Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

97results about How to "Sensitive to pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

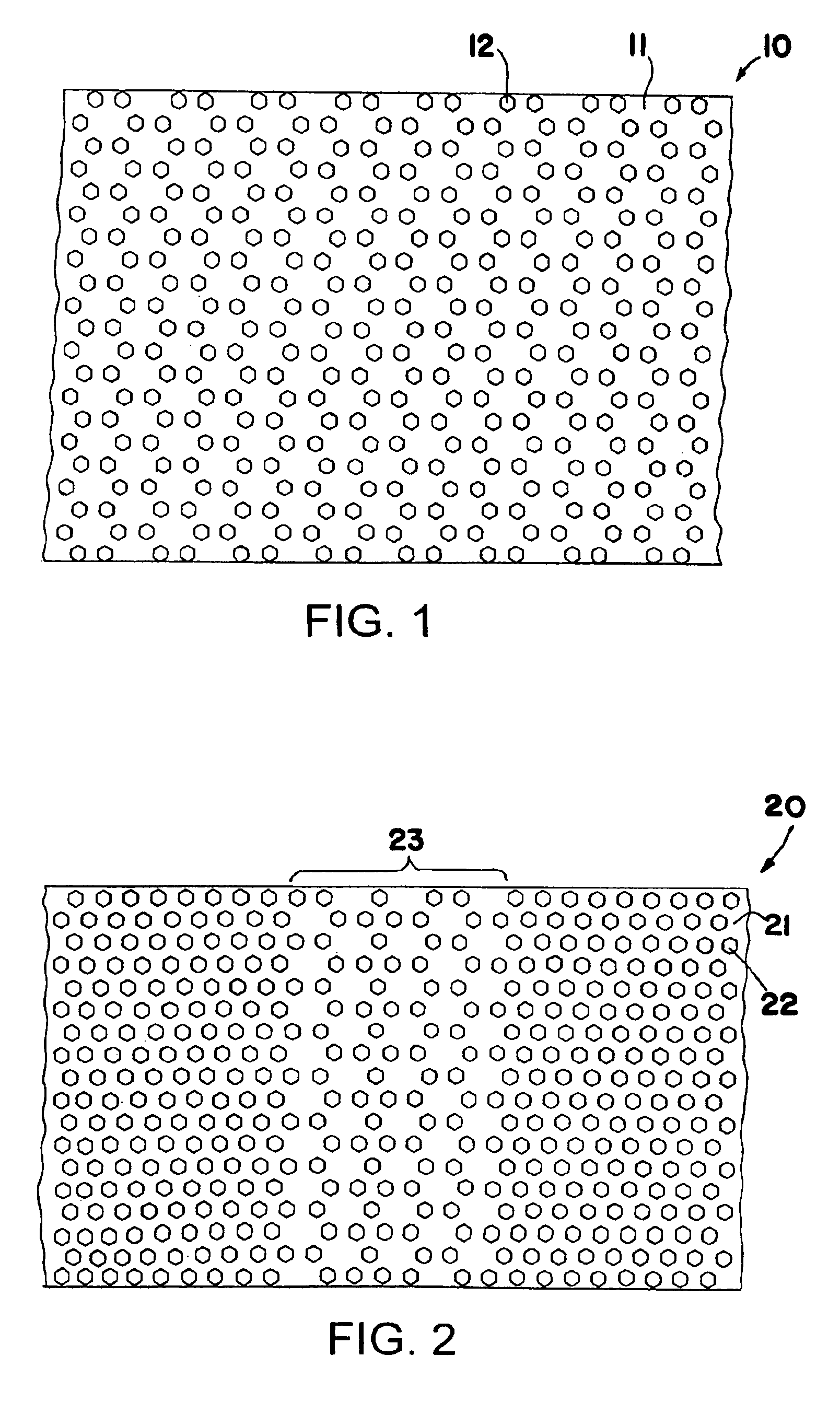

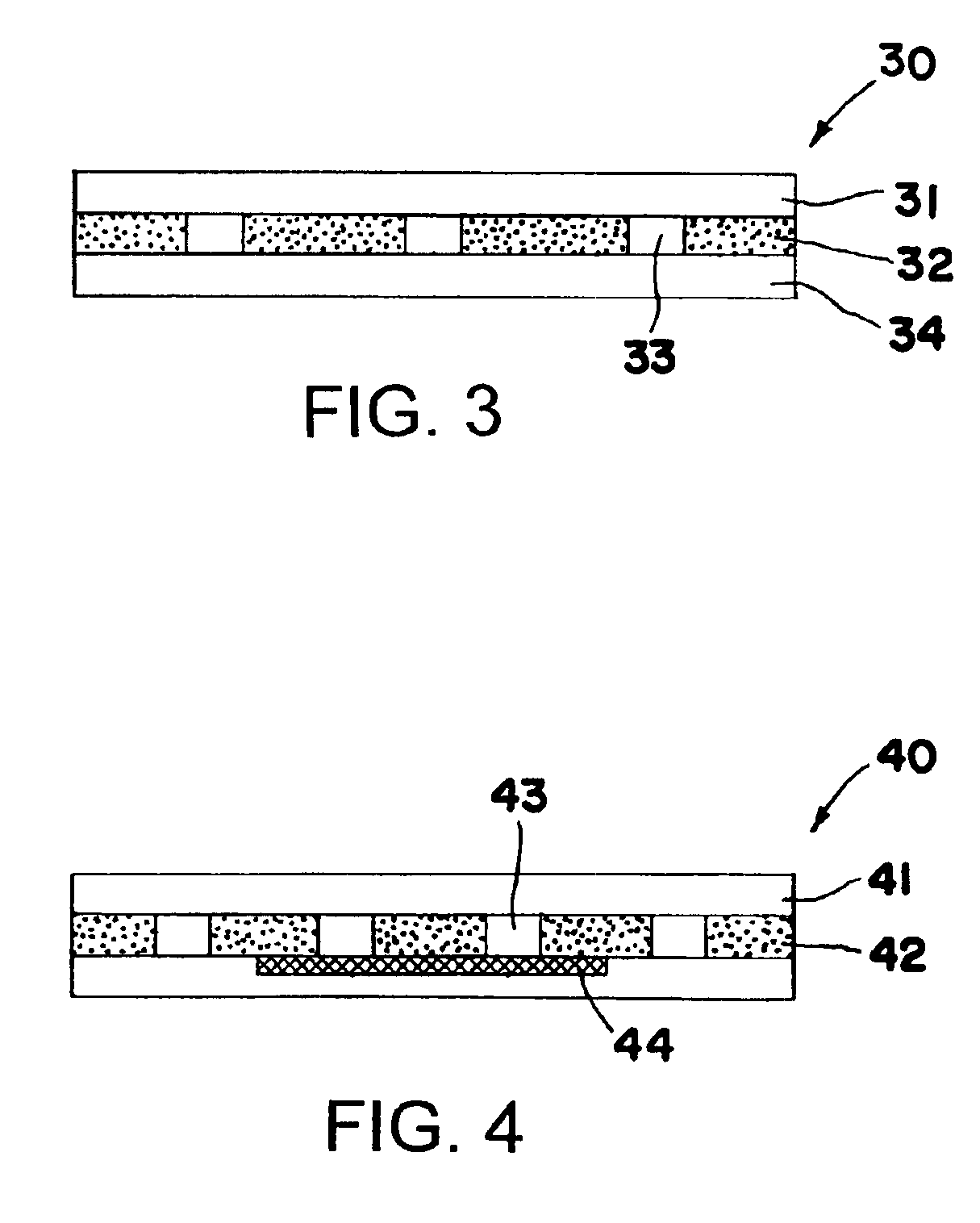

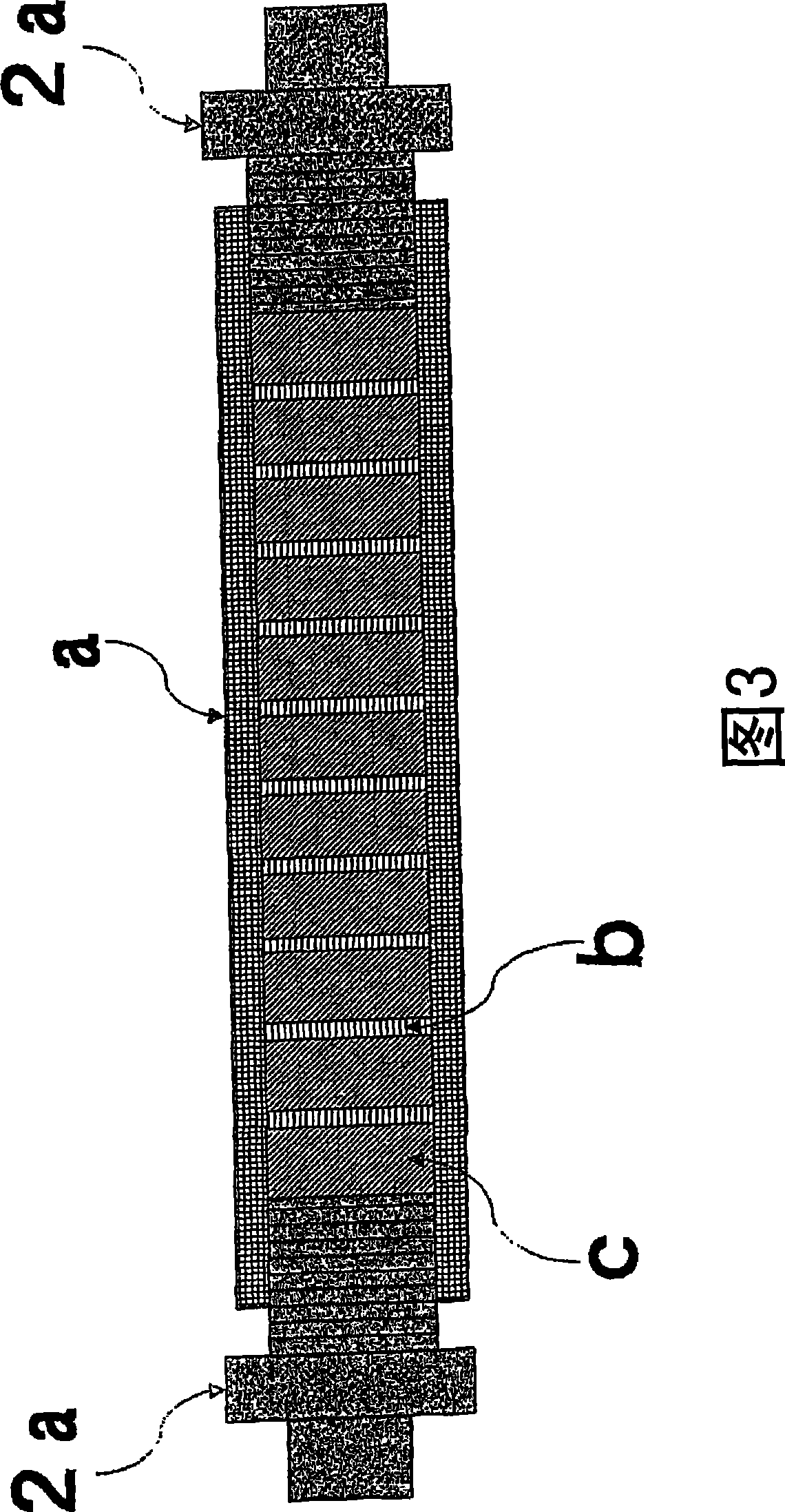

Pattern coated adhesive article

InactiveUS6953602B2Promote healingImprove breathabilityMedical devicesPretreated surfacesWater vaporRelease liner

