Electrode material for super capacitor and preparing method thereof

A technology for supercapacitors and electrode materials, applied in hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, capacitors, etc., can solve problems such as limited specific energy, low decomposition voltage, and narrow working potential window of capacitors, so as to improve specific energy , low cost, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

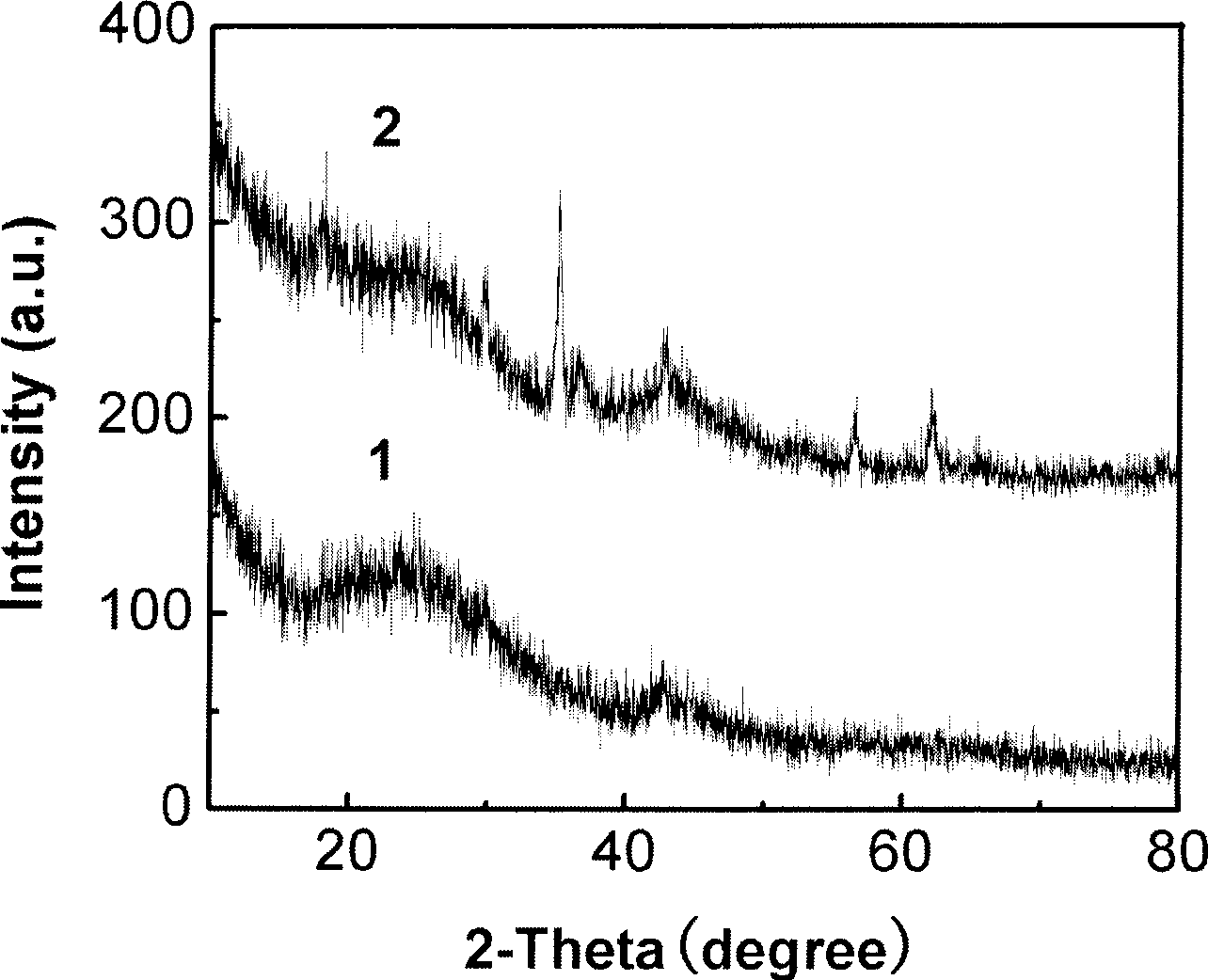

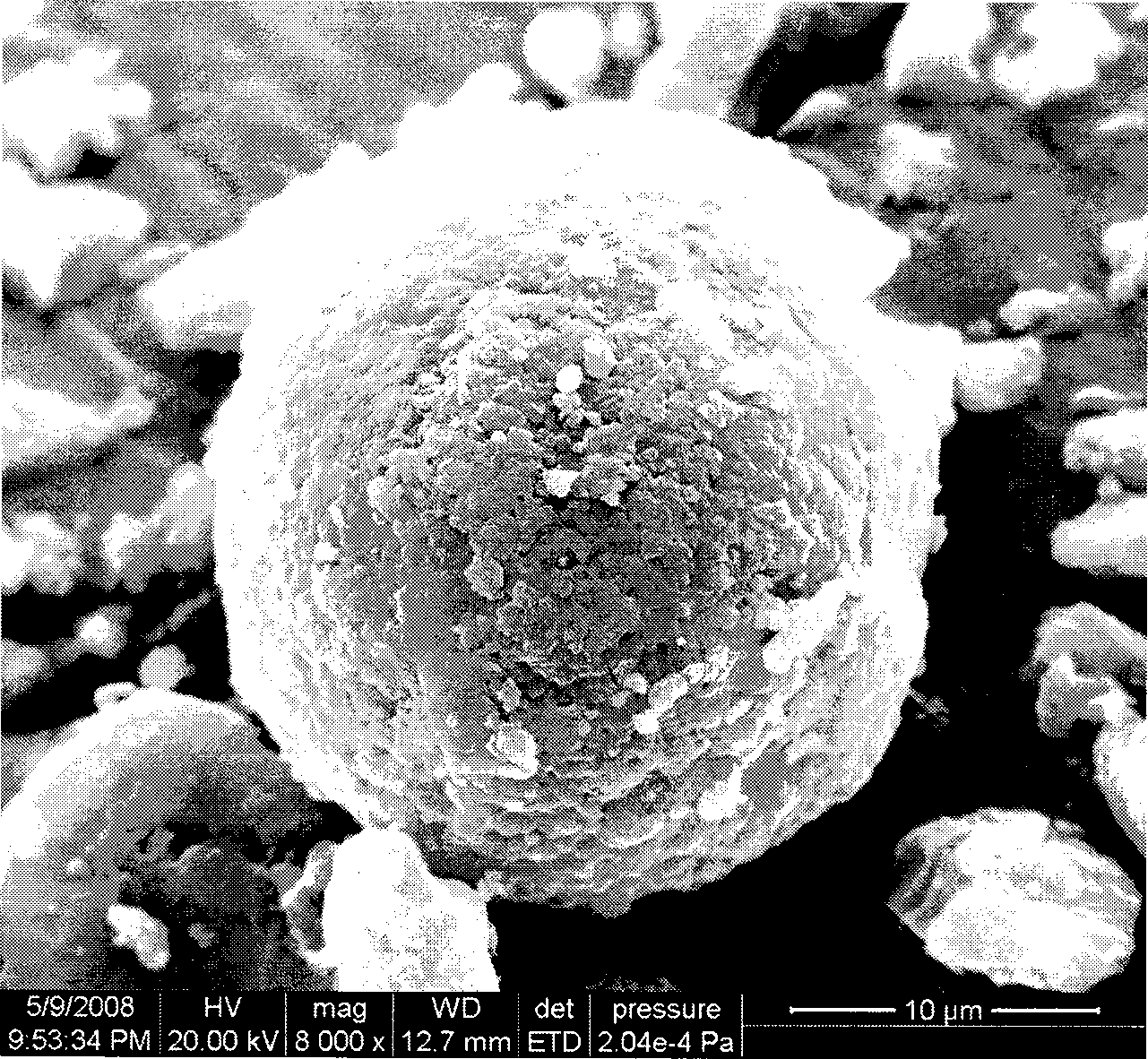

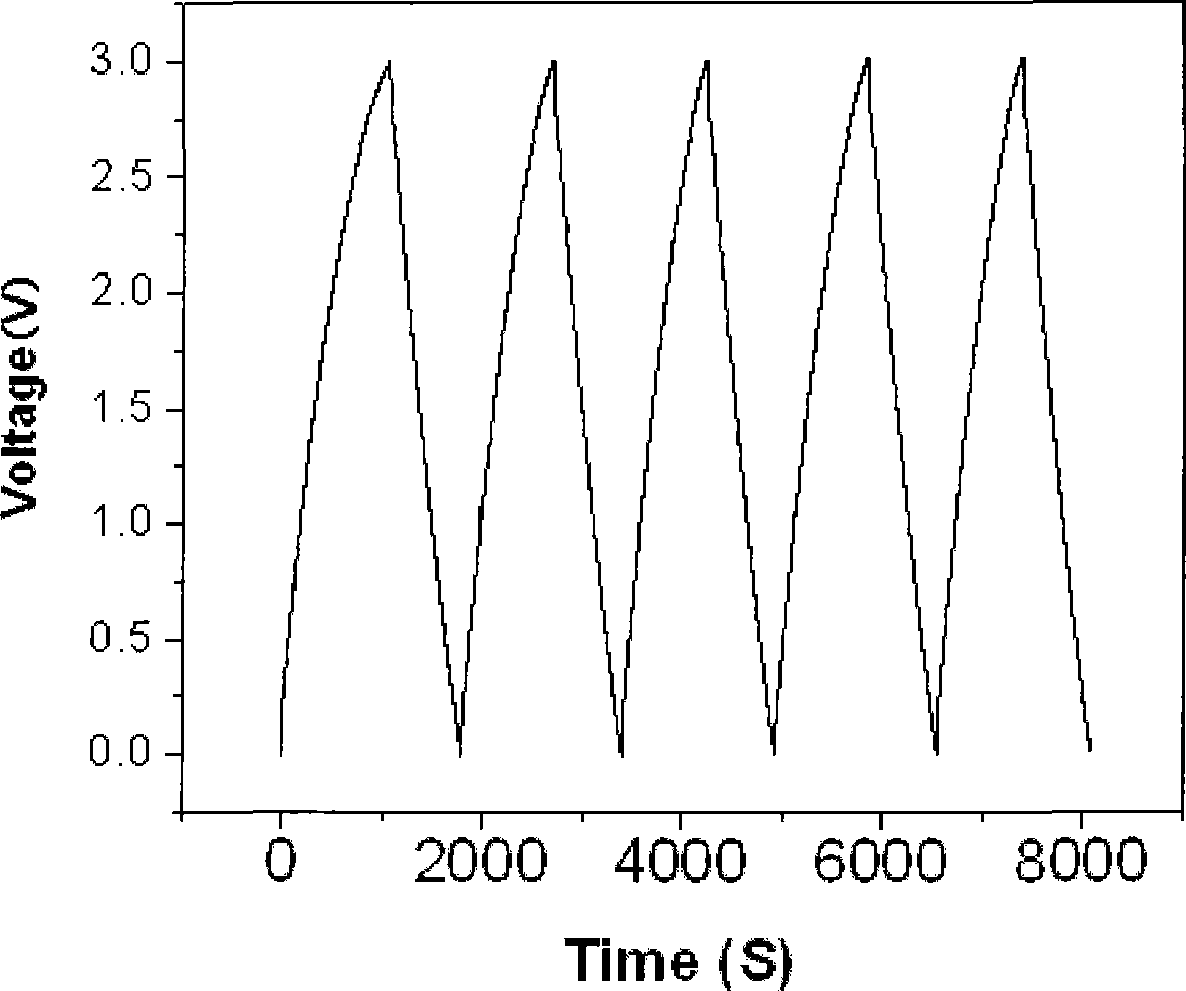

[0038] 1) Accurately weigh 10g of mesophase carbon microspheres and 80g of KOH, add an appropriate amount of deionized water to mix into a slurry, place the mixed slurry in a stainless steel burning boat, put it into a resistance furnace, and heat it at 2°C / h under the protection of an argon atmosphere. Heat up to 950°C at a heating rate of 1.5h, keep it warm for 1.5h, cool down to room temperature with the furnace, take out the product and wash it with deionized water until neutral, and dry it at 130°C to obtain 3.8g with a specific surface area of 3426m 2 / g of activated mesophase carbon microspheres;

