Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36 results about "Sodium phenylacetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium Phenylacetate is the sodium salt form of phenylacetate with ammonia detoxifying activity. Upon administration, sodium phenylacetate binds to glutamine thereby forming phenylacetylglutamine and is thus excreted by the kidneys.

Deformed steel bar slow-release quenching agent

The invention provides a deformed steel bar slow-release quenching agent which is used for preventing and slowing down deformed steel bar corrosion in air. The invention provides the deformed steel bar slow-release quenching agent which comprises the following components in parts by mass: 2 to 5 parts of sodium sulfate, 4 to 6 parts of sodium hydrate, 1 to 2 parts of starch, 5 to 7 parts of sodium bicarbonate, 6 to 8 parts of sodium phenylacetate, 5 to 8 parts of alum and 60 to 70 parts of water. The invention further provides a method for preparing the deformed steel bar slow-release quenching agent. After the use of the deformed steel bar slow-release quenching agent provided by the invention, deformed steel bar corrosion in air can be effectively prevented or slowed down.

Owner:WUXI YANGGONG MACHINERY MFG

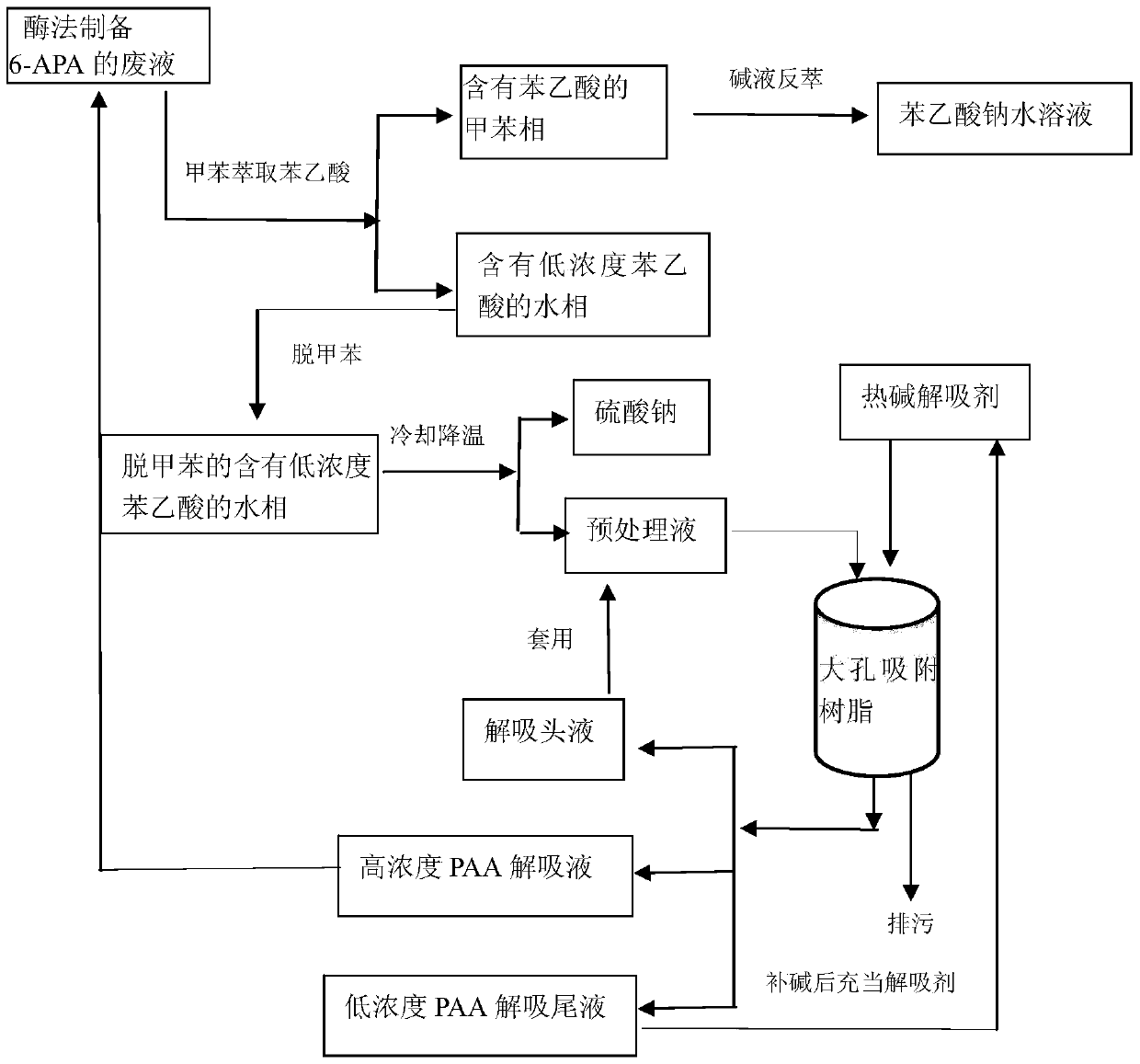

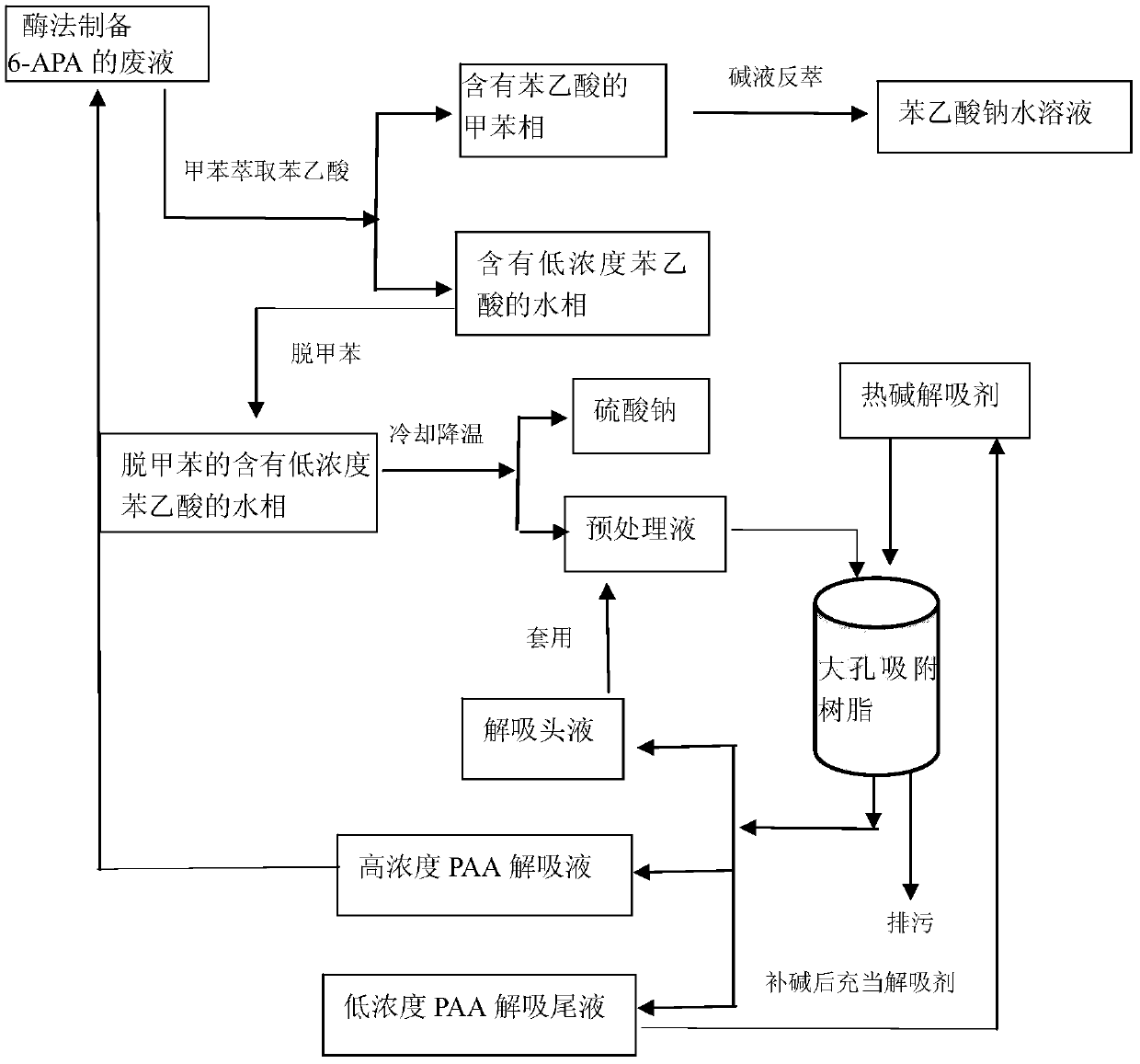

Method for recovering phenylacetic acid from waste liquid in preparation of 6-aminopenicillanic acid by enzymic method

ActiveCN106117042AQuality improvementLow incomeOrganic compound preparationAlkali metal sulfites/sulfatesPhenylacetic acidFermentation

The invention relates to a method for recovering phenylacetic acid from waste liquid in preparation of 6-aminopenicillanic acid by an enzymic method. The method comprises the following steps: 1) using toluene to extract phenylacetic acid; 2) preparing a sodium phenylacetate aqueous solution with little impurity; and 3) using macroreticular resin for recovering phenylacetic acid from a water phase containing low-concentration phenylacetic acid. According to the invention, toluene is extracted from waste liquid in preparation of 6-aminopenicillanic acid by the enzymic method, a toluene phase containing phenylacetic acid and a water phase containing low-concentration phenylacetic acid are obtained; the toluene phase containing phenylacetic acid is extracted through alkali lye to obtain the sodium phenylacetate aqueous solution with high quality, the sodium phenylacetate aqueous solution can be directly used for producing penicillin through fermentation; the water phase containing low-concentration phenylacetic acid is pretreated for recovering sodium sulfate, macroreticular resin is used for absorbing phenylacetic acid for recovery, the low concentration water after adsorption can be directly discharged, zero discharge of phenylacetic acid can be almost realized, win-win of economy and environmental protection can be achieved, the by-product sodium sulfate can be used for fermentation, and also has economic benefit.

