Air electrode catalyst and its preparing process

An air electrode and catalyst technology, applied in the field of electrochemistry, can solve problems such as high energy consumption, long drying process, and large water consumption, and achieve the effects of extensive raw material resources, simple production process, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Soak a certain amount of carbon black, or acetylene black, or their mixture with ethanol, add manganese nitrate aqueous solution dropwise while stirring at room temperature, and add commercially available Mn 3 o 4 Powder, mix well to form a paste. Dry at a temperature of 100°C-110°C, lightly grind the conglomerate into powder, and then calcinate at 340°C for 1.5 hours to completely decompose manganese nitrate, then cool naturally to room temperature.

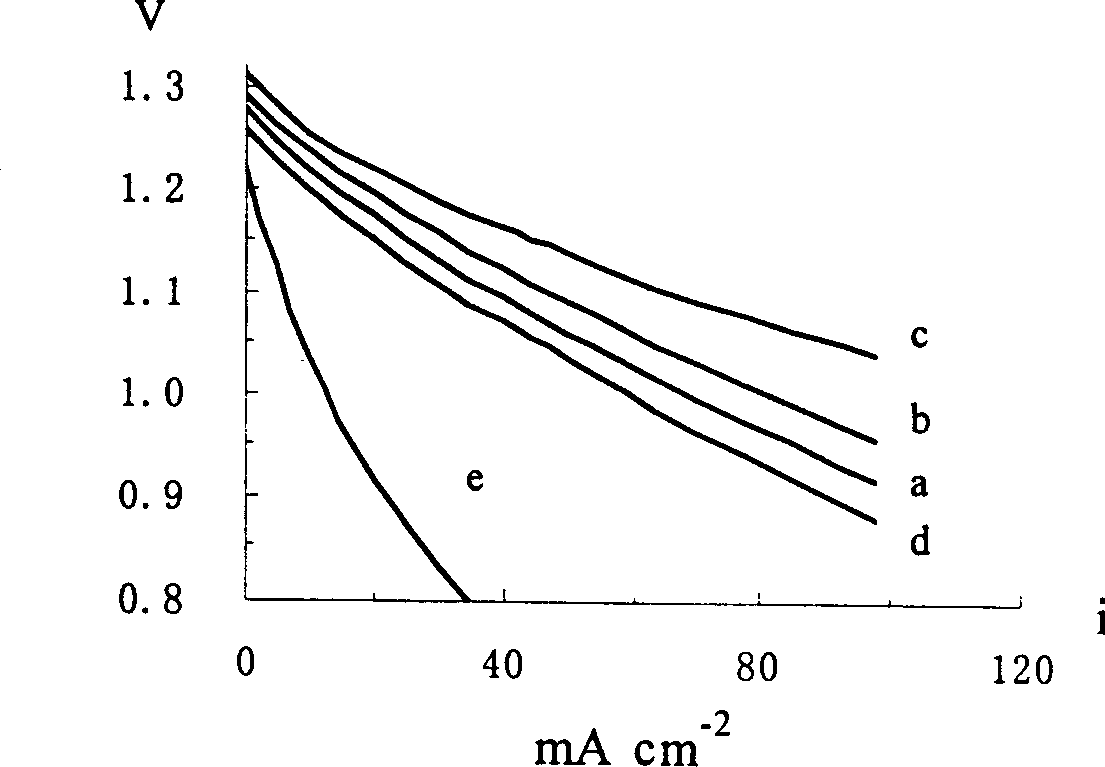

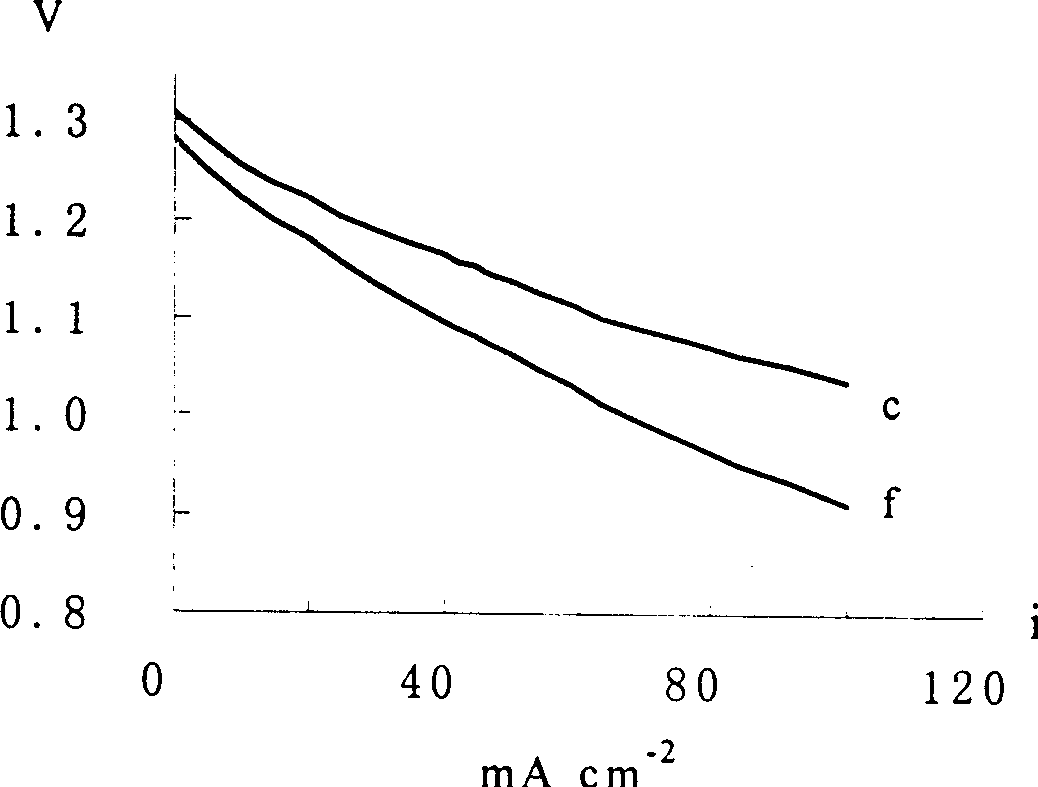

