Bismuth ferrite-lead tungstate multiferroic ceramic and preparation method thereof

A technology of multiferroic ceramics and tungsten ferric acid is applied in the field of electronic ceramics, which can solve the problems of uneven antiferromagnetic spin order and weak magnetism, and achieve the effect of suppressing impurity, improving ferromagnetism and reducing impurity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

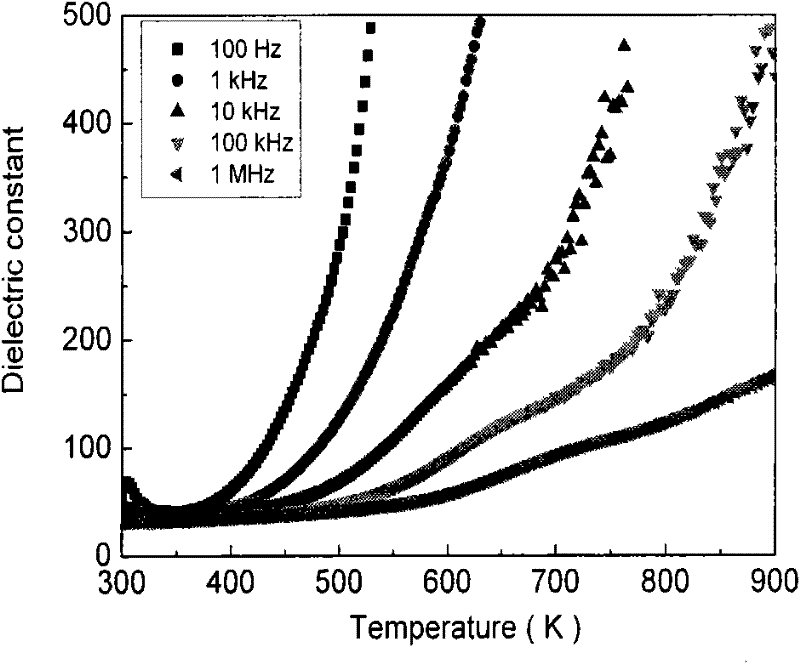

[0019] Using analytically pure grade ferric oxide, bismuth trioxide, lead oxide, tungsten trioxide, the stoichiometric ratio is 0.96BiFeO 3 -0.04Pb(W 1 / 3 Fe 2 / 3 )O 3 Weigh the ingredients; put the prepared materials into the ball mill for mixing, and mix them evenly to obtain ball abrasives; use the airflow spray granulator to granulate the ball abrasives to obtain powder particles with a particle diameter of 0.001 to 1 mm ;Put the obtained powder particles into a press to press into a ceramic body; put the formed body into a furnace for debinding, after the debinding is completed, cool with the furnace to obtain a plain piece; put the plain piece into a pre-lift Put it in a sintering furnace at 750°C, keep it warm for 0.1 hour, and then take it out to obtain 0.96BiFeO 3 -0.04Pb(W 1 / 3 Fe 2 / 3 )O 3 ceramics. figure 1 gives 0.96BiFeO 3 -0.04Pb(W 1 / 3 Fe 2 / 3 )O 3 Dielectric thermograms of ceramics.

