Manganese cerium composite oxide catalyst, its production and use

A technology of composite oxides and catalysts, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of expensive catalysts and great influence on catalyst purification effects, and achieve stability and resistance Good wet performance, low cost, high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

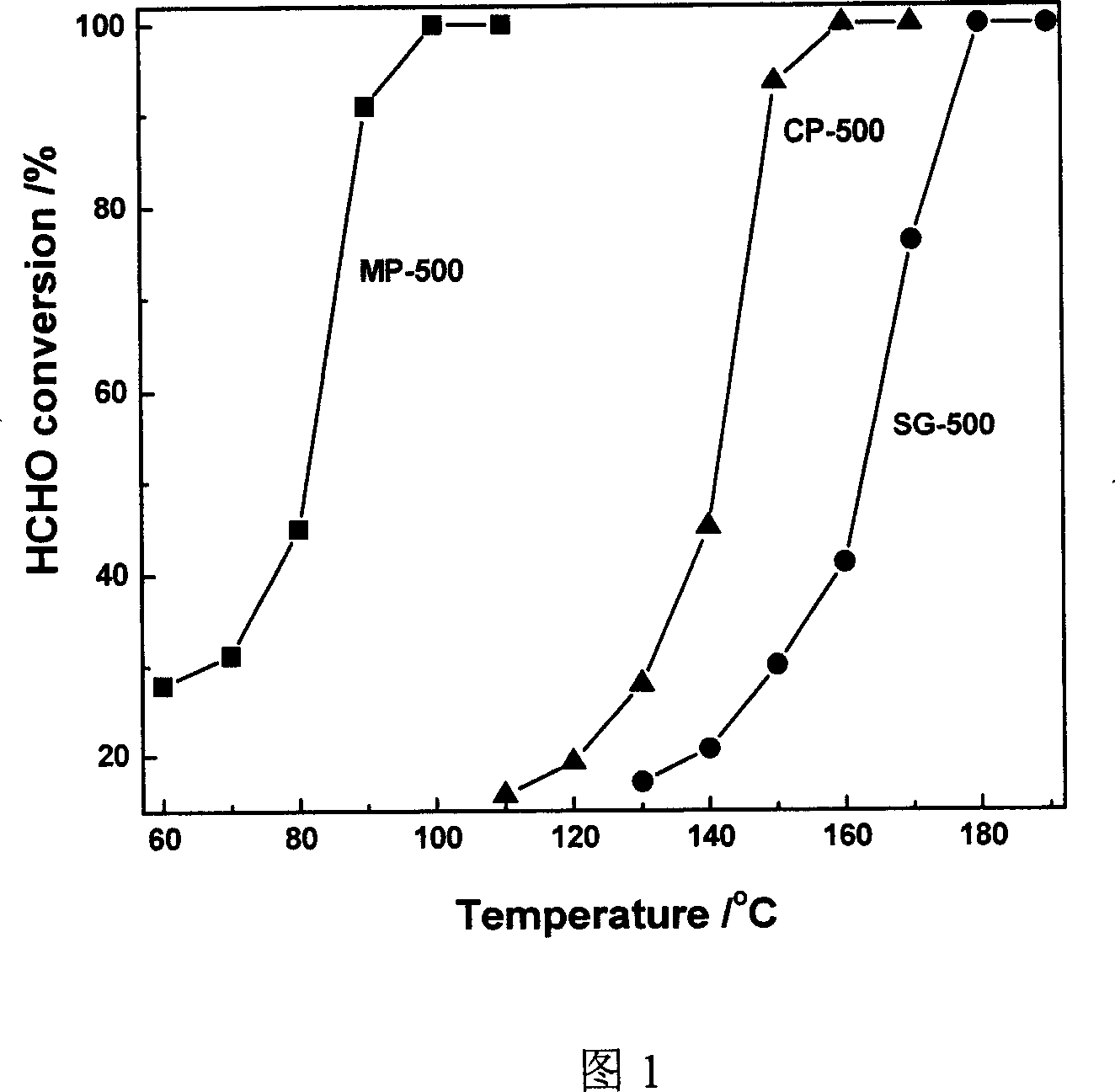

[0022] The preparation of catalyst (MP-500): add 100mL deionized water in 500mL round bottom flask, KMnO 4 (0.63g, 4.0mmol) and (NH 4 ) 2 Ce(NO 3 ) 6 (5.48g, 10.0mmol) was added and stirred to dissolve it; take 50mL containing Mn(NO 3 ) 2 ·6H 2 The aqueous solution of O (1.72g, 6.0mol) was added to the above solution under the condition of stirring, and then 2mol / L KOH solution was added to make the pH of the solution=10.5, and the precipitate obtained was stirred and aged for 6 hours at 50°C; The precipitate was filtered, washed three times with deionized water, dried at 110°C for 12 hours, and then calcined in a muffle furnace at 500°C for 6 hours to obtain an MP-500 catalyst with a Mn / Ce molar ratio of 1.0.