The invention relates to a adhesive article comprising at least one backing layer with a first and second surface and a pressure sensitive adhesive layer adhered first surface of the backing layer in a pattern, wherein the pattern of the adhesive layer has an adhesive free area of less than about 25% and wherein the adhesive article has a water vapor transmission rate of greater than about 2000 g / m2 / 24 hour. The invention also relates to a method of forming an adhesive article comprising (a) providing a release liner, (b) applying pressure sensitive adhesive in a pattern wherein the free adhesive area is less than 25%, and (c) applying a backing layer to the pressure sensitive adhesive.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

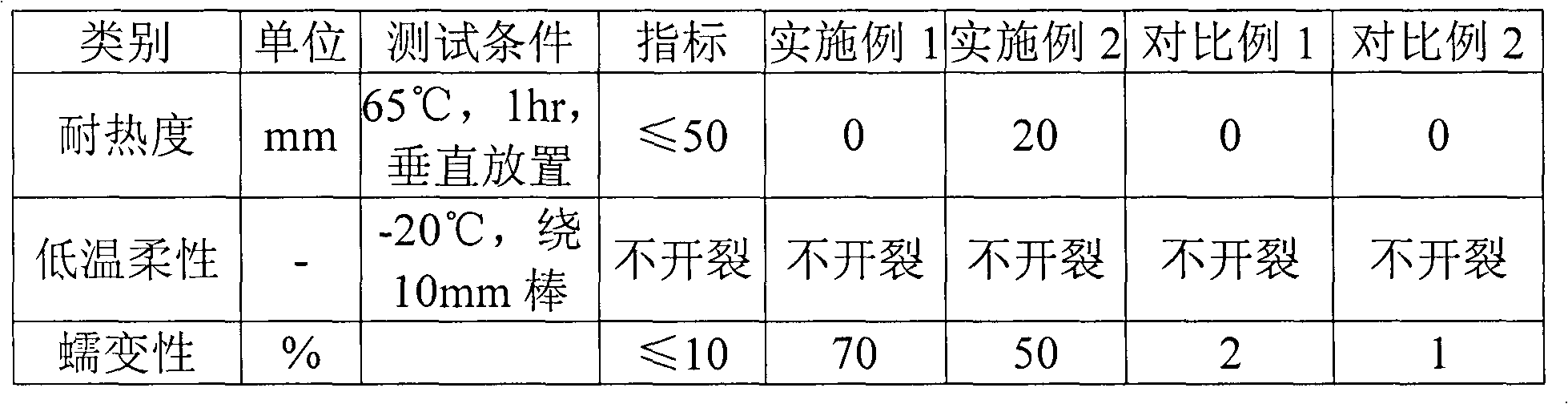

