A kind of thin dielectric material for x5r type multilayer ceramic capacitor and its preparation method

A technology of multilayer ceramics and capacitors, which is applied in the direction of fixed capacitor dielectrics, laminated capacitors, capacitors, etc., can solve problems such as short life and unsatisfactory product performance, reduce sintering temperature, improve reduction resistance, and improve sintering compactness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of the dielectric material is carried out according to the following steps:

[0036](1) Preparation of main component BaTiO by hydrothermal method 3 , where Ba / Ti=1. BaTiO 3 Add chromium oxide into the ball mill tank with zirconia as the grinding medium according to x=0.01, add deionized water (material: water=1:1.3) to mix, ball mill for 5 hours, dry, sieve (60 mesh or 80 mesh ), calcined (800-1050°C) for subsequent mixed use.

[0037] (2) Preparation method of glass powder: weigh CaO, SiO 2 , ZnO, BaO, B 2 o 3 Mix according to molar ratio 5:65:10:10:10. After mixing, add it to the ball mill tank of zirconia grinding medium, add deionized water (material: water = 1:1.2) to mix, ball mill for 4 hours, dry, pass through 80 mesh sieve, vitrify (sintering temperature 1200 ° C, heat preservation 2h), the calcined material is sand milled and dispersed until the particle size is 30-100nm.

[0038] (3) BaTi (1-x) Cr x o 3 , auxiliary additive ...

Embodiment 2

[0042] The ratio of raw materials is shown in Table 1.

[0043] In step (1), the material in the ball mill tank: water = 1:1.5, pass through a 60-mesh sieve, and the calcination temperature is 1000°C.

[0044] In step (2), the material in the ball mill tank: water = 1:1.4, the sintering temperature is 1200° C., and the temperature is kept for 2 hours.

[0045] In step (3), the material in the ball mill tank: water = 1:1.8, and ball mill for 3 hours.

[0046] The calcining temperature in step (4) is 750°C. Pass the calcined product through a 60-mesh sieve.

[0047] Step (5) Material in the ball mill tank: water = 1:1.7, after 3 hours of ball milling, dry and pass through a 60-mesh sieve.

[0048] Other operations are the same as in Example 1.

Embodiment 3~13

[0050] The ratio of raw materials is shown in Table 1. The preparation method is the same as in Example 1.

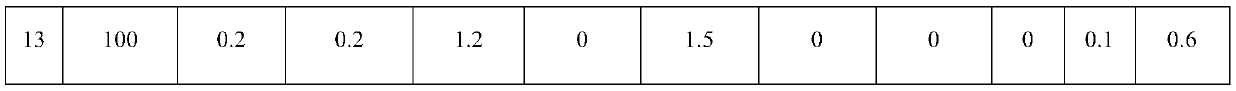

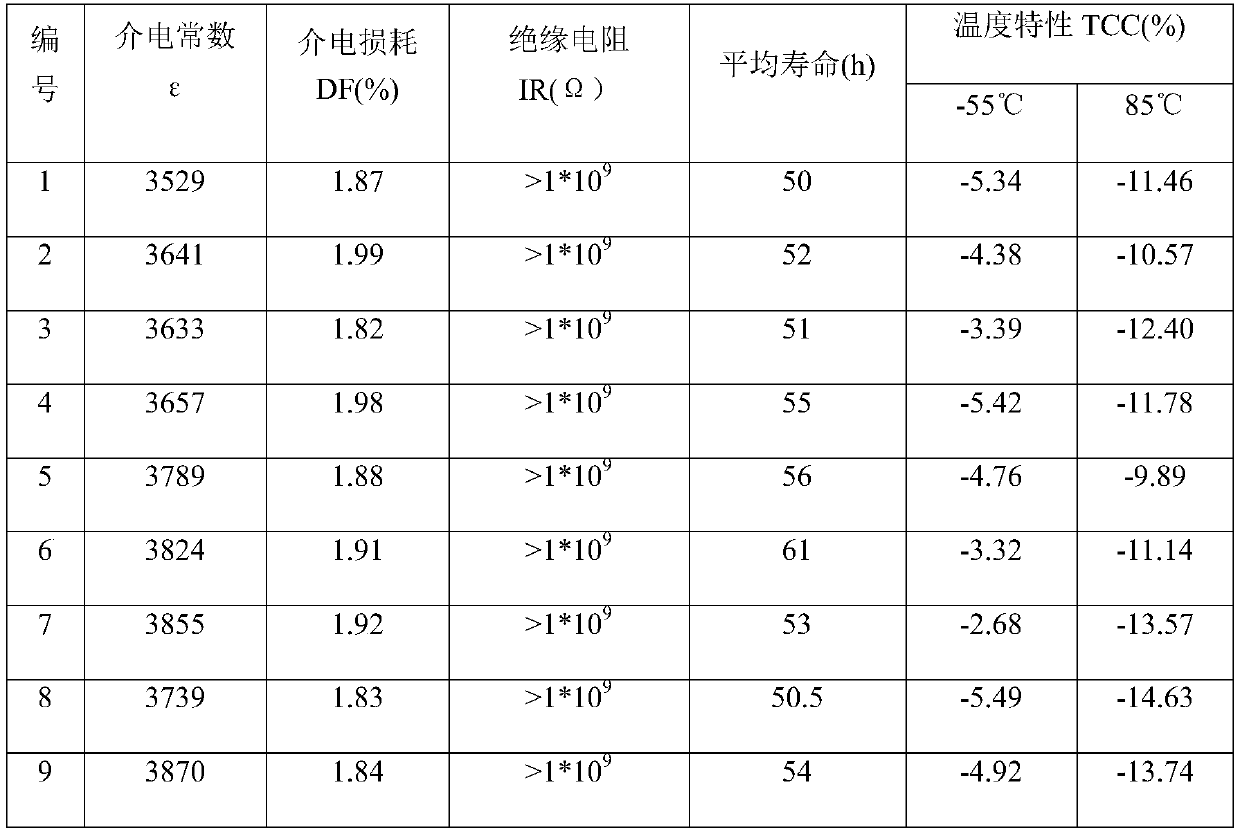

[0051] Table 1 Dielectric material composition list

[0052]

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com