Anti-reduction BME ceramic dielectric capacitor and ceramic material for capacitor

A technology of ceramic materials and capacitors, applied in the direction of fixed capacitor dielectric, capacitors, fixed capacitors, etc., can solve the problems of complex process, low production efficiency, and inapplicability to large-scale industrial production, so as to improve the dielectric constant, reduce loss, improve Anti-reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

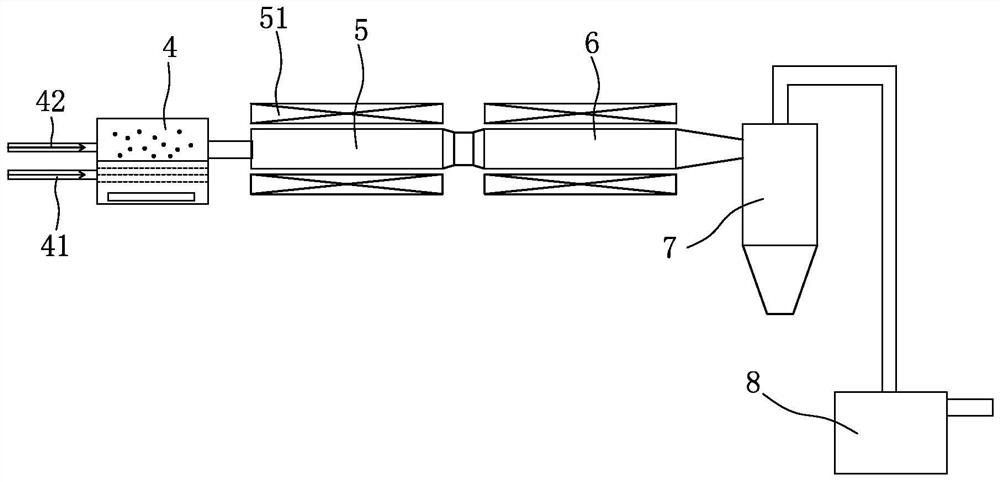

[0042] Its preparation method comprises the following steps:

[0043] Step 1, weighing and mixing the raw materials except barium titanate, nano-silicon dioxide and nano-hafnium dioxide in the ceramic material for anti-reduction BME ceramic capacitors according to their proportions, to obtain soluble salt additives;

[0044] Step 2, add deionized water to the soluble salt additive obtained in step 1, and stir for 4-8 hours to completely dissolve the additive, wherein the weight ratio of the soluble salt additive to deionized water is 1:1-2;

[0045] Step 3, add barium titanate, nano-silicon dioxide and nano-hafnium dioxide to the solution obtained in step 2, and stir the nodular ink, accompanied by ultrasonic dispersion, ultrasonic frequency 20-40kHz, make barium titanate and nano-silicon dioxide, Nano-hafnium dioxide is evenly dispersed in the solution to form a precursor mixture;

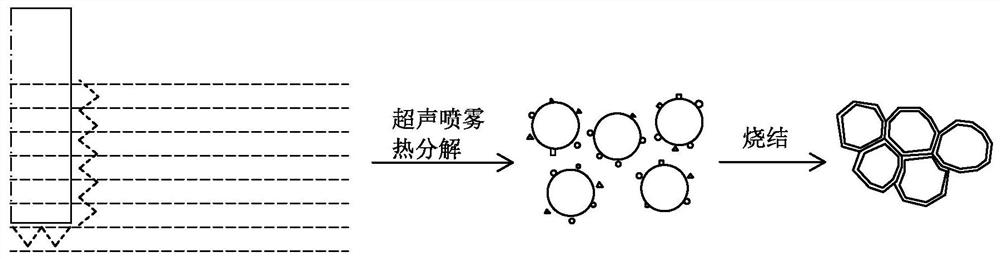

[0046] Step 4: Perform ultrasonic spray pyrolysis and granulation on the precursor mixture pr...

