Lithium battery negative electrode and preparation method thereof, lithium battery and application

A lithium battery and negative electrode technology, applied in the fields of lithium batteries and applications, lithium battery negative electrodes and their preparation, can solve problems such as unstable characteristics, hidden dangers of battery safety, and decreased battery cycle performance, and achieve excellent safety performance and cycle performance, The effect of suppressing the formation of SEI film and improving the anti-reduction ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

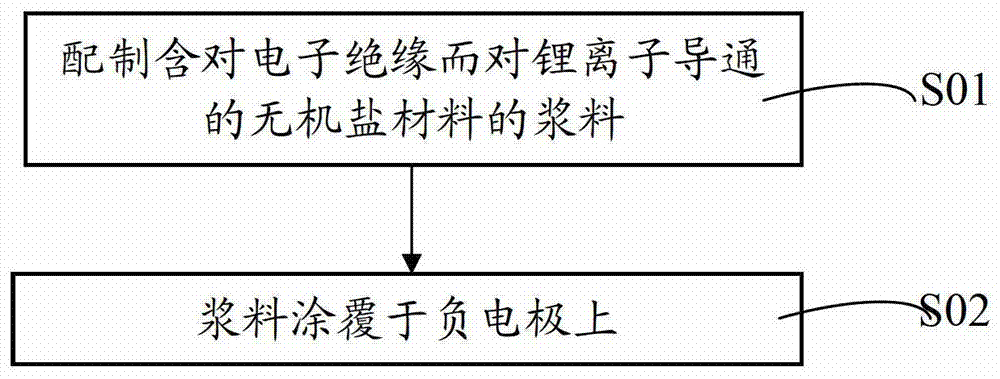

[0062] Correspondingly, the embodiment of the present invention also provides a method for preparing the negative electrode of the above-mentioned lithium battery. For the process flow of the method for preparing the negative electrode of the lithium battery, please refer to image 3 , see also figure 2 . Lithium battery negative electrode comprises the following steps:

[0063] Step S01. Prepare a slurry containing an inorganic salt material that is electrically insulating but conductive to lithium ions: mix the inorganic salt material that is electronically insulating but conductive to lithium ions with a solvent to prepare a slurry;

[0064] Step S02: coating the slurry on the negative electrode: coating the slurry prepared in step S01 on the negative electrode containing the negative electrode active material layer 2, and drying to form the protective layer 3 to obtain the negative electrode of the lithium battery.

[0065] Specifically, in the above step S01 , the mate...

Embodiment 1

[0088] A lithium battery negative electrode and a preparation method thereof, and a lithium ion battery:

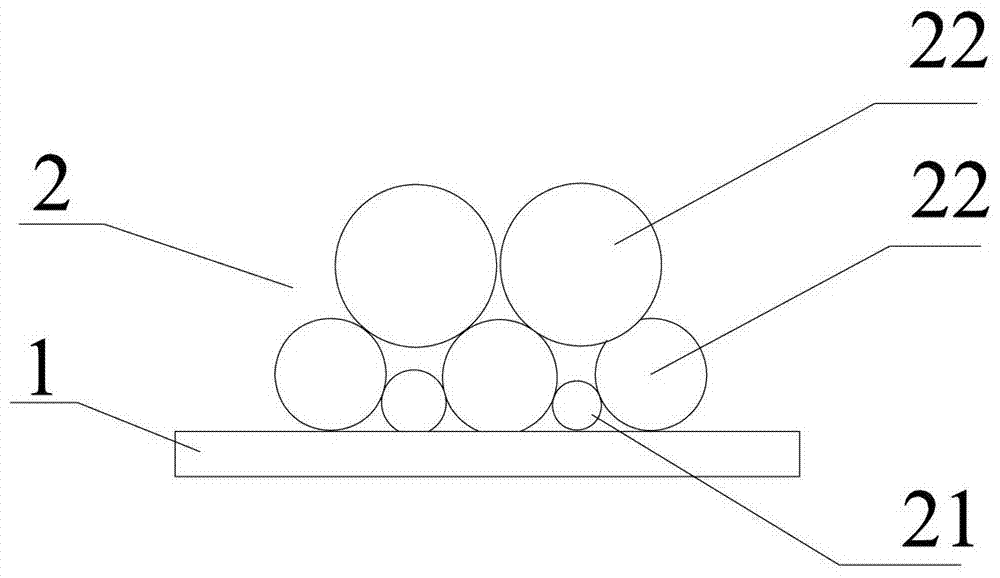

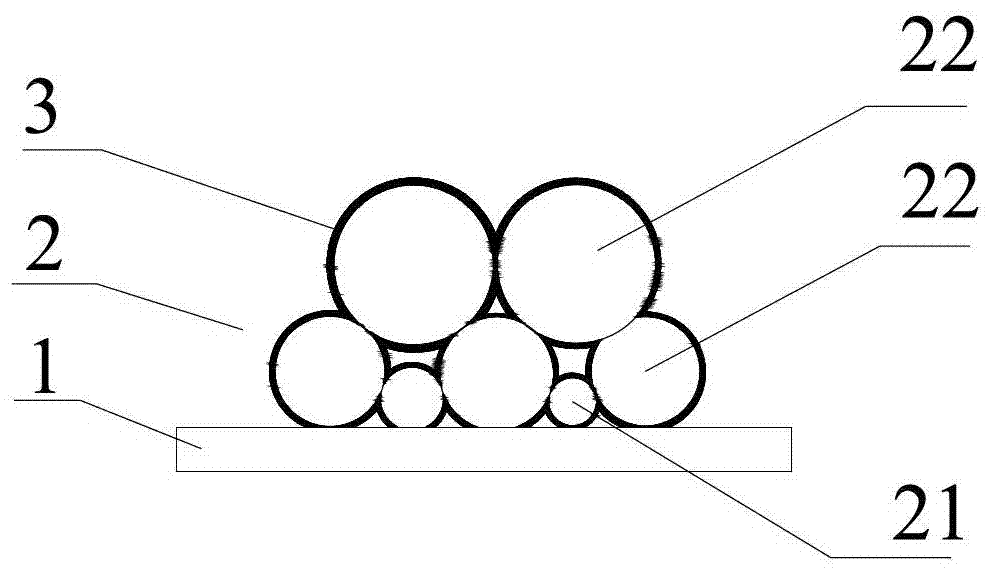

[0089] The microstructure of the negative electrode of the lithium battery is as follows: figure 2 As shown, the negative electrode of the lithium battery includes a current collector 1, a negative electrode active material layer 2 bonded to the surface of the current collector 1, and a protective layer 3 bonded to the surface of the negative electrode active material layer 2 and the pore walls of the negative electrode active material layer 2. Among them, the protective layer 3 contains lithium sulfate.

[0090] 1.1 The negative electrode of the lithium battery is prepared as follows:

[0091] 1.1.1 Preparation of the negative electrode: 94.5g of the negative electrode active material artificial graphite, 2g of the conductive agent super p, 1.5g of the thickener sodium carboxymethyl cellulose, 4g of the binder styrene-butadiene rubber emulsion (solid content 50% ) int...

Embodiment 2

[0100] A lithium battery negative electrode and a preparation method thereof, and a lithium ion battery:

[0101] The structure of the lithium battery negative electrode is the same as that of the lithium battery negative electrode in Example 1, except that the protective layer contains lithium dihydrogen phosphate, and the concentration of the protective layer precursor lithium dihydrogen phosphate solution is 8%.

[0102] 2.1 The negative electrode of the lithium battery is prepared as follows:

[0103] 2.1.1 Preparation of negative electrode: refer to the preparation of 1.1.1 negative electrode in the steps in Example 1;

[0104] 2.1.2 Preparation of lithium dihydrogen phosphate slurry containing electronic insulation and lithium ion conduction: slowly add 80 grams of lithium dihydrogen phosphate into a beaker containing 920 grams of deionized water, stir evenly, and obtain a concentration of 8% lithium dihydrogen phosphate solution;

[0105] 2.1.3 Negative electrode modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com