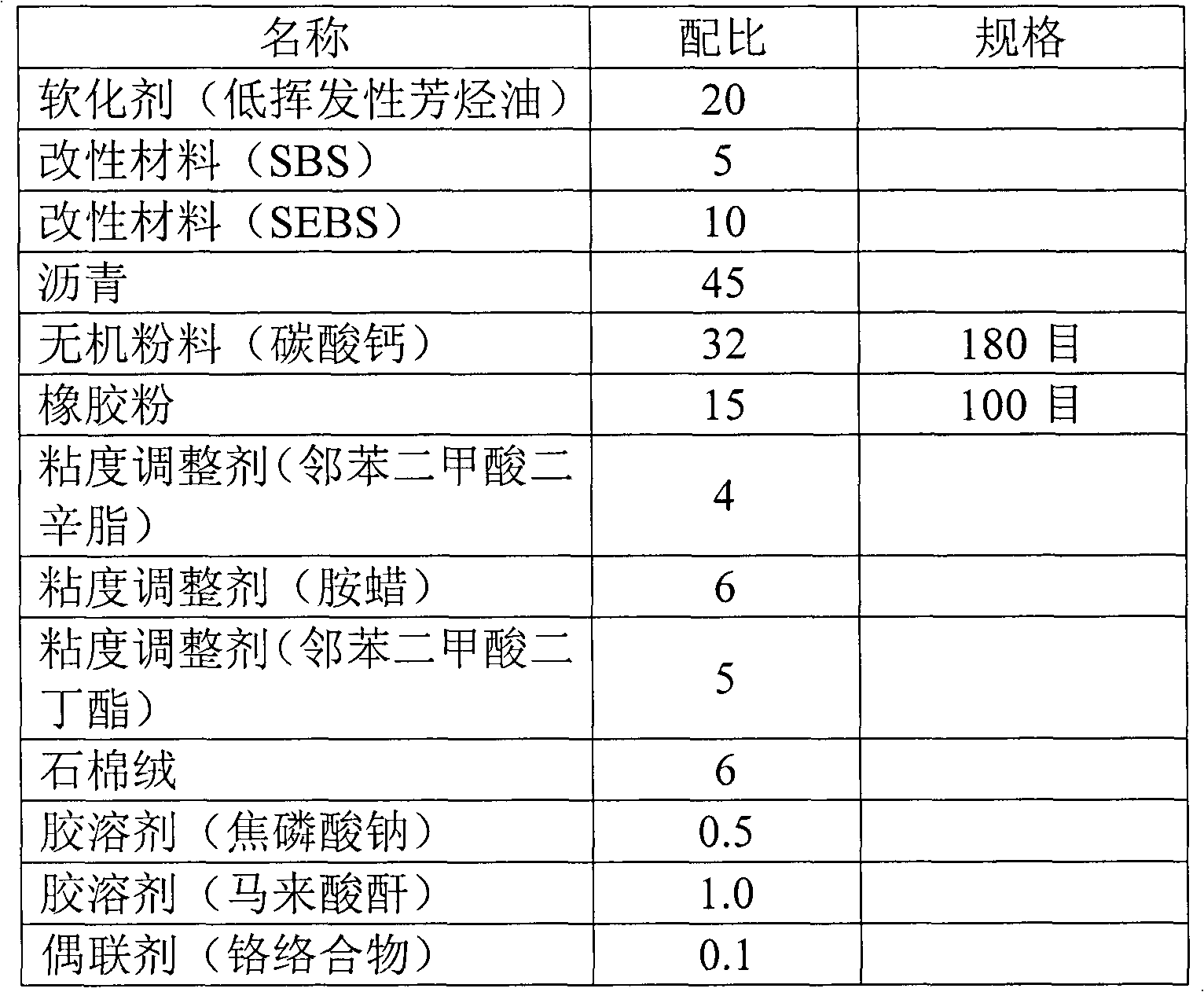

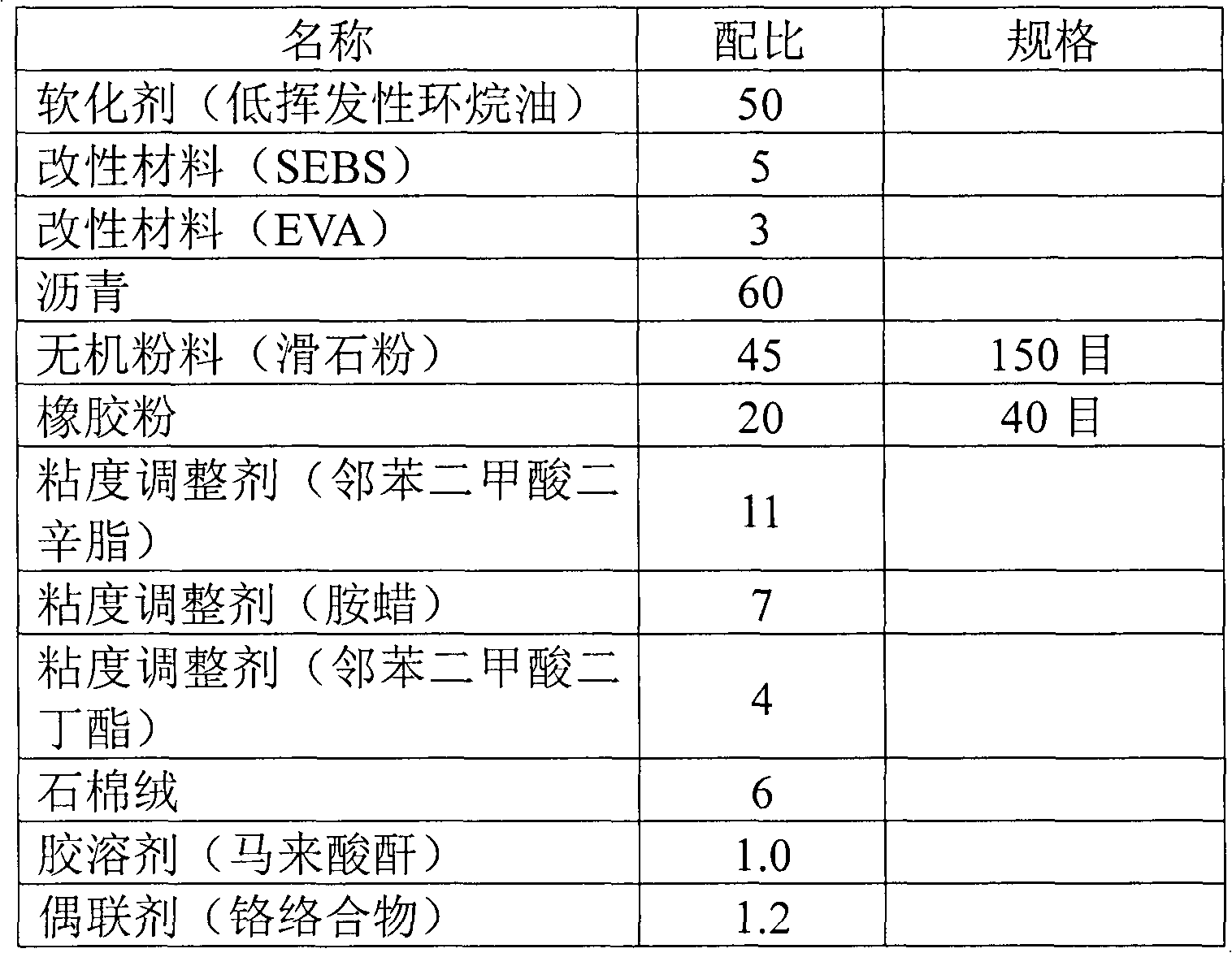

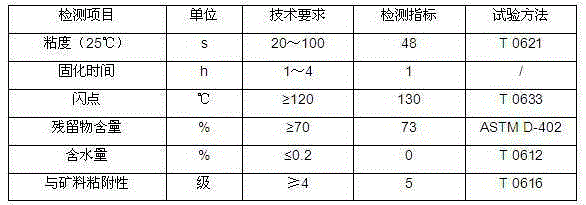

Modified asphalt composition with creeping characteristic and preparation method thereof

InactiveCN102020859AAvoid rapid agingExtended service lifeBuilding insulationsBituminous waterproofingMaterials science

The invention provides a modified asphalt composition with a creeping characteristic, which comprises the following components in parts by weight: 15-60 parts of asphalt, 3-15 parts of modifying material, 5-30 parts of rubber powder, 15-60 parts of softening agent, 15-60 parts of inorganic powder, 3-25 parts of viscosity regulating agent, 0.3-1.5 parts of peptizing agent and 0.1-2 parts of coupling agent. A preparation method of the modified asphalt composition comprises the following steps of: adding the softening agent into a reaction kettle, heating to 170 to 200 DEG C, adding the modifying material, agitating, adding the asphalt and the rubber powder, and agitating for 1-2 h to obtain an intermediate raw material; levigating the intermediate raw material to 150-250 meshes, and putting back to the reaction kettle; and finally, adding the inorganic powder, the viscosity regulating agent, the peptizing agent and the coupling agent into the reaction kettle, agitating and dispersing uniformly. The modified asphalt composition has the characteristics of excellent water-proof performance, strong binding capability and continuous binding capability, large elongation percentage and good low-temperature flexibility.

