Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

283 results about "GLYCERYL ROSINATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Products & Informations. Glyceryl Rosinate, also called Glycerol Ester of Gum Rosin (GEGR) or Ester Gum, is an oil-soluble food additive. Its high density helps keep oils in suspension in water and this property is why it is often used as a beverage stabilizer.

Semi-Permanent Mascara Compositions

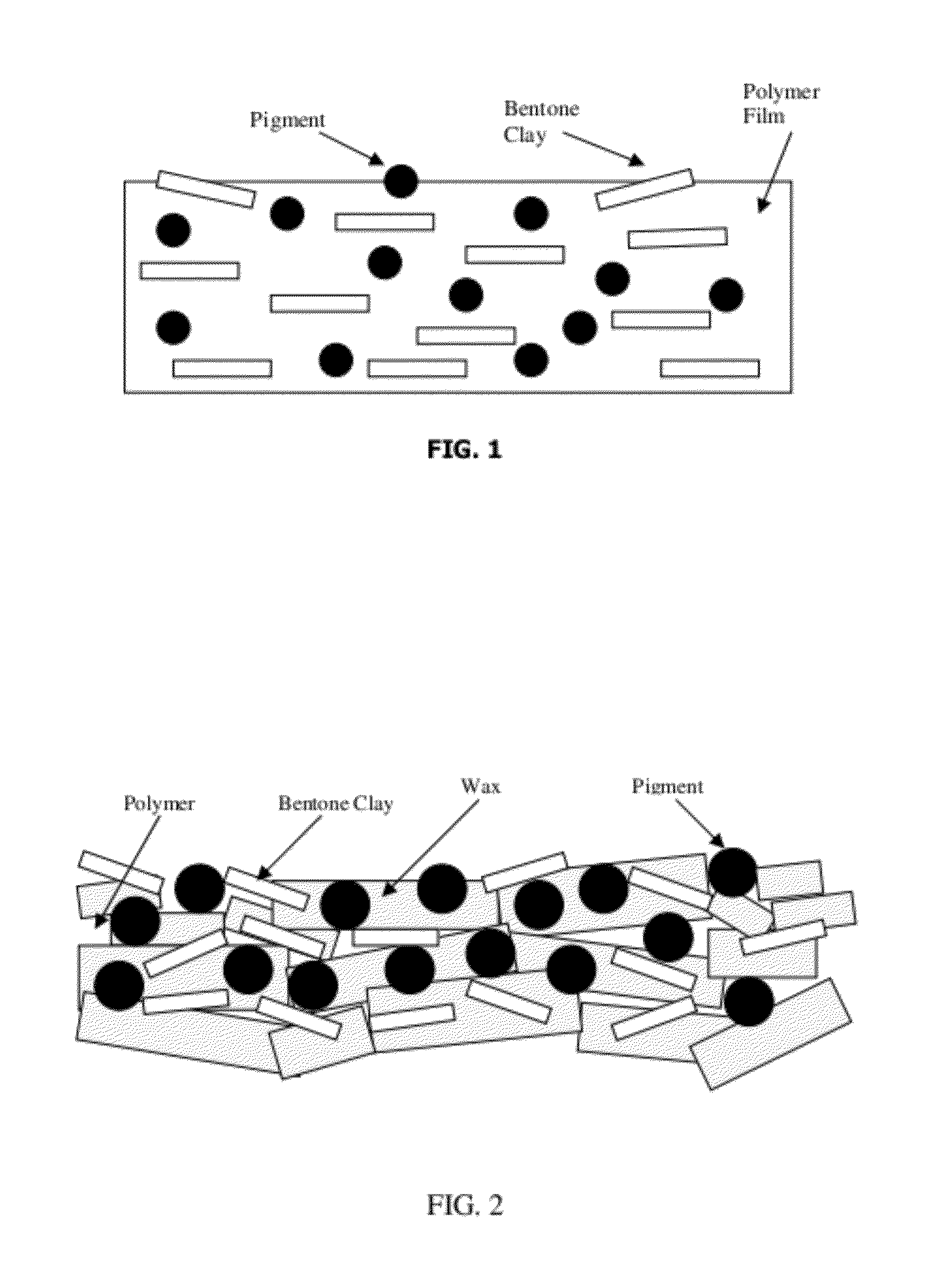

A semi-permanent mascara composition for use on eyelashes and / or eyelids that includes from 17% to 30%, by weight, of a film former selected from the group consisting of tall oil glyceride, pentaerythrityl rosinate, glyceryl rosinate, and the hydrogenated versions and mixtures thereof. Further there is from 0.1% to 14%, by weight, of a colorant and from 10% to 15%, by weight, of disteardimonium hectorite, and less than about 3% of wax. The semi-permanent mascara composition is long lasting and has excellent wear characteristics.

Owner:NOXELL CORP

Long-wear mascara compositions

InactiveUS20110094533A1Extend your lifeReduce solubilityCosmetic preparationsMake-upPentaerythritol rosinateFilm-forming agent

A cosmetic composition for use on eyelashes and / or eyelids that includes from about 15% to about 50%, by weight, of a film former selected from the group consisting of tall oil glyceride, pentaerythrityl rosinate, glyceryl rosinate, and the hydrogenated versions and mixtures thereof. Further there is from about 0.1% to about 14%, by weight, of a colorant. The cosmetic composition is long lasting and has excellent wear characteristics.

Owner:NOXELL CORP

Cold pressure-sensitive adhesive tape for pipeline anticorrosion

InactiveCN103602273AAvoid pollutionSimple construction processMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesAntioxidantEngineering

The invention provides a cold pressure-sensitive adhesive tape for pipeline anticorrosion. The cold pressure-sensitive adhesive tape can be directly used in the steel pipeline anticorrosion without a primer. The cold pressure-sensitive adhesive tape comprises a base film layer and a pressure-sensitive adhesive layer, wherein the base film layer is a high-density polyethylene sheet, and has a thickness of 0.1-0.3mm; and the pressure-sensitive adhesive layer comprises, by weight, 40-55 parts of butyl rubber, 20-35 parts of polyisobutylene, 10-25 parts of a tackifying resin, 1-8 parts of a plasticizing system, 0.1-1 part of an antioxidant, and 3-6 parts of an inorganic filler, wherein the tackifying resin is one or more of rosin glyceride, a C5 petroleum resin and a terpene resin. The cold pressure-sensitive adhesive tape can be directly used in the steel pipeline anticorrosion without a primer, so the pollution of benzene or gasoline organic solvents in the primer to the environment is avoided, and the construction technology is simplified, thereby the cold pressure-sensitive adhesive tape can be adapted to the anticorrosion of many types of pipelines.

