Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

499 results about "Manganese(II) nitrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manganese(II) nitrate are the inorganic compounds with formula Mn(NO₃)₂(H₂O)ₙ. Each formula unit is composed of one Mn²⁺ cation and two NO₃⁻ anions and varying amounts of water. Most common is the tetrahydrate Mn(NO₃)₂·4H₂O, but mono- and hexahydrates are also known as well as the anhydrous compound. Some of these compounds are useful precursors to the oxides of manganese.

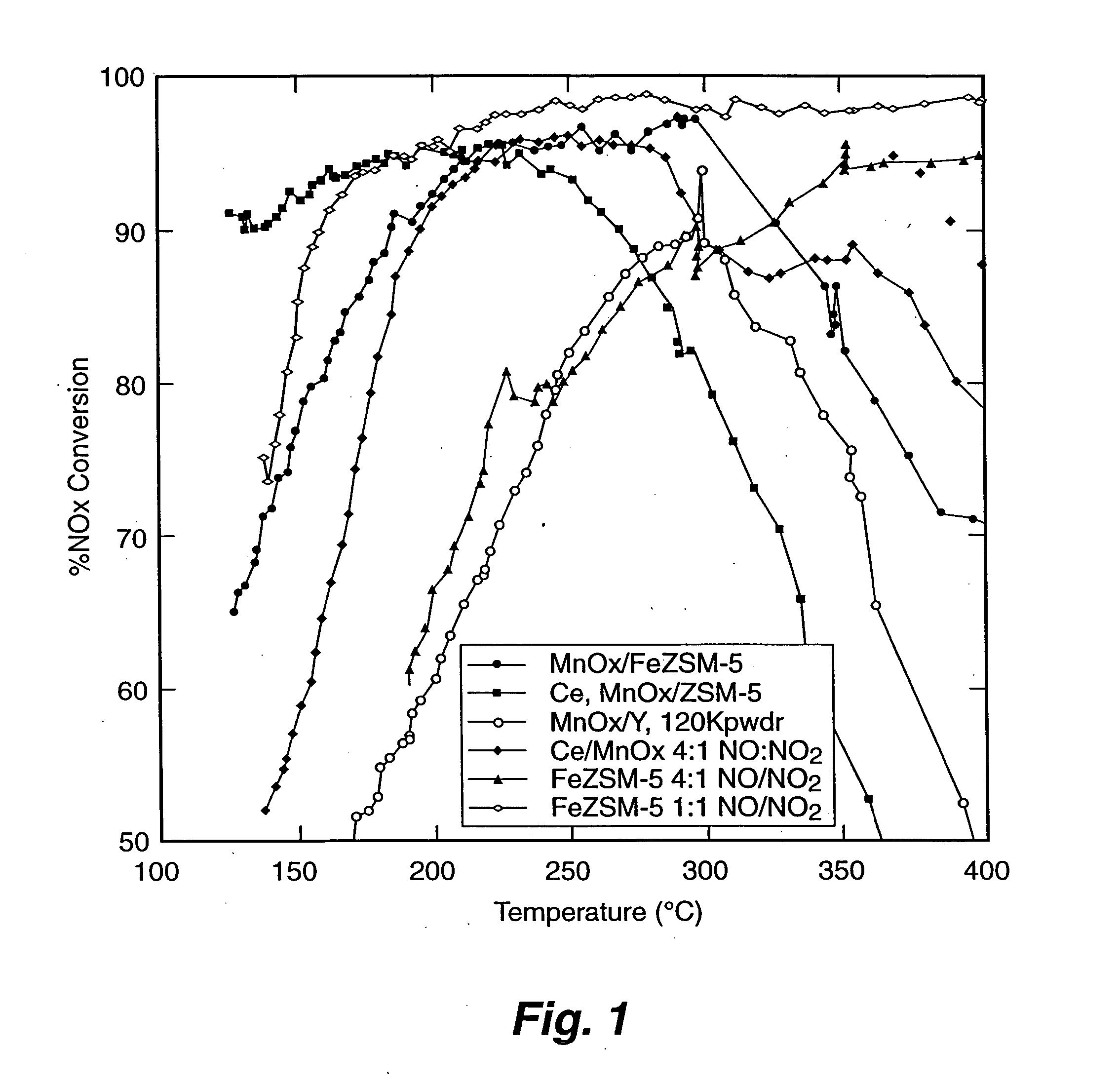

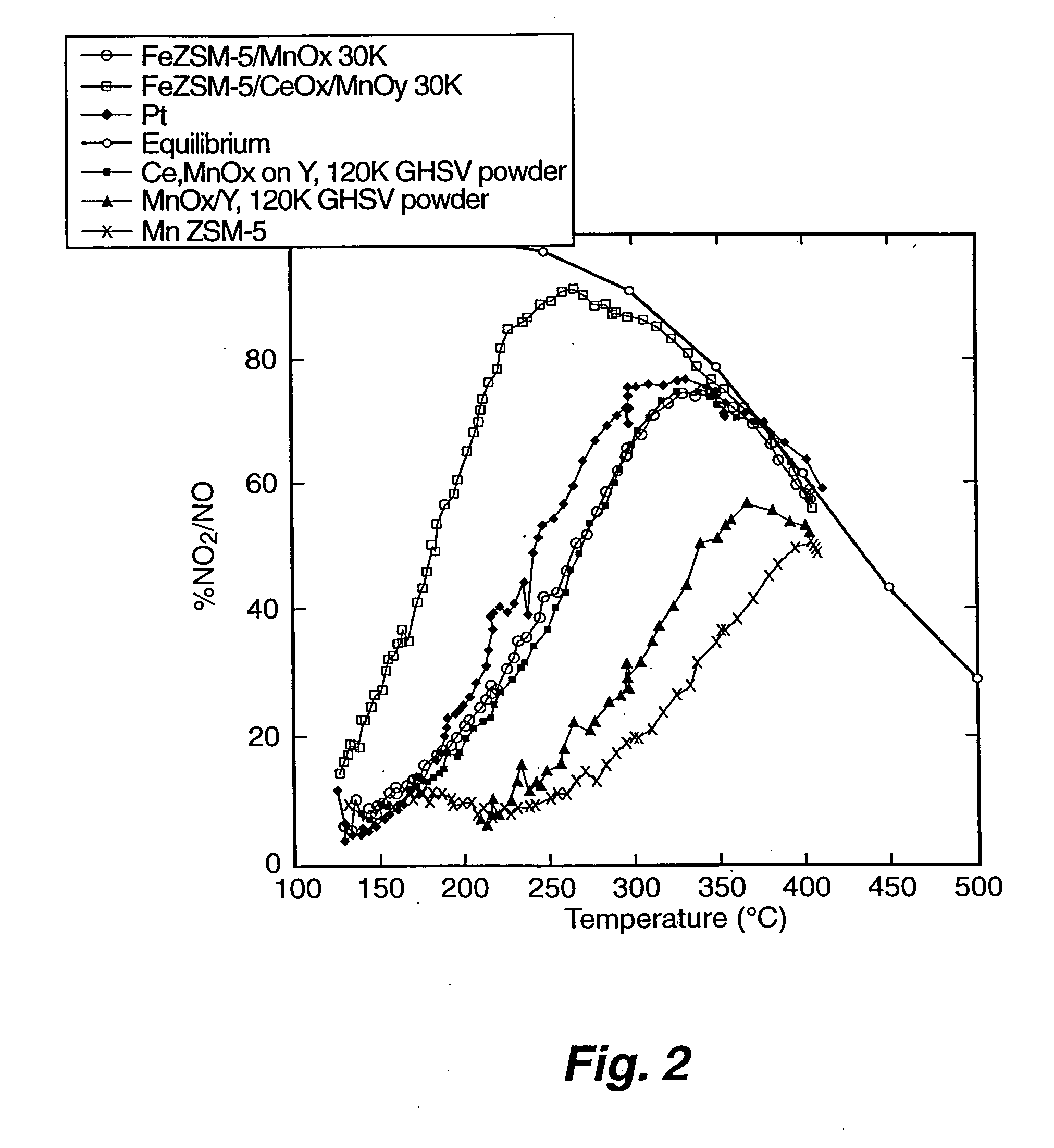

Catalyst and method for reduction of nitrogen oxides

InactiveUS20060029535A1Efficient workSelective catalytic reductionNitrous oxide captureNitrogen compoundsCerium nitrateIron salts