[0039]2) Weigh 1.0 g of the activated mesophase carbon microspheres prepared in step 1) and add to 40 g of manganese nitrate ethanol aqueous solution (ethanol: water = 5: 1) with a mass concentration of 5.0%, stir magnetically for 2 h, and let stand Adsorbed for 12 hours, suction filtered to remove excess manganese nitrate ethanol aqueous solution, and dried at room tempera...

Embodiment 2

[0044] 1) Accurately weigh 10g of mesophase carbon microspheres, 40g of KOH and 20g of NaOH, add an appropriate amount of deionized water to mix into a slurry, place it in a resistance furnace, and heat it to 1000°C at a heating rate of 1°C / min under the protection of a nitrogen atmosphere. ℃, keep warm for 0.5h, cool to room temperature with the furnace, take out the product and wash it with deionized water until neutral, and dry it at 110℃ to obtain 4.37g with a specific surface area of 3169m 2 / g of activated mesophase carbon microspheres;

[0045] 2) Weigh 2 g of the activated mesophase carbon microspheres prepared in step 1) and add them to 60 g of manganese nitrate aqueous ethanol solution (ethanol: water = 1:1) with a mass concentration of 2%, stir magnetically for 4 hours, and let stand for adsorption 20h, suction filtration to remove excess manganese nitrate ethanol aqueous solution, dry at room temperature to obtain the active mesophase carbon microsphere mixed pow...

Embodiment 3

[0050] 1) Accurately weigh 10g of mesophase carbon microspheres and 40g of NaOH, add an appropriate amount of deionized water to mix into a slurry, place it in a resistance furnace, heat it to 800°C at a heating rate of 5°C / min under the protection of a nitrogen atmosphere, and keep it warm. After 2 hours, cool down to room temperature with the furnace, take out the product, wash it with deionized water until it is neutral, and dry it at 120°C to obtain 5.17g with a specific surface area of 2987m 2 / g of activated mesophase carbon microspheres;

[0051] 2) Weigh 5 g of the activated mesophase carbon microspheres prepared in step 1) and add them to 50 g of manganese nitrate ethanol aqueous solution (ethanol: water = 3: 1) with a mass concentration of 10%, stir magnetically for 3 h, and let stand for adsorption 24h, suction filtration to remove excess manganese nitrate ethanol aqueous solution, dry at room temperature to obtain active mesophase carbon microsphere mixed powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com