Owner:JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

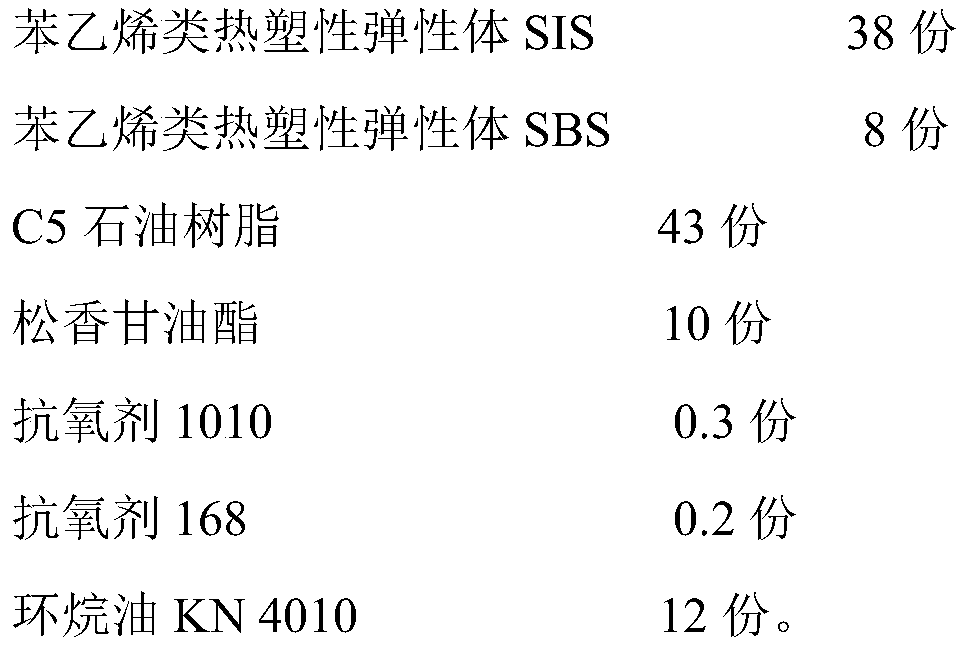

Hot-melt pressure sensitive adhesive for adhesive tapes, and preparation method thereof

InactiveCN110437778AImprove ring tackImprove peel forceMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPetroleum resinAntioxidant

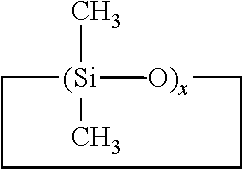

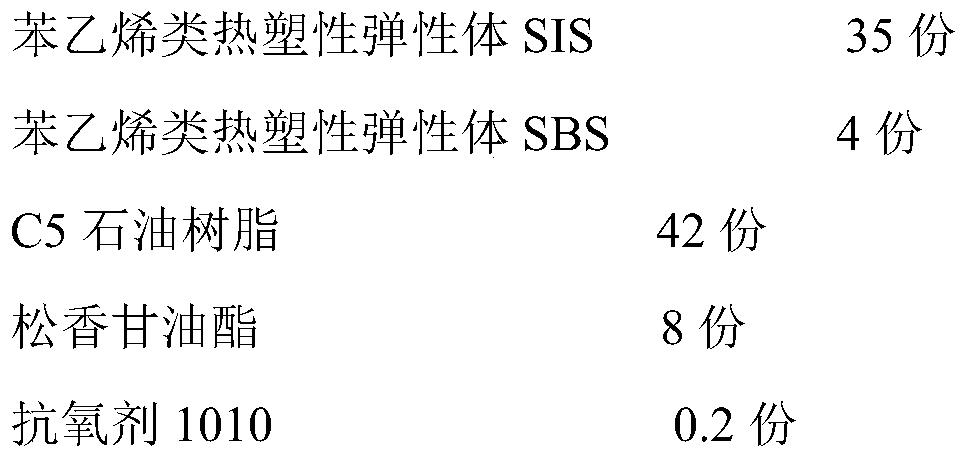

The invention relates to a hot-melt pressure sensitive adhesive, and concretely relates to a hot-melt pressure sensitive adhesive for adhesive tapes, and a preparation method thereof. The hot-melt pressure sensitive adhesive comprises a styrenic thermoplastic elastomer SIS, a styrenic thermoplastic elastomer SBS, petroleum resin, rosin glyceride, a primary antioxidant, an auxiliary antioxidant anda softener, wherein the styrenic thermoplastic elastomer SIS is a linear structure, the styrene content is 20-28%, and the diblock content is 20-28%; and the styrenic thermoplastic elastomer SBS is astar structure, the styrene content is 28-32%, and the diblock content is 12-18%. The purpose of the invention is to solve the problem of poor use performance of the adhesive tapes, caused by failedcombination of the initial adhesion, the permanent adhesion and the aging resistance of existing hot-melt pressure sensitive adhesives for adhesive tapes. The initial adhesion (the initial adhesion includes ring initial adhesion and 180 DEG peel strength) of the hot-melt pressure sensitive adhesive of the invention meets use requirements, and has a high adhesion and a good aging resistance. The present invention also provides the preparation method of the hot-melt pressure sensitive adhesive for adhesive tapes.

Owner:ZIBO LUHUA HONGJIN NEW MATERIAL CO LTD

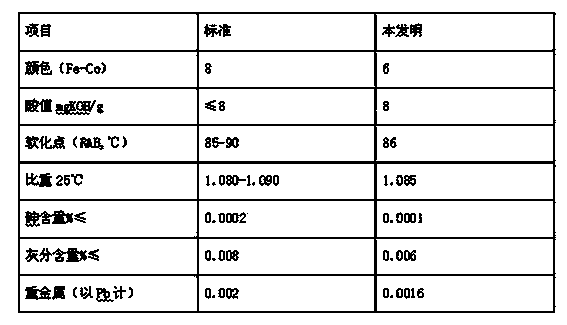

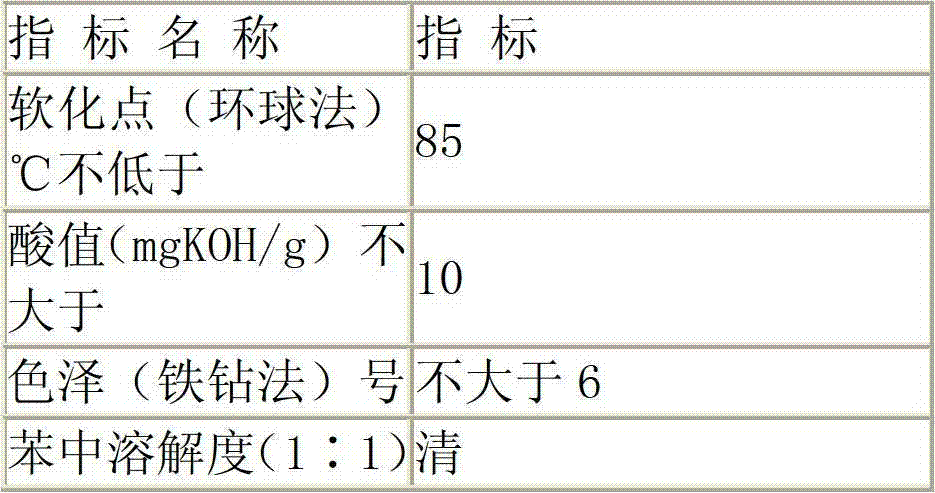

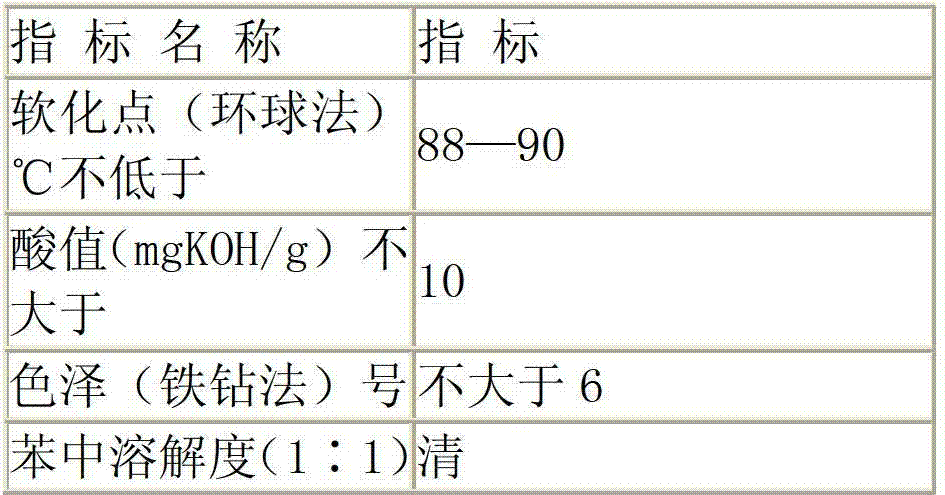

Method for preparing high-softening-point rosin glyceride from fumaric acid

InactiveCN101818027AMake up for the lack of low softening pointLow costNatural resin chemical modificationFumaropimaric acidChewing gum