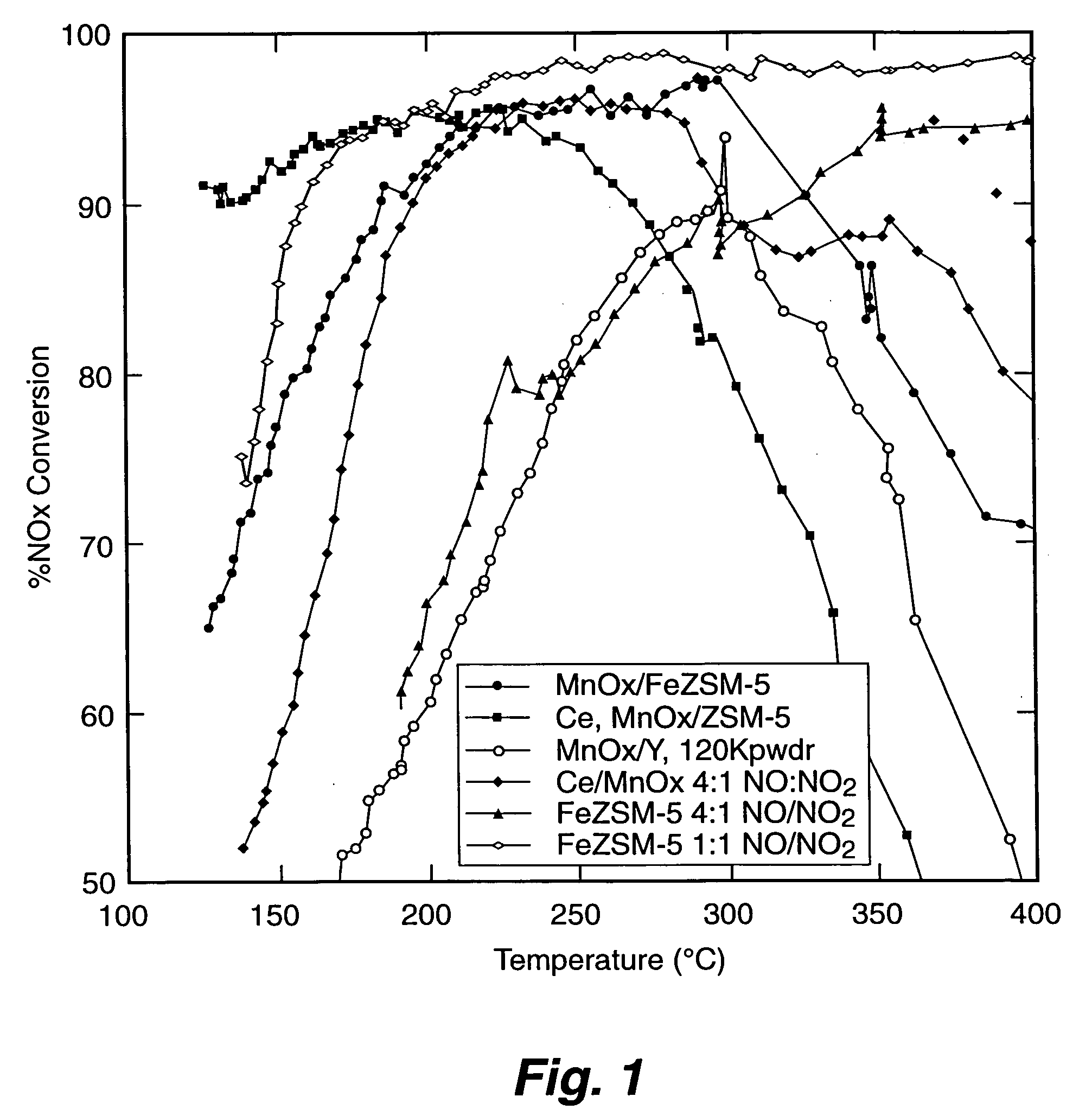

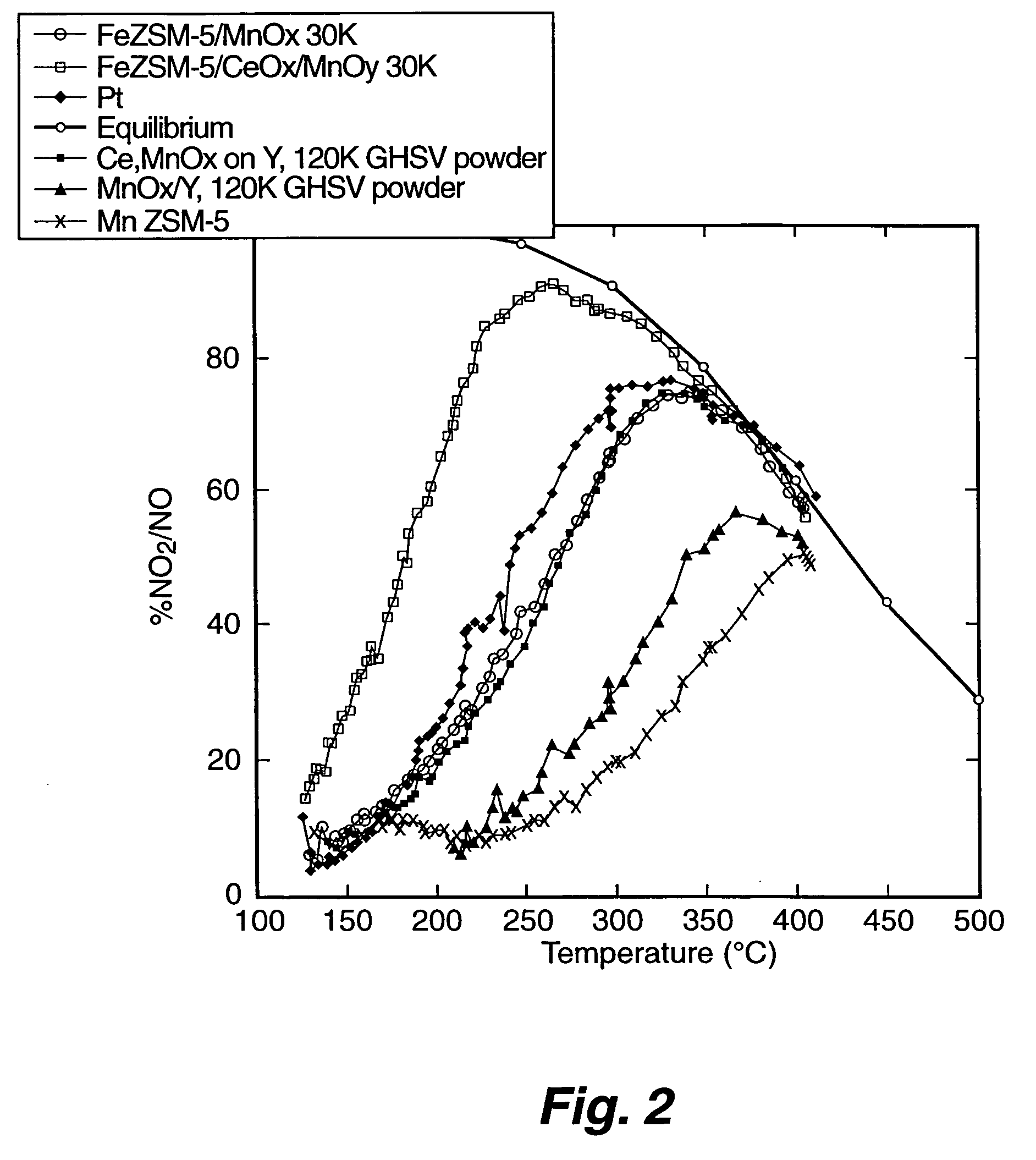

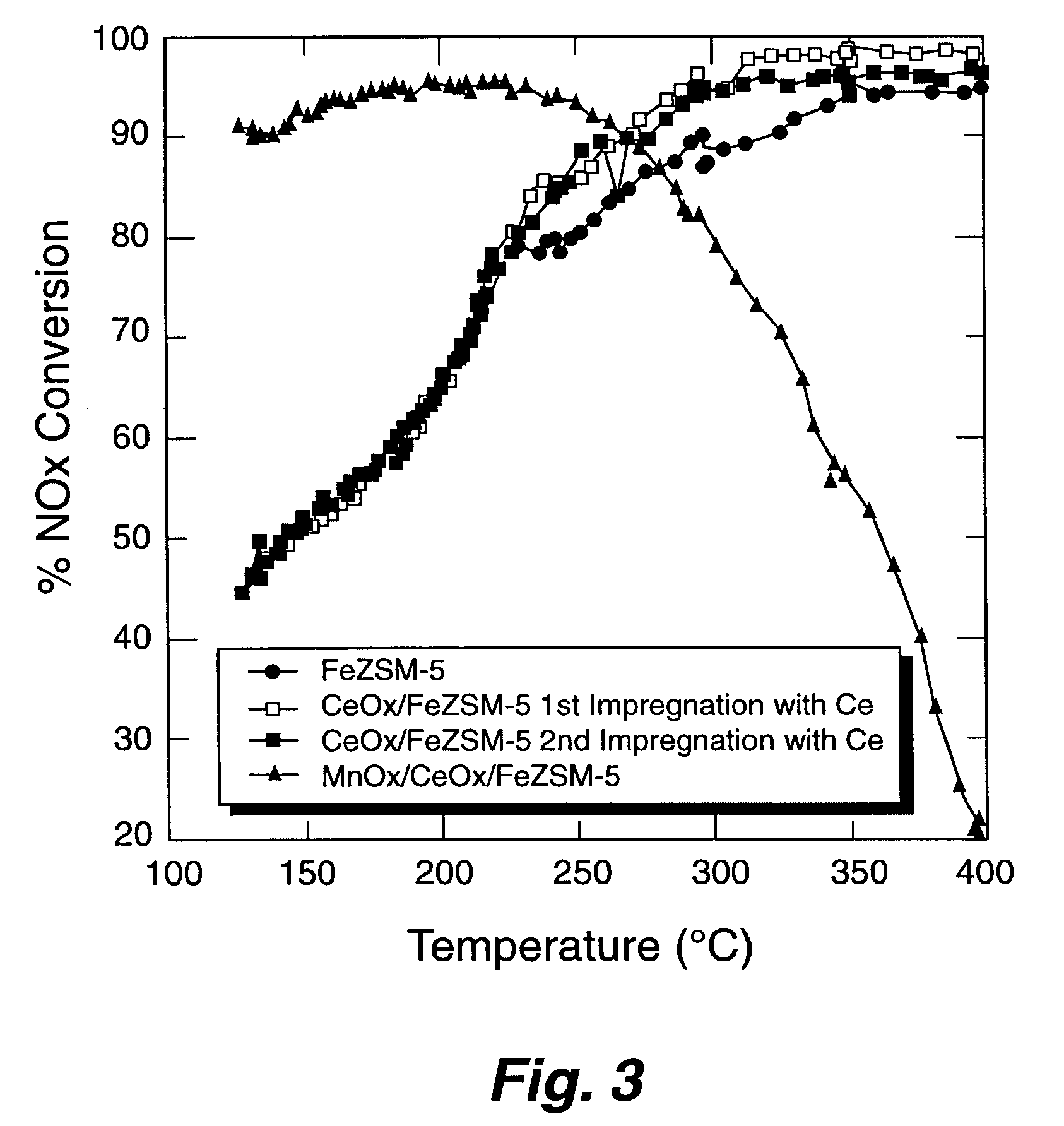

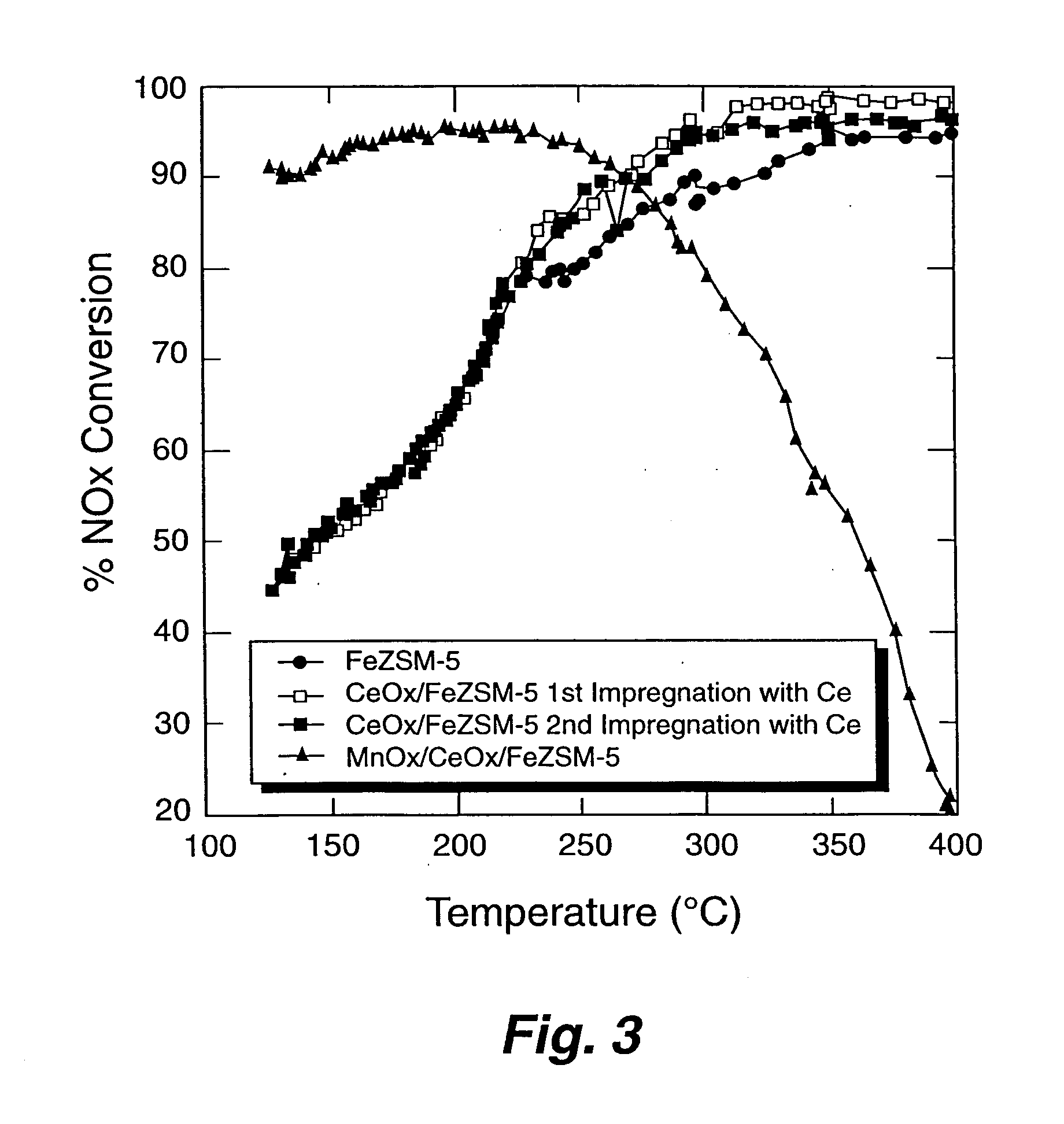

A Selective Catalytic Reduction (SCR) catalyst was prepared by slurry coating ZSM-5 zeolite onto a cordierite monolith, then subliming an iron salt onto the zeolite, calcining the monolith, and then dipping the monolith either into an aqueous solution of manganese nitrate and cerium nitrate and then calcining, or by similar treatment with separate solutions of manganese nitrate and cerium nitrate. The supported catalyst containing iron, manganese, and cerium showed 80 percent conversion at 113 degrees Celsius of a feed gas containing nitrogen oxides having 4 parts NO to one part NO2, about one equivalent ammonia, and excess oxygen; conversion improved to 94 percent at 147 degrees Celsius. N2O was not detected (detection limit: 0.6 percent N2O).

Owner:LOS ALAMOS NATIONAL SECURITY

Manganese cerium composite oxide catalyst, its production and use

InactiveCN101028595AStrong interactionHigh activityDispersed particle separationCatalyst activation/preparationNitrateManganese

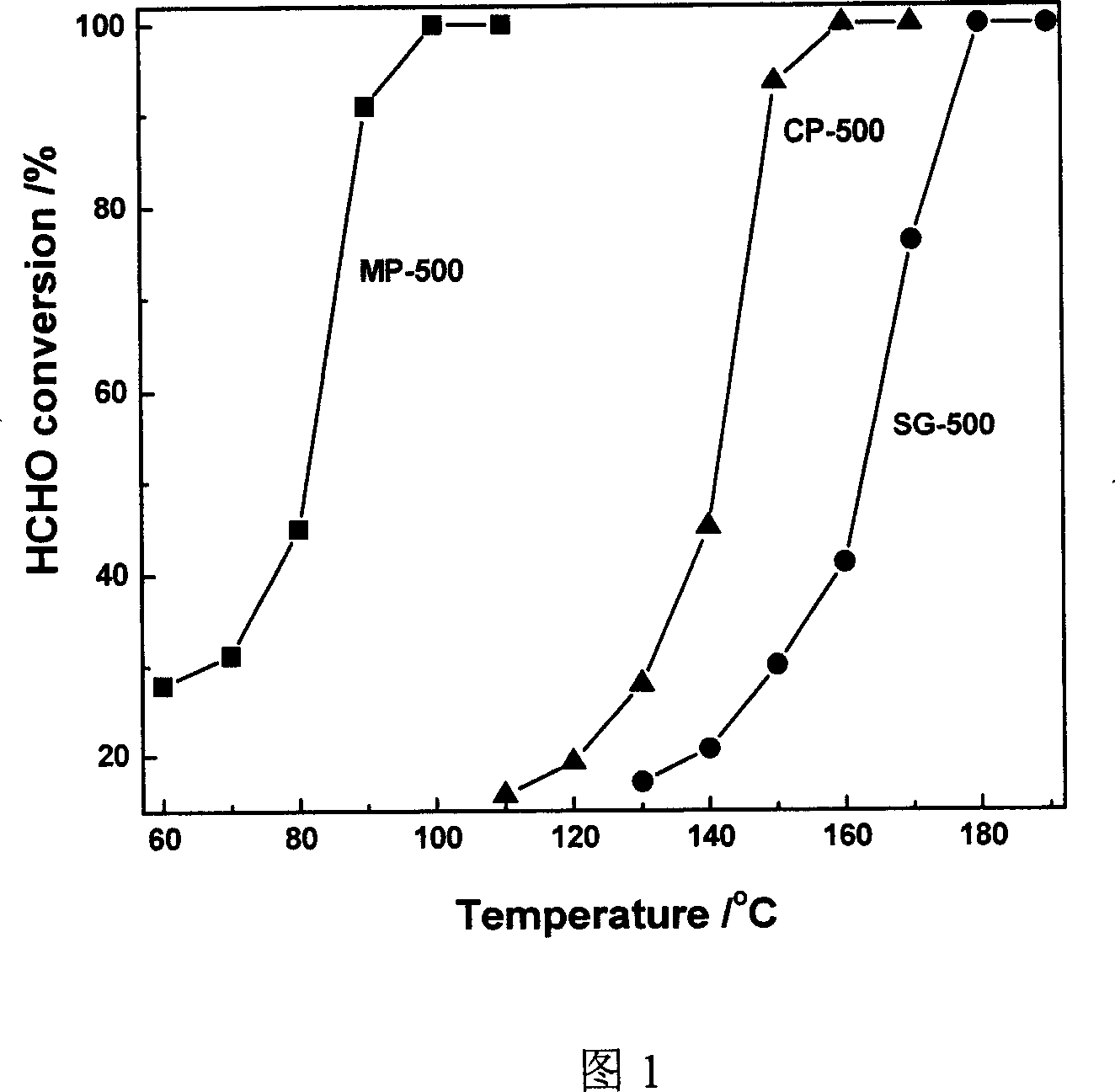

A composite Mn-Ce oxide catalyst for oxidizing the form-aldehyde into CO2 and H2O is prepared through adding soluble manganese nitrate in the solution of potassium permanganate and cerium ammonium nitrate while stirring, adding potassium hydroxide, stirring to obtain deposit, filtering, washing, drying at 80-120 deg.C and calcining.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Ordinary temp. parkerizing liquid

InactiveCN1401820AFast phosphatingFast combinationMetallic material coating processesSoftened waterManganese

An ordinary-temp phosphating liquid for the phosphate treatment of surface of iron and steel contains phosphoric acid (2-4 wt.%), zinc oxide (0.4-0.6 wt.%), zinc nitrate (0.5-1.5 wt.%), nickel nitrate (3-5 wt.%), manganese nitrate (2-4 wt.%), sodium borofluorate (0.2-1 wt.%), sodium chlorate (2-3 wt.%), citric acid (0.5-2 wt.%), and softened water (the rest). Its advantages are high stability, long film-forming time, and high film strength and resistance to corrosion.

Owner:CHINA NATIONAL HEAVY DUTY TRUCK GROUP

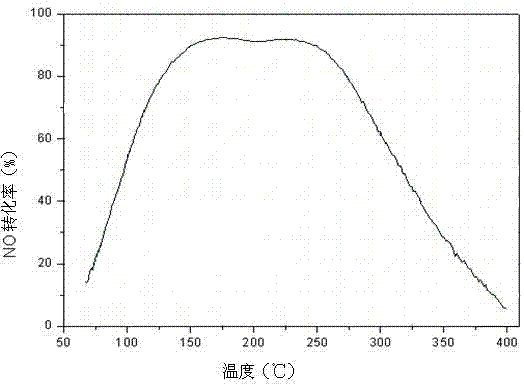

Cellular activated carbon-based denitration catalyst as well as preparation and application thereof

InactiveCN102078753ALarge specific surface areaWell-developed pore structureCatalyst carriersDispersed particle separationMANGANESE ACETATEActivated carbon

The invention discloses a catalyst for smoke denitration. The catalyst comprises the following components in percentage by weight: 77-96% of cellular activated carbon carrier, 1.3-6.5% of MnO and 2.4-18.8% of CeO2, wherein the mixture of the MnO and the CeO2 serves as an active component. The preparation method is as follows: mixing activated carbon with an organic binder, a forming auxiliary and water, carrying out vacuum extrusion molding, drying, and carbonizing, thus obtaining the cellular activated carbon carrier; and preparing the catalyst by using an isopknic impregnation method based on a mixed liquid of magnganous nitrate or manganese acetate and cerous nitrate, wherein the mixed liquid serves as an impregnation liquid. The cellular activated carbon-based denitration catalyst has the advantages of high specific surface area of cellular activated carbon, developed pore structure and small bed pressure drop, and when being used in smoke denitration, the cellular activated carbon-based denitration catalyst has high denitration activity at the wide temperature range of 80-200 DEG C.

Owner:EAST CHINA UNIV OF SCI & TECH

Ozonolysis catalyst and preparation method thereof

ActiveCN101757933ALow costSimple preparation processDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActive componentOzonolysis

The invention provides an ozonolysis catalyst which comprises metal foamed nickel and manganese or iron oxide, wherein the metal foamed nickel is adopted as a catalyst carrier and a catalyst auxiliary active component; and the manganese or iron oxide adopted as a main active component is coated on the surface of the foamed nickel by a soaking way. Obviously, the cost of preparation materials is low. The invention provides a preparation method of the ozonolysis catalyst, which comprises the following steps of: A. mixing an active component solution comprising manganese nitrate or ferric manganese nitrate; B. soaking the foamed nickel adopted as a carrier into the active component solution; and C. drying the soaked carrier and baking at a certain temperature. Accordingly, the preparation process is simple and convenient.

Owner:亚都科技集团有限公司

Catalyst and method for reduction of nitrogen oxides

InactiveUS20060159607A1Reduce the temperatureNitrous oxide captureNitrogen compoundsCerium nitrateIron salts

A Selective Catalytic Reduction (SCR) catalyst was prepared by slurry coating ZSM-5 zeolite onto a cordierite monolith, then subliming an iron salt onto the zeolite, calcining the monolith, and then dipping the monolith either into an aqueous solution of manganese nitrate and cerium nitrate and then calcining, or by similar treatment with separate solutions of manganese nitrate and cerium nitrate. The supported catalyst containing iron, manganese, and cerium showed 80 percent conversion at 113 degrees Celsius of a feed gas containing nitrogen oxides having 4 parts NO to one part NO2, about one equivalent ammonia, and excess oxygen; conversion improved to 94 percent at 147 degrees Celsius. N2O was not detected (detection limit: 0.6 percent N2O).

Owner:LOS ALAMOS NATIONAL SECURITY

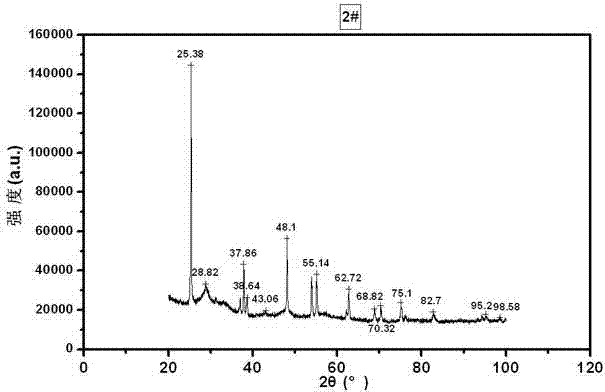

Iron-based low-temperature SCR denitration catalyst and preparation method thereof

InactiveCN104722307AObvious cost advantageLow costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAir atmosphereCerium nitrate

The invention provides an iron-based low-temperature SCR denitration catalyst and a preparation method thereof. Iron and cerium compounds are taken as active components, or iron, manganese and cerium compounds are taken as active components, titanium oxide is taken as a carrier, the molar ratio of iron, manganese and cerium is 1:(0.5-4):(0.5-1.5), and the molar ratio of iron and titanium oxide is 0.15-0.25. The preparation method comprises the steps of dissolving iron nitrate, manganese nitrate and cerium nitrate in deionized water, adding the titanium oxide, stirring intensely so as to mix the above compounds thoroughly, then performing ultrasonic mixing, putting the mixture into an oven for drying, calcining in an air atmosphere, and then grinding the mixture into powder. The iron-based low-temperature SCR denitration catalyst provided by the invention has an obvious advantage in cost, and meanwhile, the iron-based low-temperature SCR denitration catalyst has higher denitration efficiency under a medium and low temperature.

Owner:STATE GRID CORP OF CHINA +2

Microporous overcurrent ozone catalytic ceramic membrane for waste water deep treatment as well as preparation method and application method thereof

ActiveCN106745673AGuaranteed deep processing effectImprove mass transfer efficiencyWater treatment parameter controlWater contaminantsPolyethylene glycolDysprosium nitrate

The invention discloses a microporous overcurrent ozone catalytic ceramic membrane for waste water deep treatment as well as a preparation method and an application method thereof and belongs to the technical field of catalysts for waste water deep treatment. The catalytic ceramic membrane disclosed by the invention is prepared by the following steps: mixing pre-roasted and ground 400-600-mesh Al2O3 power with a catalytic component solution of dysprosium nitrate, molybdenum nitrate and manganous nitrate; and by taking hydroxypropyl methyl cellulose, polyethylene glycol and an aqueous solution of dysprosium nitrate, molybdenum nitrate and manganous nitrate as a forming assistant, pasting, mixing, extruding and forming, drying and vacuum-sintering the mixture to obtain the microporous overcurrent ozone catalytic ceramic membrane. The microporous overcurrent ozone catalytic ceramic membrane prepared by the invention creatively couples a microporous overcurrent with a catalytic ozonation technology, so that waste water passes through micron order ducts of the ceramic membrane at a relatively high flow rate by means of an external pressure different action, and therefore, the mass transfer efficiency of ozone and organic matter pollutants and the surface of the catalyst is effectively accelerated and meanwhile, the micron order ducts developing in the catalyst hugely increase the effective catalytic area of a catalytic module in a unit volume.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI

Catalyst module edge hardening liquid with activity

ActiveCN101474581AExtended service lifeIncrease usage intensityDispersed particle separationCatalyst activation/preparationAdditive ingredientAmmonium metavanadate

The invention discloses an active catalyst module edge hardening liquid, comprising the following ingredients: 30 to 50 weight percent of sodium silicate and active compositions, wherein the active compositions are one of or the mixture of two or more than two of ammonium metavanadate, green copperas and manganese nitrate, the ammonium metavanadate accounts for 0 to 1 weight percent in the hardening liquid, the manganese nitrate accounts for 0 to 5 weight percent in the hardening liquid, and the balance is water. The hardening liquid of the invention causes the end of a catalyst module to be much more antiabrasive, thereby greatly increasing the integral service life and the strength of the module; and under the same condition, the abrasion weight loss ratio of the catalyst module can be reduced by 20 percent, and the service life of the catalyst can be prolonged by more than 30 percent.

