Recycled aggregate concrete and preparation method thereof

A recycled aggregate and concrete technology, applied in the field of building materials, can solve problems such as easy cracks on the surface, seepage erosion, poor durability of marine engineering components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

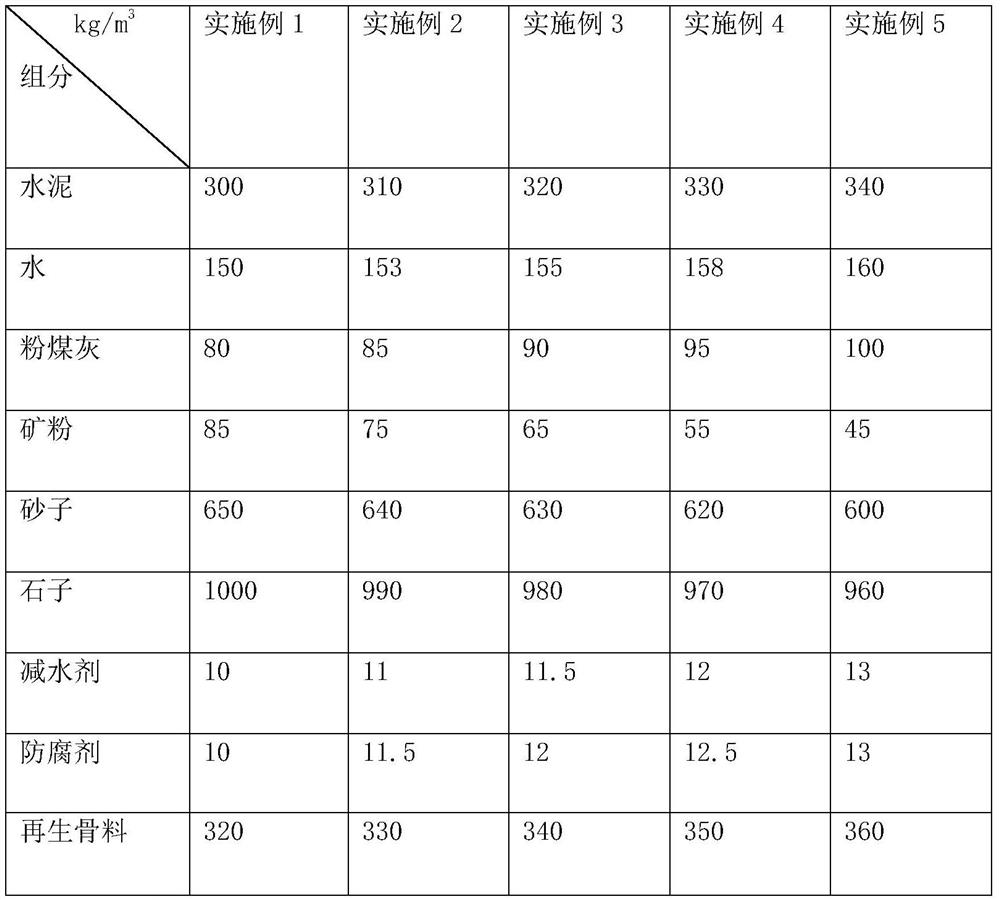

Examples

preparation example 1-6

[0037] In the preparation example 1-6, the aramid resin is selected from Shandong Jufang New Material Co., Ltd., the model is U200; the water glass is selected from Hubei Zhenghe Technology Co., Ltd., the model is S-1430B; the nano-calcium carbonate is selected from Lingshou County Aotai Mineral Products Processing Plant, the model is AT797; the silica fume is from Lingshou County Yunda Mineral Products Co., Ltd., the product number is 06; the volcanic ash is from Lingshou County Huachen Mineral Products Trading Co., Ltd., the product number is 88.

preparation example 1

[0038] Preparation Example 1: (1) Grind 10kg of construction waste to below 40mm, add water to 5kg of water glass and 3kg of nano calcium carbonate, mix well, soak for 24h under a negative pressure of 0.02MPa, the amount of water added is water glass and nano calcium carbonate 10 times the total amount of calcium carbonate, the construction waste gradation is 5-25mm continuous gradation, the needle flake particle content is 5%, the crushing index is 14%, and the bulk density is 1350kg / m 3 , water content is 1.6%, and 24h water absorption rate is 9%, and construction waste is made through removing steel bar, crushing by the waste and old concrete blocks that road reconstruction demolishes; (2) in step (1) gained construction waste, add 4kg silica fume, 5kg Volcanic ash and water, after stirring evenly, stir for 40min under a negative pressure of 0.1MPa, filter, the amount of water added is 3 times the weight of construction waste, and dry to constant weight. The average particle...

preparation example 2

[0039] Preparation example 2: (1) crush 15kg of construction waste to less than 40mm, add water to 8kg of water glass and 5kg of nanometer calcium carbonate, mix well, soak for 22h under a negative pressure of 0.05MPa, the amount of water added is waterglass and nanometer calcium carbonate 15 times the total amount of calcium carbonate, the construction waste gradation is 5-25mm continuous gradation, the needle flake particle content is 6%, the crushing index is 15%, and the bulk density is 1380kg / m 3 , moisture content is 1.7%, and 24h water absorption rate is 9.5%, and construction waste is obtained through removing steel bar, crushing by the waste concrete block that road reconstruction demolishes; (2) in step (1) gained construction waste, add 6kg silica fume, 8kg After the volcanic ash and water are evenly stirred, they are stirred for 35 minutes under a negative pressure of 0.13MPa, filtered, and the amount of water added is 4 times the weight of construction waste, and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com