The invention discloses a method for preparing high-softening-point rosin glyceride from a fumaric acid. The method comprises the following steps of: firstly, modifying rosin by using the fumaric acid; secondly, esterifying the modified rosion with glycerine; and finally, synthesizing a high-softening-point fumaric acid rosin glyceride product having a softening point of 100 to 150 DEG C. The modified rosin glyceride product prepared by the method has the characteristics of low cost, high softening point, high stability and good mouth-feel, is safe and reliable and can be applied in the industries of beverages, chewing gums and the like.

Owner:WUZHOU PINE CHEM

Aerosol photopolymer coating

InactiveCN101294049AEasy constructionColloidal particles are fine and uniformMineral oil hydrocarbon copolymer adhesivesShellac adhesivesElastomerCardboard

The invention discloses an aerosol spray adhesive, which contains two components of a base material and a propellant. In the aerosol spray adhesive, the base material and the propellant are filled together in an aerosol seal pot with a valve. The formula of the base material comprises (by weight): thermo-plastic elastomer 8 to 12 parts, terpene resin 8 to 12 parts, C9 petroleum resin 5 to 8 parts, rosin glyceride 2 to 4 parts, ethyl acetate 8 to 12 parts, butyl acetate 12 to 18 parts, extraction solvent oil No.6 30 to 50 parts, BHT 0.2 to 1.0 parts, and naphthenic oil 1 to 2 parts. The aerosol spray adhesive has the advantages that the product is filled as aerosol and sealed in a pot, so that the product can be sprayed without the need of matched facilities when in use and is convenient in construction; the sprayed adhesive particles are fine and uniform to prevent wrinkling when being used for adhering fine and thin materials; and the product can be used for adhering various materials such as paper sheets, plastics, thick paper boards, foam and metal.

Owner:GUANGDONG SANVO CHEM IND TECH

Methods of coating eyelashes and eyelids with a long-wearing mascara composition

InactiveUS20110117043A1Extend your lifeReduce solubilityCosmetic preparationsHair removalEyelidEyelash

A method of coating eyelashes and / or eyelids with a cosmetic composition that includes from about 15% to about 50%, by weight, of a film former selected from the group consisting of tall oil glyceride, pentaerythrityl rosinate, glyceryl rosinate, and the hydrogenated versions and mixtures thereof. Further there is from about 0.1% to about 14%, by weight, of a colorant. The cosmetic composition is long lasting and has excellent wear characteristics.

Owner:THE PROCTER & GAMBLE COMPANY

Efficient plasticizer

The invention discloses an efficient plasticizer. The efficient plasticizer comprises, by weight, 12-15 parts of sodium stearoyl lactylate, 10-15 parts of diacetyl tartaric acid ester of mono- and glycerides, 15-18 parts of glycerol monolaurate, 10-12 parts of glycerol ester of rosin, 8-10 parts of sodium polyacrylate, 6-8 parts of barium stearate, 8-10 parts of isopropanol, 6-8 parts of hyaluronic acid, 15-20 parts of tetrafluoroethylene, 12-15 parts of acetyl, 16-20 parts of carbitol, 20-22 parts of diethanol amine, 5-8 parts of phenoxy ethanol, 10-15 parts of acrylic modified alkyd resin, 12-15 parts of mercaptoacetic acid and 6-8 parts of chloroacetic acid. The efficient plasticizer has the advantages that plasticity and flexibility of plastic materials can be enhanced, environment protection performance is good, surface strength of the plastic materials can be also enhanced, environment pollution is reduced due to low plasticizing temperature, and product performance is improved.

Owner:司徒建辉

Medical hydrocolloid pressure-sensitive adhesive and preparation method thereof

InactiveCN104371614AGood initial adhesionFast water absorptionNon-macromolecular adhesive additivesStarch derivtive adhesivesAntioxidantIsoprene

The invention provides a medical hydrocolloid pressure-sensitive adhesive and a preparation method thereof. The pressure-sensitive adhesive is prepared from styrene-isoprene-styrene block copolymer, ester gum, acetate starch, copal, sodium alginate, sodium carboxymethyl cellulose, phthalate, polyisobutylene, an antioxidant, an auxiliary antioxidant, ammonium persulfate, diethylene glycol vinyl ether, polytrimethyldihydroquinoline and naphthenic oil. The preparation method comprises the following steps: adding the styrene-isoprene-styrene block copolymer, acetate starch, copal, antioxidant and auxiliary antioxidant into a rheometer, and compounding; adding the ester gum, phthalate, polyisobutylene, ammonium persulfate, diethylene glycol vinyl ether and naphthenic oil into the rubber mixture, and compounding; and finally, adding the rest of components into the hot-melt pressure-sensitive adhesive, and compounding to obtain the hydrocolloid pressure-sensitive adhesive. The pressure-sensitive adhesive can be easily peeled from the skin surface, and has the advantages of high water absorptivity and high controllability on water-absorbing capacity when in use.

Owner:北京精诚通医药科技有限公司

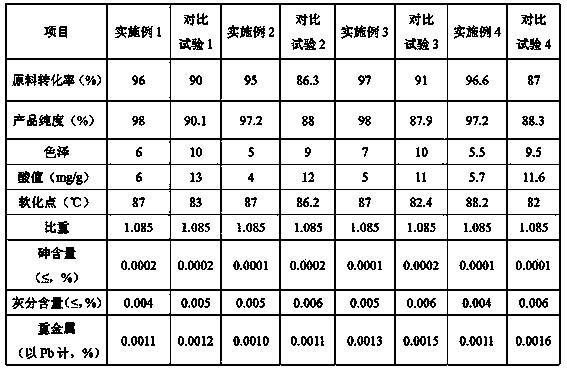

Preparation method of hydrogenated rosin glyceride

InactiveCN104194641AReduce generationImprove conversion rateNatural resin chemical modificationPalladium on carbonGlycerol

The invention discloses a preparation method of hydrogenated rosin glyceride, which comprises the following steps: adding a rosin and a palladium-carbon catalyst into a reaction kettle, introducing hydrogen gas to carry out addition reaction to obtain the hydrogenated rosin, sequentially adding glycerol and zinc oxide, and carrying out esterification reaction to obtain the hydrogenated rosin glyceride. The hydrogenated rosin glyceride has the advantages of light color, no peculiar smell, favorable mouthfeel, chewing resistance, favorable foaming property and favorable plasticity, and can be used instead of food-grade rosin glyceride as a chewing gum bodying agent in bubble gum, chewing gum, gum, sugar-free gum and other products.

