A method of using single-entry type ceramic wood

A technology of ceramics and monomers, applied in wood impregnation, wood treatment, impregnated wood, etc., can solve the problems of easy deformation, mildew, corrosion, uneven polymer, and decreased waterproof performance of wood, so that it is not easy to dry and crack. Good moth performance and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in combination with specific embodiments.

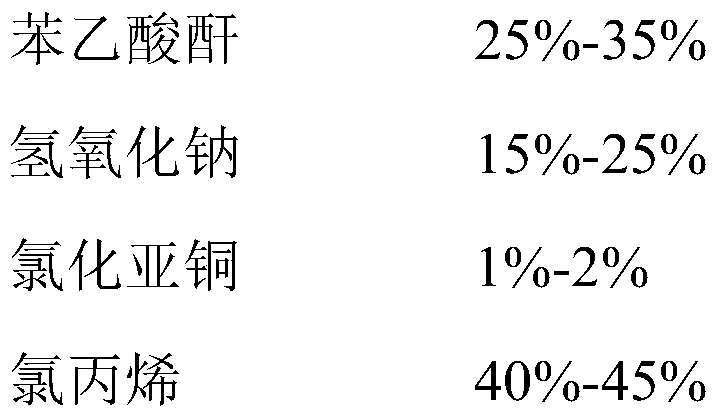

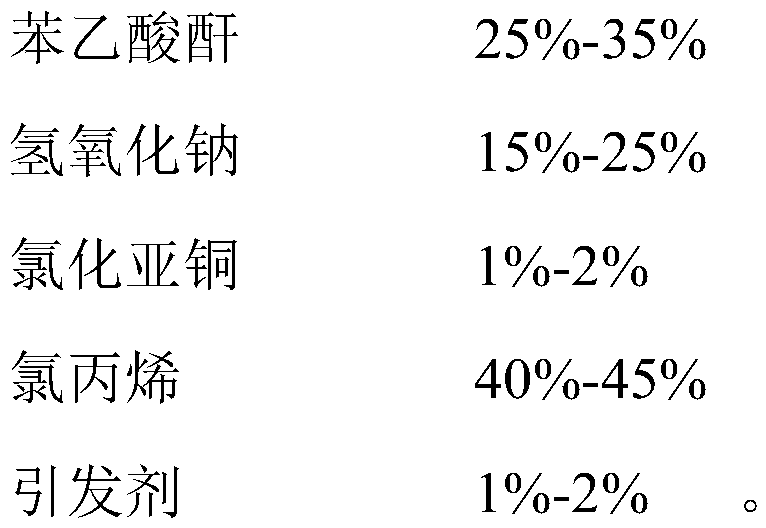

[0033] The use method of single entry type ceramic wood, ceramic wood is manufactured through the following steps:

[0034] (1) Prepare a storage container, add phenylacetic anhydride and sodium hydroxide into the storage container, stir to mix the two raw materials evenly, then add water, and then stir rapidly to make phenylacetic anhydride and sodium hydroxide use their own exothermic A reaction occurs to produce a clear, colorless solution.

[0035] (2) Put the wood into the reservoir containing the transparent and colorless solution generated in step (1), and seal the reservoir at room temperature for 10 to 24 hours, allowing the transparent and colorless solution generated in step (1) to enter the wood Inside, remove the wood when finished.

[0036] (3) Prepare a stainless steel storage tank, add diethyl ether solvent in the stainless steel storage tank, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com