Owner:JIANGSU LONGYUAN CATALYST CO LTD

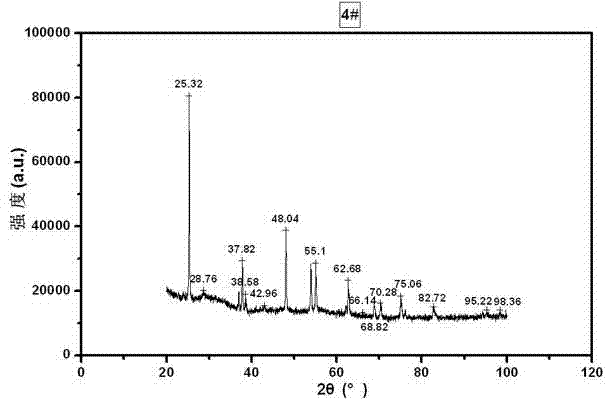

Low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3, and preparation method and application thereof

InactiveCN103433033AHigh activityImprove operating economyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAluminium nitrateCerium nitrate

The invention discloses a low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3, and a preparation method and an application thereof. The low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3 is composed of carriers and active components, wherein the carriers are TiO2 and Al2O3 and the active components are MnOx and CeO2. The molar ratio of Ce:Ti:Al:Mn in the low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3 is 0.2-0.4:1:1:0.4-1.2. The preparation method is that: the low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3 is prepared by taking titanium sulfate, aluminium nitrate, manganous nitrate and cerium nitrate as precursors and employing a coprecipitation method. The preparation cost is low, and the low-temperature denitration catalyst MnOx-CeO2-TiO2-Al2O3 has better denitration effect in a flue gas at a temperature of 150-300 DEG C.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

