Producing method for solid niobium capacitor

A technology of niobium capacitors and manufacturing methods, which is applied in the field of manufacturing solid niobium capacitors, can solve problems such as heat generation, large dispersion rate, and heat generation, and achieve the effects of improved voltage resistance, stable performance, and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

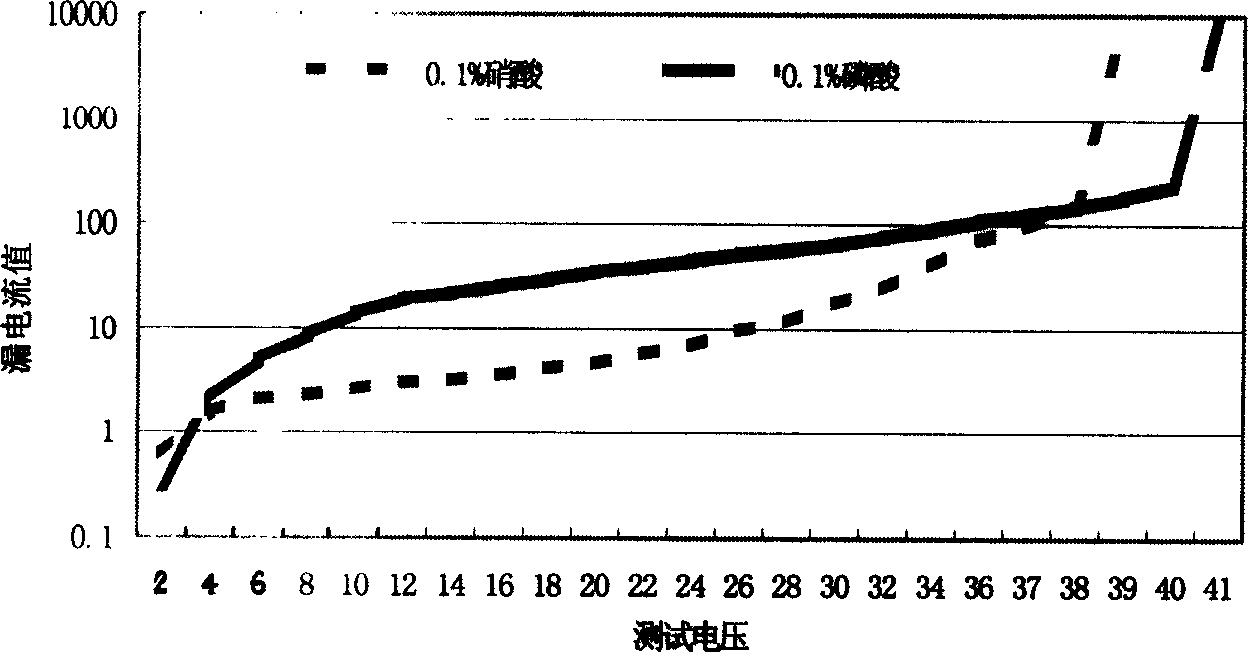

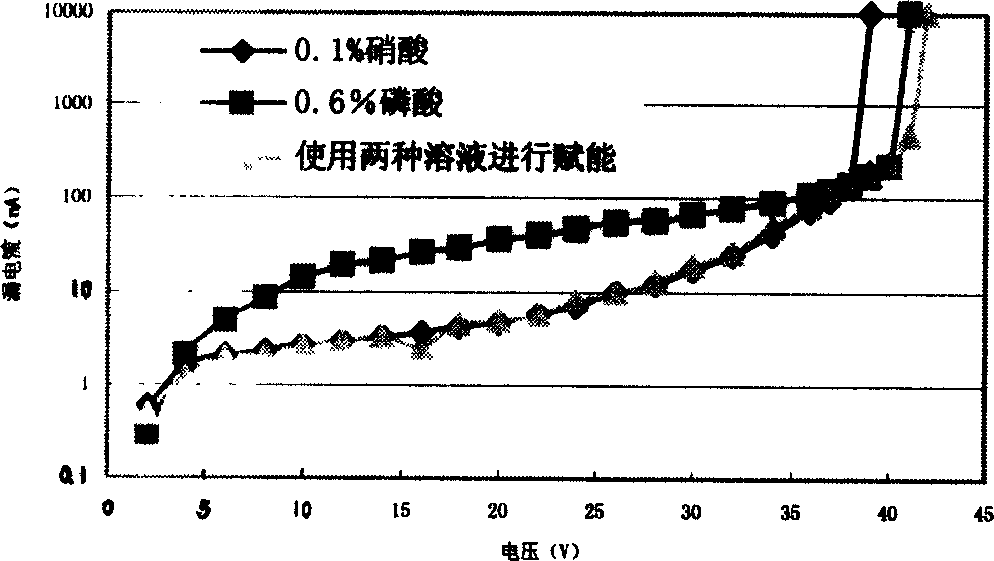

Image

Examples

Embodiment 1

[0039] 1. Powder mixing and forming:

[0040] Get 300 grams of niobium powder, weigh 12 grams of binder sodium stearate according to the weight ratio of 4%, mix the two evenly, and then press and form according to the required specifications.

[0041] 2. Binder removal, sintering, passivation:

[0042] Put 2000 pieces of the above-mentioned pressed niobium blocks in the crucible, at a temperature of 200-500°C and a vacuum pressure of 3-10×10 -3 Keep it under Pa condition for 30min, then cool it down to room temperature and take it out of the oven. This process is used to remove the binder.

[0043] Take niobium anode blocks with a single weight of 35mg and put them into the crucible according to 2000 pieces per pot, and sinter them at a temperature of 1150°C. After sintering, cool down to room temperature under vacuum conditions. Cool in a container filled with cold water for 10 minutes, take out the product, then immerse the product in pure ethanol solution, stay for 5 min...

Embodiment 2

[0056] According to the steps of Example 1, the loading capacity of each pot in Step 2 is changed to 4000, and after the sintering is completed, it is cooled in pure water (at room temperature) for 20 minutes, and all the other steps and conditions are the same as in Example 1.

Embodiment 3

[0058] According to the steps of Example 1, the concentration of nitric acid solution in Step 4 is changed to 0.3%, and all the other steps and conditions are the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com