Embodiment 2

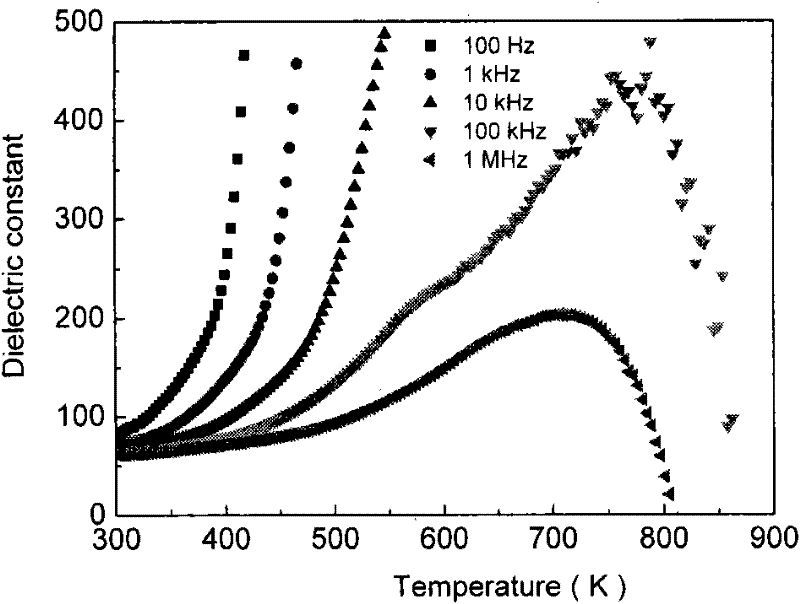

[0021] Use analytically pure grade ferric oxide, bismuth trioxide, lead oxide, tungsten trioxide, the stoichiometric ratio is 0.90BiFeO 3 -0.10Pb(W 1 / 3 Fe 2 / 3 )O 3 Weigh ingredients. Put the prepared materials into the ball mill for mixing, and mix them evenly to obtain ball abrasives; use the airflow spray granulator to granulate the ball abrasives to obtain powder particles with a particle diameter of 0.001 to 1 mm; the obtained powder The body particles are put into a press to be pressed into a ceramic green body; the formed green body is put into a furnace for debinding, and after the debinding is completed, it is cooled with the furnace to obtain a plain piece; the plain piece is put into a preheated sintering furnace at 880°C , keep it warm for 0.5 hours, and then take it out to obtain 0.90BiFeO 3 -0.10Pb(W 1 / 3 Fe 2 / 3 )O 3 ceramics. figure 2 gives 0.90BiFeO 3 -0.10Pb(W 1 / 3 Fe 2 / 3 )O 3 Dielectric thermograms of ceramics.

Embodiment 3

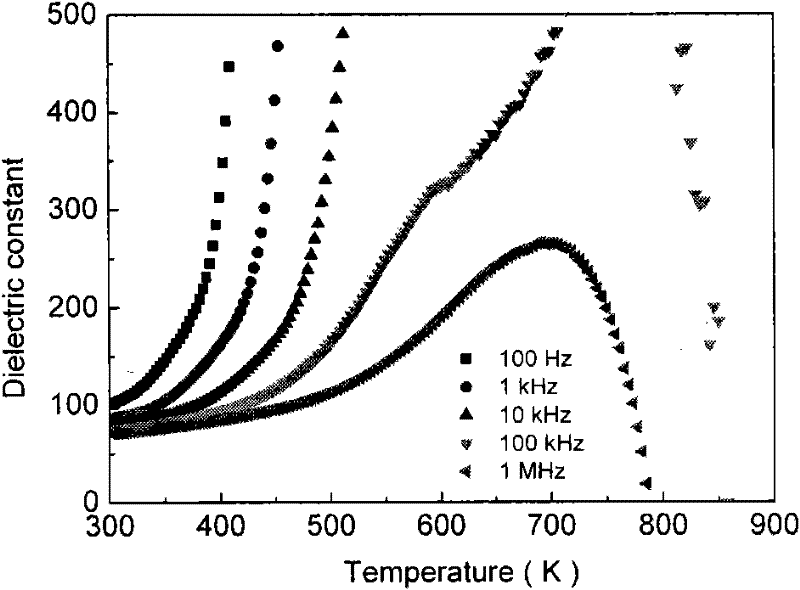

[0023] Using analytically pure grade ferric oxide, bismuth trioxide, lead oxide, tungsten trioxide, the stoichiometric ratio is 0.65BiFeO 3 -0.35Pb(W 1 / 3 Fe 2 / 3 )O 3 Weigh ingredients. Put the prepared materials into the ball mill for mixing, and mix them evenly to obtain ball abrasives; use the airflow spray granulator to granulate the ball abrasives to obtain powder particles with a particle diameter of 0.001 to 1 mm; the obtained powder The body particles are put into a press and pressed into a ceramic green body; the formed green body is put into the furnace for debinding, and after the debinding is completed, it is cooled with the furnace to obtain a plain sheet; , keep it warm for 0.9 hours, and then take it out to obtain 0.65BiFeO 3 -0.35Pb(W 1 / 3 Fe 2 / 3 )O 3 ceramics. image 3 gives 0.65BiFeO 3 -0.35Pb(W 1 / 3 Fe 2 / 3 )O 3 Dielectric thermograms of ceramics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com