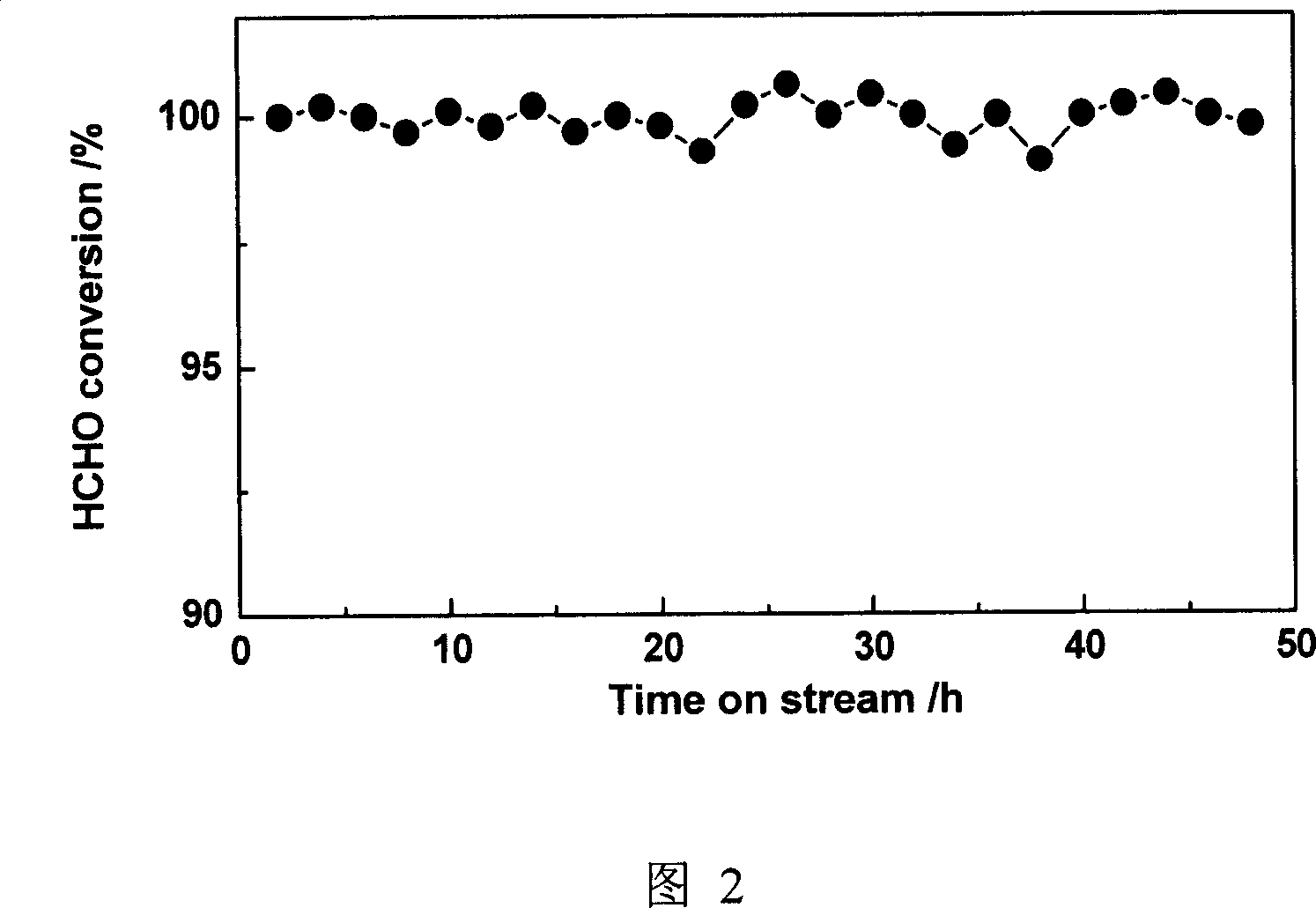

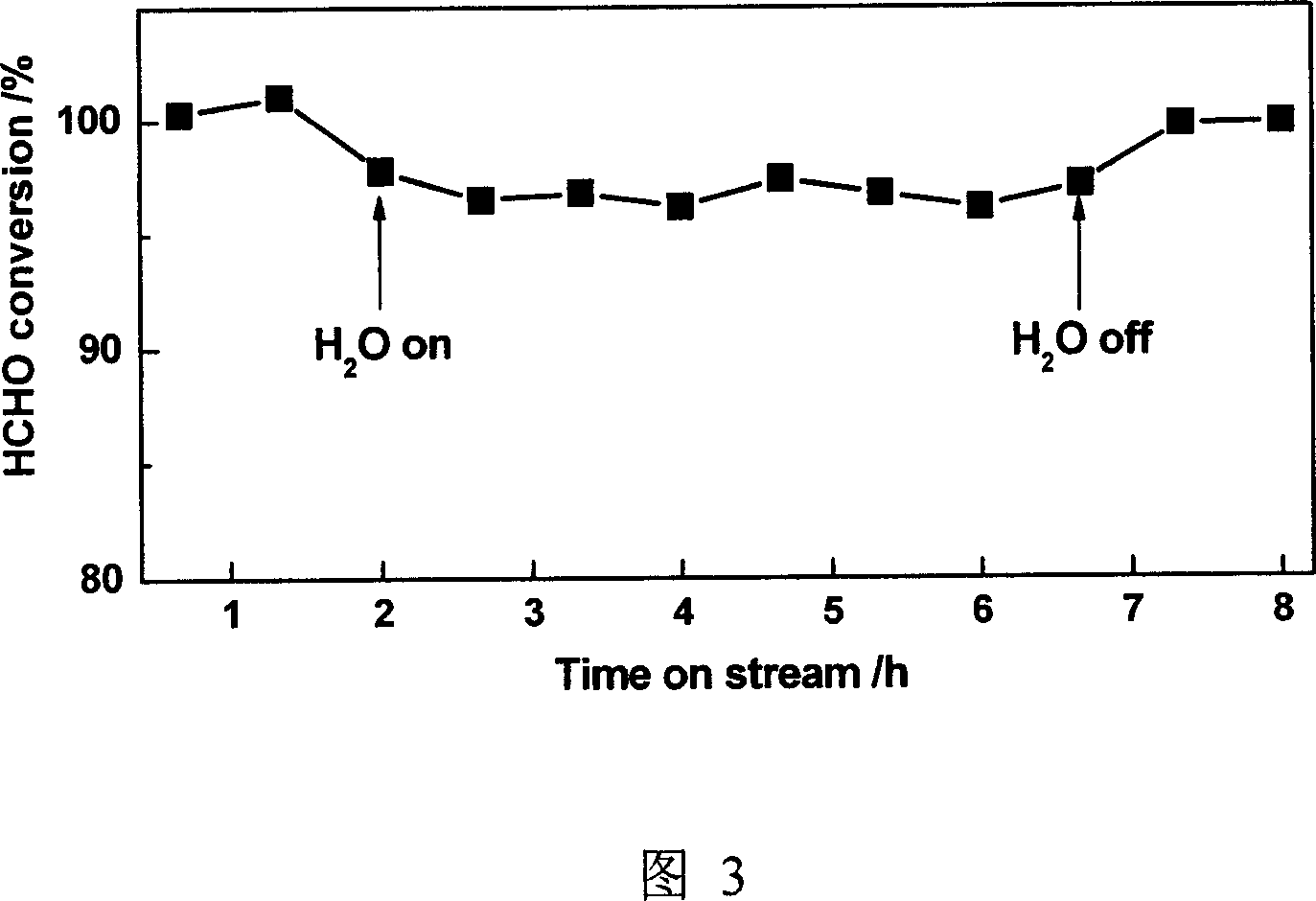

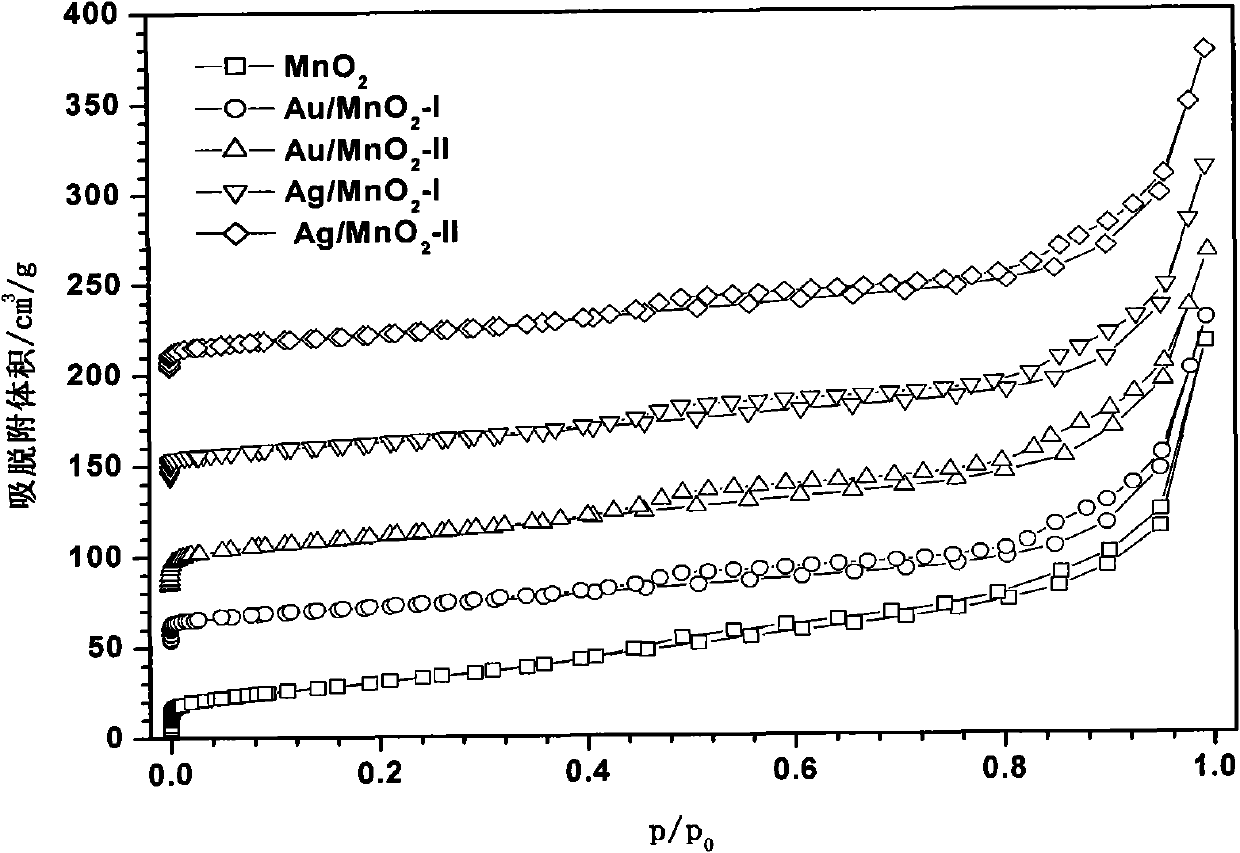

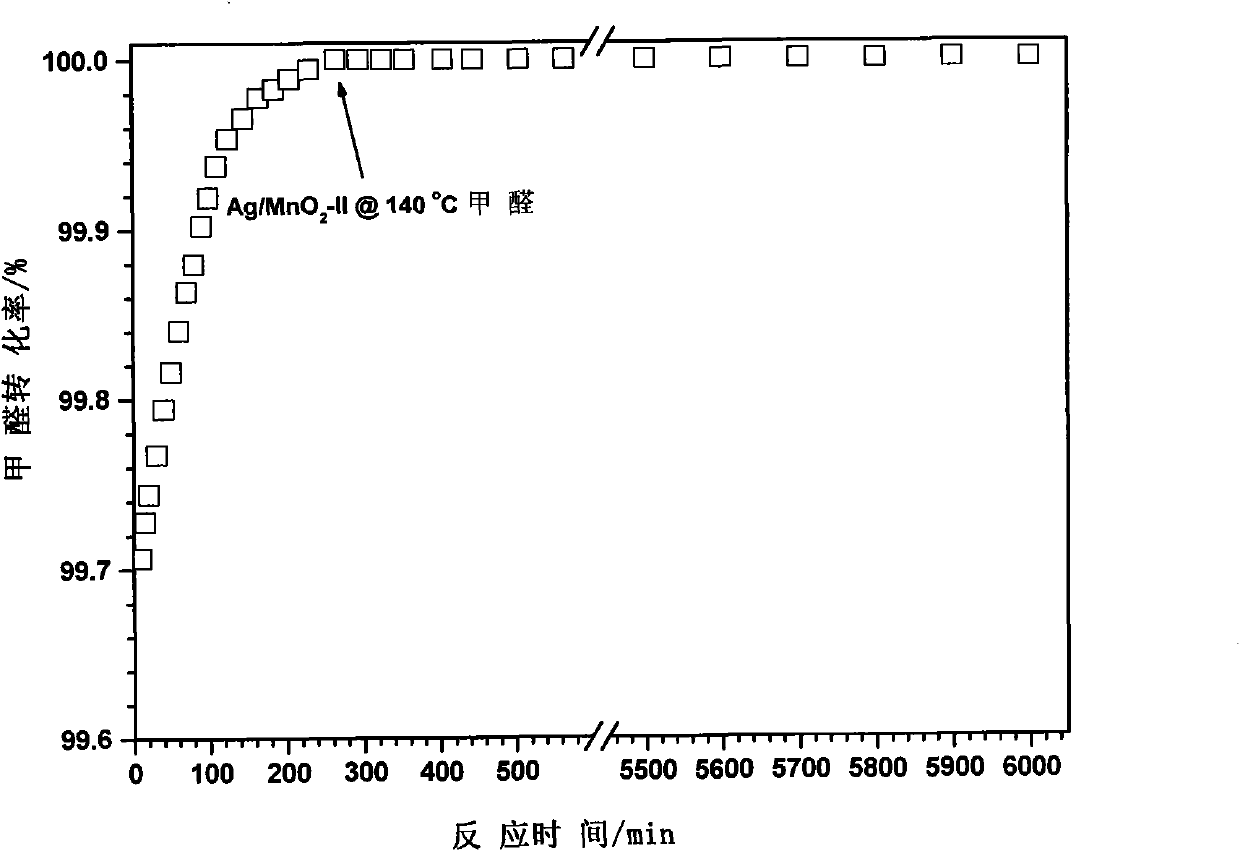

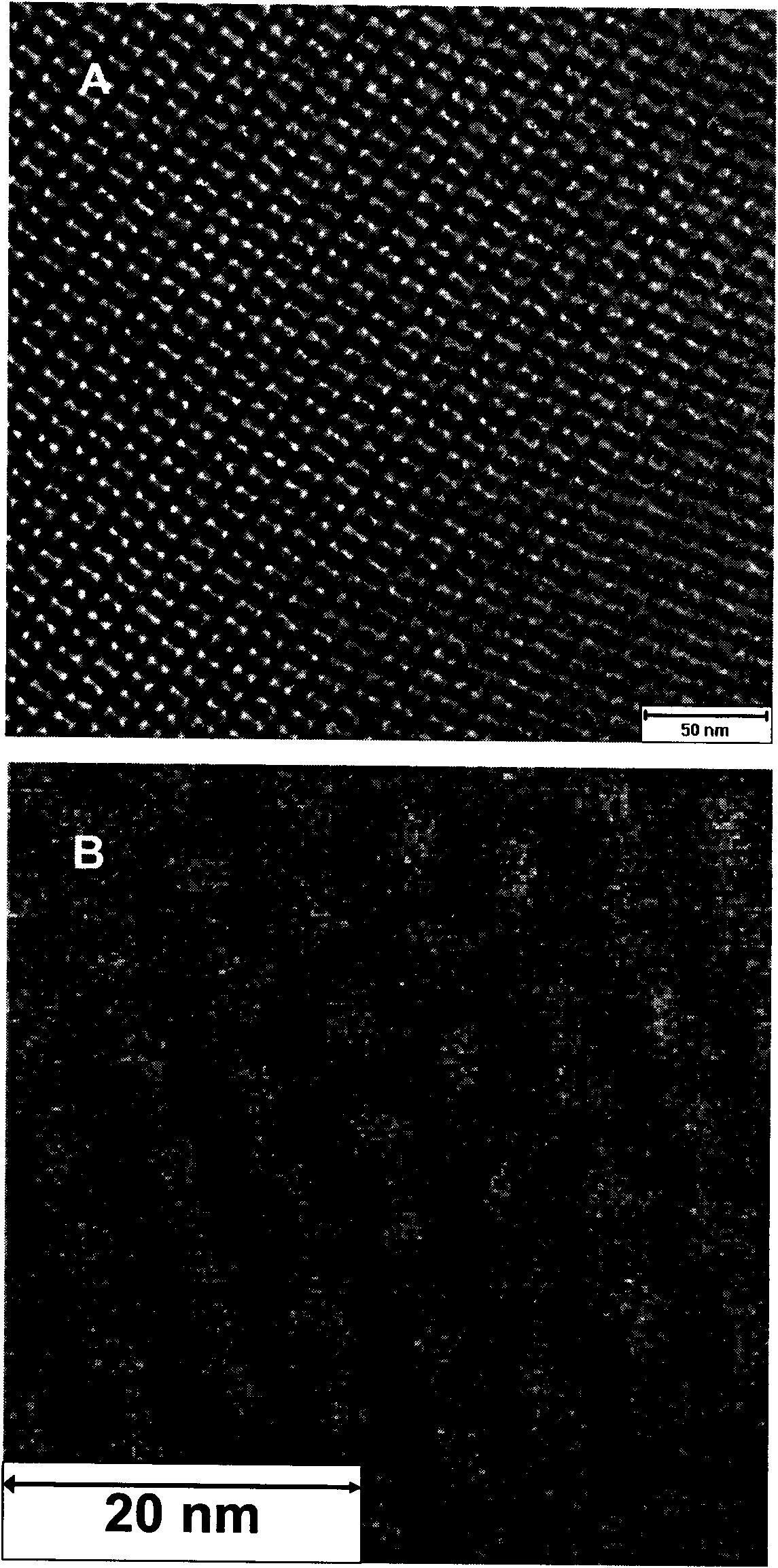

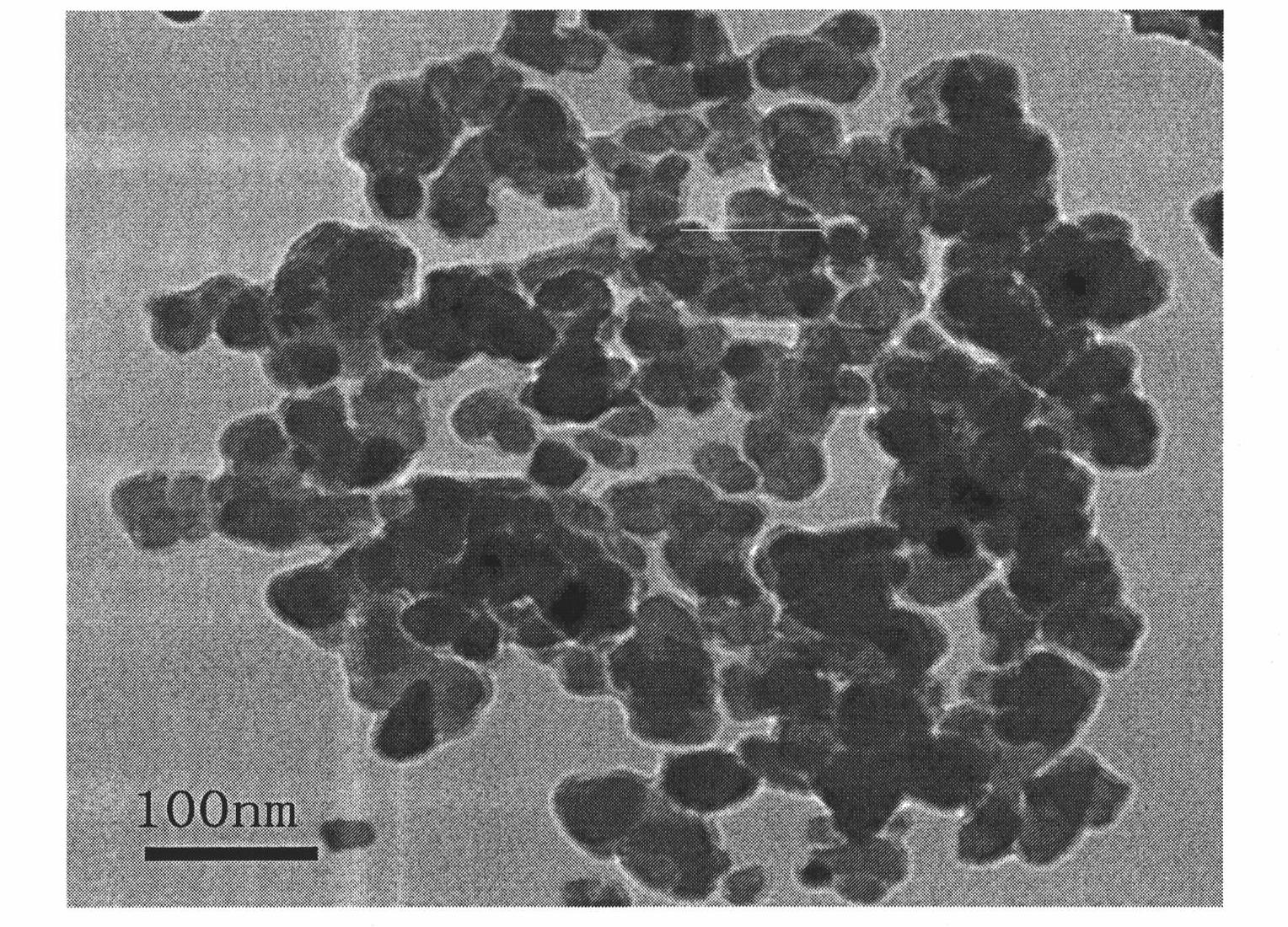

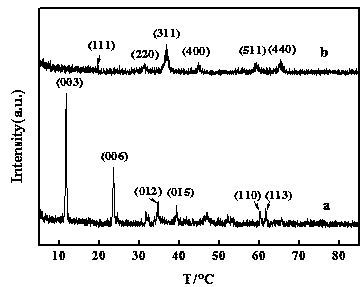

Preparation method and application of Au and Ag loaded mesoporous beta-MnO2 catalyst

InactiveCN101905159ANot much AuSmall amount of AgDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPollutionCatalytic combustion

The invention provides a preparation method and application of an Au and Ag loaded mesoporous beta-MnO2 catalyst. The preparation method comprises the steps of preparing beta-MnO2 with a three-dimensional ordered six-square hole structure, regular hole distribution (the most probable distribution ranges from 3.7 to 3.8nm) and high specific surface area (100-180m<2> / g) by the hard template method of dipping KIT-6 with manganous nitrate, drying, roasting, dissolving, washing and drying; and then loading Au or Ag on the beta-MnO2 to prepare the catalyst. The catalyst is suitable for catalytic combustion removal of formaldehyde with high airspeed (60000h<-1> to 100000h<-1>) and low concentricity (500ppm-1000ppm), can completely convert the formaldehyde into non-poisonous materials of CO2 and H2O at 140 degrees centigrade to 150 degrees centigrade and keeps the elimination ratio of 100% within 100h. The prepared catalyst has the advantages of low-cost materials, less load of noble metals, simple preparation process, strong practicability, complete elimination of formaldehyde, low temperature, high efficiency, no secondary pollution, and the like.