Owner:SHANXI WEIQIDA PHARMA IND

Method for recycling sodium phenylacetate

InactiveCN111302932AEmission reductionReduce oxidationCarboxylic compound separation/purificationSodium acetateActivated carbon

The invention provides a method for recycling sodium phenylacetate. The method comprises the following steps: acidifying a pyrolysis waste liquid for producing 6-APA, carrying out extracting with an organic solution, alkalifying an extracted organic phase with liquid caustic soda, separating a water phase, and allowing a separated water phase into a rectifying tower to remove residual organic matters; and carrying out decoloration through active carbon, removing impurities through an ultrafiltration membrane, and carrying out evaporation and concentration so as to obtain a sodium phenylacetatesolution with a concentration of more than 25%. According to the invention, through improvement of the prior art, the method provided by the invention has the following advantages: the purity and yield of a recovered sodium phenylacetate product are improved; the production cost is reduced; the problems of high acidification crystallization cost, a plurality of related hazardous chemicals and thelike in a conventional process are solved; meanwhile, the problems of heavy wastewater discharge and difficulty in treating a waste liquid in an original process are effectively solved.

Owner:UNITED LAB INNER MONGOLIA CO LTD

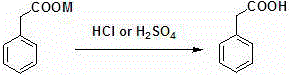

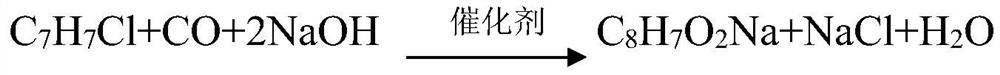

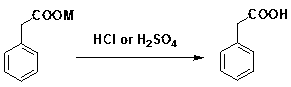

Method for synthesizing phenylacetic acid from carbonyl

InactiveCN109438215AEasy to recycleHigh activityPreparation from carboxylic acid saltsCarboxylic preparation from carbon monoxide reactionFiltrationPhenylacetic acid

The invention provides a method for synthesizing phenylacetic acid from carbonyl, and belongs to the technical field of phenylacetic acid synthesis. According to the method, benzyl chloride, sodium hydroxide and CO are taken as raw materials, a tetracarbonyl cobalt-methanol solution is taken as a catalyst, sodium phenylacetate is generated through a carbonylation reaction at a certain temperatureand pressure, and then extraction, acidification, filtration and crystallization are performed to obtain a product, namely phenylacetic acid. According to the invention, the tetracarbonyl cobalt-methanol solution is taken as a catalyst, which has better activity and economy, and is more easily recovered than metal catalysts such as rhodium, platinum, iron, manganese and the like, and the cobalt recovery rate is up to 90% or more than 90%; the process provided by the invention is performed at low pressure and low temperature, the reaction conditions are mild, the material requirements on equipment are low, no poisons or odors are produced during the process, by-products generated are easy to be separated and treated, and the process is less in pollution and environmentally-friendly; the conversion rate of the raw materials is 99% or more than 99%; the yield of phenylacetic acid is 85% or more than 85%; and the purity of phenylacetic acid is 99.0% or more than 99.0%.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

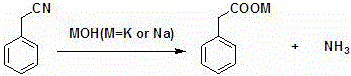

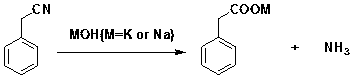

Preparation method of phenylacetic acid

InactiveCN108997106AEfficient manufacturingLow costPreparation from carboxylic acid saltsPreparation by cyanide reactionPhenylacetic acidReaction temperature

The invention provides a preparation method of phenylacetic acid. The preparation method comprises the following steps: 1) adding benzyl chloride and sodium cyanide into a reaction kettle, carrying out heating to 60-120 DEG C for carrying out a cyaniding reaction to obtain an oil phase and a water phase, wherein the reaction time is 2-12 hours, the upper layer is a crude phenylacetonitrile product, and the lower layer is a wastewater layer; 2) adding a strong alkali or a strong alkali solution into the crude phenylacetonitrile product to carry out hydrolysis, controlling the hydrolysis temperature to be 40-120 DEG C, and controlling the pH value of a reaction end point to be 8-13, so as to obtain sodium phenylacetate and ammonia gas, wherein the ammonia gas enters an absorption system; and3) adding sulfuric acid or hydrochloric acid into the sodium phenylacetate obtained in the step 2) to carry out acidification, controlling the reaction temperature to be 20-80 DEG C, controlling thepH value of a reaction end point to be 1-2, precipitating a product by crystallization after the reaction is finished, and carrying out solid-liquid separation to obtain the phenylacetic acid. The preparation method can be used for rapidly and effectively preparing phenylacetic acid, cost is low, and benefits are good.

Owner:麻城市天恒商贸有限公司

Method for synthesizing amoxicillin and generating byproduct of sodium phenylacetate solution by using semi-direct method

InactiveCN107988306AHigh yieldImprove product qualityOrganic compound preparationCarboxylic acid salt preparationPhenylacetic acidBenzylpenicillin potassium

The invention relates to a method for synthesizing amoxicillin and generating a byproduct of a sodium phenylacetate solution by using a semi-direct method and belongs to the technical field of medicine preparation. The method comprises the following steps: splitting benzylpenicillin potassium into 6-APA (Amino Penicillanic Acid) and phenylacetic acid under the action of penicillin acylase, extracting a splitting solution with dichloromethane to separate 6-APA from the phenylacetic acid, putting ammonia water into an extraction water phase, adjusting the pH value of a material liquid to be neutral, removing the dichloromethane, putting the solid 6-APA into the obtained 6-APA dissolving liquid, and synthesizing the amoxicillin together with D-methyl p-hydroxyphenylglycinate under the actionof amoxicillin synthetase. A sodium phenylacetate solution can be prepared by alkalizing the dichloromethane obtained by extracting the splitting solution, the sodium phenylacetate solution can be directly applied to fermentation production of penicillin, the step of recycling the phenylacetic acid is avoided, and the production cost is reduced.

Owner:INNER MONGOLIA CHANGSHENG PHARMA

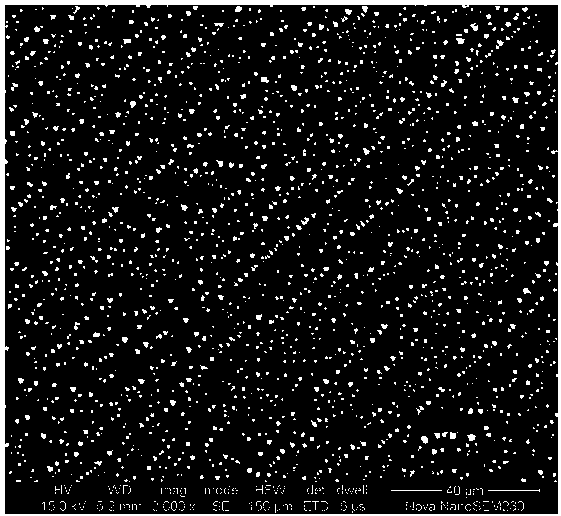

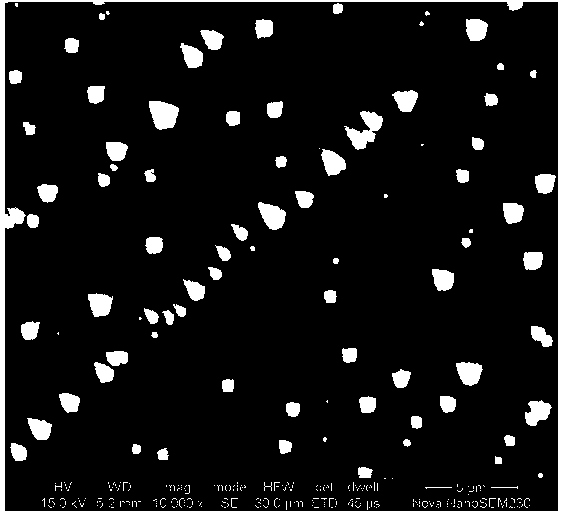

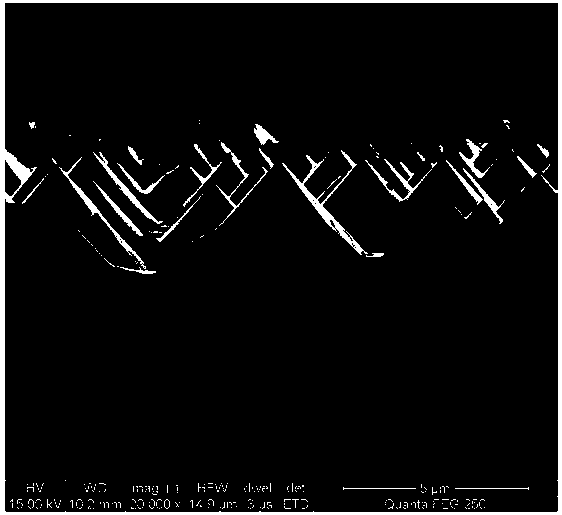

Formula of single-crystal silicon texturing additive containing polysaccharide and alcohol

