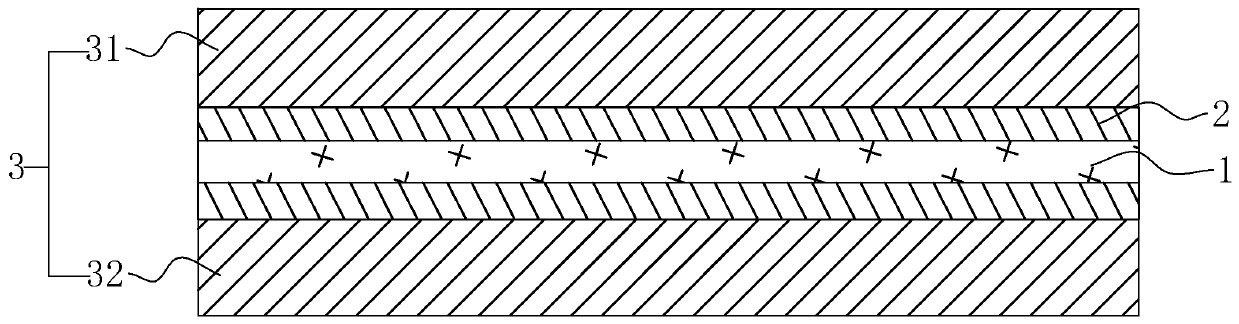

Heat-resisting conveying belt special for large junk and preparation process of heat-resisting conveying belt

A technology for heat-resistant conveyor belts and shackles, applied in the field of conveyor belts, can solve the problems of low bonding strength between EPDM rubber and the belt core, small fiber size, and high dispersion, and achieve light weight, small fiber size, and high dispersion high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