Owner:BEIJING UNIV OF TECH

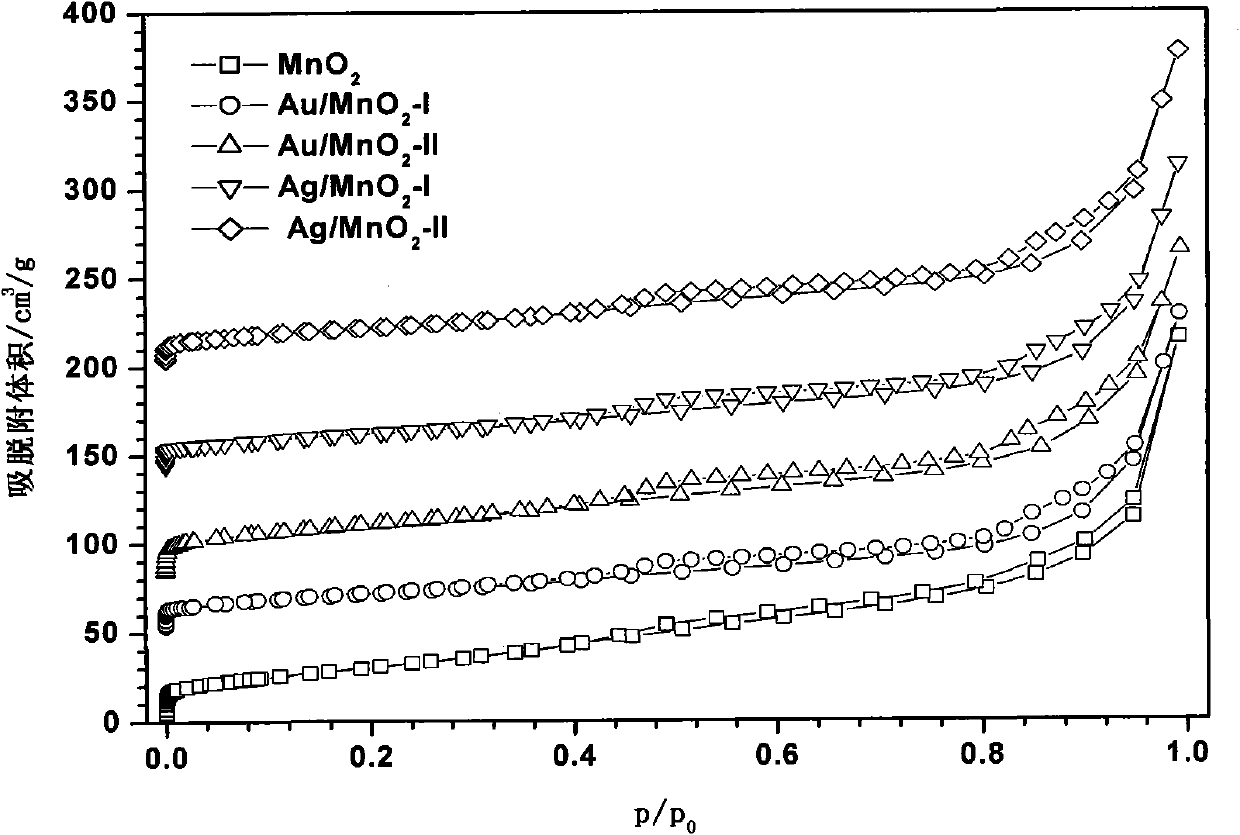

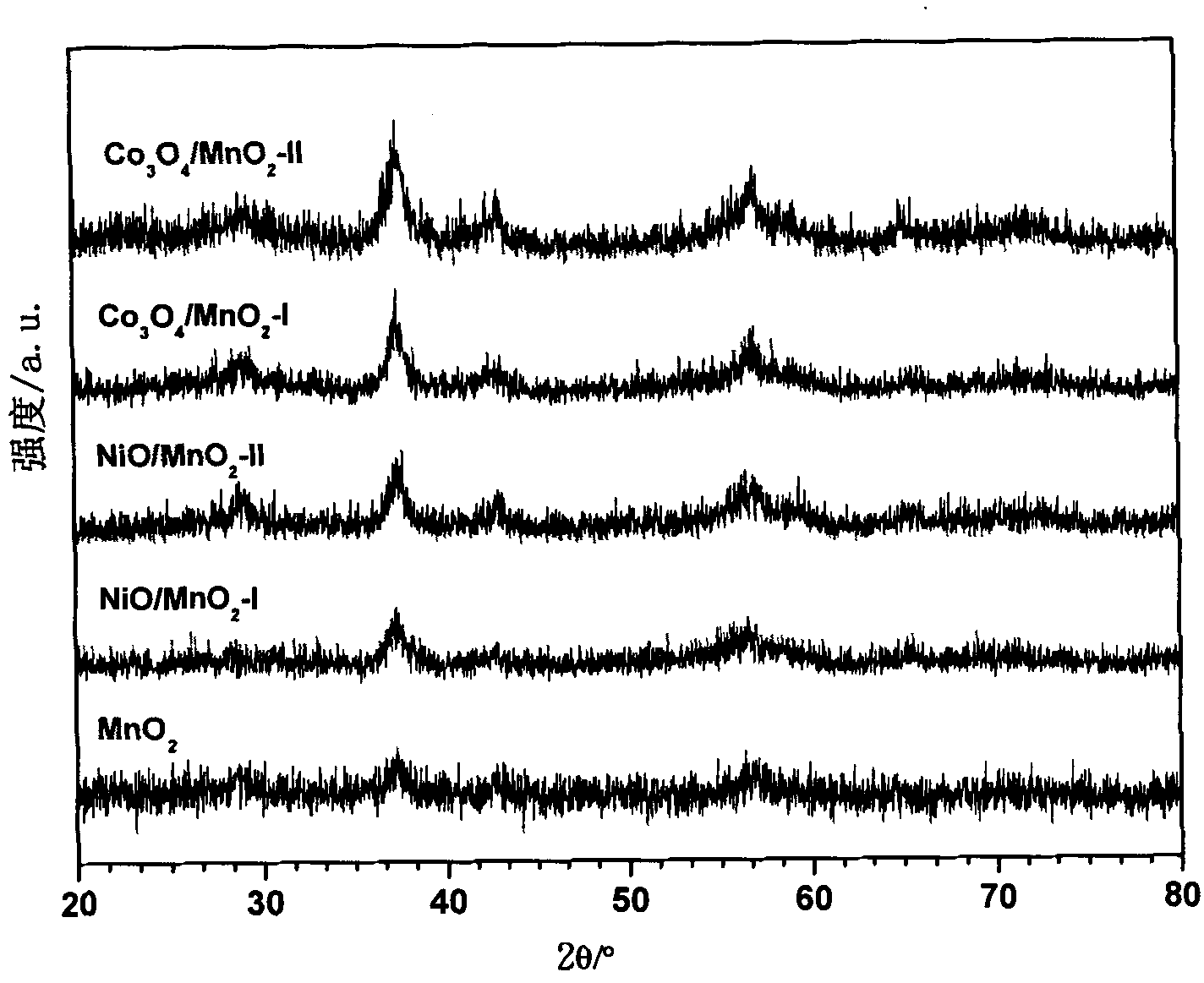

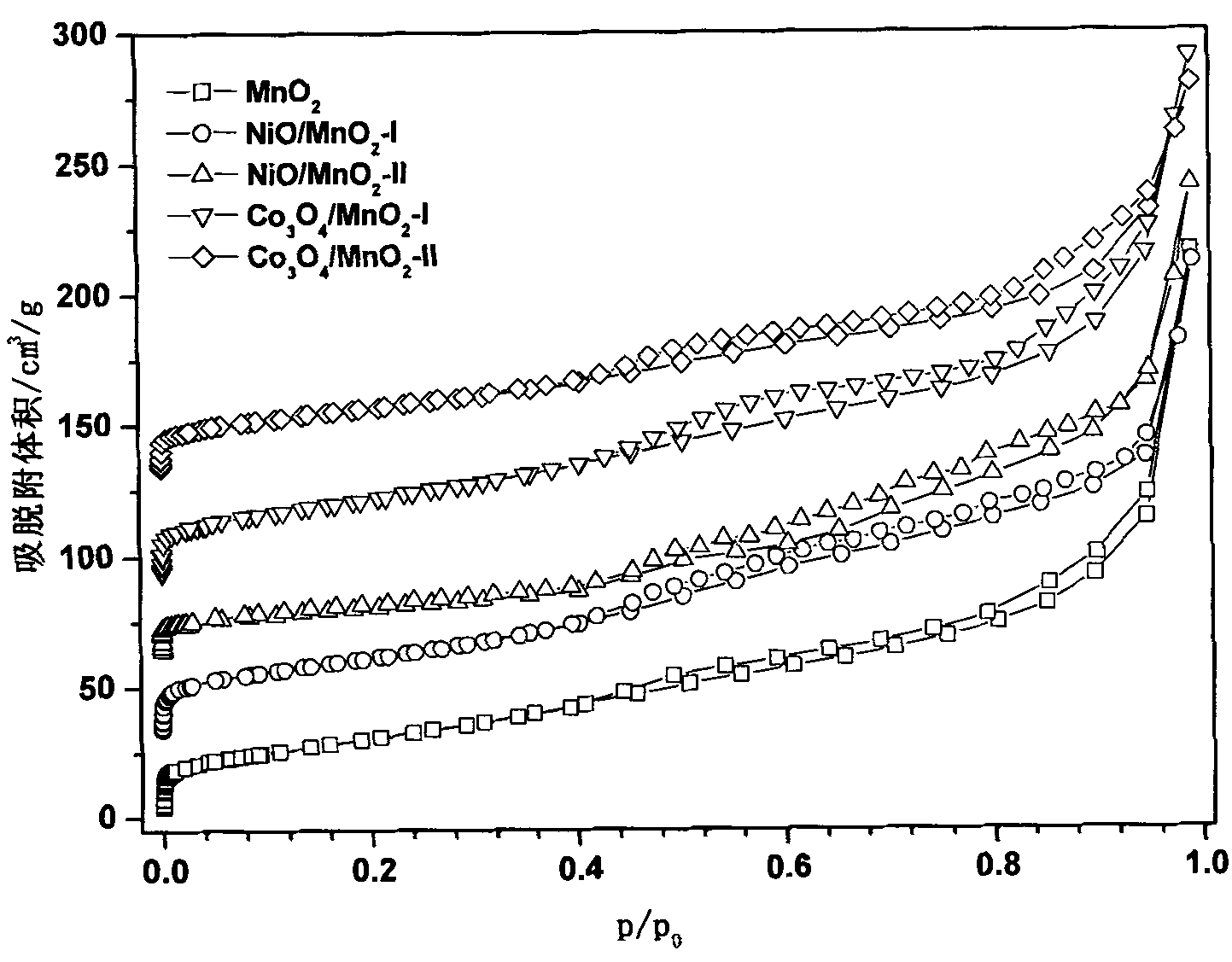

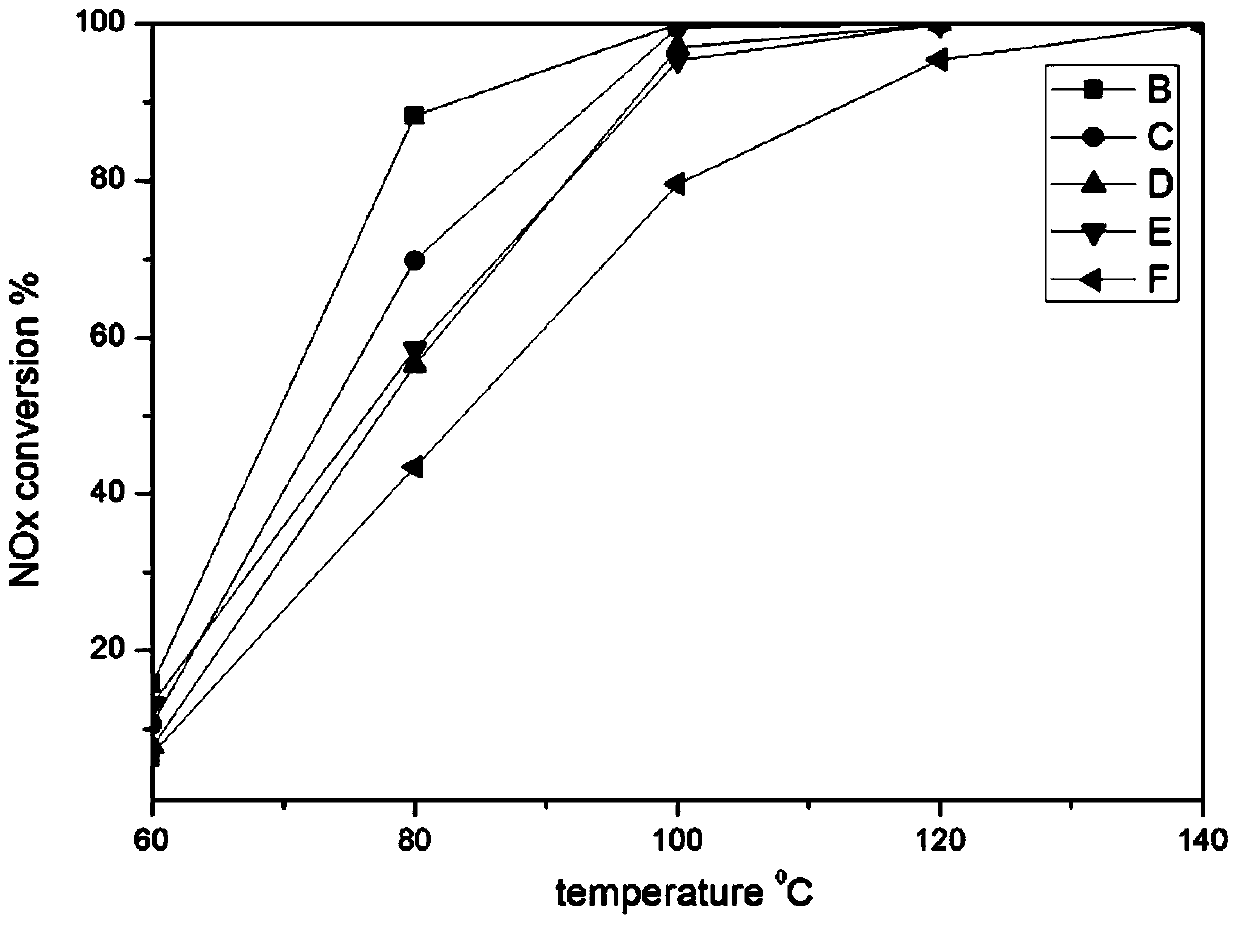

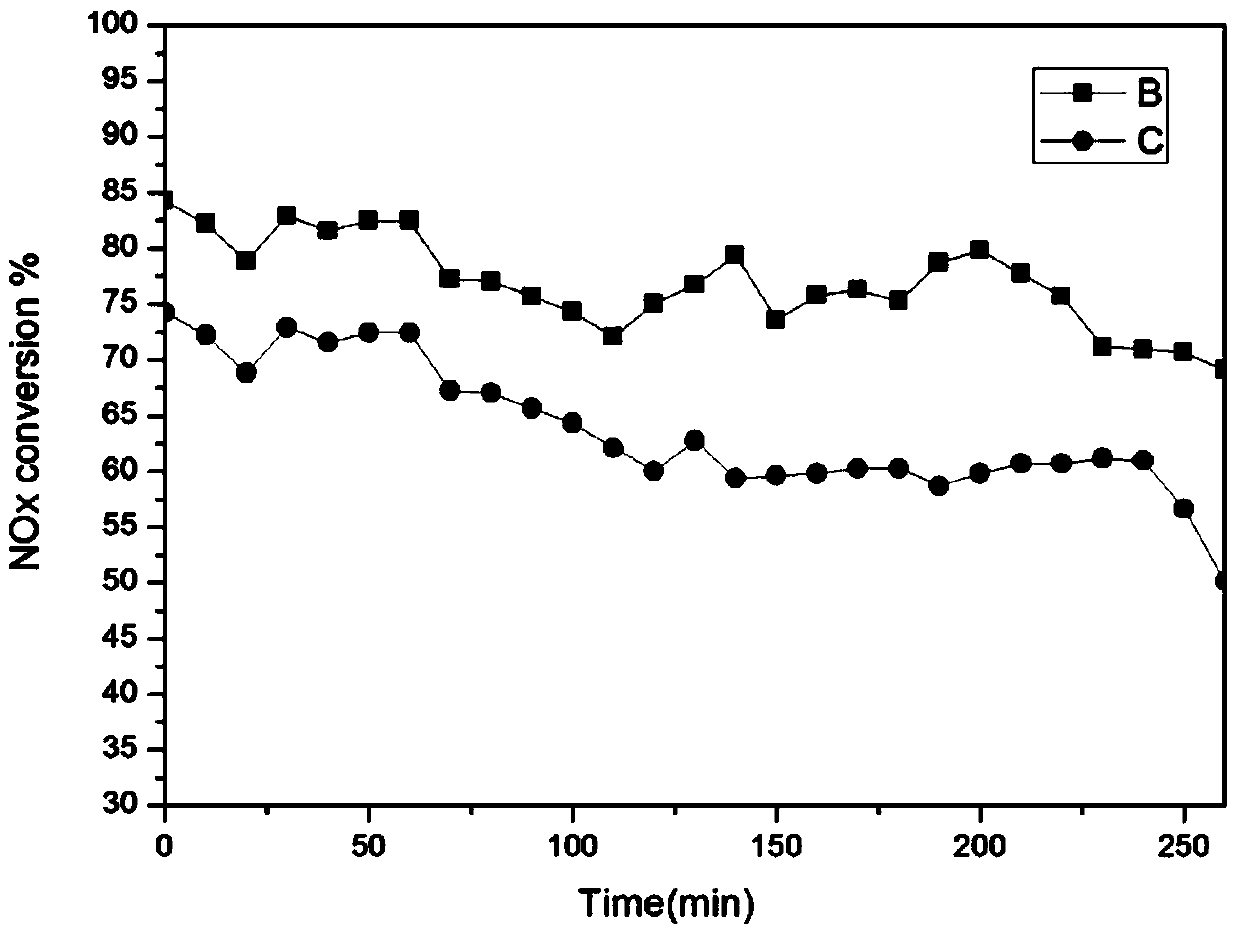

Preparation method and application of mesoporous Co3O4/ Beta-MnO2 or NiO/ Beta-MnO2 catalysts

InactiveCN101912784AHigh and low temperature catalytic combustion to eliminate activitySimple ingredientsDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAir velocityCatalytic combustion

This invention provides a preparation method and application of mesoporous Co3O4 / Beta-MnO2 or NiO / Beta-MnO2 catalysts. The mesoporous Co3O4 / Beta-MnO2 and NiO / Beta-MnO2 catalysts having an ordered 3D-hexagonal structure, a specified aperture of 3.7-3.8 nm and a high specific surface area of 100-200 sq.m / g are prepared by a hard template method, which comprises the following steps of: immersing KIT-6 into mixed solution of manganous nitrate and cobalt nitrate or mixed solution of manganous nitrate and nickel nitrate, drying, roasting, dissolving, washing and drying. The catalysts of the invention are applicable to the elimination of formaldehyde with a high air velocity of 60,000 to 100,000 h(-1) and at the low concentration of 500 to 1,000 ppm by catalytic combustion. At the temperature of 130 to 140 DEG C, the formaldehyde can be converted into nonpoisonous CO2 and H2O with a conversion rate of 100 percent, and 100 percent of elimination rate of formaldehyde can be kept within 100 hours.

Owner:BEIJING UNIV OF TECH

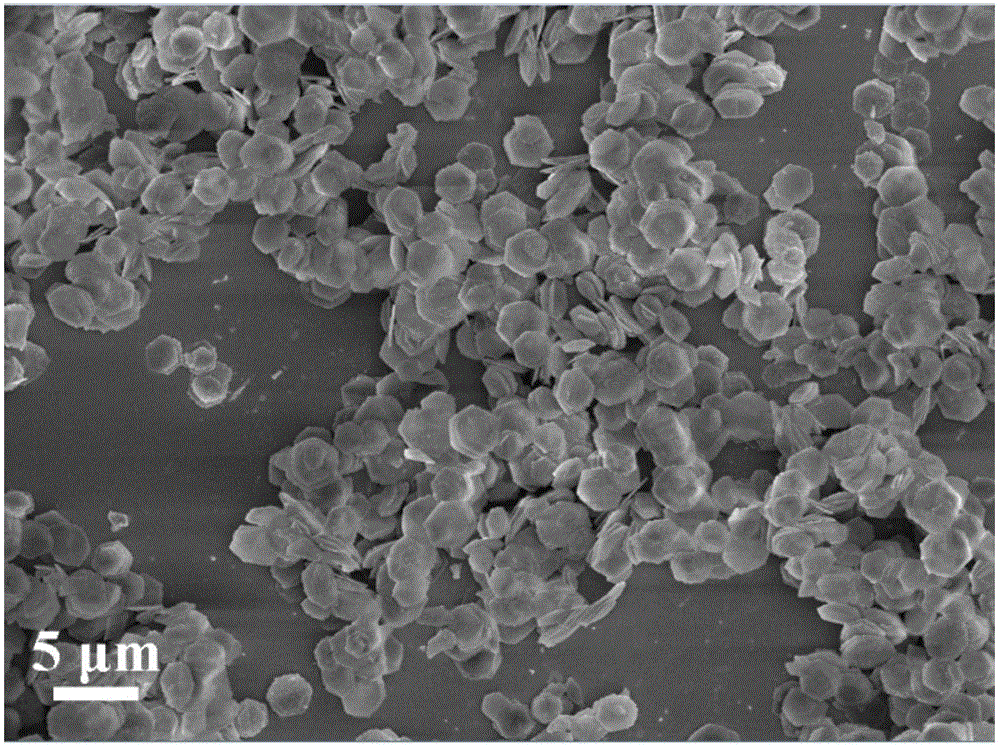

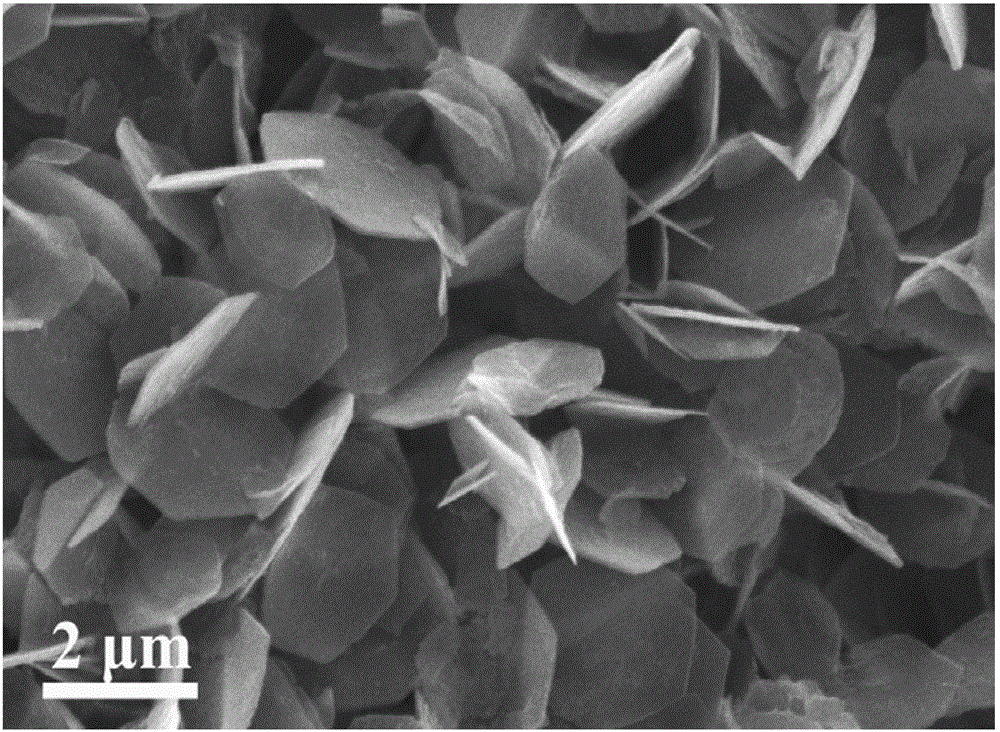

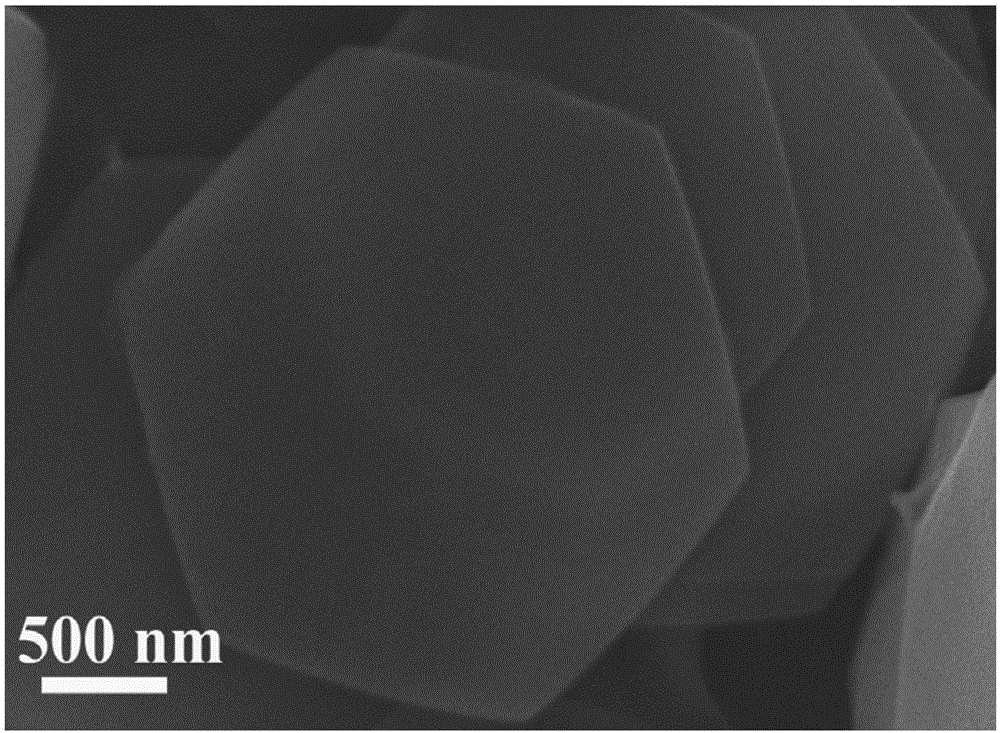

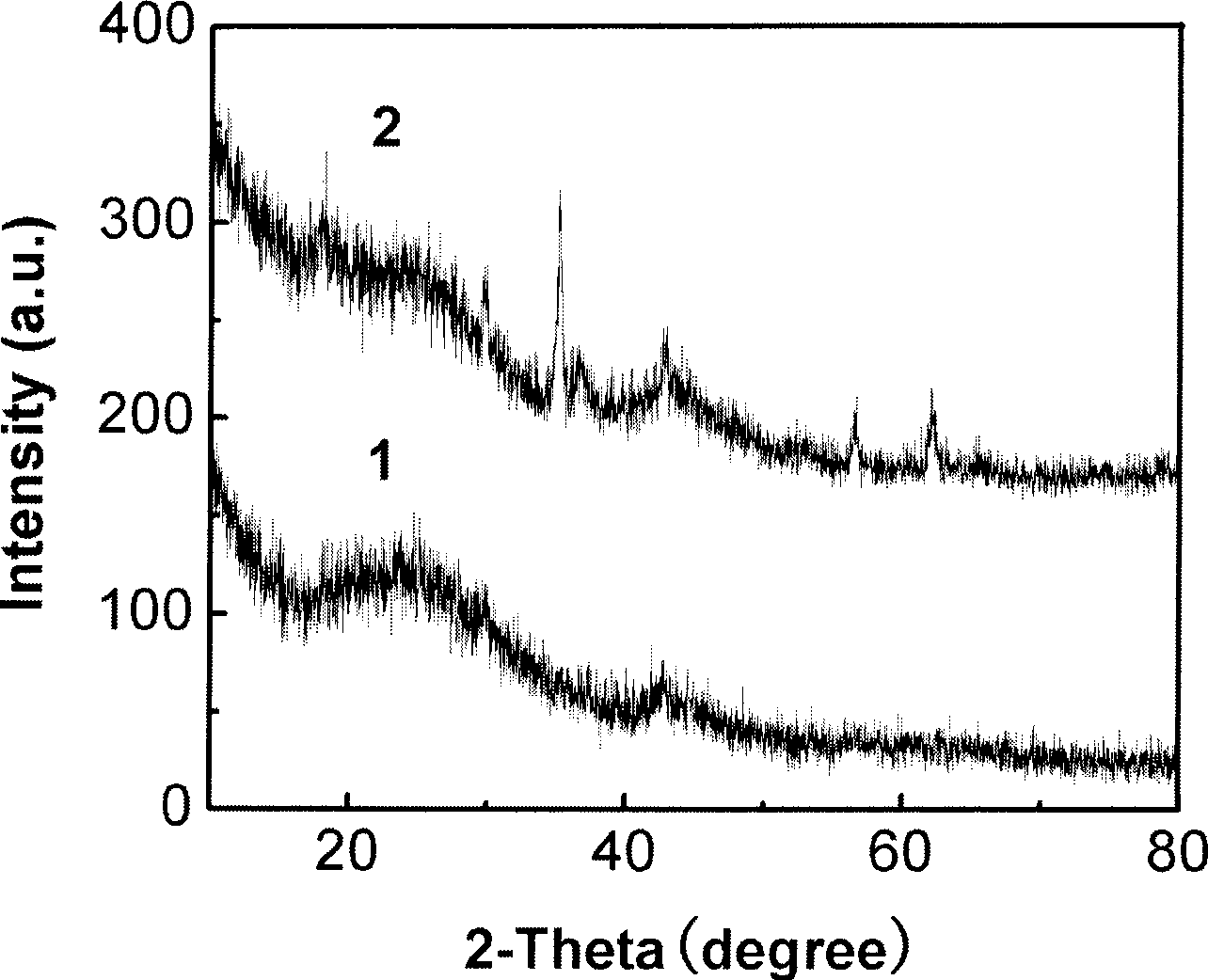

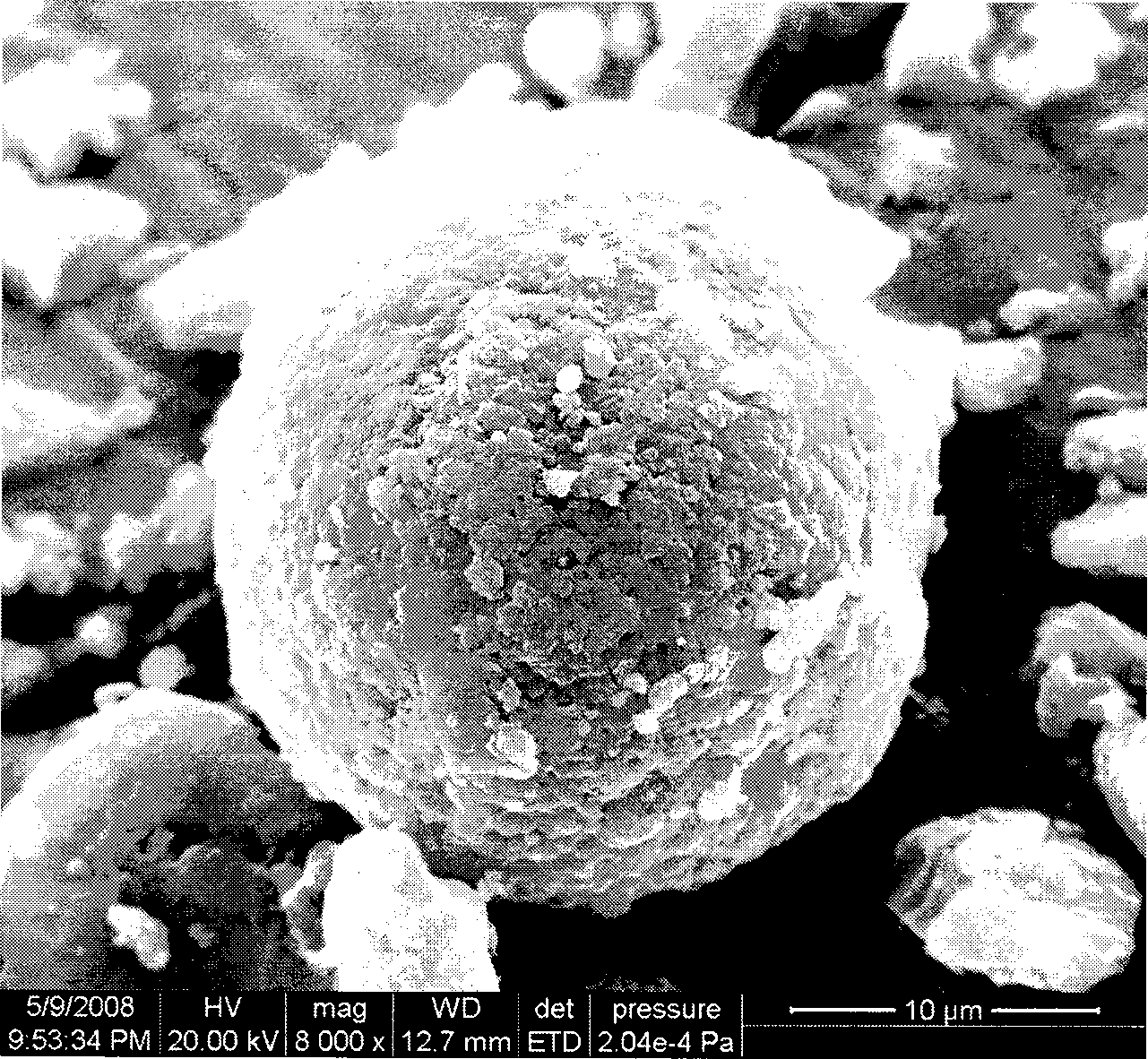

Low-temperature SCR denitration catalyst with titanium-based core-shell structure and preparation method of catalyst

InactiveCN104190408AGood dispersionImprove stabilityMaterial nanotechnologyDispersed particle separationPtru catalystActive agent

The invention provides a low-temperature SCR (Selective Catalytic Reduction) denitration catalyst with a titanium-based core-shell structure and a preparation method of the catalyst. The titanium-based core-shell structure of the catalyst is formed by use of composite nanoparticles MnOx-CeO2 as the core and TiO2 as the shell and the size range of the catalyst is from 20nm to 200nm, wherein the molar ratio of the three elements Mn, Ce and Ti is (0.05-1): (0.05-1): 1. The preparation method of the catalyst mainly comprises the following steps: (1) mixing cerous nitrate with a manganese nitrate solution, dropwise adding a sodium hydroxide solution and then shifting the mixed solution to a hydrothermal kettle, and carrying out reacting, centrifuging, washing, drying and calcining to obtain the nanoparticles MnOx-CeO2; (2) preparing the nanoparticles with the core-shell structure in a reversed-phase microemulsion with CTAB (Cetyltrimethyl Ammonium Bromide) as a surfactant, n-amyl alcohol as a cosurfactant and cyclohexane as an oil phase. The low-temperature SCR denitration catalyst with a titanium-based core-shell structure has the advantages that the titanium-based core-shell structure is constructed for the first time, the center of the catalyst is protected by use of the TiO2 shell, and the probability that the active center contacts with SO2 in flue gas is reduced, and therefore, the active center is prevented from irreversible poisoning caused by erosion of SO2.