Embodiment 1

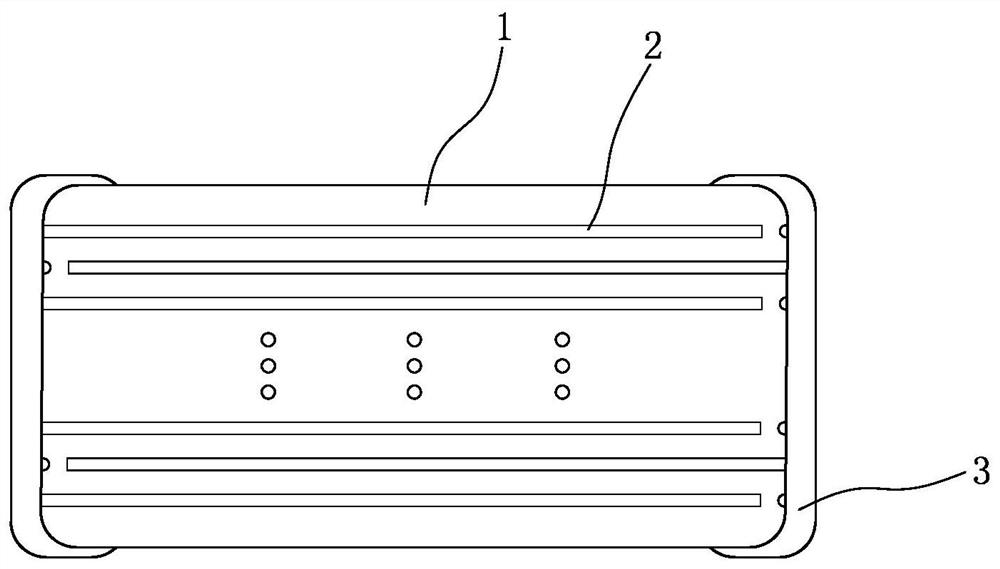

[0051] An anti-reduction BME ceramic capacitor is prepared by using ceramic material 1 for an anti-reduction BME ceramic capacitor through the following steps:

[0052] Step 1, porcelain pulp scouring: According to the weight ratio of ceramic material: ethanol: toluene: dispersant = 100:20:20:1 respectively add ceramic material, ethanol, toluene, dispersant, after ball milling for 5 hours, then according to the weight ratio of ceramic material: Dioctyl phthalate: polyvinyl butyral = 100:5:10 Add dioctyl phthalate and polyvinyl butyral, and continue ball milling for 5 hours to obtain casting slurry;

[0053] Step 2, coating: coating the prepared casting slurry into a dielectric layer, the coating thickness is ≦8um;

[0054] Step 3, printing: the nickel metal inner pole 2 is printed onto the dielectric layer, and the dielectric layer is superimposed on each other, and then subjected to hydraulic pressure and slicing to produce a green body;

[0055] Step 4, degreasing: place th...

Embodiment 2

[0067] An anti-reduction BME ceramic capacitor is prepared by using ceramic material 1 for an anti-reduction BME ceramic capacitor through the following steps:

[0068] Step 1, porcelain pulp scouring: according to the weight ratio of ceramic material: ethanol: toluene: dispersant = 100:15:15:0.5 respectively add ceramic material, ethanol, toluene, dispersant, after ball milling for 1 hour, then according to the weight ratio of ceramic material: Dioctyl phthalate: polyvinyl butyral = 100:3:20 Add dioctyl phthalate and polyvinyl butyral, and continue ball milling for 1 hour to obtain cast slurry;

[0069] Step 2, coating: coating the prepared casting slurry into a dielectric layer, the coating thickness is ≦8um;

[0070] Step 3, printing: the nickel metal inner pole 2 is printed onto the dielectric layer, and the dielectric layer is superimposed on each other, and then subjected to hydraulic pressure and slicing to produce a green body;

[0071] Step 4, degreasing: place the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com