Method for controlling machining deformation of thin-walled part

A technology for processing deformed and thin-walled parts, applied in the field of mechanical processing, can solve the problems of high cost, achieve the effects of improving efficiency, reducing production costs, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for controlling machining deformation of a thin-walled part is carried out according to the following steps:

[0024] 1. Proportioning and melting filler: take the filler in proportion, each component in the filler is paraffin wax: liquid paraffin: rosin: glyceride = 9: 1: 1: 1.5; the paraffin wax is heated to 270°C, melt half of the solid paraffin into liquid, add liquid paraffin, mix and heat for 10 minutes, add the mixed powder of rosin glyceride while stirring, mix and heat until completely melted into liquid;

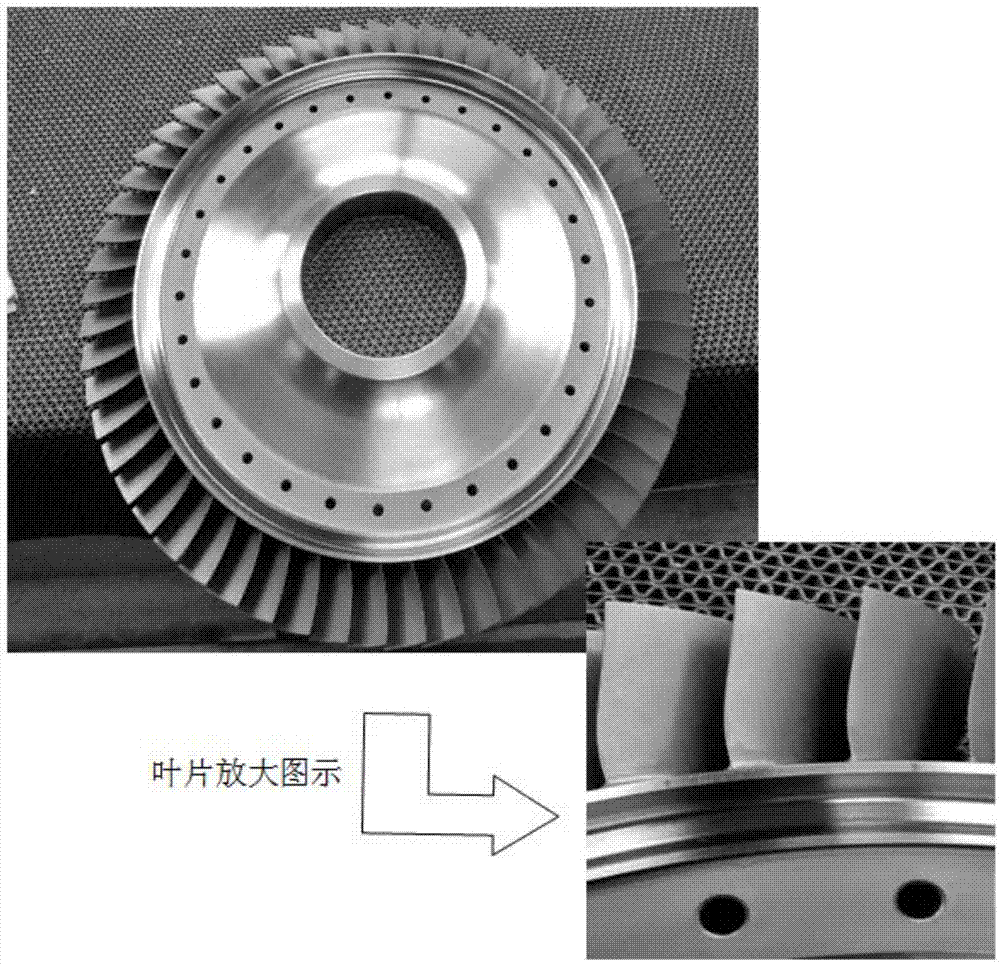

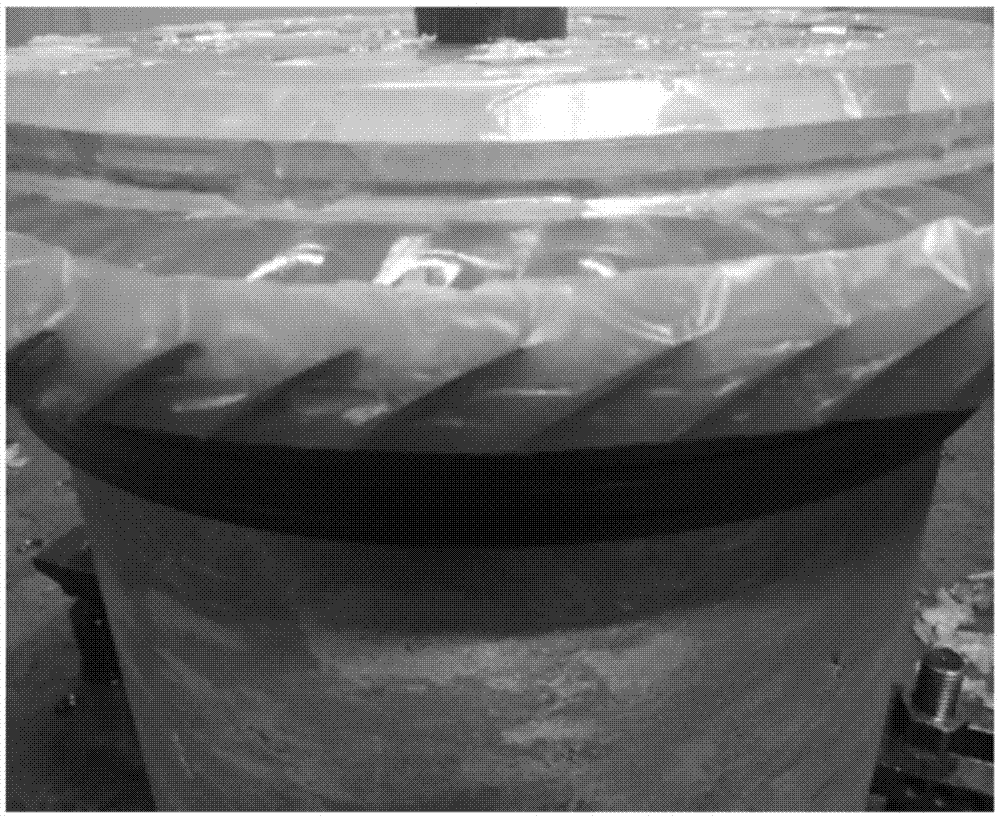

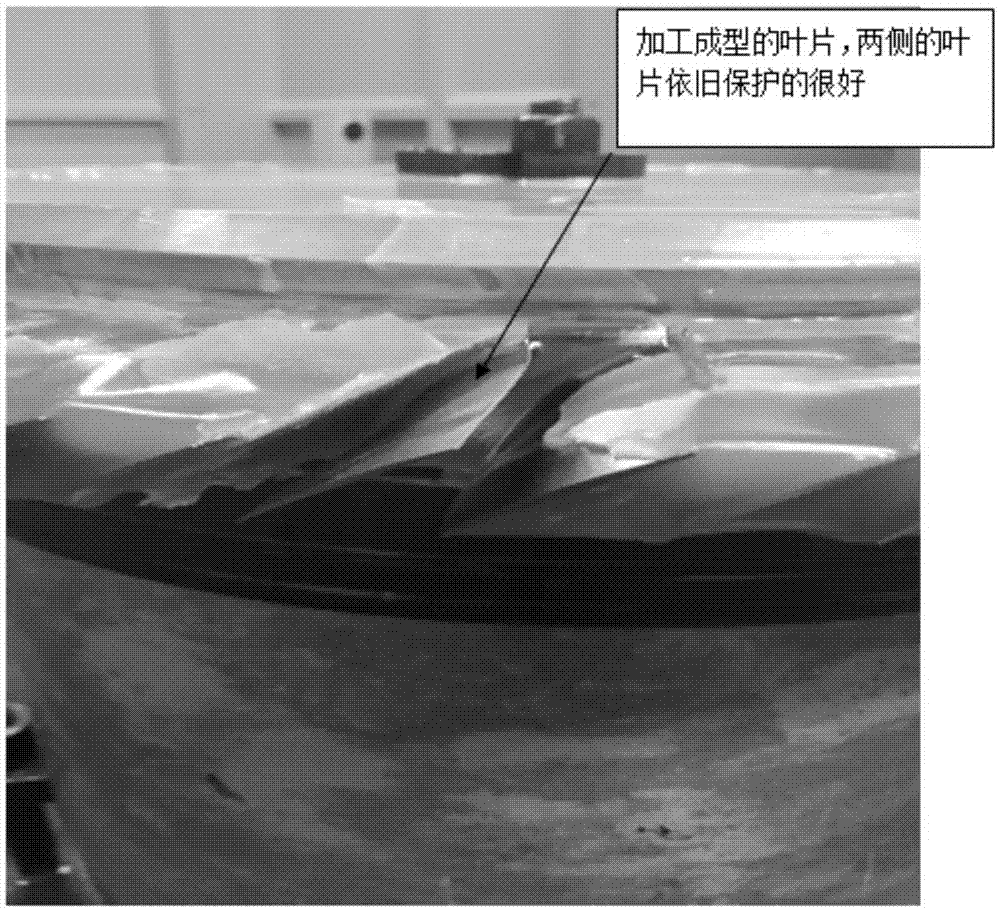

[0025] 2. Pouring filler: The state of the part before pouring filler is as follows figure 1 Shown: by figure 1 It can be seen that the thickness of the blade is very thin, and there is