Owner:NANJING NORMAL UNIVERSITY +1

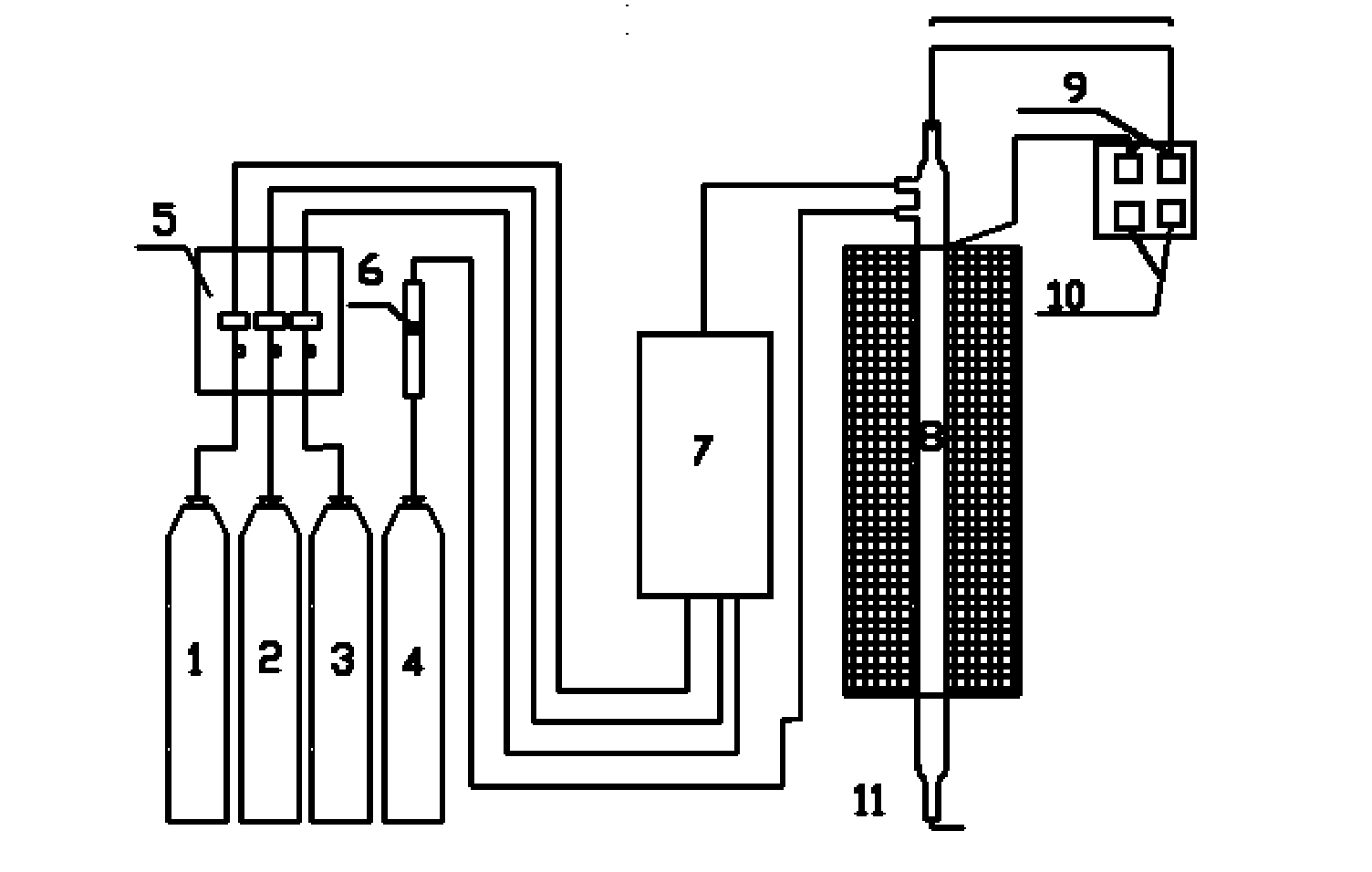

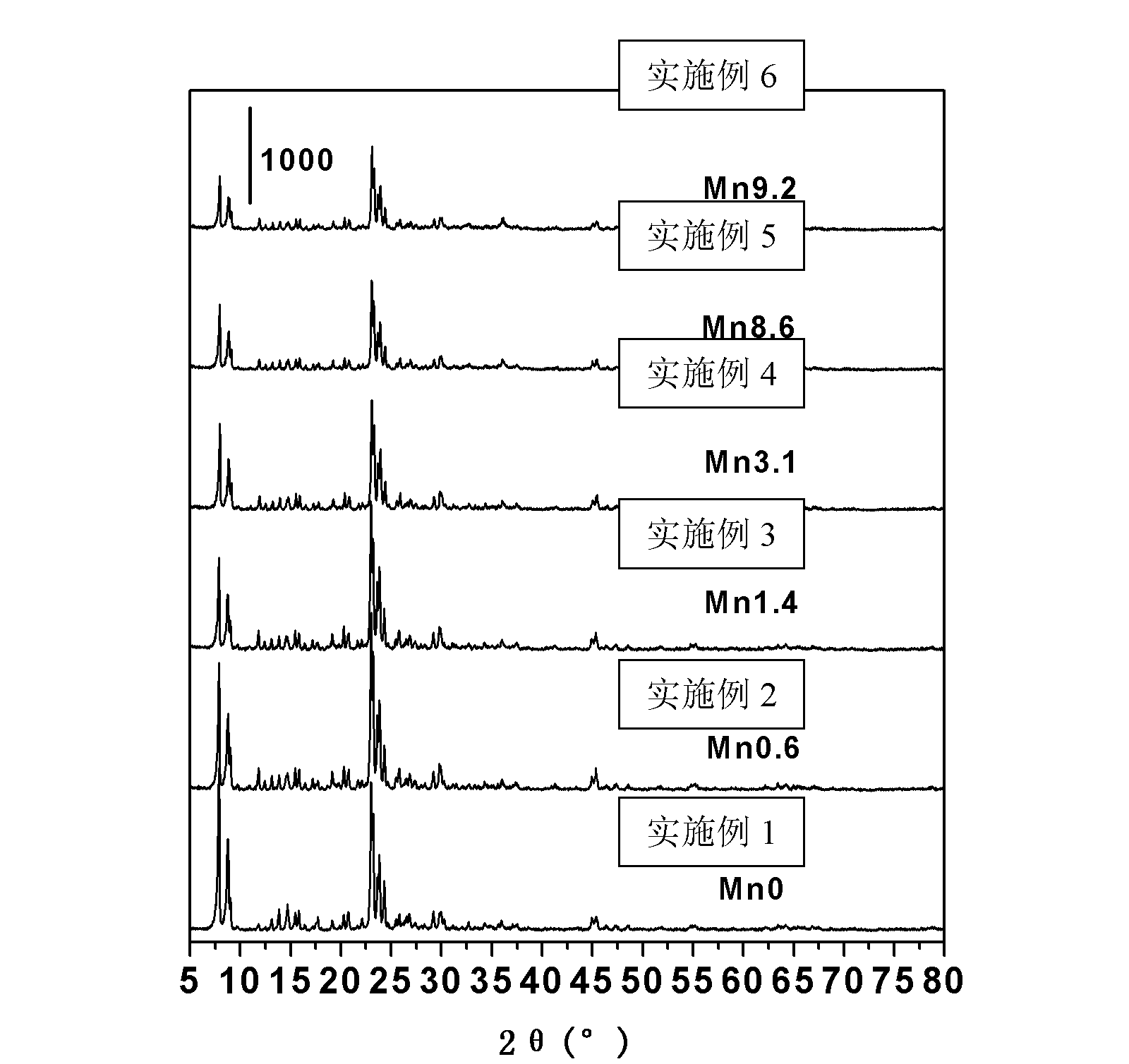

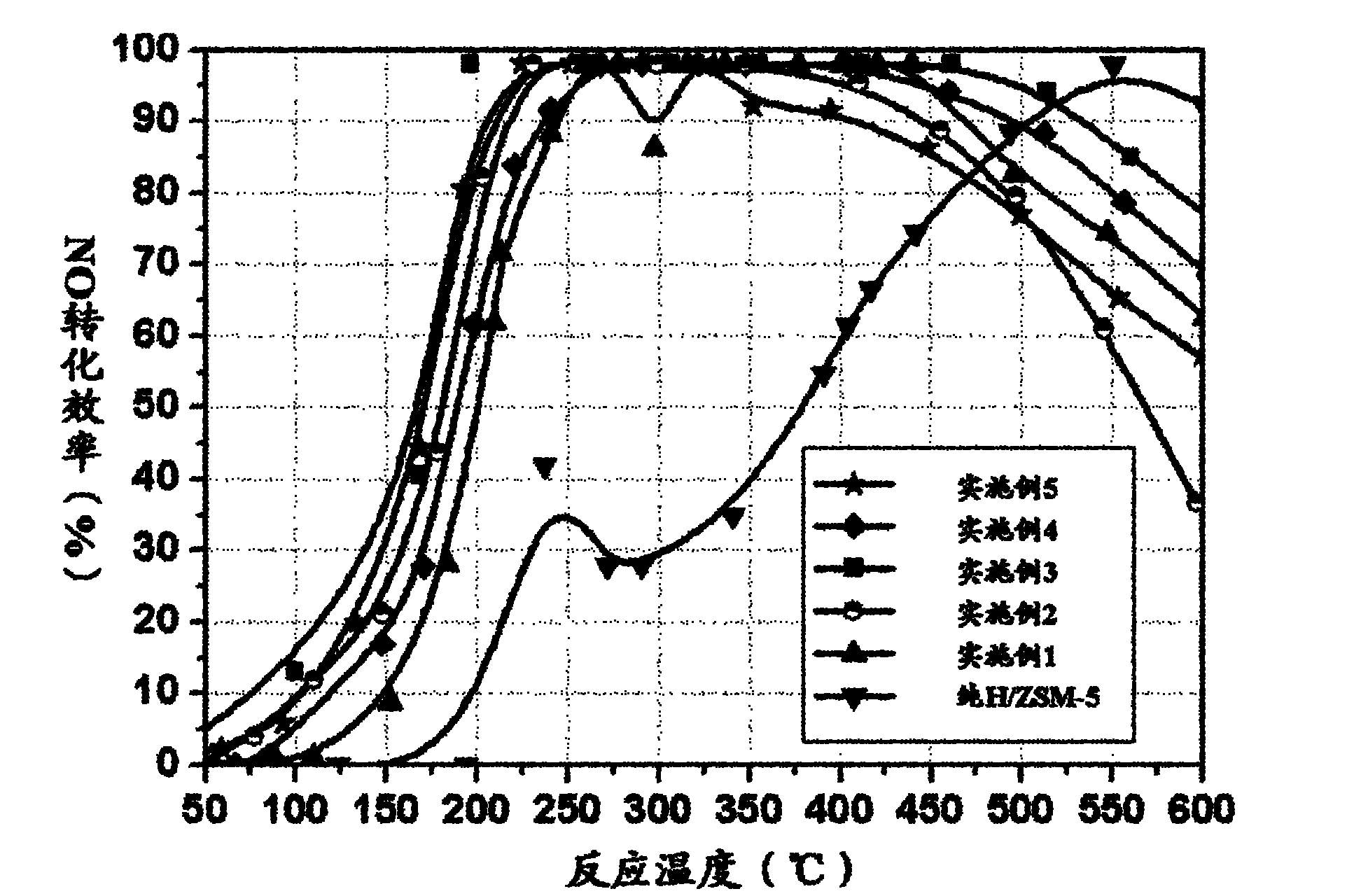

Manganese modified molecular sieve type selective catalytic reduction catalyst for diesel engine

InactiveCN102179263AExpanded high activity temperature windowHarm reductionInternal combustion piston enginesMolecular sieve catalystsIon exchangeCordierite

The invention discloses a manganese modified molecular sieve type selective catalytic reduction catalyst for a diesel engine. In the catalyst, a cordierite honeycomb ceramic is taken as a carrier material, main active ingredients are Mn2+ ions and manganese oxide particles entering a molecular sieve through ion exchange; and the residual non-exchanged H+ and a silicon-aluminum skeleton structure in the molecular sieve are respectively used as a cocatalyst and a coating matrix. In the molecular sieve powder subjected to ion exchange modification, the manganese element is 0.6 to 9.2 weight percent; and in the supported catalyst consisting of the cordierite honeycomb ceramic carrier and the coating, the coating is 5 to 15 weight percent. The preparation method comprises modification of the molecular sieve and preparation of the supported catalyst. In the catalyst, urea or ammonia is taken as a reducing agent, and NOx and HC is removed from exhaust of the diesel engine through selective catalytic reduction reaction. The Mn / ZSM-5 catalyst is prepared from a nontoxic and harmfulless H / ZSM-5 molecular sieve and manganous nitrate through ion exchange modification, and harm to the environment is reduced.

Owner:TIANJIN UNIV

High-efficiency moisture-proof ozonolysis catalyst and preparation method thereof

ActiveCN106824218AHigh Ozone Decomposition EfficiencyImprove moisture resistanceHeterogenous catalyst chemical elementsDispersed particle separationCopper nitrateSurface-active agents

The invention discloses a high-efficiency moisture-proof ozonolysis catalyst and a preparation method thereof, belonging to the technical field of ozone purification catalysts. According to the high-efficiency moisture-proof ozonolysis catalyst disclosed by the invention, the oxides of manganese, copper, nickel and cobalt are taken as active components; the preparation method of the high-efficiency moisture-proof ozonolysis catalyst is a sol-gel method; in the preparation process, manganese nitrate tetrahydrate, copper nitrate trihydrate, nickel nitrate hexahydrate and cobalt nitrate hexahydrate are dissolved in deionized water to obtain a nitrate solution; the nitrate solution is slowly added in a mixed solution of citric acid and a cationic surface active agent; after the pH value of the mixed solution is adjusted with ammonium hydroxide, constant temperature stirring is performed to obtain gel; and after the gel is dried, calcination is performed to obtain the ozonolysis catalyst. The preparation method disclosed by the invention is simple and low in costs, solves the problem that the ozonolysis catalyst is relatively poor in moisture-proof performance, and meanwhile, improves the ozonolysis efficiency; and the ozonolysis catalyst is long in service life, and the ozonolysis efficiency is not lowered when the ozonolysis catalyst is continuously used for a month.

