Preparation method of acrylic modified rosin glyceride resin

A technology of rosin glycerin ester and rosin glycerin, which is applied in the field of deep processing of rosin, can solve the problems of product types and preparation methods without major progress, slow reaction, long time consumption, etc., and achieve the effect of high softening point, stable reaction and accelerated reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

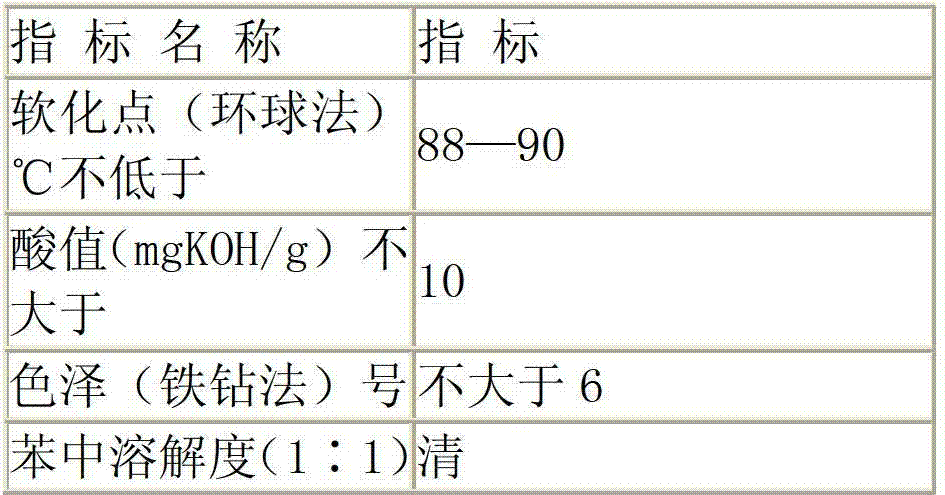

[0008] The preparation method of the acrylic acid-modified rosin glyceride resin of the present invention optimizes the proportion of materials, increases the catalyst, makes the reaction speed more than 3-5 times faster, and reacts at a lower temperature through the method of enriching polyols, so that the reaction becomes more efficient. It is stable, moderate and easy to control, so as to obtain light-colored and high-quality products. It has the characteristics of light color and high softening point. It is used in industrial sectors such as paints, inks, synthetic resins, adhesives, electronics, and chemicals. , Alcohol reaction can be made into light-colored phenolic resin and various rosin resins.

[0009] The preparation method of the acrylic acid modified rosin glyceride resin of the present invention is characterized in that: the material ratio is, rosin: acrylic acid: the molar ratio of glycerin is 1:0.3:0.5; Its technology comprises the following steps, the rosin is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com