Molybdenum-silver laminar composite material and preparation method and application thereof

A composite material, silver layer technology, applied in metal material coating process, coating, ion implantation plating and other directions, can solve the problems of natural environment and human health damage, interconnection chip performance damage, increase pollution control costs and other problems, Achieve excellent anti-oxidative corrosion and thermal fatigue resistance, solve the effect of non-dense coating, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] As an aspect of the technical solution of the present invention, it relates to a method for preparing a molybdenum-silver layered composite material (also called a silver / metal intermediate layer / molybdenum layered composite material), which includes:

[0030] At least placing a molybdenum substrate and a metal target with good solid solubility with molybdenum in a vacuum environment, and depositing a metal intermediate layer on the surface of the molybdenum substrate by a DC magnetron sputtering method;

[0031] At least placing the molybdenum substrate and the metal silver target material with the metal intermediate layer formed on the surface into a vacuum environment, and depositing a silver layer on the surface of the metal intermediate layer by a DC magnetron sputtering method; and

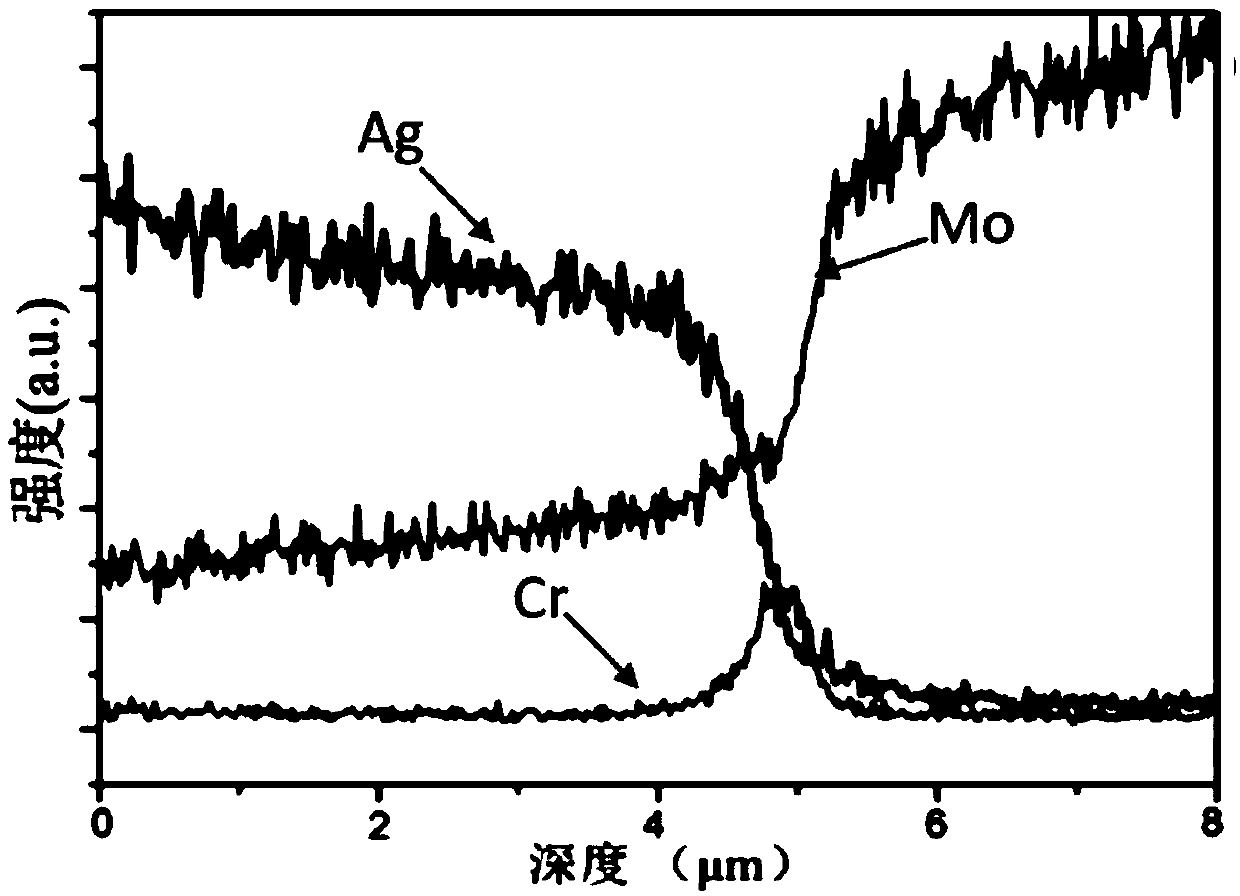

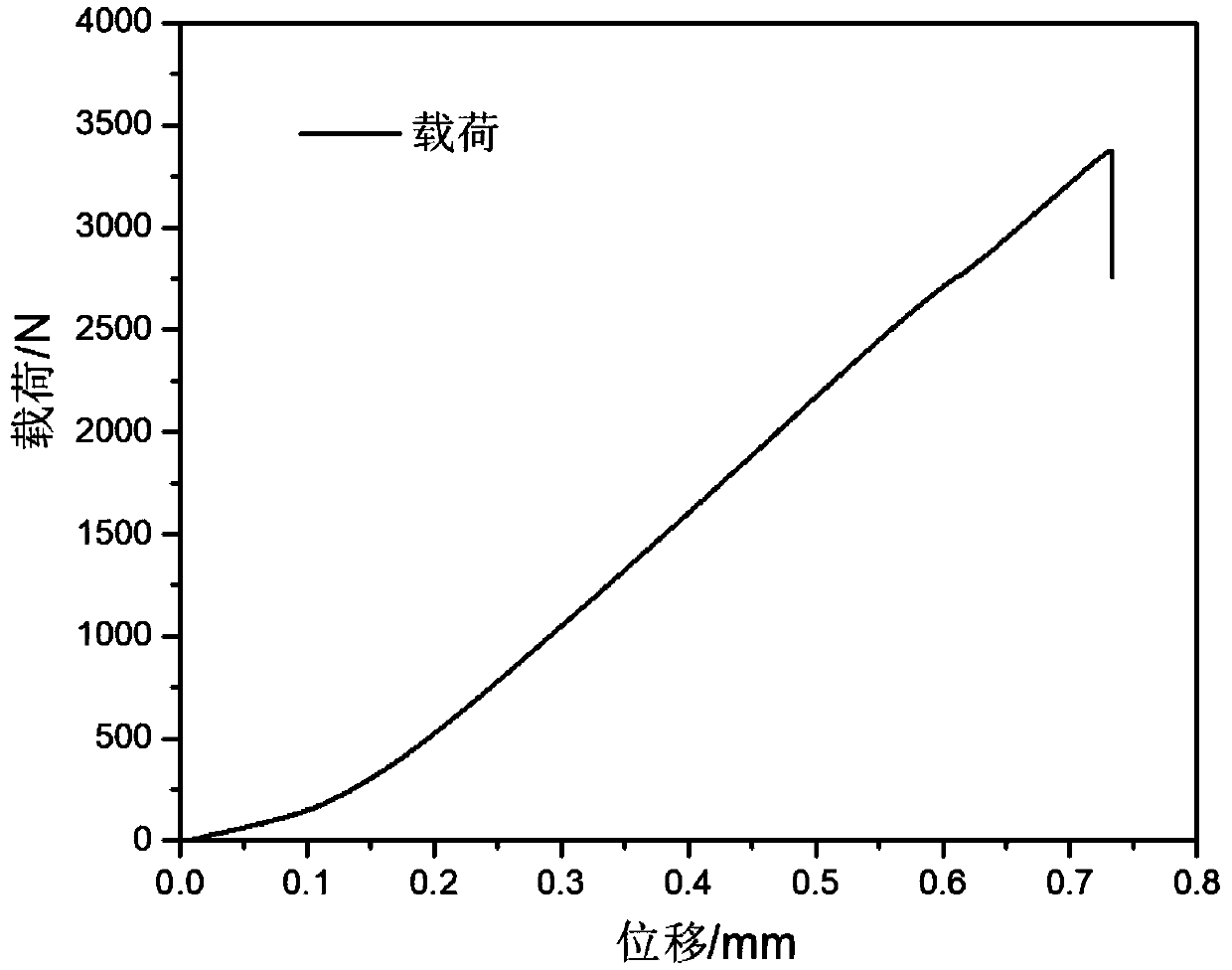

[0032] The obtained molybdenum substrate-metal intermediate layer-silver layer composite structure is annealed, so that the metal elements constituting the metal intermediate layer continuous...

Embodiment 1

[0082] (1) Mo foil pretreatment

[0083] After the molybdenum foil with a size of 50mm×50mm×0.02mm is polished with sandpaper, it is soaked in a degreasing solution (NaOH: Na 2 CO 3 : Na 2 SiO 3 = 3:2:1 mixed solution) degreasing treatment. After degreasing, rinse the surface of the Mo foil with a large amount of deionized water. Place Mo foil in 10% H 2 SO 4 Etch in the solution for 10 minutes, take it out and rinse with deionized water, then place it in deionized water for ultrasonic cleaning for 20 minutes, take it out and dry it for later use.