[0023] Preparation of the catalyst (CP-500): the metal precursor is Mn(NO 3 ) 2 ·6H 2 O and (NH 4 ) 2 Ce(NO 3 ) 6 , other steps are the same as preparing MP-500 catalyst.

[0024] The preparation of catalyst (SG-500): will (NH 4 ) 2 Ce(NO 3 ) 6 (5.48g...

Embodiment 2

[0027] Except that the calcination temperature of the catalyst is respectively 300, 400, 600 and 700 ° C, the preparation method and steps of the catalyst are the same as the MP-500 catalyst in Example 1, and the catalyst obtained in this way is designated as MP-300, MP-400, MP- 600 and MP-700. In the performance test of the catalyst, the temperature of the catalyst layer was respectively set to 60, 80 and 100° C., and the other steps were the same as in the first embodiment. The results are shown in Table 1.

Embodiment 3

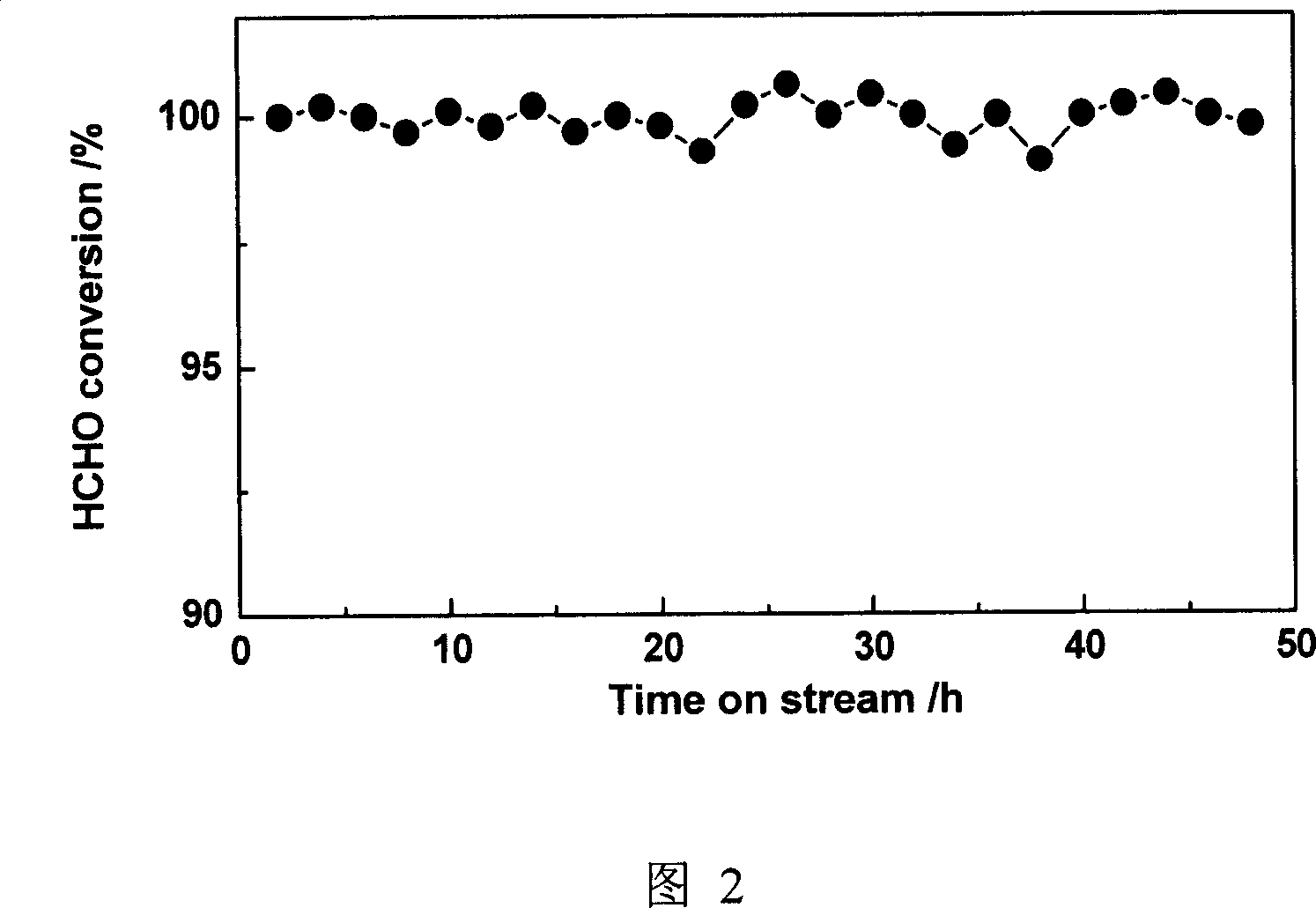

[0029] The preparation of the catalyst is the same as the MP-500 catalyst in Example 1. The stability test of the catalyst was the same as in Example 1, the temperature of the catalyst layer was set at 100° C., and the continuous reaction time was 48 hours. The results are shown in Figure 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com