InactiveCN110644055ANo toxicityNot corrosivePolycrystalline material growthAfter-treatment detailsSodium acetatePropanoic acid

The invention relates to an additive of a single-crystal silicon texturing liquid. The components of the additive are a polysaccharide, an alcohol, an organic acid sodium salt, sodium silicate and deionized water, wherein the polysaccharide is one or a mixture of more of water-soluble chitin, polyfructose, water-soluble starch, beta-cyclodextrin, and dextrin, and a weight ratio of the polysaccharide to water is 0.1-1.0:100; the alcohol is a lower alcohol, and is one or a mixture of more of n-propanol, 1,2-propanediol, n-butanol, 1,2-butanediol and tert-butanol, and a weight ratio of the alcohol to water is 1.0-3.0:100; the organic acid sodium salt is one or a mixture of more of sodium acetate, sodium formate, sodium propionate, sodium benzoate, and sodium phenylacetate, and a weight ratioof the organic aicd sodium salt to water is 0.1-1.0:100; and a weight ratio of sodium silicate to water is 0.1-1.0:100. A formula of a single-crystal silicon surface texturing agent is as follows: 30.0-50.0 mL of a NaOH solution with a concentration of 30% by weight is added into 1 L of deionized water, and 8.0-18.0 mL of the additive is added.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

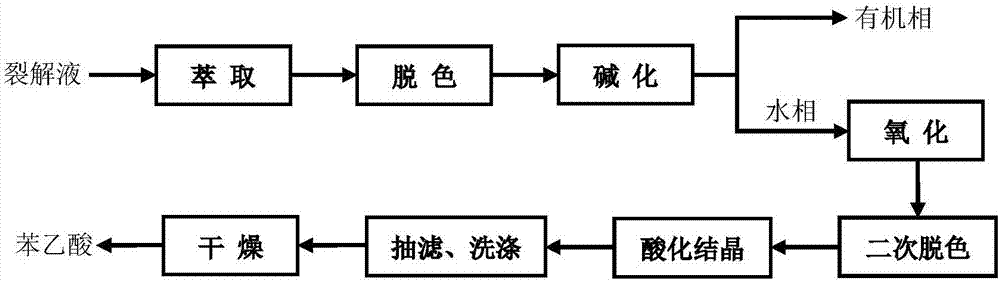

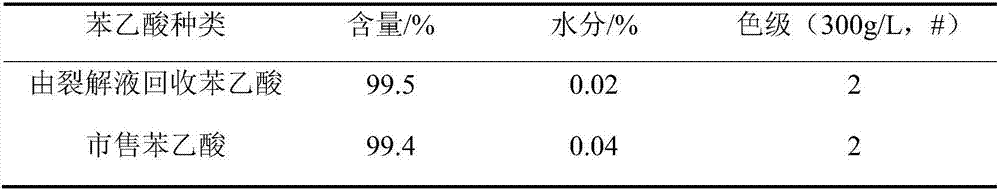

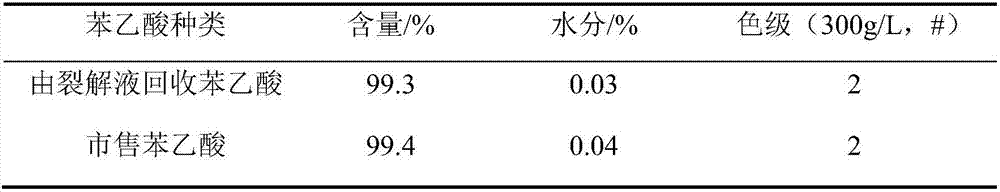

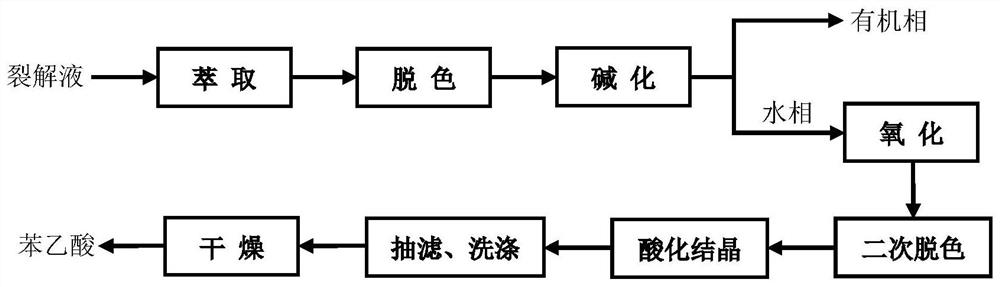

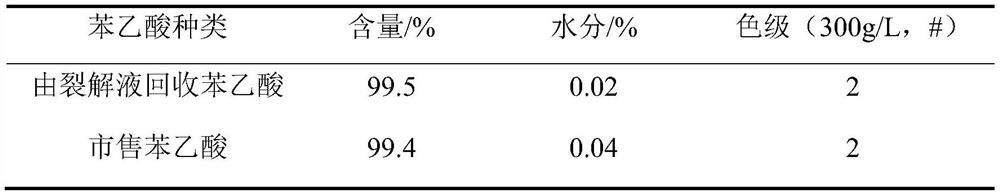

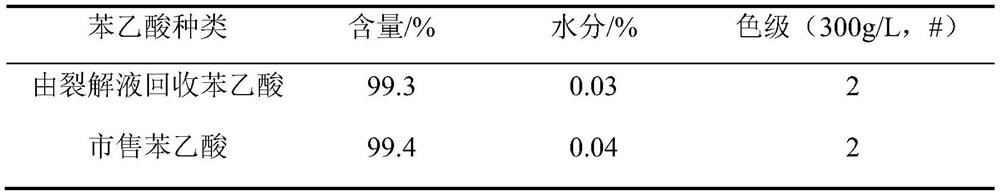

Method for recovering phenylacetic acid from benzylpenicillin potassium lysis solution

ActiveCN107382694AImprove solubilityHigh boiling pointPreparation from carboxylic acid saltsOrganic compound preparationPhenylacetic acidBenzylpenicillin potassium

The invention relates to a method for recovering phenylacetic acid from a benzylpenicillin potassium lysis solution and belongs to the technical field of pharmacy. The method for recovering the phenylacetic acid from the benzylpenicillin potassium lysis solution comprises the steps that the benzylpenicillin potassium lysis solution is extracted through an organic solvent; an organic phase is decolored through an activated carbon and alkalized through a sodium hydroxide solution; and the obtained alkalized water phase is oxidized with hydrogen peroxide and decolored with activated carbon so that a sodium phenylacetate aqueous solution with a light color can be obtained, the sodium phenylacetate aqueous solution is acidized and crystallized through concentrated sulfuric acid, washed with cold water and dried, and phenylacetic acid is obtained. The obtained phenylacetic acid product is high in quality, no waste difficult to deal with is generated in the recovering process, and the method is suitable for large-scale application.

Owner:INNER MONGOLIA CHANGSHENG PHARMA

Production process of high-quality phenylacetic acid

ActiveCN106278859AImprove qualityEfficient separationPreparation from carboxylic acid saltsCarboxylic acid salt preparationDesorptionPhenylacetic acid

The invention discloses a production process of high-quality phenylacetic acid, and relates to the technical field of phenylacetic acid production. The production process includes the following steps that 1, benzyl cyanide is added dropwise into a water solution of sodium hydroxide or potassium hydroxide in a reflux state, a water solution of sodium phenylacetate or potassium phenylacetate is obtained through heat preservation, and the pH is adjusted to be 6-8; 2, extraction and impurity removal are carried out, wherein an extraction agent used in extraction is one or more of benzene, alkyl halide and ether organic solvent; 3, the water solution of sodium phenylacetate or potassium phenylacetate obtained after extraction enters an inlet in the upper portion of a desorber, and nitrogen is blown into an inlet in the lower portion of the desorber to desorb and separate the contained organic solvent; 4, activated carbon is used for adsorbing the water solution of sodium phenylacetate or potassium phenylacetate obtained after desorption; 5, water solution of sodium phenylacetate or potassium phenylacetate obtained after adsorption is acidized to obtain high-quality phenylacetic acid. The process can effectively increase the phenylacetic acid content and achieve continuous operation and is high in yield.

