Preparation method of rosin glycerin ester

A technology of rosin glycerides and rosin, which is applied in the field of preparation of rosin glycerides, can solve the problems of increasing energy consumption, increasing production costs, reducing the purity and conversion rate of finished rosin glycerides, and achieving cost savings and improving the conversion rate of finished products , Reduce the effect of impurities and by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] First vacuum distill the rosin and then cool it to obtain solid refined rosin; put the obtained solid refined rosin, glycerin, and zinc oxide into a reaction vessel for esterification to obtain the present rosin glyceride, the reaction temperature is 270 ° C, and the reaction time is 2 hours;

[0015] The molar ratio of solid refined rosin to glycerin is 3:1; the mass percentage of zinc oxide added to the total mass of solid refined rosin is 0.05%.

Embodiment 2

[0017] First vacuum distill the rosin and then cool it to obtain solid refined rosin; put the obtained solid refined rosin, glycerin, and zinc oxide into a reaction vessel for esterification to obtain the present rosin glyceride, the reaction temperature is 275 ° C, and the reaction time is 3 hours;

[0018] The molar ratio of solid refined rosin to glycerin is 3:1; the amount of zinc oxide added is 0.08% by mass of the total mass of solid refined rosin.

Embodiment 3

[0020] First, the rosin is vacuum distilled and then cooled to obtain solid refined rosin; the obtained solid refined rosin, glycerin, and zinc oxide are put into a reaction vessel for esterification to obtain the present rosin glyceride, the reaction temperature is 280 ° C, and the reaction time is 4 hours;

[0021] The molar ratio of the solid refined rosin to the glycerol is 3:1; the amount of zinc oxide added is 0.1% by mass of the total mass of the solid refined rosin.

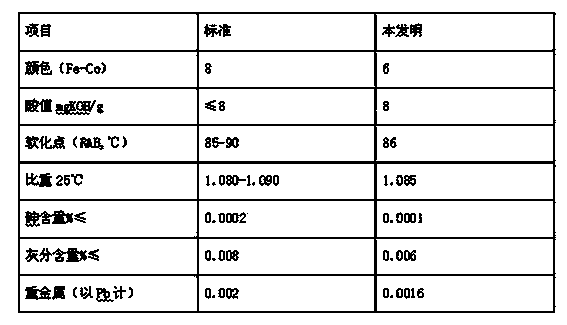

[0022] The quality index of the present invention is as table 1:

[0023] Table 1

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com