Low-temperature denitration MnOx-CuO-TiO2 catalyst as well as preparation method and application thereof

A mnox-cuo-tio2, low-temperature denitrification technology, applied in the field of low-temperature flue gas denitrification, can solve the problems of short service life of catalyst, catalyst poisoning, etc., and achieve the effects of easy operation, improved water resistance, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

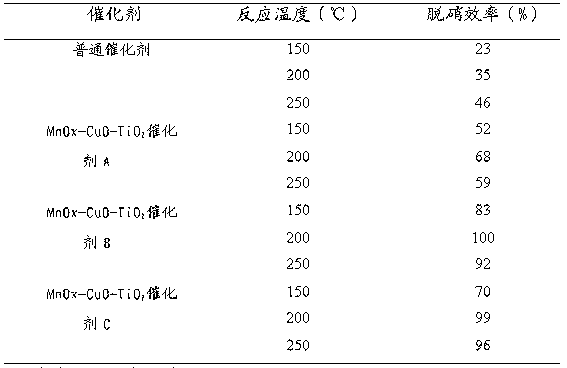

Embodiment 1

[0050] A low-temperature denitrification MnOx-CuO-TiO 2 Catalyst A is calculated based on the molar ratio of the metal elements Mn, Ti, and Cu contained, wherein Mn:Ti:Cu is 0.2:1:0.1.

[0051] The above-mentioned low-temperature denitrification MnOx-CuO-TiO 2 The preparation method of catalyst A specifically comprises the steps:

[0052] (1) Prepare A and B solutions

[0053] ①, the preparation of A solution:

[0054] 2.416g Cu (NO 3 ) 2 ·3H 2 O was dissolved in 40ml of absolute ethanol, and 34.2ml of butyl titanate was slowly added at room temperature using a polytetrafluoroethylene stirring paddle at a controlled stirring rate of 200rpm to obtain A solution;

[0055] The amount of soluble copper salt, butyl titanate and absolute ethanol used in the above solution A is calculated by molar ratio, that is, copper in soluble copper salt: titanium in butyl titanate: absolute ethanol is 1:10 : 68.6;

[0056] ②, the preparation of B solution:

[0057] 8ml 50%Mn (NO 3 ) ...

Embodiment 2

[0064] A low-temperature denitrification MnOx-CuO-TiO 2 Catalyst B is calculated based on the molar ratio of the metal elements Mn, Ti, and Cu contained, wherein Mn:Ti:Cu is 0.4:1:0.2.

[0065] The above-mentioned low-temperature denitrification MnOx-CuO-TiO 2 The preparation method of catalyst B, the steps are as follows:

[0066] (1) Prepare A and B solutions

[0067] ①, the preparation of A solution:

[0068] 4.832g Cu (NO 3 ) 2 ·3H 2 O was dissolved in 40ml of absolute ethanol, and 34.2ml of butyl titanate was slowly added at room temperature using a polytetrafluoroethylene stirring paddle at a controlled stirring rate of 200rpm to obtain A solution;

[0069] The amount of soluble copper salt, butyl titanate and absolute ethanol used in the above solution A is calculated by molar ratio, that is, copper in soluble copper salt: titanium in butyl titanate: absolute ethanol is 1:5 : 34.3;

[0070] ②, the preparation of B solution:

[0071] 16ml 50%Mn (NO 3 ) 2 ·6H ...

Embodiment 3

[0078] A low-temperature denitrification MnOx-CuO-TiO 2 Catalyst C, the catalyst is calculated according to the molar ratio of the metal elements Mn, Ti and Cu contained, wherein Mn:Ti:Cu is 0.6:1:0.2.

[0079] The above-mentioned low-temperature denitrification MnOx-CuO-TiO 2 The preparation method of catalyst C, the steps are as follows:

[0080] (1) Prepare A and B solutions

[0081] ①, the preparation of A solution:

[0082] 4.832gCu (NO 3 ) 2 ·3H 2 O was dissolved in 40ml of absolute ethanol, and 34.2ml of butyl titanate was slowly added at room temperature using a polytetrafluoroethylene stirring paddle at a controlled stirring rate of 200rpm to obtain A solution;

[0083] The amount of soluble copper salt, butyl titanate and absolute ethanol used in the above solution A is calculated by molar ratio, that is, copper in soluble copper salt: titanium in butyl titanate: absolute ethanol is 1:5 : 34.3;

[0084] ②, the preparation of B solution:

[0085] 24ml 50%Mn (NO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com