Owner:HEBEI CHENGXIN

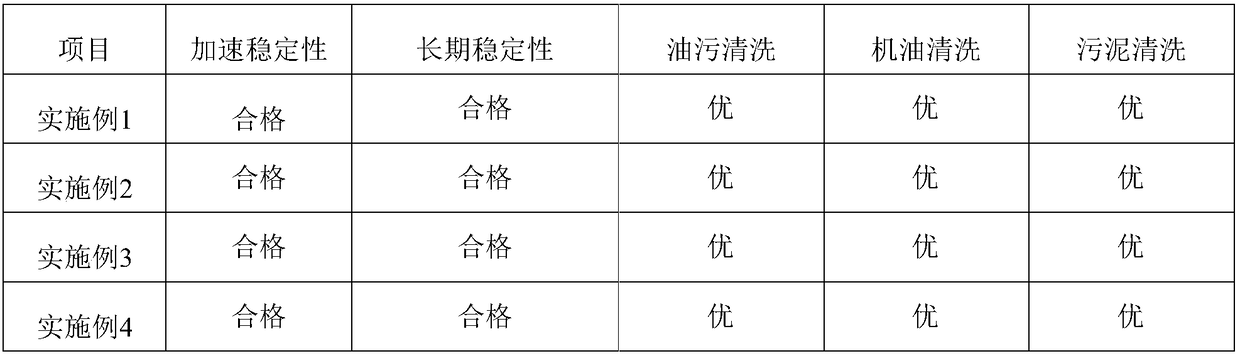

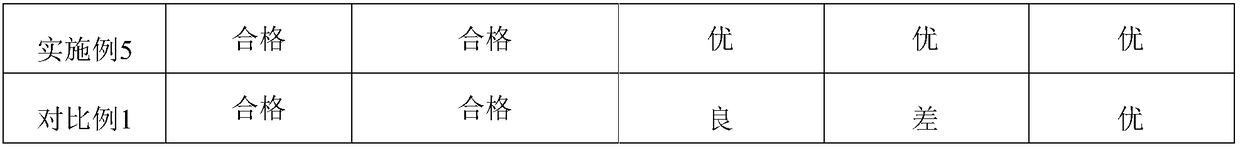

All-round cleaning agent and preparation method thereof

InactiveCN108998257AEasy to cleanBeautiful colorInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSulfonateCleansing Agents

The invention provides an all-round cleaning agent. The cleaning agent is prepared from 3-6 parts by mass of mixed sodium salt and 4-5 parts by mass of lauryl dimethyl ammonium oxide, wherein the mixed sodium salt contains sodium xylene sulfonate, sodium benzene sulfonate and sodium phenylacetate in a mass ratio of (2-5):(1-3):(3-6). The all-round cleaning agent has high cleaning effect, attractive product color and excellent cleaning effect on various impurities such as stains, scale, oil stains and the like, and has wide application in industrial and agricultural production and life.

Owner:河北晨晨环境科技有限公司

Preparation method for phenylacetic acid

InactiveCN107698433AEfficient manufacturingLow costPreparation from carboxylic acid saltsPreparation by cyanide reactionPhenylacetic acidReaction temperature

The invention provides a preparation method for phenylacetic acid. The method comprises the following steps: 1) adding benzyl chloride and sodium cyanide into a reaction kettle, raising the temperature to 60-120 DEG C, and performing a cyanation reaction for 2-12h to obtain an oil phase and a water phase, wherein the upper layer is a crude product of phenylacetonitrile, and the lower layer is a waste-water layer; 2) adding a strong alkali or a strongly-alkaline solution into the crude product of the phenylacetonitrile, performing hydrolysis, wherein the hydrolysis temperature is 40-120 DEG C,and controlling the pH at a reaction endpoint to be 8-13 to obtain sodium phenylacetate and an ammonia gas, wherein the ammonia gas enters an absorption system; and 3) adding sulfuric acid or hydrochloric acid into the sodium phenylacetate obtained by the step 2) for acidification, wherein the reaction temperature is 20-80 DEG C, enabling the pH at a reaction endpoint to be 1-2, after a reaction is finished, precipitating a product by crystallization, and performing solid-liquid separation to obtain the phenylacetic acid. The preparation method provided by the invention can quickly and effectively prepare the phenylacetic acid, and has low costs and good benefits.

Owner:潍坊滨海石油化工有限公司

Formula of monocrystalline silicon texturing additive containing polyol and PEG

InactiveCN110846721ASmall sizeNarrow distributionPolycrystalline material growthAfter-treatment detailsSodium acetateButanedioic acid

The invention relates to an additive formula of a monocrystalline silicon texturing liquid containing a polyol and PEG. The additive formula comprises the following components: the polyol, PEG, an organic acid sodium salt, an inorganic salt and deionized water; w herein the polyol is one or a mixture of more of MPD, ethylene glycol, 1, 2-propylene glycol, glycerol and 1, 4-butanediol, and the weight ratio of the polyol to water is (0.5-2.5): 100; the PEG comprises one or a mixture of more of PEG 200, PEG 400, PEG 600, PEG 800 and PEG 1000, and the weight ratio of the PEG to water is (1.0-3.0):100; the organic acid sodium salt is one or a mixture of more of sodium succinate, sodium oxalate, sodium benzoate, sodium phenylacetate and sodium isophthalate, and the weight ratio of the organic acid sodium salt to water is (0.1-1.0): 100; the inorganic salt is one or a mixture of more of NaCl, KCl, Na2SO4, K2SO4 and Na2SiO3, and the weight ratio of the inorganic salt to water is (0.1-1.0): 100. The formula of the monocrystalline silicon surface texturing agent is as follows: 20.0-40.0 mL of a NaOH solution with the weight percentage concentration of 30% is added to 1 L of deionized water,and 8.0-18.0 mL of the additive is added.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

Disposal method of sodium phenylacetate deesterification liquid generated by cracking penicillin G potassium salt crystallization mother liquor

ActiveCN109970226AReduce energy consumptionWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentLiquid wasteDialysis membranes

The invention provides a disposal method of sodium phenylacetate deesterification liquid generated by cracking a penicillin G potassium salt crystallization mother liquor and belongs to the technicalfield of pharmaceutical wastewater disposal. The method comprises the steps of mixing a sodium phenylacetate deesterification liquid and active carbon, removing a penicillin degradation product, and conducting filtering to obtain a predisposed sodium phenylacetate deesterification liquid; carrying out primary dialysis on the predisposed sodium phenylacetate deesterification liquid to obtain a primary dialysate and a primary concentrated liquid, wherein the cut-off molecular weight of a dialysis membrane used for the primary dialysis is 6,000-10,000 Da; performing secondary dialysis on the primary dialysate to obtain a secondary dialysate and a secondary concentrated liquid, wherein the cut-off molecular weight of a dialysis membrane used for secondary dialysis is 1,000-4,000 Da; concentrating the secondary dialysate and returning the secondary dialysate to a penicillin fermentation working section. According to the disposal method, there is no need to add hydrogen peroxide or conduct crystallization and crystallization remelting, the amount of generated waste liquid is small, and the energy consumption is low.

Owner:同舟纵横(厦门)流体技术有限公司 +1

Formula of composite texturing liquid additive for preparing fine pyramid single crystal silicon texture

ActiveCN110644056AReduce reflectionGood texture effectPolycrystalline material growthAfter-treatment detailsTripropylene glycolSodium acetate

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

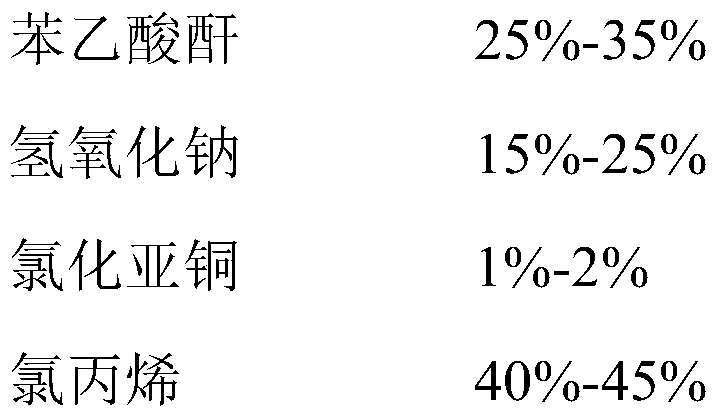

EVA adhesive film for solar battery and preparation method thereof

InactiveCN107286870AGood light transmissionStrong anti-aging abilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesAcetic anhydridePolymer science

The invention discloses an EVA adhesive film for solar cells and a preparation method thereof. The adhesive film includes the following raw materials: ethylene-vinyl acetate copolymer, sodium phenylacetate, nano-carbon, aluminum foam, copper foam, phenalkamine, ethylmethyltrichlorosilane, aluminum tripolyphosphate, ethylene peroxide resin, alkyd resin , castor oil, acetic anhydride, cellulose acetate, carbon tetrachloride, polypropylene alcohol. Weigh raw materials; sodium phenylacetate, nano-carbon, phenalkamine, trichlorosilane, aluminum tripolyphosphate, ethylene peroxide resin, alkyd resin, castor oil, acetic anhydride, cellulose acetate, carbon tetrachloride , polypropanol into the reaction kettle, heating and melting while stirring to obtain the first mixture; put ethylene-vinyl acetate copolymer and the first mixture into the three-roll blender to extrude the masterbatch, and stretch it on the copper drum to obtain the film. The EVA adhesive film of the invention has high transparency, good weather resistance, low melting point and anti-aging, and the solar cell prepared by using the adhesive film has a long service life.