Owner:WUZHOU CAYIN GUM

Pain relieving fitness paste and production method thereof

InactiveCN102824452AThe formula is scientific and reasonableKeep active ingredientsHydroxy compound active ingredientsAntipyreticSalvia miltiorrhizaMENTHOL CRYSTALS

The invention relates to a pain relieving fitness paste and a production method thereof which are mainly used for providing medication for treating the pain caused by osteomyelitis, arthritis and hyperosteogeny. The pain relieving fitness paste is prepared from 90-120g of radix salviae miltiorrhizae, 90-120g of safflower, 90-120g of caulis spatholobi, 90-120g of fructus gardeniae, 45-65g of radix clematidis, 45-65g of radix angelicae pubescentis, 45-65g of pricklyash peel, 130-165g of borneol, 90-120g of camphora and 90-120g of menthol crystal. The production method comprises the following steps of: grinding the radix salviae miltiorrhizae, safflower, caulis spatholobi, fructus gardeniae, radix clematidis, radix angelicae pubescentis and pricklyash peel into coarse powder; percolating the coarse powder with ethanol; concentrating the percolate into extract; extracting the dregs with gasoline to obtain extraction oil; preparing rubber paste, rosin, zinc oxide, wool fat, yellow vaseline, liquid paraffin, gasoline or SIS, liquid paraffin, glycerol ester of rosin and 2,6-butylated hydroxytoluene into a matrix; adding the extract, extraction oil, borneol, camphora and menthol crystal; and smearing the obtained product on the base cloth, covering with an anti-sticking layer, and slicing. Through the invention, the formula is scientific and reasonable, the active ingredients are maintained to the greatest degree, and the curative effect is improved.

Owner:吕秀兰 +1

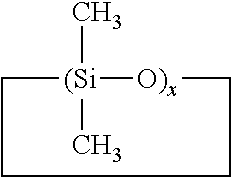

Nanometer titania reinforced concrete mold release agents

ActiveCN105345919AExcellent mold releaseSmooth demouldingCeramic shaping apparatusForm treatmentReinforced concreteRosin

The invention discloses nanometer titania reinforced concrete mold release agents, and relates to the technical field of concrete mold releasing. The nanometer titania reinforced concrete mold release agents comprise, by weight, 5-8 parts of nanometer titania, 80-90 parts of glycerol ester of rosin, 50-60 parts of polyether modified silicone, 15-20 parts of zeolite powder, 15-20 parts of volcanic soil, 12-18 parts of octadecanamide, 10-15 parts of polyamide resin, 10-15 parts of saponin powder, 10-15 parts of emulsified oil, 8-12 parts of spans, 6-10 parts of lubricating grease, 6-10 parts of rice bran wax, 4-7 parts of tartaric acid, 30-40 parts of mandarin oil and 300-350 parts of water. The nanometer titania reinforced concrete mold release agents have good mold release performance, enable a mold plate and concrete to be smoothly released, keep the surface of concrete smooth and keep edges tidy and undamaged.

Owner:滁州京安工贸有限责任公司

Lithium battery positive pole with high capacity and high security and preparation method thereof

ActiveCN106299376ALower crystallization melting temperatureIncrease stickinessCell electrodesSecondary cellsEpoxyPolymer science

The invention provides a lithium battery positive pole with high capacity and high security and a preparation method thereof. the lithium battery positive pole is prepared from, by weight, 98 parts of positive active material, 0.5-1 part of conductive agent, 0.02-0.05 part of lithium carbonate, 0.8-1.5 parts of adhesion agent and 50 parts of solvent, wherein the adhesion agent comprises, by weight, 5-8 parts of polyvinylidene fluoride, 3-5 parts of glycerol ester of rosin, 2-3 parts of epoxy resin and 0.3-0.6 part of carboxymethyl cellulose sodium. According to the preparation method, PVDF composite lycerol ester of rosin, carboxymethyl cellulose sodium and epoxy resin are used as the adhesion agent to solve the existing problems that when PVDF is used alone as the adhesion agent, crystalline melting temperature is high, charging load and discharging load are high, the adhesive layer of the electrode is easy to peel partly or completely from a current collector, the load characteristic becomes bad, thus capacity deterioration is resulted in. The lithium battery positive pole prepared from the formula has the advantages of high capacity and high security, and the service life of the batter is greatly prolonged.

Owner:ZHANGZHOU WANBAO ENERGY TECH CO LTD

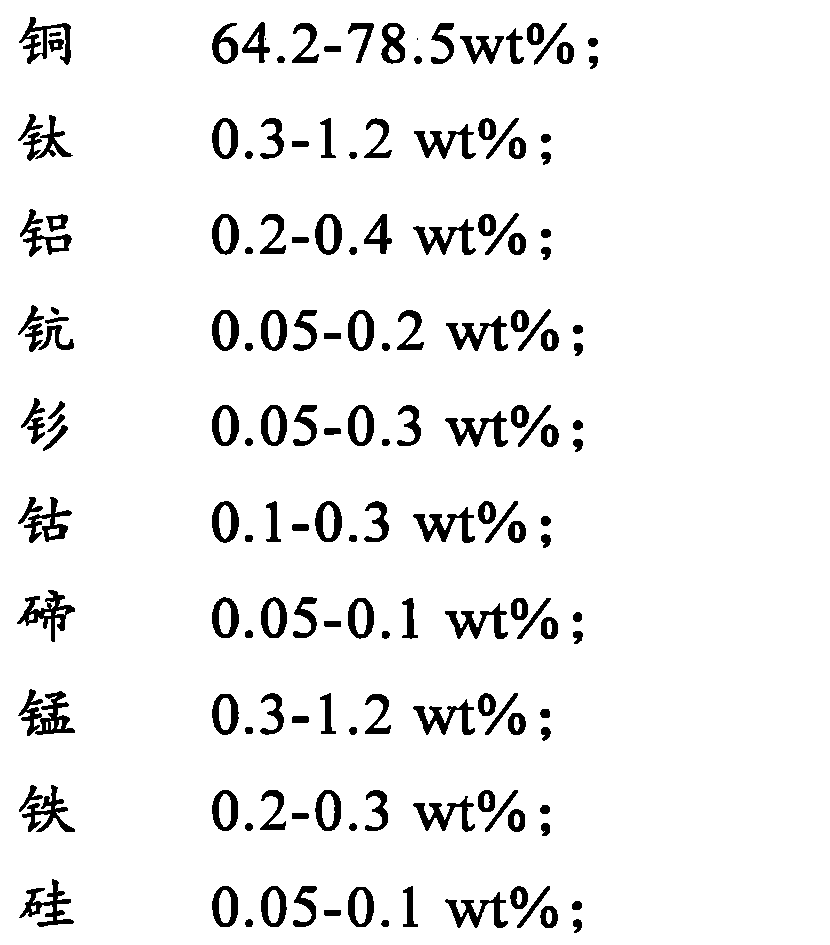

Investment casting technology for copper alloy casting

ActiveCN105057593AHigh strengthImprove toughnessFoundry mouldsFoundry coresMicrocrystalline waxDecomposition

The invention provides an investment casting technology for a copper alloy casting. Chlorcosane, Fischer-tropsch wax, stearic acid, glycerol ester of rosin, microcrystalline wax, polypropylene wax, polyisobutene, polyurethane elastomers and aldehyde resin serve as mold materials; and the polyisobutene, the polyurethane elastomers and the aldehyde resin are inserted into the chlorcosane, the Fischer-tropsch wax, the microcrystalline wax, the polypropylene wax and the stearic acid in a penetrating manner, and a formed structure has the good strength and the good heat stability. As for coatings adopted in the investment casting technology, cristobalite has the complete chemical inertness, and splitting decomposition can not occur at a quite high temperature; fused alumina has the beneficial effects of being high in melting point, compact in structure, good in heat conductivity and the like, the thermal expansion coefficient is small, and thermal expansion is even; and boron nitride is quiet low in friction coefficient, quite good in high-temperature stability and heat shock resistance, quite high in strength and heat conduction coefficient and lower in expansion coefficient. In this way, the copper alloy casting obtained with the investment casting technology for the copper alloy casting is high in strength and good in tenacity, no crack is generated on the surface, and the product quality is reliable.

