Preparation method of corrosion-resistant baffle surface coating for TFT (thin film transistor) process and coating

A surface coating, corrosion-resistant technology, used in coatings, anti-corrosion coatings, metal material coating processes, etc., can solve problems such as short circuits, TFT film black spots, affecting the display quality of LED and OLED displays, and achieve simple process operations. , the effect of good sphericity and small porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation process of a corrosion-resistant baffle surface coating for a TFT process, comprising the following steps:

[0042] ⑴Powder preparation:

[0043] ① Take the powder raw material (in the powder raw material, Al 2 O 3 90wt%; TiO 2 10wt%) and deionized water (deionized water is used as dispersant, deionized water: powder raw material weight ratio=13:5), mechanically mixed for 1h to form slurry;

[0044] ②Add PVA as a binder (PVA is polyvinyl alcohol, the mass of PVA is 3wt% of the mass of the slurry) in the slurry formed in ①, and mechanically mix for 2h to form a granulated slurry.

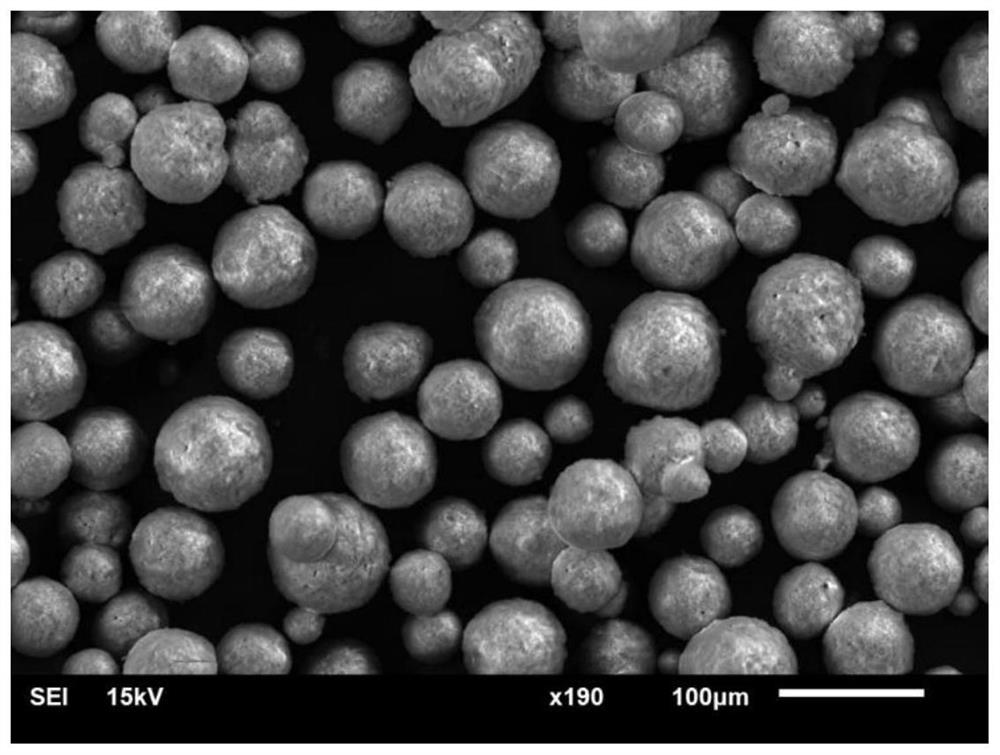

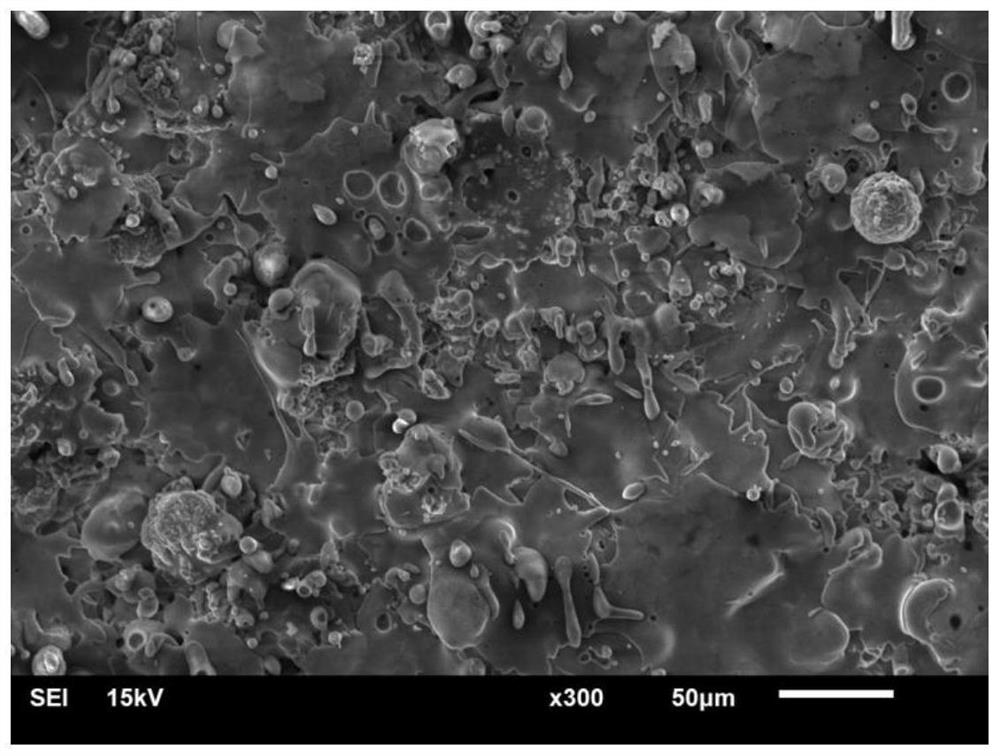

[0045] ③ Spray and granulate the granulated slurry formed in ② in a spray granulator to form composite ceramic spray particles: During the spray granulation process, the temperature of the drying room is maintained at about 250°C, and the air inlet temperature of the spray granulator is 250°C, and the outlet temperature is 250°C. The air temperature was 117°C, and the atomiz...

Embodiment 2

[0054] A preparation process of a corrosion-resistant baffle surface coating for a TFT process, comprising the following steps:

[0055] ⑴Powder preparation:

[0056] ① Take the powder raw material (in the powder raw material, Al 2 O 3 90wt%; TiO 2 10wt%) and deionized water (deionized water is used as dispersant, deionized water: powder raw material weight ratio=13:5), mechanically mixed for 1h to form slurry;

[0057] ②Add PVA as a binder (PVA is polyvinyl alcohol, the mass of PVA is 3wt% of the mass of the slurry) in the slurry formed in ①, and mechanically mix for 2h to form a granulated slurry.

[0058] ③ Spray and granulate the granulated slurry formed in ② in a spray granulator to form composite ceramic spray particles: During the spray granulation process, the temperature of the drying room is maintained at about 250°C, and the air inlet temperature of the spray granulator is 250°C, and the outlet temperature is 250°C. The air temperature was 117°C, and the atomiz...

Embodiment 3

[0066] A preparation process of a corrosion-resistant baffle surface coating for a TFT process, comprising the following steps:

[0067] ⑴Powder preparation:

[0068] ① Take the powder raw material (in the powder raw material, Al 2 O 3 89.8wt%; TiO 2 10wt%; CeO 2 0.2wt%) and deionized water (deionized water is used as dispersant, deionized water: powder raw material weight ratio=13:5), mechanically mixed for 1h to form slurry;

[0069] ②Add PVA as a binder (PVA is polyvinyl alcohol, the mass of PVA is 3wt% of the mass of the slurry) in the slurry formed in ①, and mechanically mix for 2h to form a granulated slurry.

[0070] ③ Spray and granulate the granulated slurry formed in ② in a spray granulator to form composite ceramic spray particles: During the spray granulation process, the temperature of the drying room is maintained at about 250°C, and the air inlet temperature of the spray granulator is 250°C, and the outlet temperature is 250°C. The air temperature was 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com