Owner:JURONG GCL SYST INTEGRATION TECH CO LTD

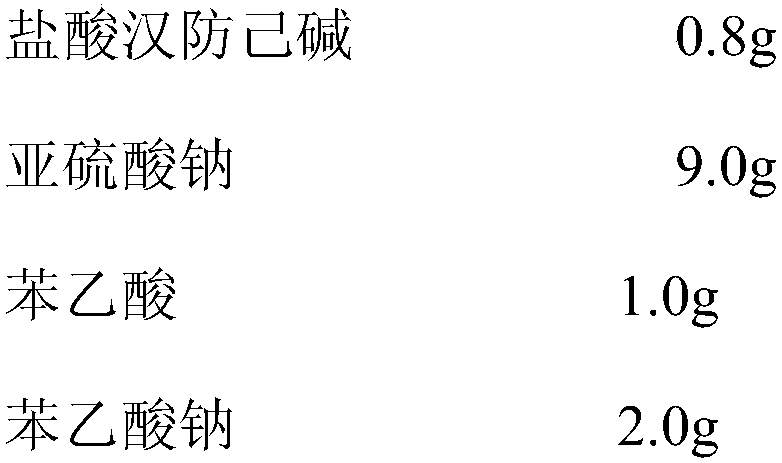

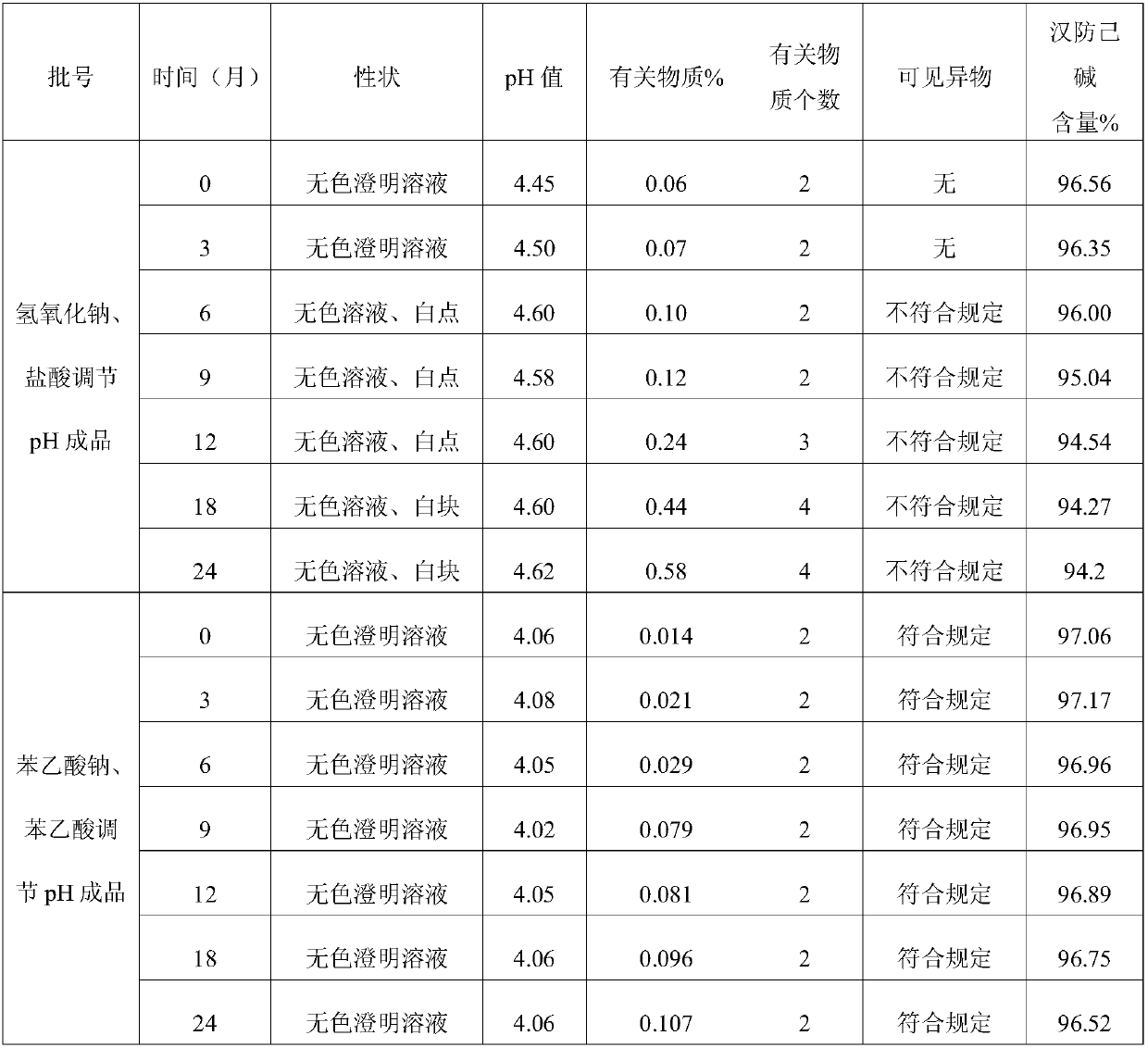

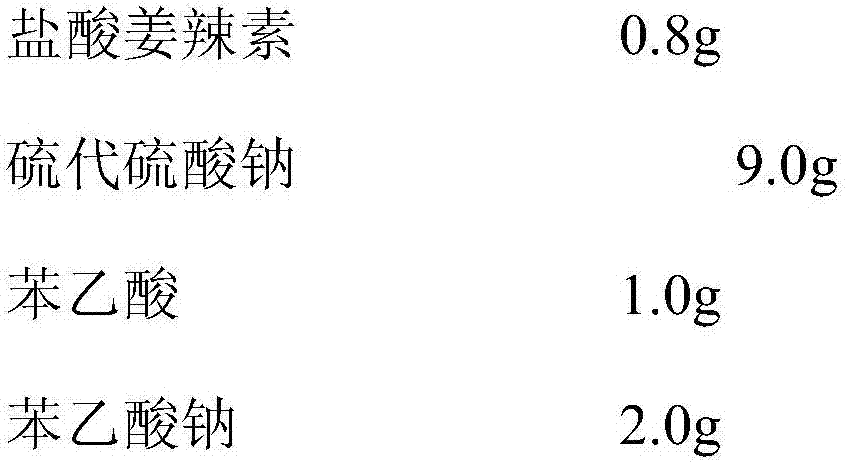

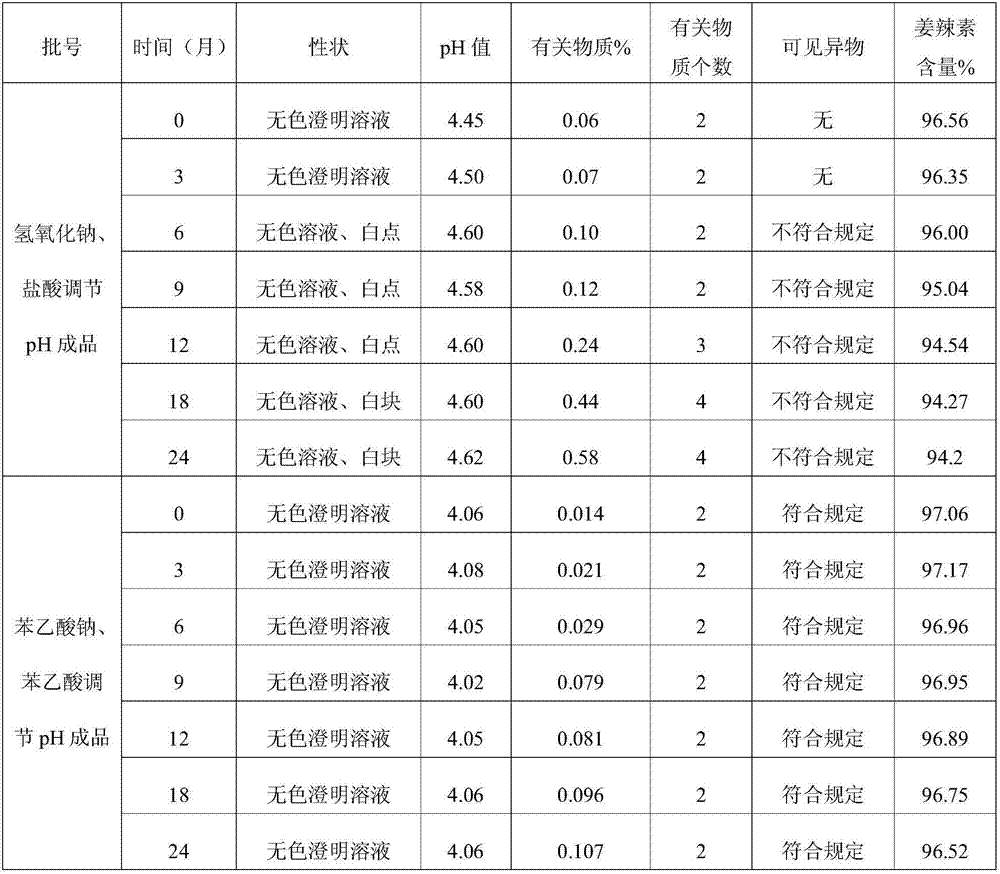

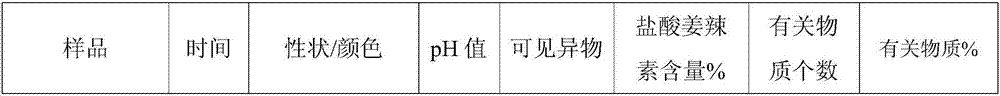

Injection medicine composition of tetrandrine

InactiveCN107744501AStable pHDecrease of tetrandrine degradation substancesOrganic active ingredientsAntipyreticHydrogenPhenylacetic acid

The invention discloses an injection medicine composition of tetrandrine. The injection medicine composition is characterized in that salt of tetrandrine is dissolved into injection water, and phenylacetic acid and / or sodium phenylacetate is used as a pH (potential of hydrogen) adjuster and is added to adjust the pH value of medicine liquid, so as to obtain the injection medicine composition; theusage amount of the phenylacetic acid and / or sodium phenylacetate is 0.1mg to 200.0mg / 100ml. The injection medicine composition has the advantages that the pH value of the injection liquid is more stable; compared with the prior art, the content of degrading matters of the tetrandrine is greatly reduced; under the condition of avoiding using other cosolvents increasing the clinical application risk, the clarification degree of the tetrandrine injection liquid is improved, and especially the problems of small white spots, white blocks, and solution turbidity under the condition of longer storage time are solved when the tetrandrine injection liquid adopts the prior art product; after checking, the content of visible foreign matters in the product meets the requirement of medicine quality standard, and the injection medicine composition is suitable for clinical medicine application and popularization.

