Method for enhancing taste of rice noodles by taking fresh rice as raw material

A technology of taste and raw materials, which is applied in the fields of enhancing the taste of rice noodles and strengthening the nutrition of rice noodles, can solve the problems of easy introduction of peculiar smell, beany smell of rice noodles, etc., achieve low strip breaking rate, increase nutritional value, and improve cooking characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

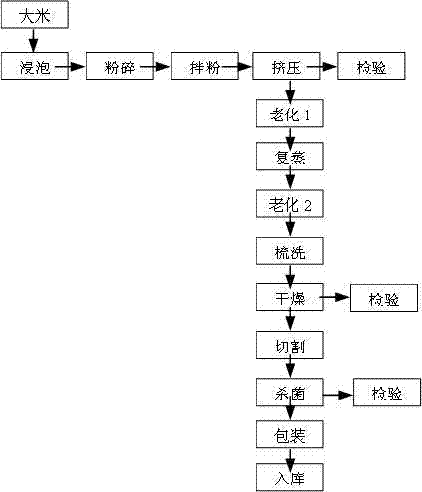

Method used

Image

Examples

Embodiment 1

[0030] (1) Raw materials: fresh early indica rice

[0031] (2) Soaking: Soak the cleaned raw materials in water for 4 hours;

[0032] (3) Crushing: After the raw rice is fully soaked and drained, it is pulverized with a hammer mill;

[0033] (4) Flour mixing: add 1% dietary fiber and 6% rice protein to the crushed rice flour and mix evenly, and adjust the moisture content to 36%;

[0034] (5) Extrusion: Extrude the mixed materials through a twin-screw extruder, and the freshly extruded rice noodles are preliminarily evacuated and cut under the action of the fan;

[0035] (6) Aging 1: Send the extruded rice noodles into an environment with a temperature of 30-36°C and a humidity of 80%-85% for aging for 19 hours;

[0036] (7) Re-steaming: put the rice noodles aged for 1 into the steam cabinet, and re-steam for 1-2 minutes;

[0037] (8) Aging 2: Send the re-steamed rice noodles into an environment with a temperature of 55-60°C and a humidity of more than 98% for aging for 5 h...

Embodiment 2

[0043](1) Raw materials: fresh late indica rice

[0044] (2) Soaking: Soak the cleaned raw materials in water for 3 hours;

[0045] (3) Crushing: After the raw rice is fully soaked and drained, it is pulverized with a hammer mill;

[0046] (4) Flour mixing: add 0.5% dietary fiber and 4% rice protein to the crushed rice flour and mix evenly, and adjust the moisture content to 36%;

[0047] (5) Extrusion: Extrude the mixed materials through a twin-screw extruder, and the freshly extruded rice noodles are preliminarily evacuated and cut under the action of the fan;

[0048] (6) Aging 1: Send the extruded rice noodles into an environment with a temperature of 30-36°C and a humidity of 80%-85% for aging for 18 hours;

[0049] (7) Re-steaming: put the rice noodles aged for 1 into the steam cabinet, and re-steam for 1-2 minutes;

[0050] (8) Aging 2: Send the re-steamed rice noodles into an environment with a temperature of 55-60°C and a humidity of more than 98% for aging for 4 h...

Embodiment 3

[0056] (1) Raw materials: mix fresh early indica rice and late indica rice at a ratio of 4:1;

[0057] (2) Soaking: Soak the cleaned raw materials in water for 4 hours;

[0058] (3) Crushing: After the raw rice is fully soaked and drained, it is pulverized with a hammer mill;

[0059] (4) Flour mixing: add 2% dietary fiber and 10% rice protein to the crushed rice flour and mix evenly, and adjust the moisture content to 32%;

[0060] (5) Extrusion: squeeze the mixed material through a twin-screw extruder;

[0061] (6) Aging 1: Send the extruded rice noodles into an environment with a temperature of 30-36°C and a humidity of 80%-85% for aging for 18 hours;

[0062] (7) Re-steaming: put the rice noodles aged for 1 into the steam cabinet, and re-steam for 1-2 minutes;

[0063] (8) Aging 2: Send the re-steamed rice noodles into an environment with a temperature of 55-60°C and a humidity of more than 98% for aging for 4 hours;

[0064] (9) Freshen up: Put the aged 2 rice noodles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com