[0017] The obtained catalyst is made into an air electrode according to the traditional method, and this is used as the positive electrode, the zinc sheet is used as the negative electrode, and 7 mol / L KOH is used as the electrolyte solution to form a zinc-air battery. The voltage and current density curves of the formed zinc-air battery are as follows: figure 1 and figure 2 shown. From figure 1 It can be seen that the auxiliary catalyst Mn 3 o 4 When the content is different, the volt-ampere characteristics of th...

Embodiment 2

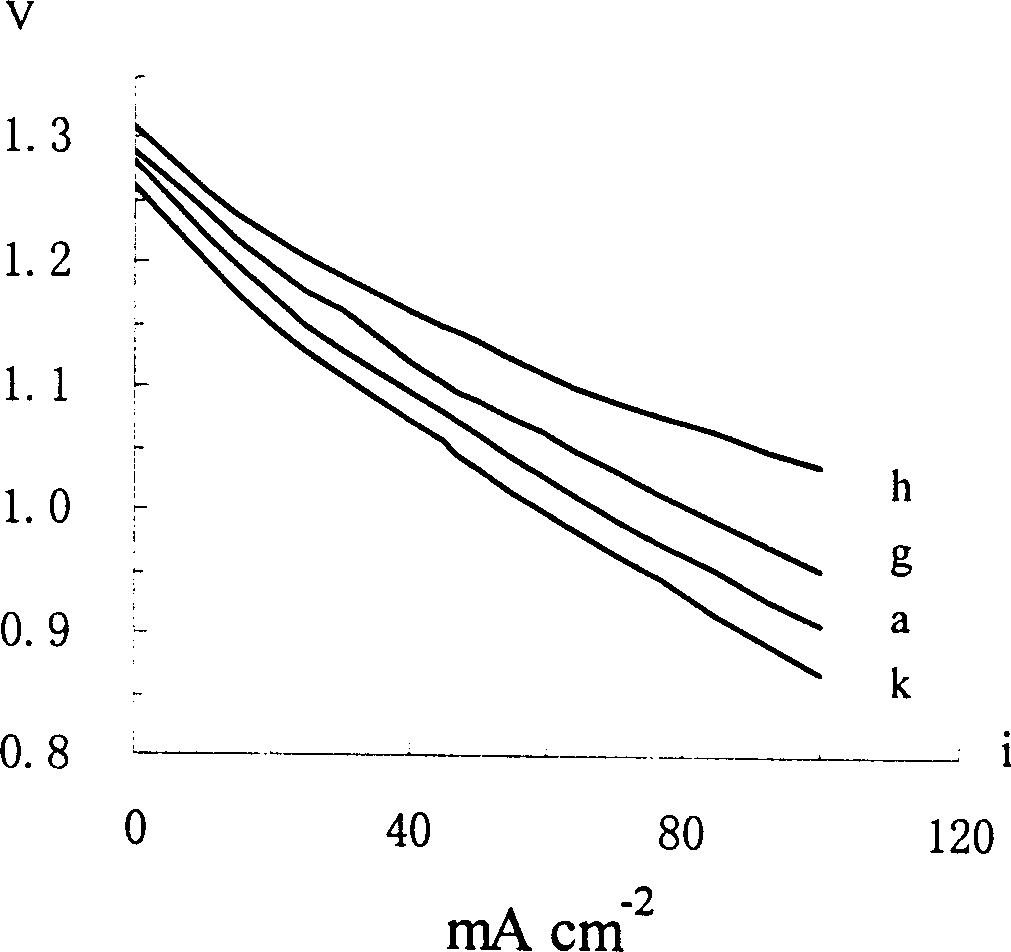

[0019] Take Mn 2 o 3 Instead of Mn in Example 1 3 o 4 , using the same preparation method as in Example 1 to prepare an air electrode, and form a zinc-air battery as in Example 1, and measure the voltage and current density of the zinc-air battery composed of air electrodes with different components and contents curve like image 3 shown. Wherein the curve h is the volt-ampere characteristic when the catalyst is the optimum component and content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com