Owner:CHENGDU XIANXIANXIAN BIOTECH CO LTD

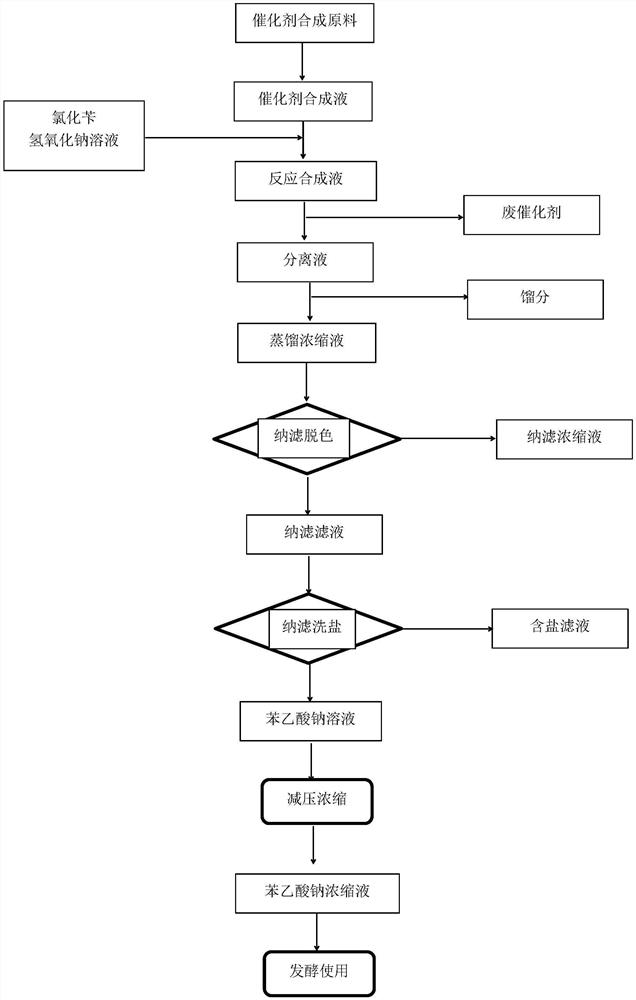

In-situ carbonylation method straight-through liquid sodium phenylacetate synthesis method and application

ActiveCN112430182ASynthetic conditions are mildProcess stabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSodium acetatePtru catalyst

The invention discloses an in-situ carbonylation method straight-through liquid sodium phenylacetate synthesis method, which comprises the following steps of adopting cobalt salt and carbon monoxide as raw materials, adopting methanol as a solvent, adopting sodium thiosulfate, sodium sulfide and manganese metal as auxiliary materials, and carrying out low pressure synthesis under a stirring condition to obtain a cobalt carbonyl catalyst, introducing carbon monoxide into the catalyst system, adding benzyl chloride and liquid caustic soda in situ, and carrying out low-pressure synthesis under astirring condition to obtain sodium phenylacetate, carrying out in-situ aeration, cobalt and manganese precipitation and solid-liquid separation in a synthesis system, collecting a separation solution, and distilling to obtain a distilled concentrated solution, and performing decoloration, salt leaching and concentration on the distilled concentrated solution to obtain a sodium phenylacetate concentrated solution which can be directly used for penicillin fermentation. The synthesis method disclosed by the invention is simple to operate, continuous in process unit, free of repeated process units in the process and in accordance with atom economy, and the prepared sodium phenylacetate is high in purity and high in yield. No acidic wastewater is generated in the process treatment process, nophenylacetic acid containing peculiar smell is generated, the wastewater treatment cost is low, and the process is environmentally friendly.

Owner:INNER MONGOLIA CHANGSHENG PHARMA

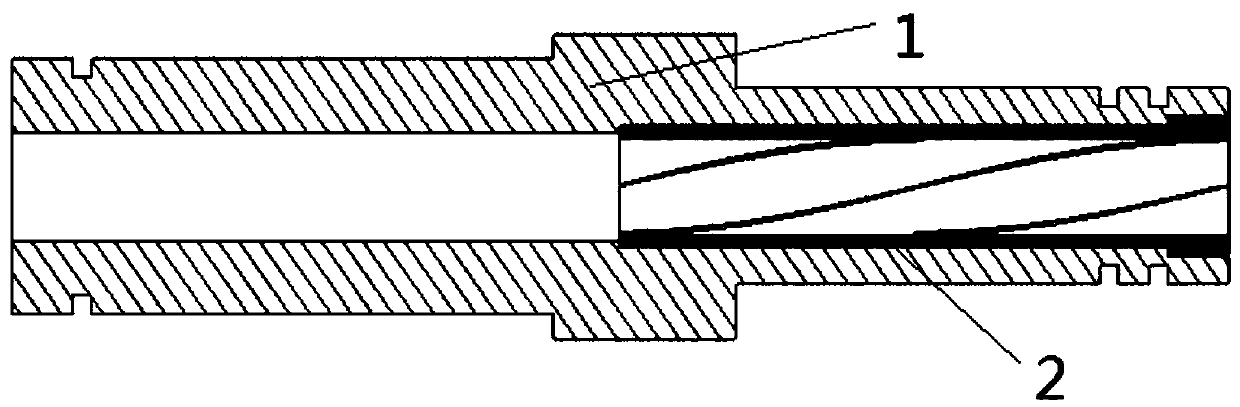

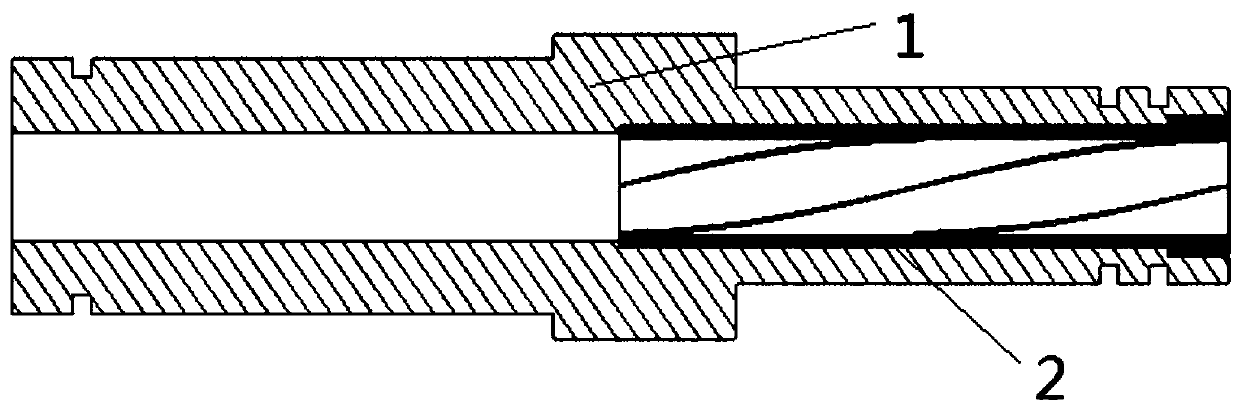

Synthetic method of furbenicillin acid

The invention relates to a method for synthesizing furbenicillin acid, which comprises the following steps: adding 6-APA into halogenated alkane, and dissolving the 6-APA by an alkalizer to obtain a solution a; dissolving alpha-furanuride sodium phenylacetate in the halogenated alkane, and esterifying the solution to obtain an estolide solution b of alpha-furanuride phenyl acetic acid; and after the solution a and the solution b are subjected to a condensation reaction at a temperature of between 20 DEG C below zero and zero DEC, adjusting pH to be between 5.5 and 6.7 to make the solution split phase, reclaiming an organic phase, adding an extracting agent into a water phase, acidifying and layering the solution, and dripping the extracting agent into the organic phase to separate out furbenicillin acid crystal. The method for synthesizing the furbenicillin acid fully adopts water avoidance reaction, the yield of products reaches more than 78 percent, the purity is improved to more than 90 percent, the content of the total impurities is reduced to below 10 percent, and the method has the advantages of simple production process and stable quality.

Owner:朗致集团江西医药有限公司

Safe environmental-friendly cleaning solution

The invention relates to a safe environmental-friendly cleaning solution which is prepared from the following raw materials in parts by weight: 4-8 parts of polyoxyethylene sorbitan monooleate, 2.5-6 parts of 1,3-dimethyl-2-imidazolone, 1.5-6 parts of amide biphthalate, 2.3-7 parts of fatty acid polyoxyethylene ether, 3.6-8 parts of p-hydroxy sodium phenylacetate, 1.3-4 parts of triethanolamine, 4.4-8.7 parts of polydimethyl siloxane fluid, 4.1-7.6 parts of lauryl sodium sulfate and 3.4-6.7 parts of butyl methacrylate. The safe environmentally friendly cleaning solution disclosed by the invention has the beneficial effects of being safe and environmentally friendly, reducing the pollution on the environment, meeting the requirement on cleaning, completing the cleaning of equipment and being widely applied to metal equipment, composite metallic materials and the like.