Owner:ACAD OF ENVIRONMENTAL PLANNING & DESIGN GRP CO LTD NANJING UNIV

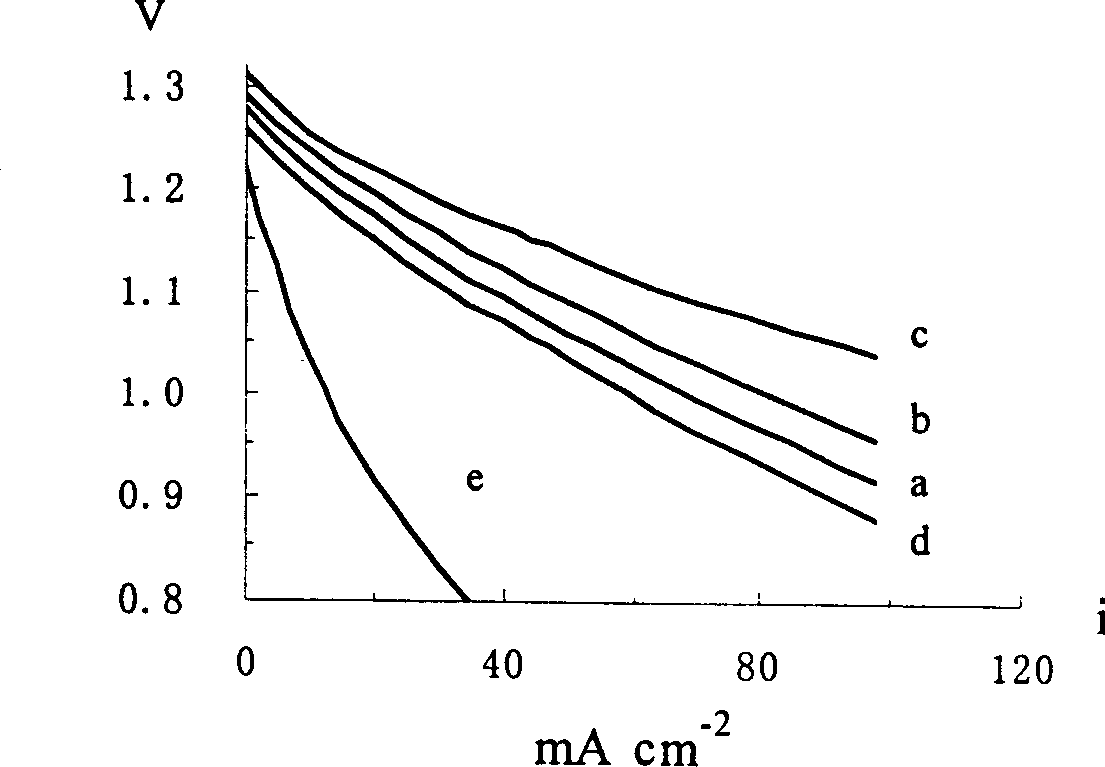

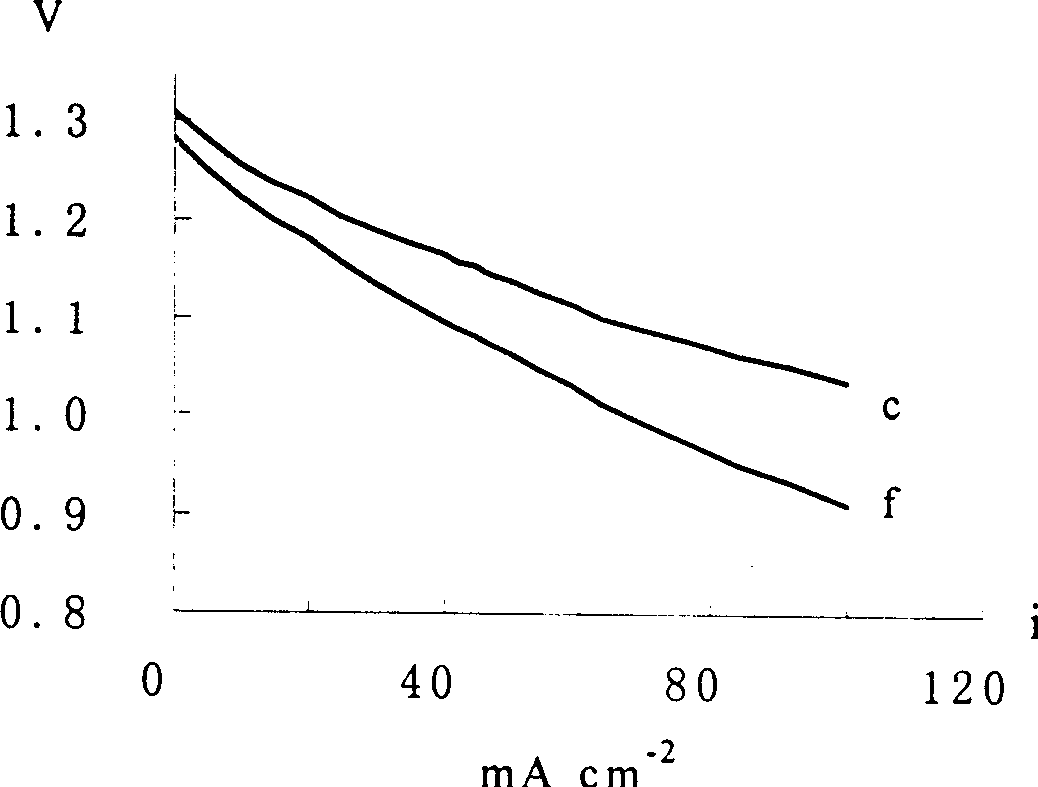

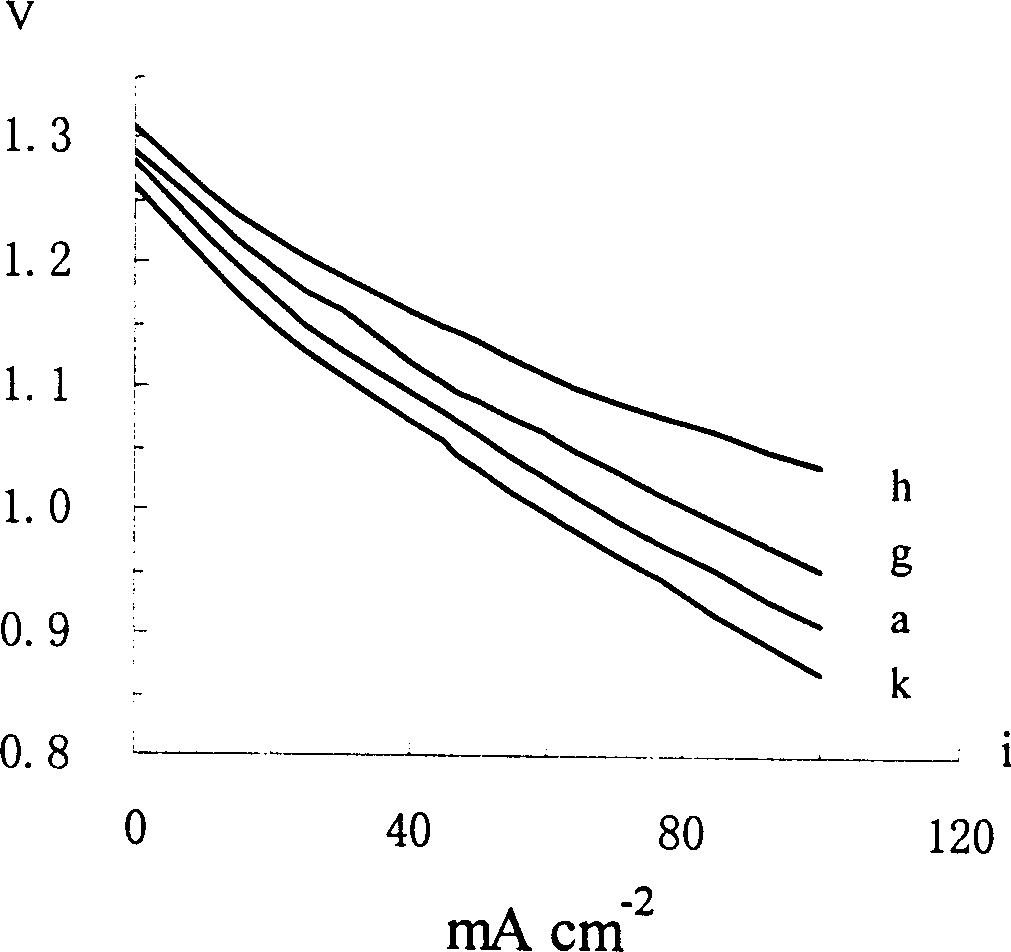

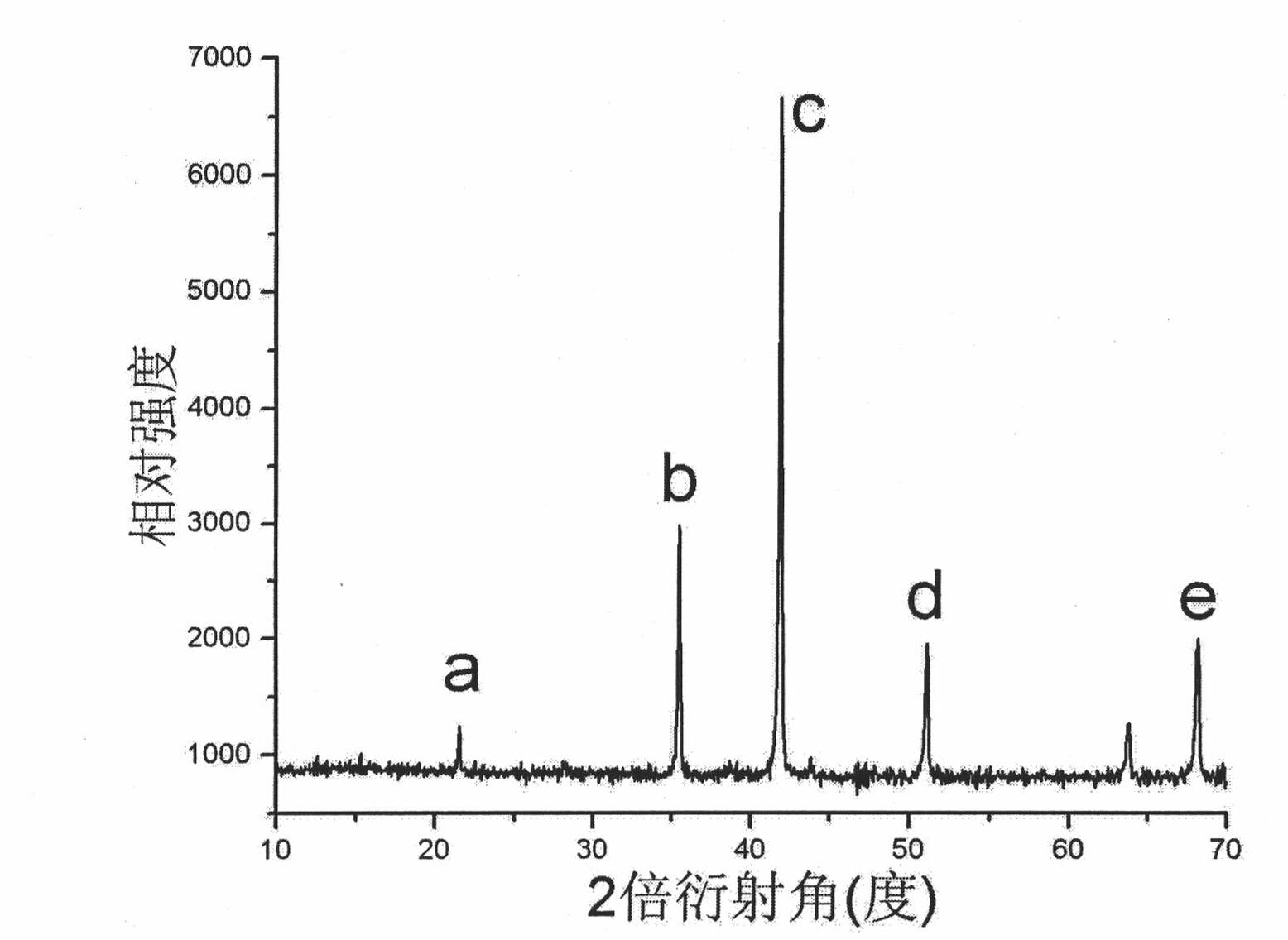

Air electrode catalyst and its preparing process

InactiveCN1396308AExtensive resourcesLow priceFuel and primary cellsManganese/lead dioxide electrodesHydrogenComposite oxide

A catalyst for air electrode is a composite oxide of managnese: MnO2-Mn3O4 / Mn2O3, where MnO2 is primary catalyst and Mn3O4 or Mn2O3 is co-catalyst. It is prepared through a adding Mn3O4 or Mn2O3 powder to carbon powder as carrier, adsorbing solution of manganese nitrate by carrier, and thermal decomposing to obtain MnO2. Its advantages are high catalytic activity and low cost.

Owner:CHONGQING UNIV

Method for synthesizing nano alumina powder

InactiveCN101456568AWide variety of sourcesLow costChemical industryAluminium oxides/hydroxidesInorganic saltsSingle crystal

The invention discloses a method for synthesizing alumina nano powder, which comprises: firstly, dissolving aluminum inorganic salt into deionized water, and adding a dispersant for stirring and mixing; secondly, dissolving copper nitrate, manganese nitrate and tetrabutyl titanate into absolute ethyl alcohol, and using concentrated nitric acid and acetic acid to adjust the pH value to be between 2.5 and 4.5; thirdly, uniformly mixing the two solutions, placing the mixture in a water bath or an oven at a temperature of between 80 and 100 DEG C, and obtaining dried gel after a period of time; and fourthly, placing the dried gel into a high-aluminum crucible, and roasting the dried gel at a temperature of between 800 and 1,100 DEG C to obtain the alumina nano powder. Raw materials adopted by the method have wide sources and low cost, and are easily obtained; the preparation technology is simple and controllable; the high-temperature stable alpha-Al2O3 nano powder with fine particle diameter, uniformly distributed particles and single crystal phase can be synthesized at a low temperature; and the prepared alumina nano powder is used for preparing alumina ceramics, and has the advantages of obviously saving energy and reducing consumption because the sintering temperature can be reduced to be less than 1,250 DEG C.

Owner:CHINA JILIANG UNIV

Spinel powder with high temperature conductivity and synthesis method and application thereof

InactiveCN106587938AMatch high temperature oxidation resistanceGood high temperature oxidation resistanceFuel cellsSynthesis methodsOxidation resistant

The invention discloses spinel powder with high temperature conductivity and a synthesis method and application thereof, complexing agent citric acid and binder polyvinylpyrrolidone are dissolved in turn in distilled water, then a Cu salt and a Co salt are dissolved into the distilled water, and finally a manganese nitrate solution is added; the obtained mixed solution is stirred magnetically for 2-3h at room temperature, then thermally insulated for 4-6h at 40 DEG C, then thermally insulated for 2-4h at 80 DEG C, and thermally insulated for 2-4h at 100 DEG C to form a colloid; the colloid is heated to 220 DEG C and thermally insulated for 8-15h for volatilization of organic compounds for formation of solid powder. The spinel powder improves the high temperature oxidation resistance and conductive properties of a metal connector in a solid oxide fuel cell in an oxidizing atmosphere, and inhibits cathode poisoning caused by Cr diffusion in a metal matrix, and the spinel powder can be used for the preparation of a metal connector surface used as a corrosion resistant conductive layer.

Owner:JIANGSU UNIV OF SCI & TECH

Coating slurry, preparation method and application thereof

ActiveCN102861594AStrong adhesionHigh specific surface area of the coatingCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsCopper nitrateCerium

The invention discloses a coating slurry, a preparation method and an application thereof. The solid content of the coating slurry is 20%-50%, and its pH is 2.5-6.5. According to the solid content, the coating slurry contains the following components of: by weight, 40-80 wt% of pseudoboehmite, 5-40 wt% of zirconium oxide and cerium oxide, 5-40 wt% of lanthanum oxide, 1-15 wt% of nanometer titania, 1-10 wt% of copper nitrate, 0.5-15 wt% of manganese nitrate and 1-10 wt% of aluminum nitrate. The preparation method of the coating slurry comprises the following steps of: weighing an appropriate amount of pseudoboehmite, cerium-zirconium oxide or nitrate, nano-sized TiO2, copper, manganese and aluminum nitrate, putting into a ball milling tank for ball milling so as to obtain an uniform slurry; taking out the slurry which has undergone ball milling, adding concentrated nitric acid and stirring to prepare the coating slurry. The application of the coating slurry comprises the following steps of: immersing a cordierite carrier into the coating slurry for 10-30 min, taking out, blowing off residual liquid in pore canal, drying at the temperature of 90-130 DEG C for 5-7 hours, and roasting in the air of 500-600 DEG C, so as to prepare a coating-containing catalytic combustion catalyst carrier. The coating slurry provided by the invention has high solid content, is easy to coat, and has strong adhesion with a carrier and high specific surface area.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing active carbon loaded with manganese oxide by hydrothermal method and device thereof

ActiveCN107352540AImprove conversion rateImprove loading efficiencyGas treatmentCarbon compoundsActivated charcoal powderActivated carbon

The invention relates to a method for preparing active carbon loaded with manganese oxide by a hydrothermal method and a device thereof. The method comprises the following steps: firstly carrying out equivalent-volume impregnation on vacuumdryingactive carbon and potassium permanganate solution, then putting the active carbon, the potassium permanganate solution and mixed solution of manganese nitrate and nitric acid together into a hydrothermal crystallization device for reaction, cooling and separating obtained solid-liquid mixture, washing and drying solid-phase products, calcining in inertial gas to obtain modified active carbon powder loaded with the manganese oxide; and the modified active carbon powder has good property in low-temperature NO catalytic oxidation, and the conversion rate is 48.5%-58.3%. The invention also discloses the device for implementing the method for preparing the active carbon loaded with the manganese oxide by the hydrothermal method. The equipment is high in automation degree, clean in production process, simple in process and low in cost.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

Black nanophase ceramics pigment and preparation method thereof

The invention discloses a black nanophase ceramics pigment and a preparation method thereof, the method comprises: dissolving ammonium oxalate, ammonium formate, ammonium acetate and ammonium propionate in water and then mixing evenly with chromic nitrate, manganous nitrate, ferric nitrate and cobalt nitrate, heating the mixture at the temperature of 400-500 DEG C, and combusting until no air gives out to obtain the black nanophase ceramics pigment. The invention has simple reaction conditions, and the raw materials such as the nitrates, the ammonium acetate and the like are medicaments with low price and abundant resource; and the invention is benefit to large-scale industrialized production. The prepared black nanophase ceramics pigment has black color, high temperature-resistance, stable performance and good dispersibility.

Owner:SOUTH CHINA UNIV OF TECH

Room temperature nitric oxide adsorption/ catalytic oxidation catalyst and preparation method thereof

InactiveCN103769081ASimple preparation processHigh adsorption/catalytic oxidation efficiencyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumCatalytic oxidation

The invention provides a room temperature nitric oxide adsorption / catalytic oxidation catalyst, and is characterized in that: the catalyst uses manganese cerium solid solution as an active component, the manganese cerium solid solution content is 100%, and the molar ratio of manganese to cerium is 2:3-1:1. The preparation method comprises the following steps: dissolving ammonium ceric nitrate and potassium permanganate in deionized water; dissolving manganese nitrate in the deionized water; dissolving a potassium hydroxide solution in the deionized water; pouring a manganese nitrate solution into an ammonium ceric nitrate and potassium permanganate mixed solution, using a mechanical stirrer for full and evenly stirring; heating the mixed solution to 70 to 80 DEG C for homoiothermy; dropwise adding a potassium hydroxide solution until the pH is 8-9; washing and drying a obtained sedimentation, and then baking at 300-400 DEG C for 3-4 hours to obtain the room temperature nitric oxide adsorption / catalytic oxidation catalyst. The method has the characteristics of simple preparation process, high adsorption / catalytic oxidation efficiency and the like.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Activated carbon capable of removing formaldehyde

InactiveCN104353417AEffective protectionLow costGas treatmentPhysical/chemical process catalystsBASIC CUPRIC CARBONATEActivated carbon

The invention relates to the technical field of activated carbon, and particularly relates to active carbon capable of removing formaldehyde. Coaly activated carbon acts as a carrier framework material, and 0.5wt%-3wt% of basic cupric carbonate, 0.5wt%-3wt% of manganous nitrate, 0.5wt%-3wt% of cerous nitrate, 0.01wt%-0.1wt% of silver nitrate and 40wt%-60wt% of adhesive (tar) are loaded on the carrier framework material. In the process of activated carbon preparation, chemical medicines and pulverized coal are mixed directly, and then the mixture is subjected to layering, carbonization and activation, so that the activated carbon for removing formaldehyde is prepared. Compared with other preparation methods, the production cost can be lowered greatly.

Owner:SHANXI XINHUA CHEM

Three-dimensional nitrogen-doped capsule-shaped carbon paper electrode material and preparation method thereof

ActiveCN106653401AIncrease capacityRich sourcesHybrid capacitor electrodesHybrid/EDL manufactureHigh energyReaction temperature

The invention discloses a three-dimensional nitrogen-doped capsule-shaped carbon paper electrode material and a preparation method thereof. The method disclosed by the invention comprises the following steps: firstly with manganese nitrate and aluminum nitrate as raw materials, and urea as an alkali source, carrying out stirring and backflow at a certain temperature to obtain an Mg-Al layered metal hydroxide Mg-Al LDH; adding a certain amount of dopamine after carrying out cooling, carrying out stirring for a certain period of time at normal temperature to obtain a PL composite material coated with dopamine; then, carrying out a once etching-roasting-twice etching process to obtain a three-dimensional nitrogen-doped capsule-shaped carbon paper electrode material HCF2. According to the three-dimensional nitrogen-doped capsule-shaped carbon paper electrode material disclosed by the invention, the preparation process and the necessary equipment are simple, the raw material sources are rich, and the reaction temperature is relatively low; the obtained three-dimensional nitrogen-doped capsule-shaped carbon paper electrode material HCF2 not only has good thermal stability, high crystallinity and high energy density and power density, but also has high morphology controllability, thereby being one of the ideal energy materials.