Owner:NINGBO TIANYE PRECISION CASTING

Luminous slurry and preparation method thereof

The invention discloses luminous slurry and a preparation method thereof. A formula of the luminous slurry comprises the following raw materials according to parts by weight: 80-120 parts of polyvinyl chloride powder, 15-25 parts of polyester, 5-15 parts of gelatin, 2-8 parts of colophony glyceride, 5-15 parts of ethanol ethyl ester, 40-60 parts of water treatment luminous powder, 20-40 parts of UV varnish, 40-60 parts of polyurethane acrylic acid complex and 5-15 parts of accelerator. The method comprises the following steps: mixing the polyvinyl chloride powder, the polyester, the gelatin and the colophony glyceride, heating, dissolving hotly, adding the ethanol ethyl ester after cooling, and stirring evenly; adding the water treatment luminous powder into the UV varnish and stirring evenly; and adding the polyurethane acrylic acid complex after mixing and stirring substances prepared in the two previous steps evenly, stirring evenly, regulating the thickness of mixed liquid by using the accelerator, and stirring evenly. The luminous slurry can replace the prior ink, printing ink, paint, chromatic wall paint, oil paint and the like and has the advantages of environmental protection, durability and luminous performance.

Owner:王建军

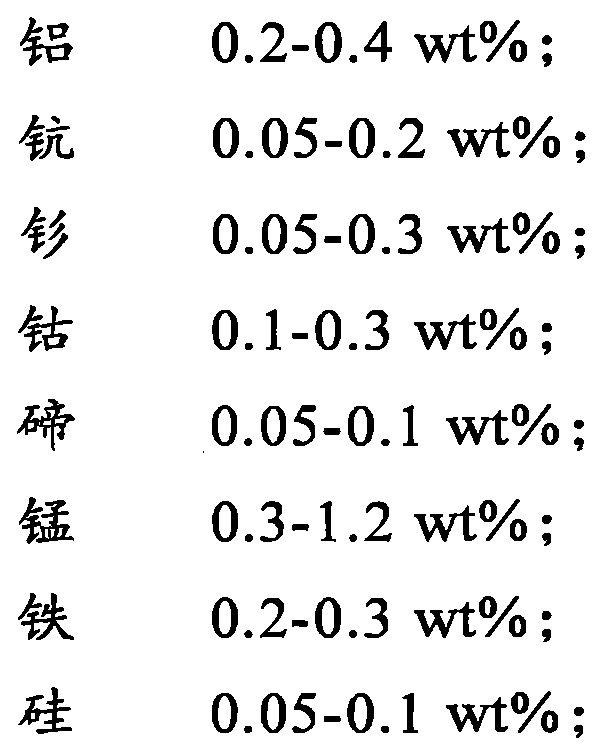

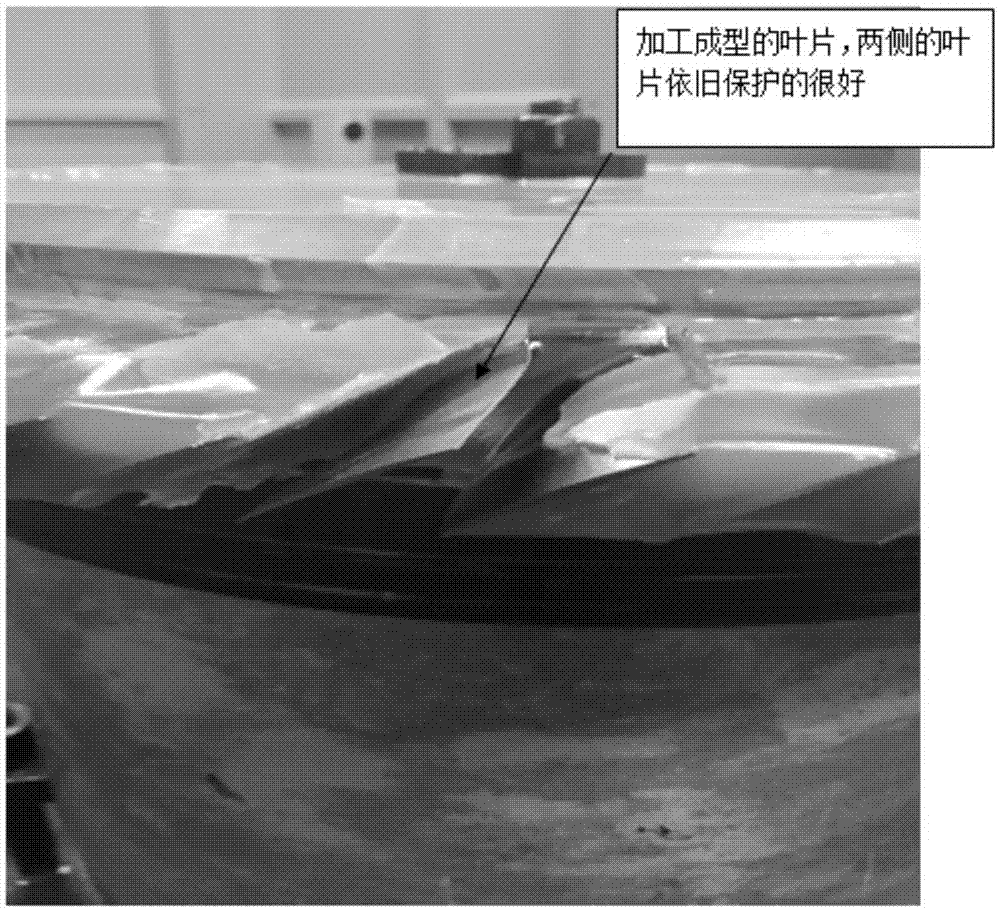

Method for controlling machining deformation of thin-walled part

The invention belongs to the technical field of machining, and relates to a method for controlling machining deformation of a thin-walled part. The method comprises the following steps that 1, a filling agent is prepared and molten, wherein the mass percent ratio of solid paraffin to liquid paraffin to rosin to glyceride is 9-10:1:1-1.5:1-1.5, the solid paraffin is heated so that half of the solid paraffin can be molten into liquid, liquid paraffin is added, mixed powder of rosin and glyceride is added while stirring, and heating is carried out till the solid paraffin is fully molten into liquid; and 2, the filling agent is poured, wherein the part needing pouring is protected, the liquid filling agent is poured after being cooled for 5 minutes-10 minutes, cooling is carried out for 3 minutes after pouring the liquid filling agent by a quarter of volume, the liquid filling agent continues to be poured by a quarter of volume after liquid cannot flow, the step is repeatedly executed till the part needing to be supported is fully covered through pouring, cooling is carried out for 6 hours-8 hours at the natural temperature after pouring is finished, and then subsequent machining can be carried out. The method is used for controlling machining deformation of the part, machining chatter marks on the surface of a blade are eliminated, and subsequent polishing treatment on the blade is greatly reduced.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Feather picking wax applied to livestock and birds processing and preparation method thereof