Owner:QINGDAO QIYUAN ZHENDONG ELECTRIC

A kind of method that reclaims phenylacetic acid from penicillin potassium lysate

ActiveCN107382694BImprove solubilityHigh boiling pointPreparation from carboxylic acid saltsOrganic compound preparationSodium acetatePhenylacetic acid

The invention relates to a method for recovering phenylacetic acid from a benzylpenicillin potassium lysis solution and belongs to the technical field of pharmacy. The method for recovering the phenylacetic acid from the benzylpenicillin potassium lysis solution comprises the steps that the benzylpenicillin potassium lysis solution is extracted through an organic solvent; an organic phase is decolored through an activated carbon and alkalized through a sodium hydroxide solution; and the obtained alkalized water phase is oxidized with hydrogen peroxide and decolored with activated carbon so that a sodium phenylacetate aqueous solution with a light color can be obtained, the sodium phenylacetate aqueous solution is acidized and crystallized through concentrated sulfuric acid, washed with cold water and dried, and phenylacetic acid is obtained. The obtained phenylacetic acid product is high in quality, no waste difficult to deal with is generated in the recovering process, and the method is suitable for large-scale application.

Owner:INNER MONGOLIA CHANGSHENG PHARMA

A kind of production technology of high-quality phenylacetic acid

ActiveCN106278859BImprove qualityEfficient separationPreparation from carboxylic acid saltsCarboxylic acid salt preparationPhenylacetic acidDesorption

The invention discloses a production process of high-quality phenylacetic acid, and relates to the technical field of phenylacetic acid production. The production process includes the following steps that 1, benzyl cyanide is added dropwise into a water solution of sodium hydroxide or potassium hydroxide in a reflux state, a water solution of sodium phenylacetate or potassium phenylacetate is obtained through heat preservation, and the pH is adjusted to be 6-8; 2, extraction and impurity removal are carried out, wherein an extraction agent used in extraction is one or more of benzene, alkyl halide and ether organic solvent; 3, the water solution of sodium phenylacetate or potassium phenylacetate obtained after extraction enters an inlet in the upper portion of a desorber, and nitrogen is blown into an inlet in the lower portion of the desorber to desorb and separate the contained organic solvent; 4, activated carbon is used for adsorbing the water solution of sodium phenylacetate or potassium phenylacetate obtained after desorption; 5, water solution of sodium phenylacetate or potassium phenylacetate obtained after adsorption is acidized to obtain high-quality phenylacetic acid. The process can effectively increase the phenylacetic acid content and achieve continuous operation and is high in yield.

Owner:HEBEI CHENGXIN

Gingerol pharmaceutical composition for injection

InactiveCN107970427AStable pHDecreased substancesAntibacterial agentsNervous disorderPhenylacetic acidCLARITY

The invention discloses a gingerol pharmaceutical composition for injection. The pharmaceutical composition for injection is prepared mainly by the steps of dissolving salt of gingerol into water forinjection, adding phenylacetic acid and / or sodium phenylacetate as pH regulator(s) for regulating the pH value of liquid medicine, wherein the dosage of the phenylacetic acid and / or the sodium phenylacetate is 0.1-200.0mg / 100ml. The gingerol pharmaceutical composition can enable the pH value of injection to be more stable, and greatly reduces gingerol degradation substances compared with the priorart; under the premise of avoiding the use of other co-solvents which increase the risk of clinical application, the clarity of the gingerol injection is improved, and the problems that the ginger injection prepared from the products in the prior art has small white spots, white blocks and turbid solution after being stored for a long time can be particularly solved, and the visible foreign matter examination of the product is enabled to be in compliance with the provisions of the drug quality standards; therefore, the gingerol pharmaceutical composition for injection is convenient for clinical medication and promotion.