Owner:SHANGHAI INST OF TECH

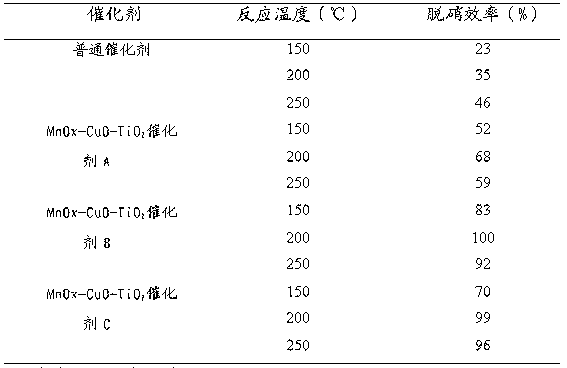

Low-temperature denitration MnOx-CuO-TiO2 catalyst as well as preparation method and application thereof

InactiveCN103055889AHigh activityImprove operating economyDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

The invention discloses low-temperature denitration MnOx-CuO-TiO2 catalyst as well as a preparation method and application thereof. The low-temperature denitration MnOx-CuO-TiO2 catalyst comprises two parts of a carrier and active components, wherein the carrier is TiO2; the active components consist of MnOx and CuO; MnOx is one of MnO2, Mn3O4 and Mn2O3 or a mixture consisting of more than two thereof; and the mol ratio of metal elements Mn, Ti and Cu in the low-temperature denitration MnOx-CuO-TiO2 catalyst is (0.2-0.6): 1: (0.1-0.2). The preparation method adopts butyl titanate, manganous nitrate and copper nitrate as precursors, and uses the sol-gel method to prepare the MnOx-CuO-TiO2 catalyst, so that the preparation cost is low, the industrial promotion is convenient, and better denitration effect is provided in smoke with the temperature of 150-250 DEG C.

Owner:上海电气电站环保工程有限公司 +1

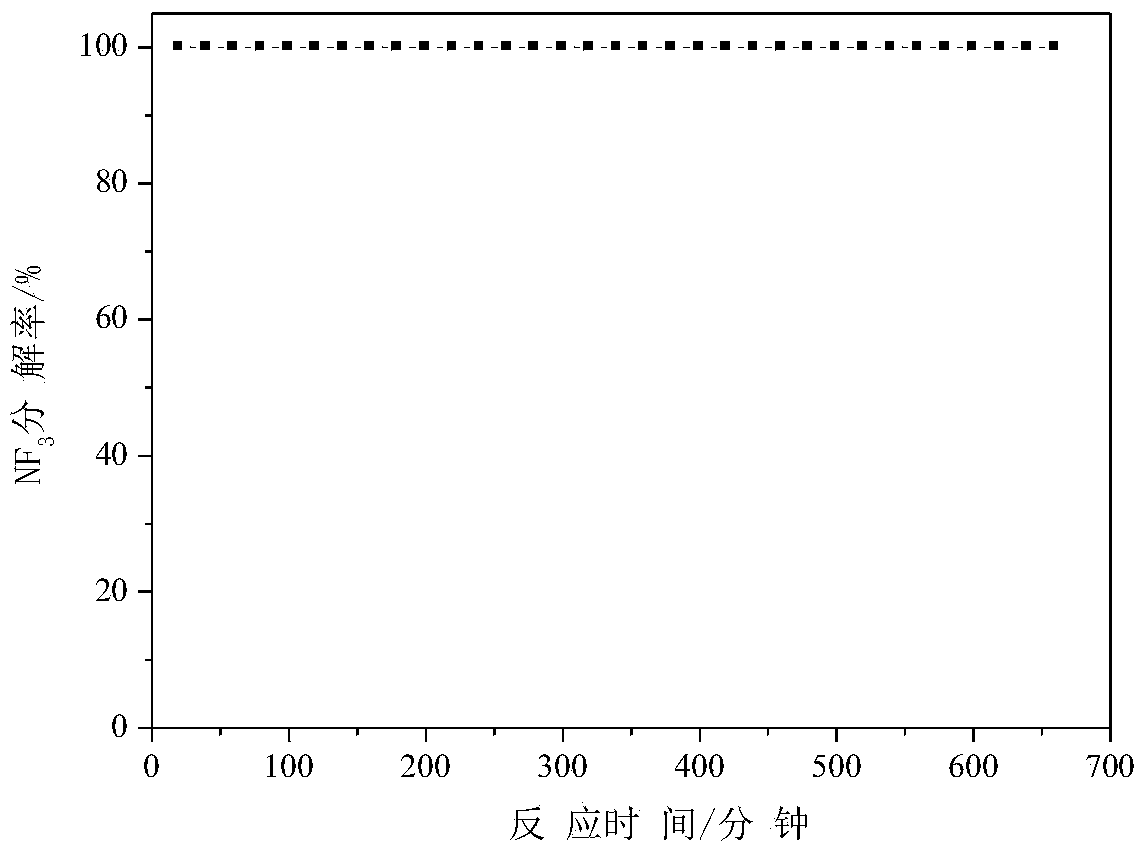

Composition and preparation method of high-activity defluorinating agent for nitrogen trifluoride anhydrous decomposition reaction

InactiveCN103961985ANo harmSimple preparation processDispersed particle separationMANGANESE ACETATEDecomposition

The invention relates to composition and a preparation method of a high-activity defluorinating agent for a nitrogen trifluoride anhydrous decomposition reaction. The composition and the preparation method are characterized in that the defluorinating agent consists of aluminum oxide coated with manganese oxide and adopts a core-shell structure, the aluminum oxide is the core (matrix), and the manganese oxide is the shell (auxiliary); aluminum oxide particles are impregnated in a manganese nitrate or manganese acetate solution with an incipient wetness method and then calcined to prepare the defluorinating agent, wherein the mass percent of manganese to aluminum oxide is 2-10%. The prepared defluorinating agent has the outstanding characteristics as follows: raw materials are cheap and easy to obtain, the preparation process is simple, and preparation process parameters are easy to control. The defluorinating agent is used for decomposing nitrogen trifluoride exhaust gas emitted in the electronic industrial process and is high in reactivity and wide in application range.

Owner:YANTAI UNIV

Low-temperature SCR (Selective Catalytic Reduction) denitration catalyst with multilevel macroporous-mesoporous structure and preparation method thereof

InactiveCN103084166AImprove denitrification effectImprove sulfur resistanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActive componentSURFACTANT BLEND

The invention relates to a low-temperature SCR (Selective Catalytic Reduction) denitration catalyst with a multilevel macroporous-mesoporous structure and a preparation method thereof. The preparation method is characterized by drying and roasting to obtain the multilevel macroporous-mesoporous catalyst by using oxide of Mn as an active component and TiO2 with the multilevel macroporous-mesoporous structure as a carrier. During the preparation of the catalyst, the oxide of Mn is added in the form of manganous nitrate; TiO2 adopts tetrabutyl titanate as a titanium source; and a surfactant is added to form the multilevel macroporous-mesoporous structure. The catalyst comprises the following components in percentage by weight: 6%-30% of oxide of Mn and 70%-94% of TiO2. The denitration activity of the catalyst reaches 90% at 100 DEG C, and reaches 100% at 120 DEG C; and when 30ppm of SO2 is ventilated for 8 hours, the denitration activity of the catalyst at 120 DEG C still can be kept at 80% or higher.

Owner:DALIAN UNIV OF TECH

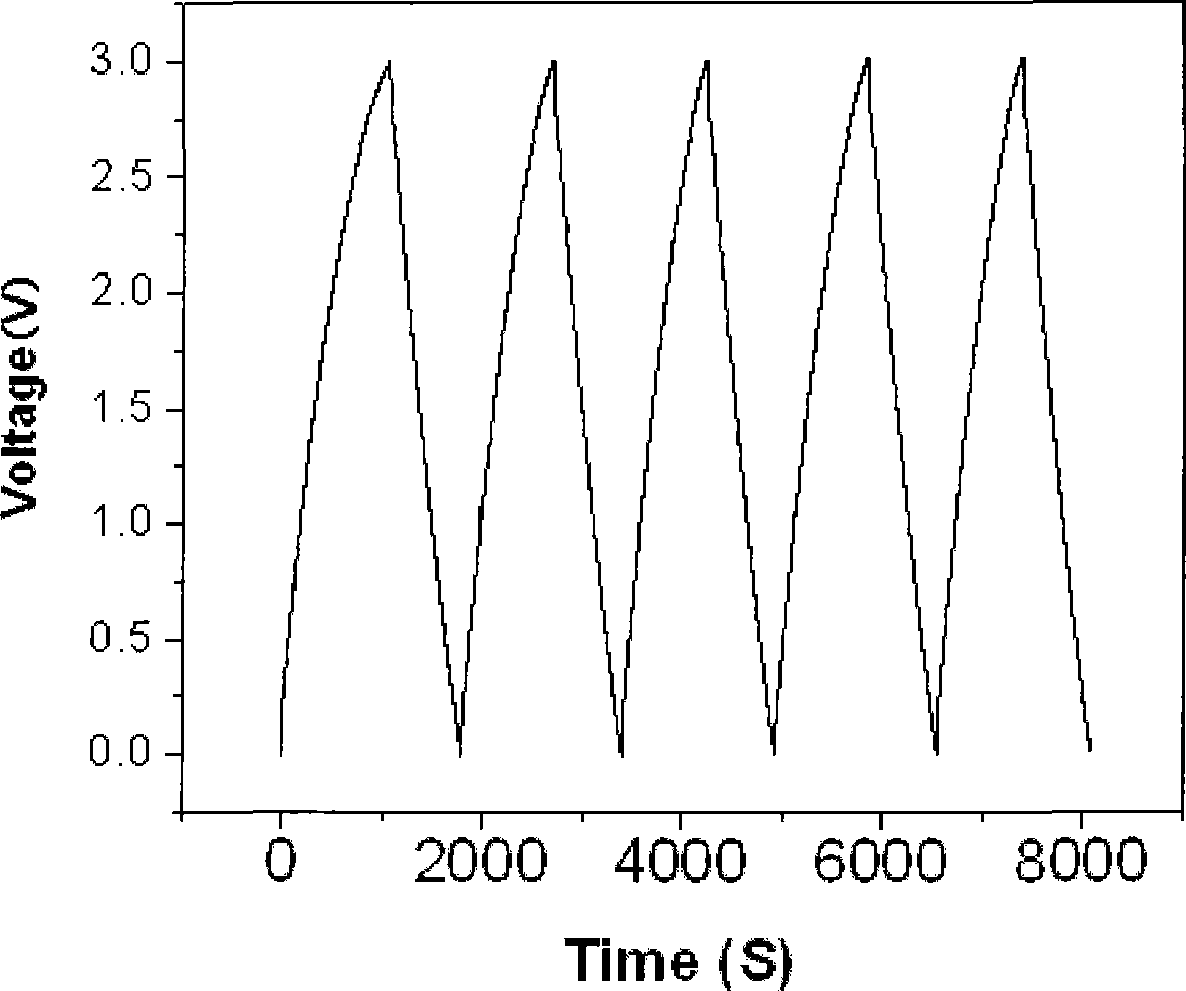

Electrode material for super capacitor and preparing method thereof

ActiveCN101393800ASimple processLow costHybrid capacitor electrodesElectrolytic capacitorsMass ratioMicrosphere

The invention relates to an electrode material used by a super capacitor. The electrode material is an activated meso-carbon micro-bead / manganese oxide compound electrode material, and comprises the following components by weight: 1 part of the activated meso-carbon micro-beads with the specific surface area to be 2500-3500m<2> per g; and 10-40 parts of an ethanol solution of manganese nitrate. The preparation method for the electrode material used by the super capacitor comprises the following steps: the meso-carbon micro-beads and an activating agent are weighted according to a certain mass ratio, mixed into pulpous state with water, and activated after being placed into a resistor furnace, thereby obtaining the activated meso-carbon micro-beads; the activated meso-carbon micro-beads are added into the ethanol solution of manganese nitrate and subjected to absorption, thereby obtaining an intermediate product, that is mixed powder body; and then the mixed powder is placed into the resistor furnace for heating reaction, thereby obtaining the activated meso-carbon micro-bead / manganese oxide compound electrode material. The activated meso-carbon micro-bead / manganese oxide compound electrode material prepared by the method has the characteristics of high output voltage, high single electrode specific capacity and high specific energy.

Owner:GUANGXI NORMAL UNIV

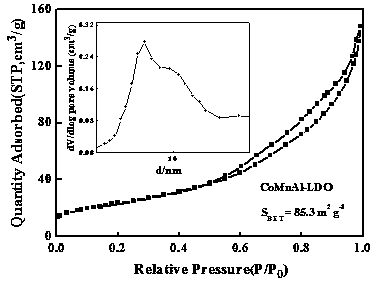

Preparation method and application of low-temperature flue gas denitration catalyst based on CoMnAl layered double hydroxide

ActiveCN108927170ALarge specific surface areaImprove thermal stabilityGas treatmentDispersed particle separationHexamethylenetetramineFiltration

The invention discloses a preparation method and application of a low-temperature flue gas denitration catalyst based on CoMnAl layered double hydroxide. The preparation of the catalyst is divided into two steps. The first step comprise: by taking cobalt nitrate nonahydrate, aluminum nitrate nonahydrate and a manganese nitrate solution with a mass fraction of 50% as raw materials, taking hexamethylenetetramine (HMT) as a precipitant and taking deionized water as a solvent and a detergent, performing solution preparation, hydrothermal treatment, suction filtration, washing and drying to obtaina CoMnAl layered double hydroxide precursor (CoMnAl-LDH); and the second step comprises roasting the obtained CoMnAl layered double hydroxide precursor to obtain a CoMnAl composite oxide catalyst (CoMnAl-LDO). After subjected to tableting and sieving, the prepared catalyst has good catalytic activity, high N2 selectivity and good water resistance and sulfur resistance when applied to low-temperature (90-300 DEG C) ammonia selective catalytic reduction (NH3-SCR) denitration reactions.

Owner:TAIYUAN UNIV OF TECH

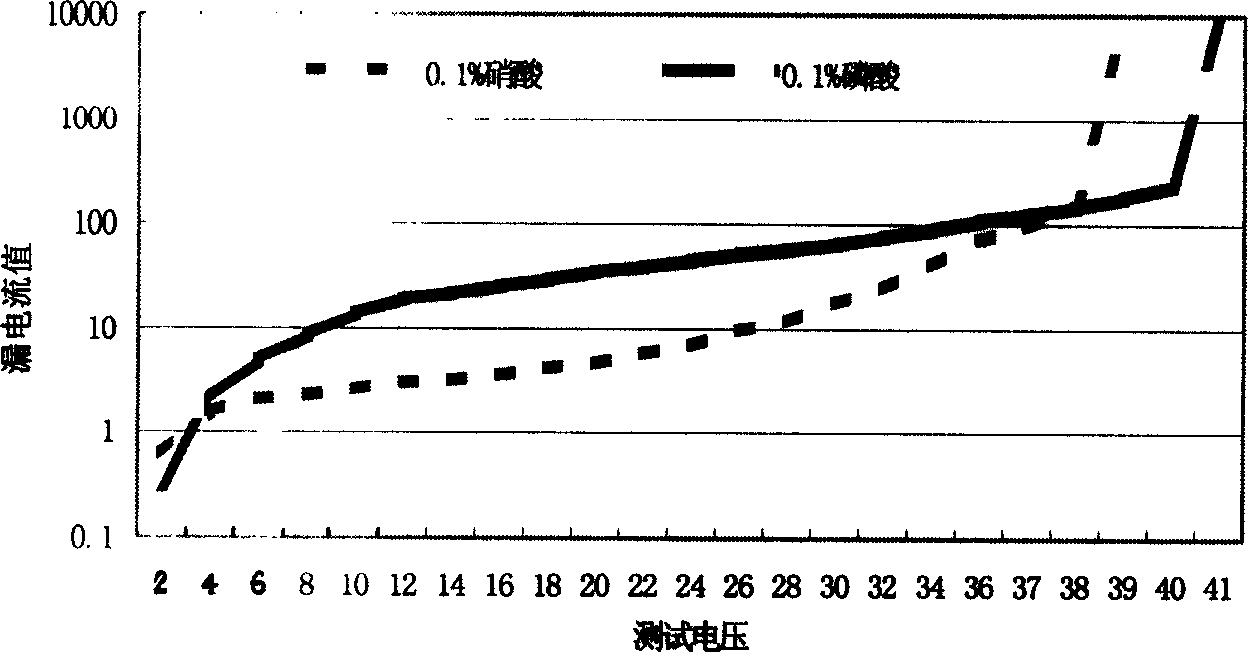

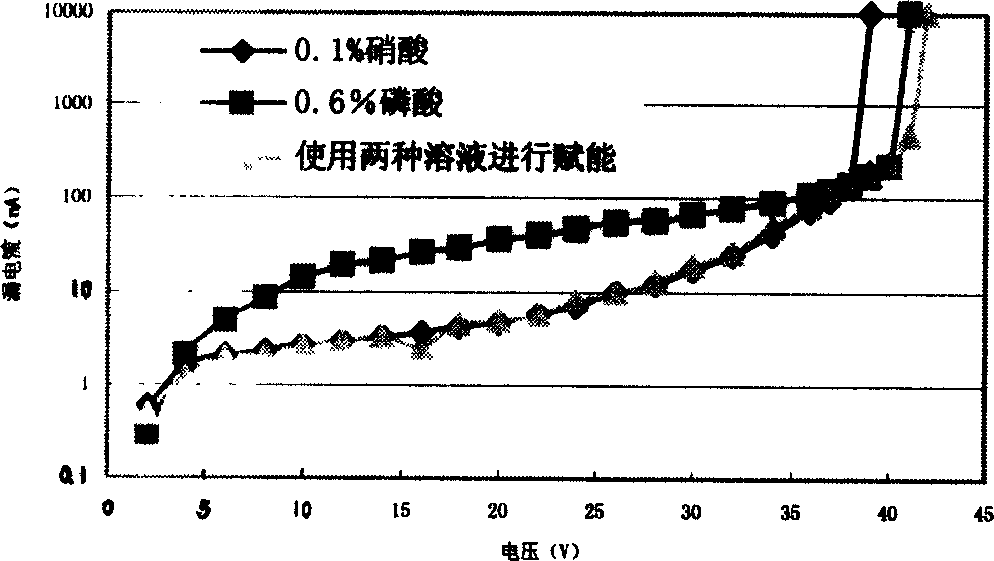

Producing method for solid niobium capacitor

InactiveCN1614725AReduce leakage currentImprove pressure resistanceSolid electrolytic capacitorsCapacitor electrodesNiobium capacitorNiobium

The method includes following steps: sintering; welding; forming; capsulizing; assembling; molding. The main technical character is: 1, the sinter cake is passivated by using cool pure water to reduce oxygen update rate of Niobium anode block; 2, in forming process the activate is made alternatively by using nitric acid solution and phosphoric acid solution, by this way the product in one hand gets the virtue of undercurrent due to using nitric acid solution, in other hand the product also has virtue of resistant to voltage due to using phosphoric acid solution; 3, in capsule process the cathode of niobium capacitor is made by using alternate immersion in manganous nitrate and silica gel solution.

Owner:宁夏星日电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com