InactiveCN101595903AMeet food safety and hygiene requirementsImprove hair removal efficiencySlaughtering accessoriesPoultry processingFood additiveMicrocrystalline wax

The invention relates to a feather picking wax applied to livestock and birds processing and a preparation method thereof, belonging to the technical field of mastic material. In the invention, food additive rosin glyceride-like material, food grade paraffin and / or premium microcrystalline wax are listed in the main formula; polyvinyl acetate EVA or stearate, epoxidized soybean oil and antioxidant are added to the raw materials listed in the main formula and heated and mixed with the main formula, the feather picking wax product applied to livestock and birds processing is obtained by forming and packaging; the product conforms to national food additive safety and health standards and internationally recognized FDA standards. Applied to feather picking of heads and feet of livestock such as the pig, the cow, the sheep and feather picking of poultry such as the duck and the goose, the product of the invention is safe, nontoxic and highly efficient.

Owner:WUXI XINDA ROSIN & ESTER SYST

Preparation method of rosin glycerin ester

InactiveCN103436174AImprove conversion rateReduce the presence of impuritiesNatural resin chemical modificationReaction temperatureEsterification reaction

The invention discloses a preparation method of rosin glycerin ester, which relates to the technical field of rosin deep processing. The preparation method comprises the following steps of performing vacuum distillation on rosin, then cooling to obtain solid refined rosin; and placing the obtained solid refined rosin, glycerine and zinc oxide in a reaction container, and performing an esterification reaction for 2-4 hours at a temperature of 270-280 DEG C to obtain the rosin glycerin ester. Compared with the prior art, the preparation method disclosed by the invention has the advantages of simple process, low production cost and high conversion rate.

Owner:WUZHOU PINE CHEM

Gravure pearlescent ink compound for tipping paper and preparation method thereof

The invention discloses a gravure pearlescent ink compound for tipping paper and a preparation method thereof. The gravure pearlescent ink compound for tipping paper is prepared from the following rawmaterials by weight: 5-25 parts of polyvinyl butyral resin, 5-20 parts of cellulose acetate butyrate, 1-10 parts of aldehyde ketone resin, 1-10 parts of rosin glycerin ester, 1-10 parts of an antisettling agent, and 50-80 parts of a solvent. The gravure pearlescent ink compound provided by the invention adopts reasonable collocation of a variety of non-toxic and transparent resins in the formula,and is synthesized by a blending process. The ink compound has the characteristics of good gloss, excellent pearlescent pigment wet dispersion and directional arrangement properties, strong adhesion,good printing adaptability, fast drying, precipitation prevention, wide application range and the like.

Owner:玉溪接装纸制造有限公司

Low-temperature 3PE dry film hot melt adhesive for pipeline joint coating and corrosion prevention and preparation method of low-temperature 3PE dry film hot melt adhesive

InactiveCN110028915AMeet construction needsSolve the needs of joint anticorrosion constructionNon-macromolecular adhesive additivesMacromolecular adhesive additivesElastomerPolymer science

The invention relates to a low-temperature 3PE dry film hot melt adhesive for pipeline joint coating and corrosion prevention. The low-temperature 3PE dry film hot melt adhesive is prepared by kneading a rubber elastomer, bonding resin, tackifying resin, a plasticizer, an antioxidant and a filler and conducting extruding, wherein the rubber elastomer is two or more of a styrene-isoprene-styrene block copolymer, a styrene-ethylene-butene-styrene block copolymer, butyl rubber and ethylene propylene diene monomer; the bonding resin is one or two of an ethylene-vinyl acetate maleic anhydride grafted modified material and an ethylene-acrylate-maleic anhydride terpolymer; the tackifying resin is one or more of terpene resin, C5 petroleum resin and rosin glyceride; and the plasticizer is polyisobutene or naphthenic oil. The low-temperature dry film hot melt adhesive disclosed by the invention is used for pipeline joint coating and corrosion prevention, meets the construction requirements in an extremely cold environment, and meets the pipeline joint coating and corrosion prevention construction requirements in cold regions; and the adhesive has the advantages of excellent adhesion and sealing property, good low-temperature flexibility, higher peel strength and stable performance.

Owner:江苏达胜热缩防护用品有限公司

Substrate-free low temperature reactive hot melt adhesive tape and glue used by same, and preparation methods of hot melt adhesive tape and glue

ActiveCN108250993AQuick unblockSave equipment costPolyureas/polyurethane adhesivesMacromolecular adhesive additivesKetoneSolvent

The invention discloses a formula and a preparation method of substrate-free low temperature reactive hot melt adhesive tape. The adhesive tape consists of substrate-free dry glue and a double-sided release film or double-sided release paper; the glue is prepared from 100-150 parts of thermoplastic polyurethane, 50-150 parts of rosin glyceride, 1-40 parts of a blocked crosslinking agent, 1-10 parts of a wetting leveling agent, 1-10 parts of a defoaming agent, 1-10 parts of a rheological agent, 0.1-5 parts of an anti-aging agent and 100-400 parts of a mixed solvent of ketones and esters; the substrate-free low temperature reactive hot melt adhesive tape is prepared by coating a substrate with the glue, drying, winding, and cutting. By designing the deblocking temperature of the crosslinkingagent and the softening point of the resin, the adhesive tape can be stored and transported at room temperature, and can realize a bonding strength of 2-3 N / mm<2> at a lower heating temperature (90-110 DEG C) and a lower pressure (1-2 bar). Therefore, the substrate-free low temperature reactive hot melt adhesive tape can solve the problems that the existing low-temperature hot melt adhesive is low in bonding strength, and the low-temperature reactive hot-melt adhesive requires special storage and transportation conditions; the substrate-free low temperature reactive hot melt adhesive tape cangreatly reduce the raw material storage and transportation costs of the electronic device manufacturer, and meets the bonding requirements for small parts of the current electronic products.

Owner:SUZHOU SHIHUA NEW MATERIAL TECH

Structural pressure-sensitive adhesive, structural pressure-sensitive adhesive tape and preparation method of structural pressure-sensitive adhesive and structural pressure-sensitive adhesive tape

ActiveCN102234497ASensitive to pressureWith structural adhesive propertiesFilm/foil adhesivesEster polymer adhesivesEpoxyCarvacryl acetate

The invention discloses a structural pressure-sensitive adhesive, a structural pressure-sensitive adhesive tape and a preparation method of the structural pressure-sensitive adhesive and the structural pressure-sensitive adhesive tape. The structural pressure-sensitive adhesive comprises a constituent A and a constituent B. The constituent A is obtained by polymerizing acrylic acid-2-ethylhexyl ester, butyl acrylate, vinylacetate, methyl methacrylate, acrylic acid, glycerol ester of hydrogenated rosin, dibenzoyl peroxide, ethyl acetate and epoxy resin in a reactor. The constituent A is coatedon a base material to manufacture a pressure-sensitive adhesive tape; the constituent B, which is polyfunctional organic amine epoxy hardener 2,4,6-tri(dimethylamino methyl)phenol, is painted on the surface of a pasted object; the pressure-sensitive adhesive tape is pasted on the surface of the pasted object to form the structural pressure-sensitive adhesive tape. The structural pressure-sensitive adhesive tape disclosed by the invention has pressure sensitivity at the beginning of use, and has the performances of structural adhesives at the later stage of use; the proportion of the tackinessagent A and the curing agent B is unnecessary to be determined, so the adhesive tape is convenient to use; in addition, the bonding strength is large, thus the structural pressure-sensitive adhesive tap is very suitable for field application.