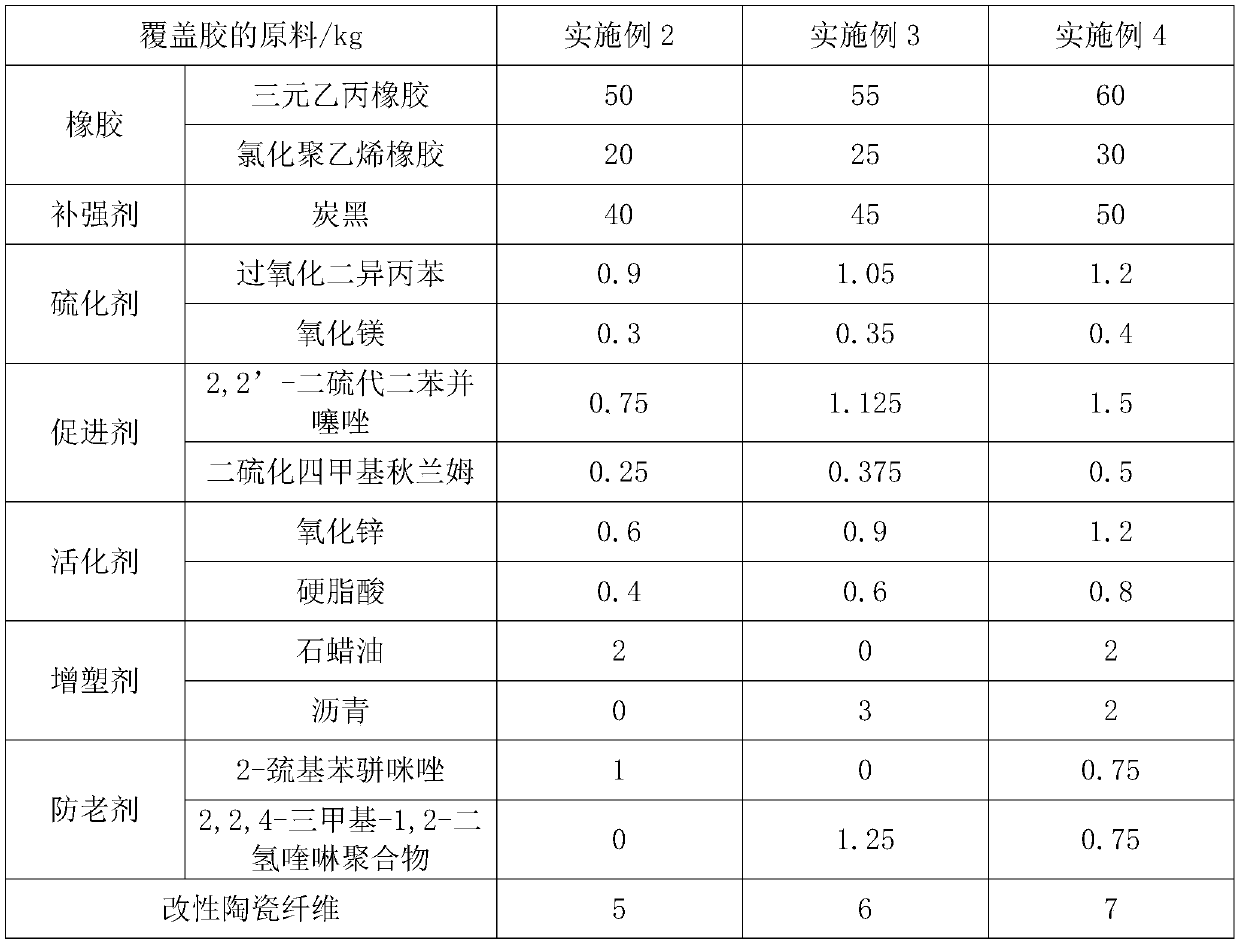

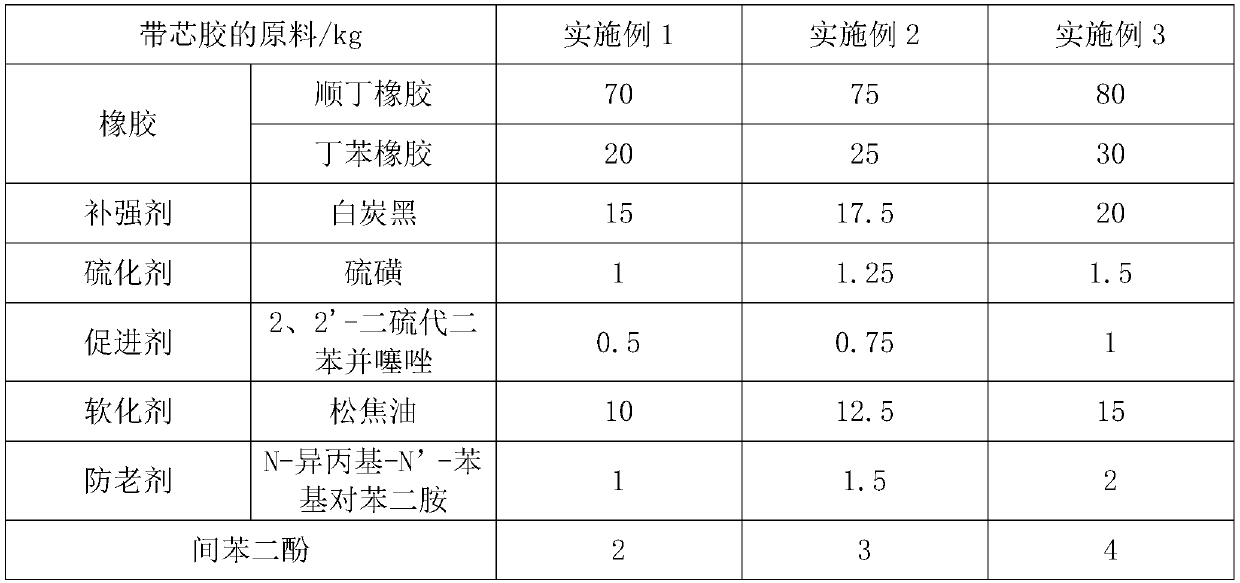

Examples

preparation example 1

[0051] Preparation example 1: ① Dispersion treatment: Cut the ceramic fiber into short fibers with a length of 2mm, then immerse it in 50wt% ethanol solution, and ultrasonically treat it for 5 minutes;

[0052] ②Preparation of impregnation solution: Take 6kg of polyethylene glycol, 3kg of montmorillonite, 1kg of rosin glyceride, 1kg of silane coupling agent, 0.3kg of diphenylmethane bismaleimide and 0.2kg of diethylene glycol dibenzoate kg, stirred at a speed of 1000r / min for 10min to obtain the impregnating solution;

[0053] ③Take 10kg of the ceramic fiber treated in step ①, immerse it in the immersion solution at 120°C and keep it warm for 1h; then place it at 150°C and bake it for 5min to obtain the modified ceramic fiber.

preparation example 2

[0054] Preparation example 2: ① Dispersion treatment: Cut the ceramic fiber into short fibers with a length of 3mm, then immerse it in 50wt% ethanol solution, and ultrasonically treat it for 7.5min;

[0055] ②Preparation of impregnating solution: take polyethylene glycol 8kg, montmorillonite 4kg, rosin glyceride 1.5kg, silane coupling agent 1.5kg, diphenylmethane bismaleimide 0.4kg and diethylene glycol dibenzoic acid Ester 0.3kg, stir it for 12.5min with the speed of 1250r / min, obtain impregnation solution;

[0056] ③Take 12.5kg of the ceramic fiber treated in step ①, immerse it in the immersion solution at 125°C, and keep it warm for 1.5h; then place it at 155°C, and bake it for 7.5min to obtain the modified ceramic fiber.

preparation example 3

[0057] Preparation example 3: ① Dispersion treatment: Cut the ceramic fiber into short fibers with a length of 4mm, then immerse it in 50wt% ethanol solution, and ultrasonically treat it for 10min;

[0058] ②Preparation of impregnating solution: take polyethylene glycol 10kg, montmorillonite 5kg, rosin glyceride 2kg, silane coupling agent 2kg, diphenylmethane bismaleimide 0.5kg and diethylene glycol dibenzoate 0.4 kg, stirring it for 10-15min at a speed of 1500r / min to obtain an impregnation solution;

[0059] ③Take 15kg of the ceramic fiber treated in step ①, immerse it in the immersion solution at 130°C and keep it warm for 2h; then place it at a temperature of 160°C and bake it for 10min to obtain the modified ceramic fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mooney viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com