no support between the two blades, and the deformation of the blade is very easy to occur during processing. Protect the parts that need to be poured, using plastic bags: CORTEC BLUE for protection; cool the above liquid filler for 5-10 minutes before pouring, po...

Embodiment 2

[0032] A method for controlling machining deformation of a thin-walled part is carried out according to the following steps:

[0033] 1. Proportioning and melting the filler: take the filler in proportion, each component in the filler is paraffin wax: liquid paraffin: rosin: glyceride=10: 1: 1.3: 1.3; the paraffin wax is heated to 270°C, melt half of the solid paraffin into liquid, add liquid paraffin, mix and heat for 10 minutes, add the mixed powder of rosin glyceride while stirring, mix and heat until completely melted into liquid;

[0034] 2. Pouring filler: The state of the part before pouring filler is as follows figure 1 Shown: by figure 1 It can be seen that the thickness of the blade is very thin, and there is no support between the two blades, and the deformation of the blade is very easy to occur during processing. Protect the parts that need to be poured, using plastic bags: CORTEC BLUE for protection; cool the above liquid filler for 5-10 minutes before pourin...

Embodiment 3

[0037] A method for controlling machining deformation of a thin-walled part is carried out according to the following steps:

[0038] 1. Proportioning and melting the filler: take the filler in proportion, each component in the filler is paraffin wax: liquid paraffin: rosin: glyceride = 10: 1: 1: 1.5; the paraffin wax is heated to 270°C, melt half of the solid paraffin into liquid, add liquid paraffin, mix and heat for 10 minutes, add the mixed powder of rosin glyceride while stirring, mix and heat until completely melted into liquid;

[0039] 2. Pouring filler: The state of the part before pouring filler is as follows figure 1 Shown: by figure 1 It can be seen that the thickness of the blade is very thin, and there is no support between the two blades, and the deformation of the blade is very easy to occur during processing. Protect the parts that need to be poured, using plastic bags: CORTEC BLUE for protection; cool the above liquid filler for 5-10 minutes before pouring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com