Owner:中国航天科技集团公司第四研究院第四十二所

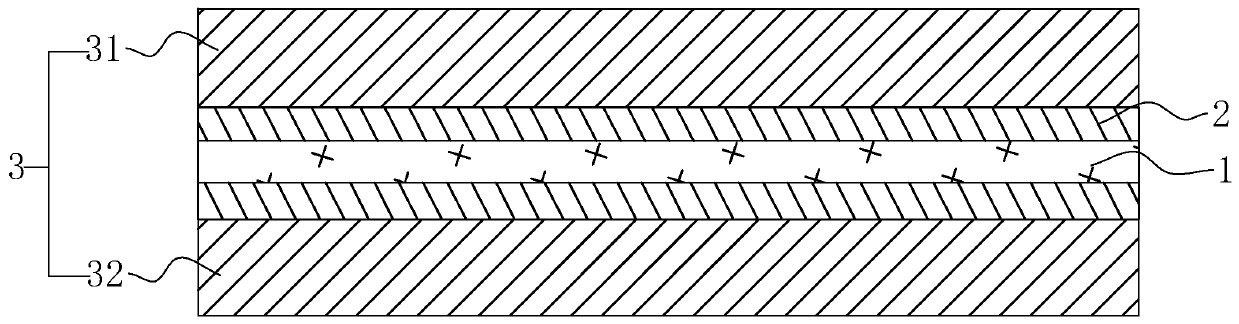

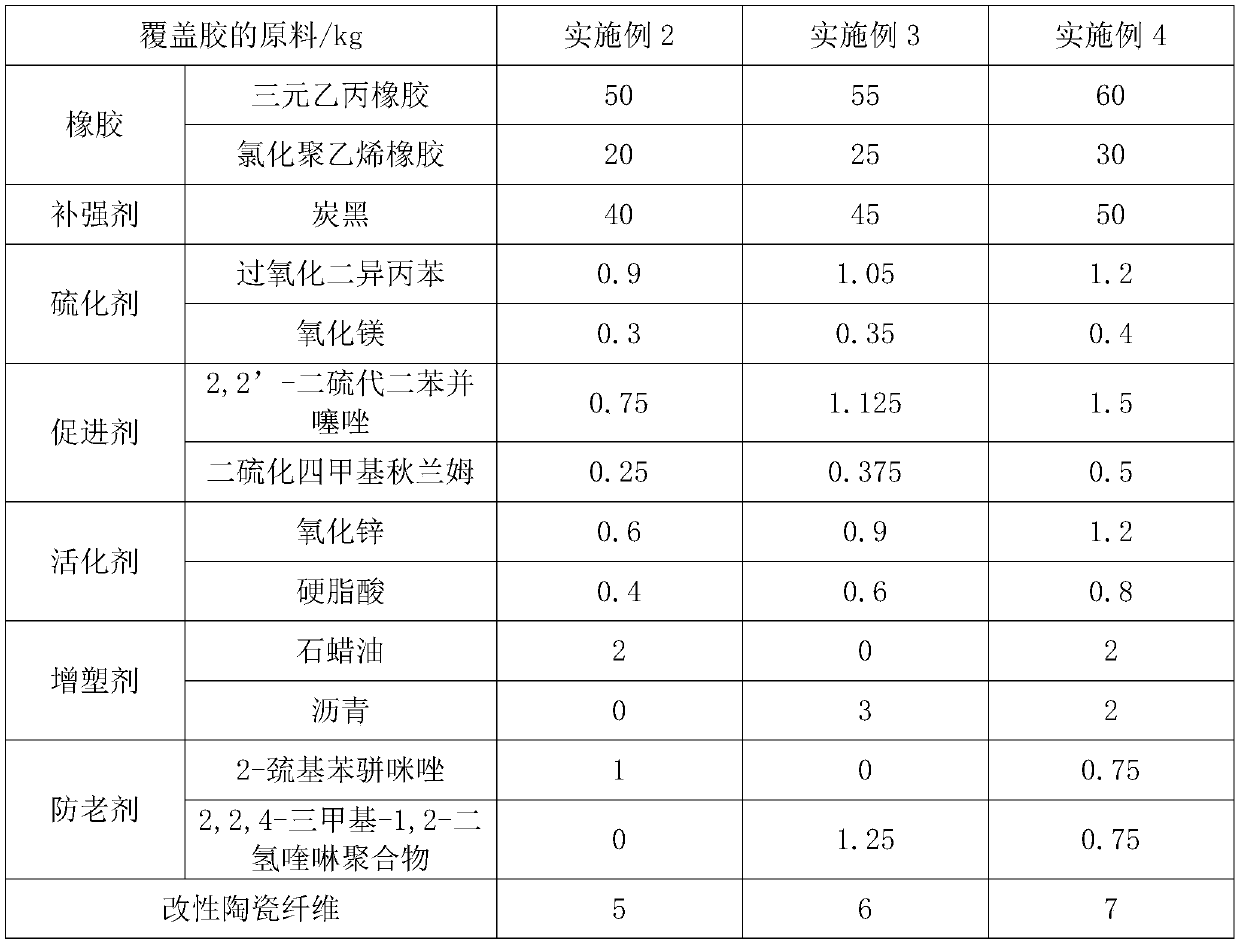

Heat-resisting conveying belt special for large junk and preparation process of heat-resisting conveying belt

InactiveCN109809106AImprove heat resistanceHigh bonding strengthConveyorsSynthetic resin layered productsFiberPolyethylene glycol

The invention discloses a heat-resisting conveying belt special for a large junk and a preparation process of the heat-resisting conveying belt. According to the technical scheme, the heat-resisting conveying belt special for the large junk comprises a belt core, belt core rubber and coverage rubber. The coverage rubber comprises upper coverage rubber and lower coverage rubber. The coverage rubberis formed by polymerizing raw materials which include EPDM, chlorinated polyethylene rubber, carbon black, modified ceramic fibers, a vulcanizing agent, an accelerant, an activation agent, a plasticizer and an anti-aging agent. Ceramic fibers are immersed into impregnation liquid formed by polyethylene glycol, imvite, glycerol ester of rosin, a silane coupling agent, BMDPM and diethylene glycol dibenzoate, and the modified ceramic fibers are obtained through modification treatment. The bonding strength of the modified ceramic fibers is high, the bonding force of the modified ceramic fibers and rubber can be improved, the defect that the bonding strength of EPDM and the belt core is low can be overcome, heat resistance of the conveying belt is improved, and meanwhile the interlayer bondingstrength of EPDM and the belt core is improved.