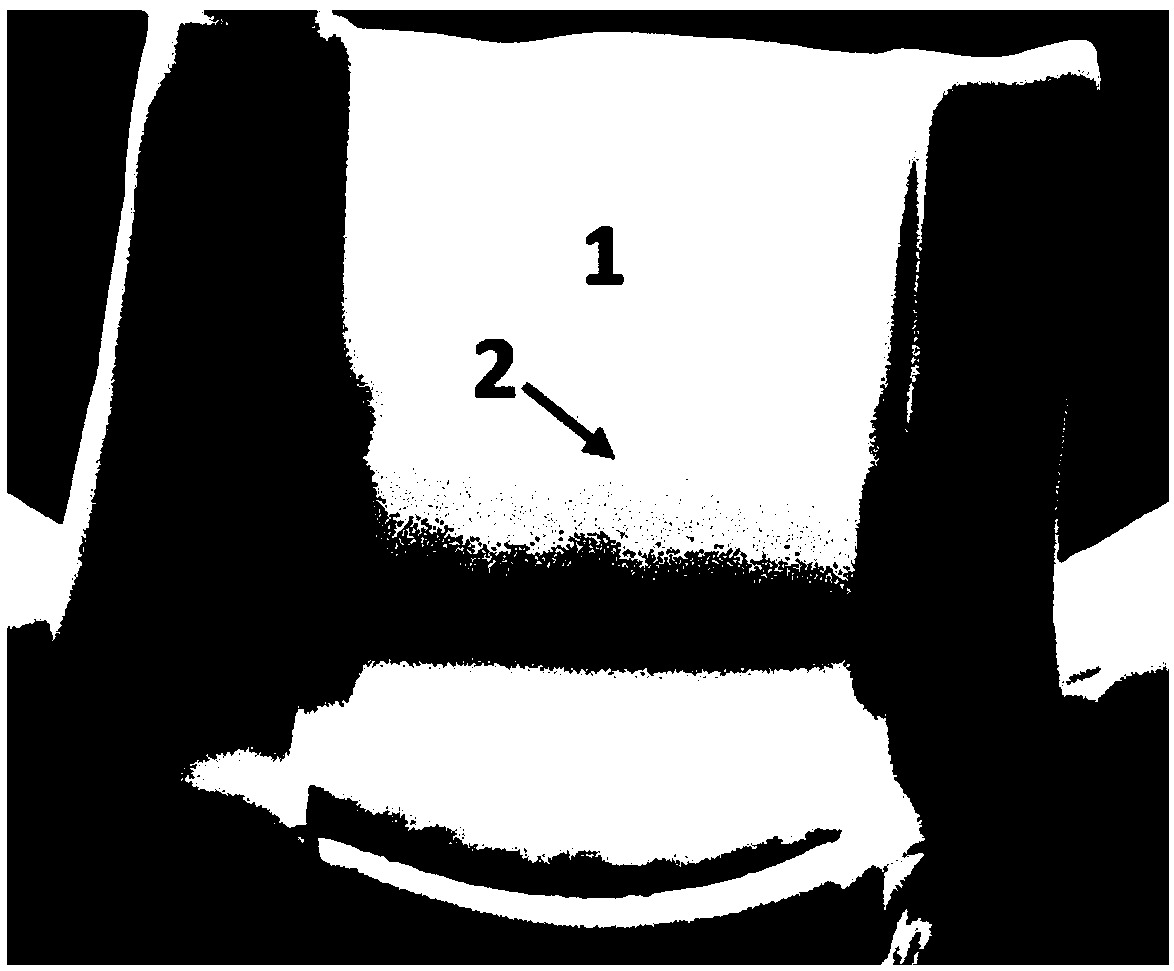

[0084] (2) Magnetron sputtering deposited Cr intermediate layer

[0085] Place the Mo foil processed in step (1) in a vacuum coating chamber. Using metal Cr with a purity of 99.99% as the target and high-purity Ar as the working gas, pre-evacuated to 5×10 -3 Below Pa, after 30 minutes of plasma cleaning treatment, turn on the pulse DC power supply of the Cr target, and deposit the Cr intermediate layer on the surface of the Mo foil. Th...

Embodiment 2

[0097] In this embodiment, the substrate is exactly the same as that in Example 1. A Cr intermediate layer and an Ag layer are sequentially deposited on the surface of the substrate to prepare a Mo / Cr / Ag layered composite material. The preparation method is as follows:

[0098] (1) Same as step (1) in Example 1;

[0099] (2) Magnetron sputtering deposited Cr intermediate layer

[0100] Place the Mo foil processed in step (1) in a vacuum coating chamber. Using metal Cr with a purity of 99.99% as the target and high-purity Ar as the working gas, pre-evacuated to 5×10 -3 Below Pa, after 30 minutes of plasma cleaning treatment, turn on the pulse DC power supply of the Cr target, and deposit the Cr intermediate layer on the surface of the Mo foil. The Cr target sputtering power was 500W, the bias voltage was -85V, the working pressure was 0.5Pa, and the deposition time was 10min. A Cr layer (hereinafter referred to as Mo / Cr composite material) was deposited on the surface of the Mo foil....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com