A processing heat treatment process of aluminum alloy extruded profiles

A technology for extruding profiles and aluminum alloys, which is applied in the field of aluminum alloy processing to achieve the effects of stress relief, hardness improvement and excellent comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

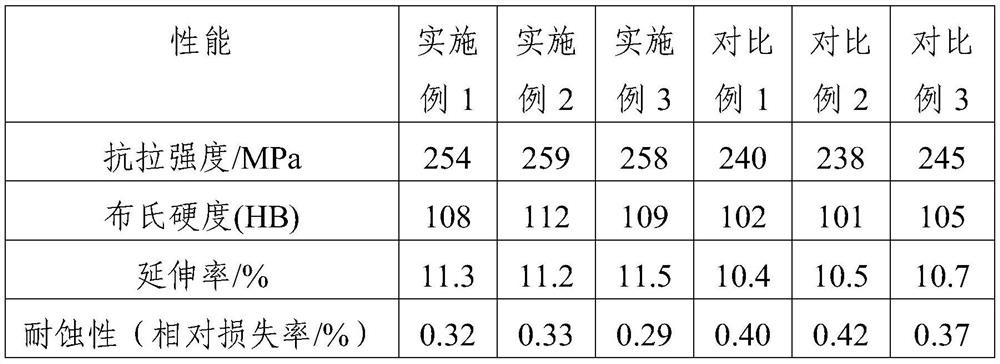

Examples

Embodiment 1

[0023] A processing and heat treatment process for aluminum alloy extruded profiles, comprising the following steps:

[0024] (1) Homogenize the heat treatment of 6063 aluminum alloy ingots, specifically: heat preservation at 535°C for 12 hours, and then air-cool to room temperature; Heat treatment, so that the temperature of the aluminum alloy ingot is 450°C, the temperature of the extrusion die is 460°C, and the temperature of the extrusion cylinder is 430°C; and then the extrusion treatment is performed to obtain a 6063 aluminum alloy extrusion profile;

[0025] Among them, the 6063 aluminum alloy ingot is composed of the following components by weight percentage: Mg: 0.49%, Si: 0.38%, Fe≤0.18%, Zn≤0.02%, Mn≤0.03%, Ti≤0.05%, and the balance is Al and not Avoid impurities.

[0026] (2) Quenching the 6063 aluminum alloy extruded profile obtained in step (1), specifically: first heating up to 460°C at a rate of 30°C / 10min, keeping it warm for 4 hours, and then cooling to room...

Embodiment 2

[0029] A processing and heat treatment process for aluminum alloy extruded profiles, comprising the following steps:

[0030] (1) Homogenize the heat treatment of 6063 aluminum alloy ingots, specifically: heat preservation at 535°C for 12 hours, and then air-cool to room temperature; Heat treatment, so that the temperature of the aluminum alloy ingot is 450°C, the temperature of the extrusion die is 460°C, and the temperature of the extrusion cylinder is 430°C; and then the extrusion treatment is performed to obtain a 6063 aluminum alloy extrusion profile;

[0031] Among them, the 6063 aluminum alloy ingot is composed of the following components by weight percentage: Mg: 0.49%, Si: 0.38%, Fe≤0.18%, Zn≤0.02%, Mn≤0.03%, Ti≤0.05%, and the balance is Al and not Avoid impurities.

[0032] (2) Quenching the 6063 aluminum alloy extruded profiles obtained in step (1), specifically: first heating up to 455°C at a rate of 30°C / 10min, keeping it warm for 4h, and then cooling to room tem...

Embodiment 3

[0035] A processing and heat treatment process for aluminum alloy extruded profiles, comprising the following steps:

[0036](1) Homogenize the heat treatment of 6063 aluminum alloy ingots, specifically: heat preservation at 535°C for 12 hours, and then air-cool to room temperature; Heat treatment, so that the temperature of the aluminum alloy ingot is 450°C, the temperature of the extrusion die is 450°C, and the temperature of the extrusion cylinder is 425°C; and then the extrusion treatment is performed to obtain a 6063 aluminum alloy extrusion profile;

[0037] Among them, the 6063 aluminum alloy ingot is composed of the following components by weight percentage: Mg: 0.51%, Si: 0.38%, Fe≤0.18%, Zn≤0.02%, Mn≤0.03%, Ti≤0.05%, and the balance is Al and not Avoid impurities.

[0038] (2) Quenching the 6063 aluminum alloy extruded profiles obtained in step (1), specifically: first heating up to 460°C at a rate of 30°C / 10min, keeping it warm for 3.5h, and then cooling to room te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com