Owner:青岛环球输送带有限公司

Rosin glycerin ester production method

ActiveCN105754485AHigh softening pointHigh purityNatural resin chemical modificationSodium acetateSodium acetrizoate

The invention belongs to the technical field of deep processing or rosin and discloses a rosin glycerin ester production method.Rosin glycerin ester is prepared from, by weight, 100 parts of rosin, 0.0001-0.0002 part of anthraquinone, 0.0001-0.0002 part of tetraethoxysilane, 5-8 parts of hydroquinone, 0.001-0.002 part of 4,4'- thio-bis(6-tert-butyl-3-methyl phenol), 15-25 parts of glycerin and 0.01-0.02 part of sodium acetate.The rosin glycerin ester production method includes: refining the rosin, adding the tetraethoxysilane, the hydroquinone, the glycerin and the sodium acetate under the condition of stirring, and reacting under a specific pressure and at a specific temperature; adding the anthraquinone and the 4,4'- thio-bis(6-tert-butyl-3-methyl phenol), and distilling under a specific pressure and at a specific temperature.The rosin glycerin ester produced according to the method has the advantages of high softening point and high purity.

Owner:FINJET CHEM IND LTD

Cross-interface penetration adhesive

ActiveCN103709973AExtended opening hoursImprove permeabilityMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesAntioxidantPetroleum

The invention relates to the hot melt adhesive field, and especially discloses a cross-interface penetration adhesive which can achieve penetration adhesion to a surface film or a gold stamping layer. The penetration adhesive is composed of, by weight, 1-10 parts of ethylene-acrylic acid copolymer wax, 2-12 parts of paraffin, 10-18 parts of maleic anhydride grafting EVA, 10-21 parts of EVA with a high VA content, 6-15 parts of metallocene catalysis polyolefin, 10-18 parts of dehydrated malic acid abietin, 10-25 parts of rosin glyceride, 1-8 parts of liquid-state C5 petroleum resins, 0.5-2 parts of leveling agents, 1-6 parts of plasticizers, 0.2-1.2 parts of high-molecular coupling agents and 0.2-1 part of antioxidants. The obtained cross-interface penetration adhesive can penetrate through printing ink and the like and adheres to internal organic matters, the adhesion fastness is raised and the service life is prolonged.

Owner:浙江固特新材料科技股份有限公司

Hot-melt glue and preparation method thereof

The invention relates to hot-melt glue, which comprises the following components in parts by weight: 23-28 parts of thermoplastic elastomer, 22-27 parts of thermoplastic rubber, 16-23 parts of terpene resin, 15-23 parts of rosin glycerol ester, 0.8-1.3 parts of antioxidant, and 8-15 parts of white naphthenic oil. A preparation method for the hot-melt glue comprises the steps: (1) adding the white naphthenic oil into a reaction boiler, and agitating for 10 minutes; (2) adding the thermoplastic elastomer and the thermoplastic rubber, and continuously agitating until the thermoplastic elastomer and the thermoplastic rubber are molten; and (3) then feeding other active ingredients into the reaction boiler, agitating for 90-100 minutes, and discharging, thus obtaining the non-dry adhesive glue. The hot-melt glue is glue with an environment-friendly effect, and the glue prepared by adopting the method has good physical performance, and has the advantages of stable holding power and initial adhesion and the like.

Owner:上海金大塑胶有限公司

Preparation method of rosin glycerol ester

InactiveCN103045097AQuick responseSmooth responseNatural resin chemical modificationGlycerolReaction temperature

The invention discloses a preparation method of a rosin glycerol ester. The rosin glycerol ester is prepared from 100 parts of rosin, more than 50 parts of glycerol, and 1.5-2.6 parts of zinc oxide; after rosin reacts with glycerol under the action of a catalyst, and the rest glycerol is removed at a high temperature in vacuum so as to obtain a rosin glycerol ester product provided by the invention. The preparation method has the advantages of low reaction temperature, easiness in control, in high reaction speed improved by 3-5 times, low product production cost and good quality.

Owner:何丽萍

Preparation method of charcoal particle drying agent

The invention relates to a drying agent and in particular relates to a preparation method of a charcoal particle drying agent. The preparation method of the charcoal particle drying agent comprises the following steps: uniformly mixing the raw materials; carrying out electronic radiation crosslinking treatment; and processing the raw materials into particles, strips or sheets. The raw materials comprise the following components in parts by weight: 60-80 parts of bamboo charcoal powder, 15-25 parts of bentonite, 10-13 parts of calcium chloride, 9-12 parts of magnesium sulfate, 5-8 parts of starch, 4-9 parts of attapulgite ore, 6-11 parts of hard gypsum ore, 1-3 parts of bamboo leaf oil, 3-7 parts of adhesive liquid, 0.1-0.5 part of capraldehyde, 0.2-0.4 part of linalool, 0.02-0.06 part of thymol, 0.6-0.9 part of glyceryl triabietate and 5-8 parts of a moisture absorption additive. The moisture absorption additive is selected from polyvinyl alcohol fiber, polyoxyethylene fiber, alginate fiber and mulberry silk; the adhesive liquid comprises phthalic anhydride, furfuryl alcohol, triethylene glycol, glutaric acid, butantriol, zinc oxide powder, magnesium oxide, chloroprene rubber, elastic rubber, softening oil, dimethyl carbonate, benzoyl peroxide, acetic ether, an emulgator, flour, nano-silver, a fire retardant, methylcellulose and deionized water. The drying agent is high in drying performance and fresh and natural in smell, and has a good deodorizing effect.

Owner:临泉县双狐皮件加工股份有限公司

Preparation method of acrylic modified rosin glyceride resin

InactiveCN102965022AQuick responseSmooth responseNatural resin chemical modificationChemical industryAdhesive

The invention discloses a preparation method of an acrylic modified rosin glyceride resin. The mole ratio of the rosin to the acrylic acid to the glycerol is 1:0.3:0.5. A process comprises the following steps of: heating and fusing the rosin in the presence of inert gases, heating to 180-200 DEG C, controlling the dropping of the acrylic acid at a speed of finishing adding in 45-50 minutes, adding 1-1.6 parts of glycerol and zinc oxide, heating to 250-260 DEG C and reacting for 80-90 minutes to obtain products. The acrylic modified rosin glyceride resin has the characteristics of light color and high softening point and the like, can be used in industrial departments such as paint, ink, synthetic resin, adhesives, electron, chemical industry and the like and also can be reacted with phenolic aldehydes and alcohols for preparing light-colored phenolic resins and various abietins.

Owner:李先兰

Method for preparing rosin glycerin ester

The invention discloses a method for preparing rosin glycerin ester and belongs to the technical field of rosin deep processing.The rosin glycerin ester is prepared from, by weight, 100 parts of rosin, 0.0001-0.0002 part of tetraethyl orthosilicate, 5-8 parts of hydrogen peroxide, 0.001-0.002 part of cetyl trimethyl ammonium bromide, 15-25 parts of glycerin and 0.01-0.02 part of sodium acetate.The method comprises the steps that rosin is refined, tetraethyl orthosilicate, hydroquinone, glycerin and sodium acetate are added, and then stirring and reacting are carried out at constant temperature and the pressure below the triple point for 2-4 hours; anthraquinone and 4,4'-sulfo-di(6-tert-butyl-3-methylphenol) are added, and then distillation is carried out at the pressure ranging from -0.1 MPa to 0 and the temperature ranging from 180 DEG C to 200 DEG C.The prepared rosin glycerin ester product has the advantages of being high in purity and light in color.

Owner:FINJET CHEM IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com