Owner:成都源来来科技有限公司

Synthetic method of furbenicillin acid

Owner:朗致集团江西医药有限公司

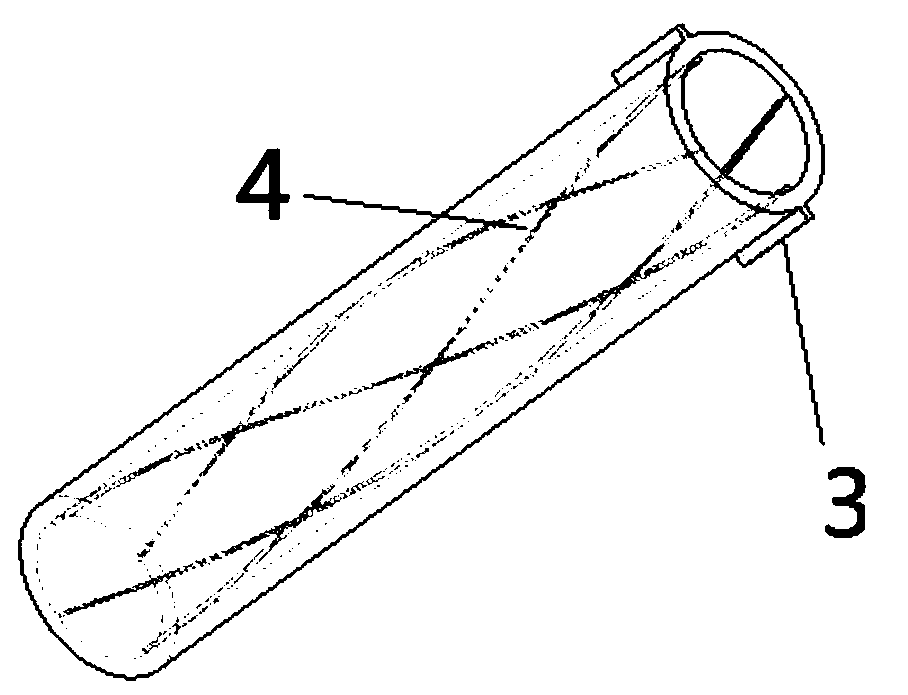

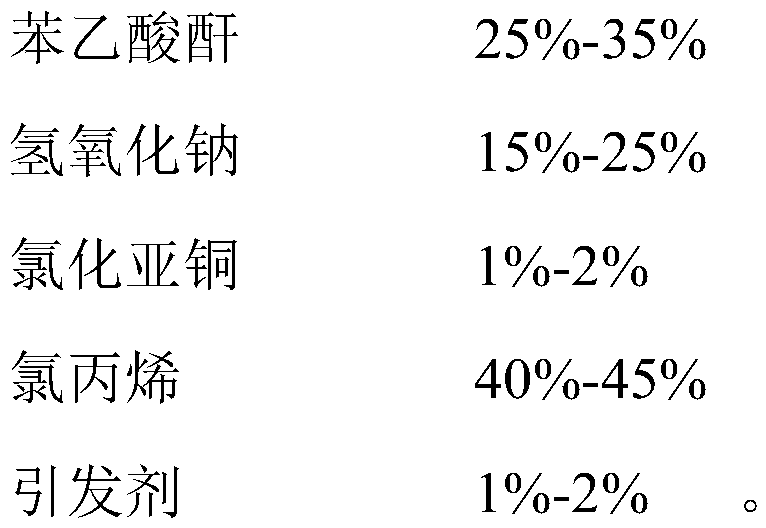

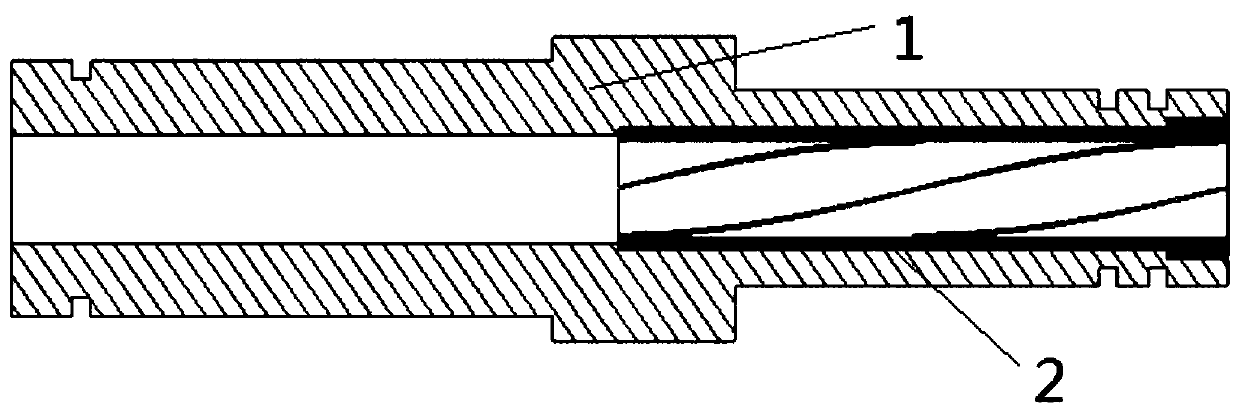

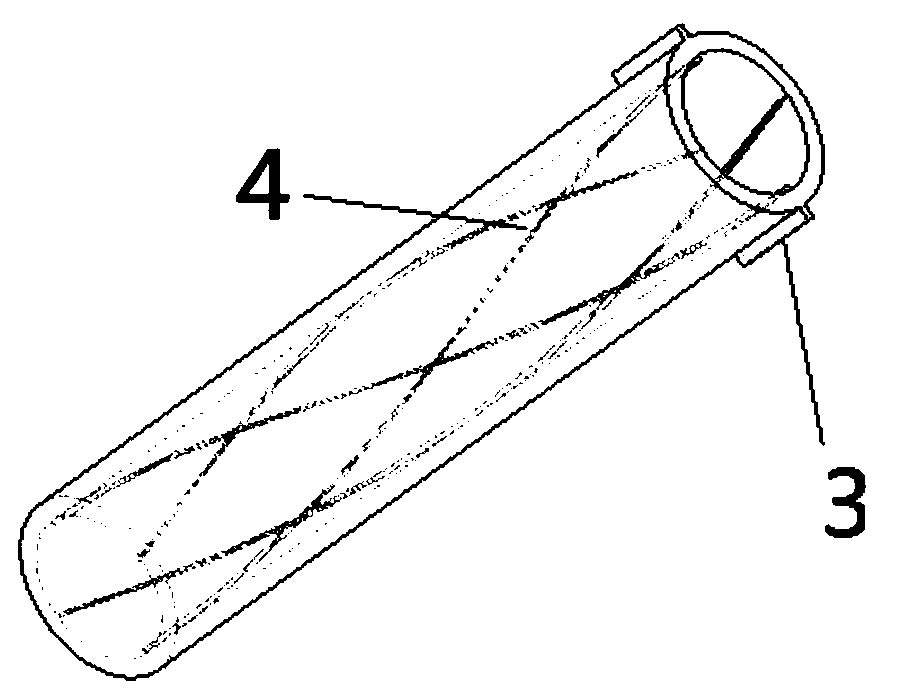

A method of using single-entry type ceramic wood

ActiveCN108789705BStable network structureImprove thermal stabilityWood treatment detailsPressure impregnationFiberSodium acetate

The invention discloses an application method of single body entry type ceramic wood. During ceramic wood preparing, sodium phenylacetate and chloropropene prepared through the reaction of phenylacetic acid and sodium hydroxide enters wood, allyl phenylacetate is generated, then, a high-molecular polymer is generated, and a net-shaped structure is formed by the high-molecular polymer and wood fiber. The interior-exterior structure, rigidity and strength of the ceramic wood can be consistent, and the interior and exterior waterproof performance, corrosion resisting performance, mothproof performance, anti-mold performance, safety performance and size stability of the ceramic wood are guaranteed, and therefore the ceramic wood can be directly used on the premise that coating of a coat is notconducted; and when the surface of the ceramic wood is old-fashioned, the performance of the ceramic wood is not influenced after grinding.

Owner:中吉亚(山东)新材料有限公司

Deformed steel bar slow-release quenching agent

The invention provides a slow-release quenching agent for threaded steel to prevent and slow down the corrosion of threaded steel in the atmosphere. A slow-release quenching agent for threaded steel provided by the invention comprises the following components in parts by mass: 2-5 parts of sodium sulfate, 4-6 parts of sodium hydroxide, 1-2 parts of starch, and 5-7 parts of sodium bicarbonate 6-8 parts of sodium phenylacetate, 5-8 parts of alum, and 60-70 parts of water. The invention also provides a preparation method of the slow-release quenching agent for rebar. The slow-release quenching agent for rebars of the invention can effectively prevent and slow down the corrosion of rebars in the atmosphere.

Owner:WUXI YANGGONG MACHINERY MFG

A kind of processing method of the sodium phenylacetate deesterification liquid that penicillin g potassium salt crystallization mother liquor pyrolysis produces

ActiveCN109970226BReduce energy consumptionWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentDialysis membranesSodium acetate

Owner:同舟纵横(厦门)流体技术有限公司 +1

Screen detergent

InactiveCN108611198AEasy to cleanEasy to useInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPhosphoric acidPropionitrile

Disclosed is a screen detergent. The screen detergent is mainly prepared from 3-8 parts of hydroxybutyric acid, 10-15 parts of mint juice, 5-10 parts of dioxide, 4-8 parts of sodium phenylacetate, 9-11 parts of castor oil, 8-16 parts of pyrrolidone, 5-10 parts of tri-ethyl alcohol, 10-24 parts of dihydroterpinyl acetate, 10-22 parts of tableware cleaning agent, 3-8 parts of polyoxyethylene, 1-12 parts of acrylic acid, 3-8 parts of ethyl alcohol, 8-12 parts of osmanthus flower fragrance, 6-12 parts of propionitrile, 6-13 parts of alcohol, 5-15 parts of phosphoric acid, 1-5 parts of polyethylene, 8-15 parts of dioxidase, 7-18 parts of pyrimidine, 20-29 parts of sorbic acid, 8-14 parts of amyl alcohol, 10-16 parts of sunflower dew, 8-18 parts of loquat leaves and 8-15 parts of aluminum oxide.The detergent can clean a screen conveniently and more thoroughly, is good in decontamination effect and convenient to use and does not damage hands.

Owner:薄福成

Method for recovering phenylacetic acid from waste liquid of enzymatically preparing 6-aminopenicillanic acid

ActiveCN106117042BQuality improvementEasy to operateOrganic compound preparationAlkali metal sulfites/sulfatesPhenylacetic acidFermentation

The invention relates to a method for recovering phenylacetic acid from waste liquid in preparation of 6-aminopenicillanic acid by an enzymic method. The method comprises the following steps: 1) using toluene to extract phenylacetic acid; 2) preparing a sodium phenylacetate aqueous solution with little impurity; and 3) using macroreticular resin for recovering phenylacetic acid from a water phase containing low-concentration phenylacetic acid. According to the invention, toluene is extracted from waste liquid in preparation of 6-aminopenicillanic acid by the enzymic method, a toluene phase containing phenylacetic acid and a water phase containing low-concentration phenylacetic acid are obtained; the toluene phase containing phenylacetic acid is extracted through alkali lye to obtain the sodium phenylacetate aqueous solution with high quality, the sodium phenylacetate aqueous solution can be directly used for producing penicillin through fermentation; the water phase containing low-concentration phenylacetic acid is pretreated for recovering sodium sulfate, macroreticular resin is used for absorbing phenylacetic acid for recovery, the low concentration water after adsorption can be directly discharged, zero discharge of phenylacetic acid can be almost realized, win-win of economy and environmental protection can be achieved, the by-product sodium sulfate can be used for fermentation, and also has economic benefit.

Owner:SHANXI WEIQIDA PHARMA IND

Chromium-free passivator

InactiveCN111041465AIncreasing the thicknessImprove compactnessMetallic material coating processesSodium bicarbonatePhosphoric Acid Esters

The invention discloses a chromium-free passivator. Every 1 l of the chromium-free passivator is prepared from components by mass including 50% of amino silane or / and epoxy silane, 2% of polyacrylic acid, 5% of tetraethoxysilane, 5% of starch, 5% of sodium phenylacetate, 2% of polyurethane, 8% of melamine, 1% of cold-drawn polypropylene fibers, 4% of phosphorus-containing polyalcohol, 3% of polyamide polyethylene glycol, 1% of sodium bicarbonate, 3% of starch phosphate, 2% of isopropanol, 5% of polyurethane, 3% of liquid paraffin, 2% of iron oxide yellow, 1% of rare earth ions, 1% of barium dioxide nano-particles and the balance water. According to the passivator, as multiple kinds of organic phosphoric acid, multiple kinds of metal ions and multiple kinds of nano-particles are chelated todifferent degrees, on one hand, the thickness and the density of a passivation film can be enhanced; and meanwhile the passivation film (inorganic film) obtained after chelating is completed can display colors to a certain degree on the surface of an aluminum alloy.

Owner:南京明仁光电科技有限公司

A compound texturizing liquid additive formula for preparing fine and dense pyramid monocrystalline silicon texture

ActiveCN110644056BNo toxicityNot corrosivePolycrystalline material growthAfter-treatment detailsTripropylene glycolSodium acetate

The invention relates to an additive for monocrystalline silicon texturing liquid. The components of the additive include polyvinylpyrrolidone (PVP), diol, benzene-containing organic acid salt, sodium silicate and deionized water. Among them, PVP is a mixture of one or more of PVP‑K12, PVP‑K15, PVP‑K17, PVP‑K25, PVP‑K30, and the weight ratio to water is 0.2‑1.0:100; A mixture of one or more of ethylene glycol, triethylene glycol, tetraethylene glycol, dipropylene glycol and tripropylene glycol, with a weight ratio of 1.0‑3.0:100 to water; containing benzene Organic acid salt is a mixture of one or more of sodium benzoate, potassium benzoate, sodium phenylacetate, sodium terephthalate and sodium isophthalate, with a weight ratio of 0.1‑1.0:100 to water; sodium silicate and water The weight ratio is 0.1‑1.0:100. The formula of the monocrystalline silicon surface texturing agent is: add 25.0-45.0 mL of NaOH solution with a concentration of 30% by weight in 1 L of deionized water, and add 10.0-20.0 mL of this additive.

Owner:HUNAN INSTITUTE OF SCIENCE AND TECHNOLOGY

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com