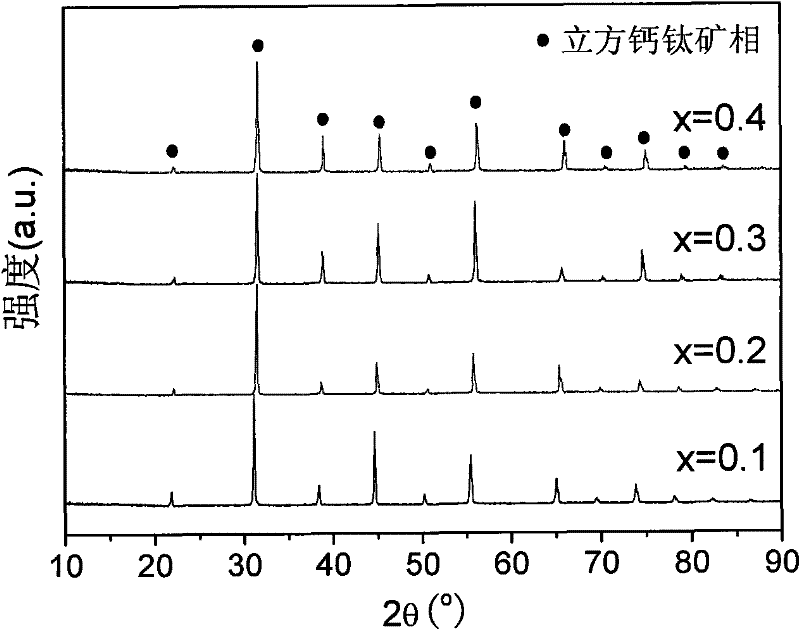

[0021] Analysis of Ba by XRD 0.9 Sr 0.1 co 0.7 Fe 0.2 Nb 0.1 o 3-δ 、Ba 0.8 Sr 0.2 co 0.7 Fe 0.2 Nb 0.1 o 3-δ 、Ba 0.7 Sr 0.3 co 0.7 Fe 0.2 Nb 0.1 o 3-δ and Ba 0.6 Sr 0.4 co 0.7 Fe 0.2 Nb 0.1 o 3-δ The phase structure composition, the result is as follows figure 1 shown. The test results show that the oxygen-permeable membrane materials in each ratio form a single cubic perovskite structure. This shows that the Sr element in...

Embodiment 3

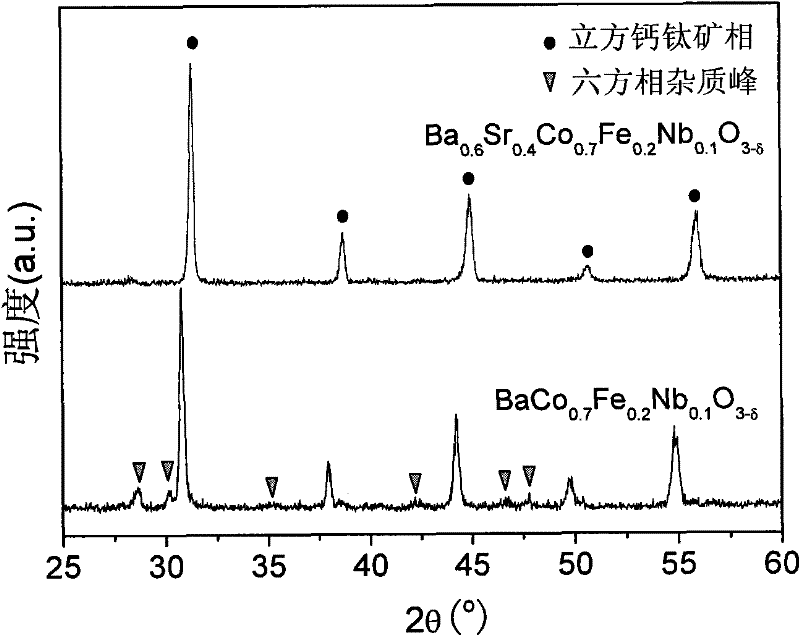

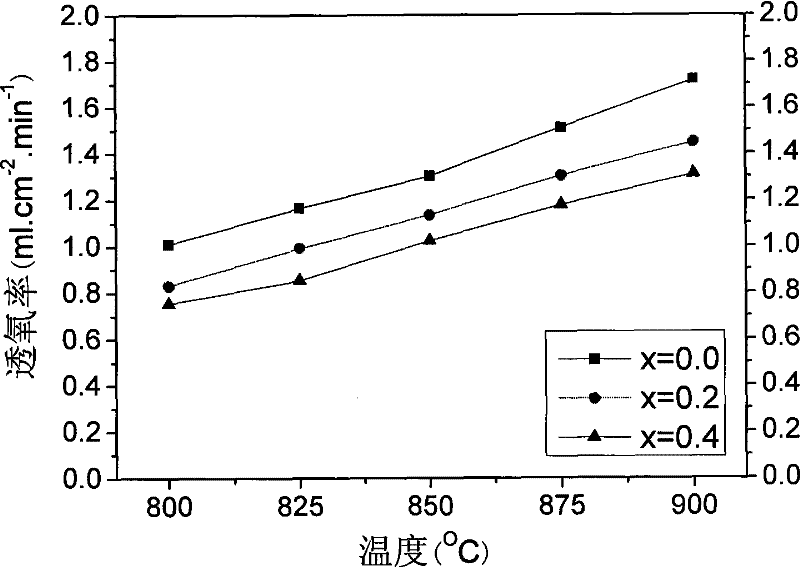

[0023] Test the oxygen permeable membrane material BaCo 0.7 Fe 0.2 Nb 0.1 o 3-δ And Ba after doping Sr element in it 0.6 Sr 0.4 co 0.7 Fe 0.2 Nb 0.1 o 3-δ Phase structure stability under high temperature and low oxygen partial pressure conditions. BaCo 0.7 Fe 0.2 Nb 0.1 o 3-δ with Ba 0.6 Sr 0.4 co 0.7 Fe 0.2 Nb 0.1 o 3-δ The diaphragm is put into a porcelain boat, and the porcelain boat is placed in a tube furnace with both ends sealed. One end of the furnace tube is fed with pure argon gas, and the other end is connected with a conduit to lead into water, and the gas flow rate is controlled at about 100ml / min. The heat treatment system during the test is: 5°C / min to 850°C; then slowly rise the temperature from 850°C to 900°C for 10 hours; then quench the diaphragm into ice-salt water with a molar concentration of 5%, and use XRD to characterize it Changes in the phase structure of the membrane surface. The result is as figure 2 Shown, BaCo 0.7 Fe 0.2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com