Owner:ZHEJIANG WOPUMAN HIGH NEW MATERIALS

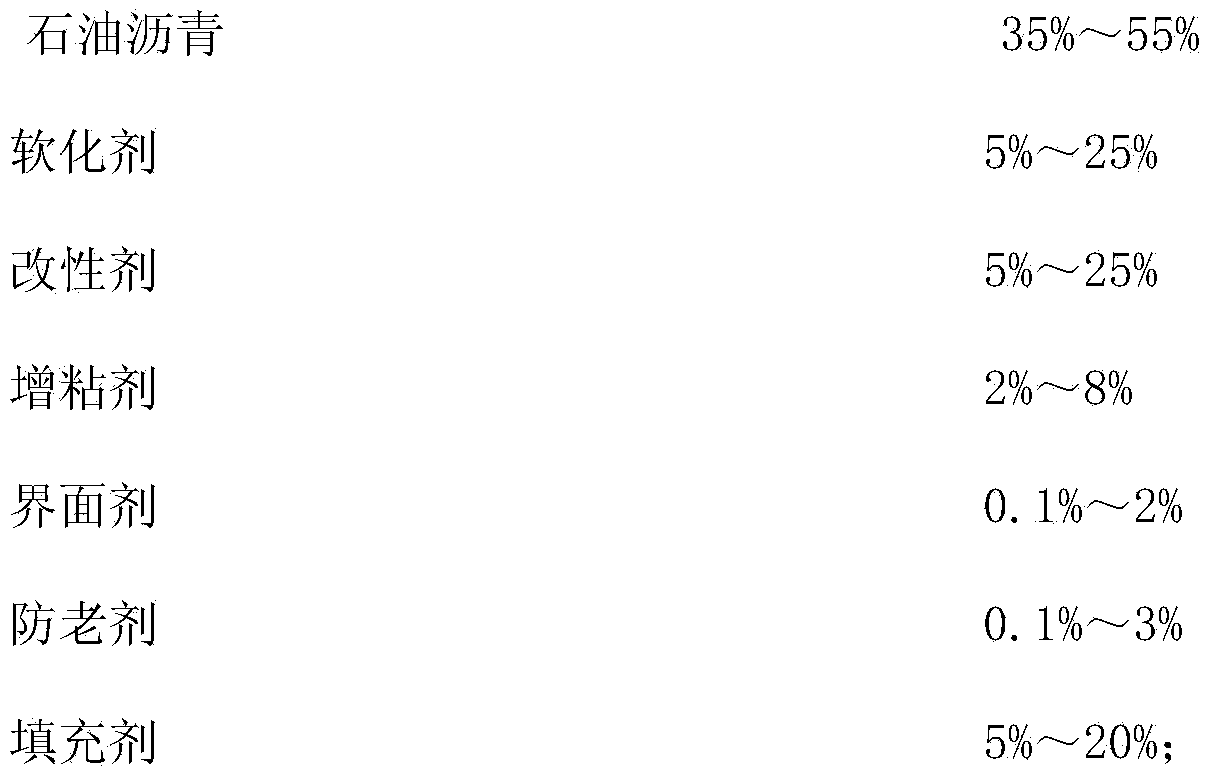

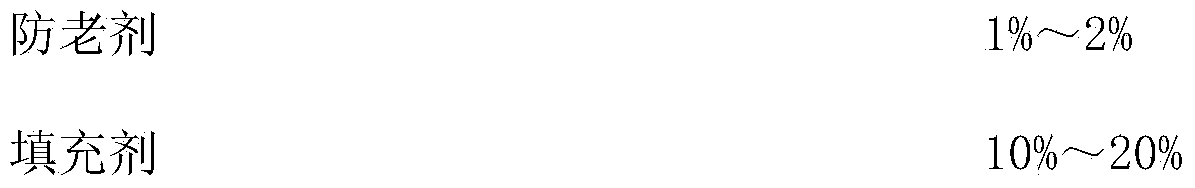

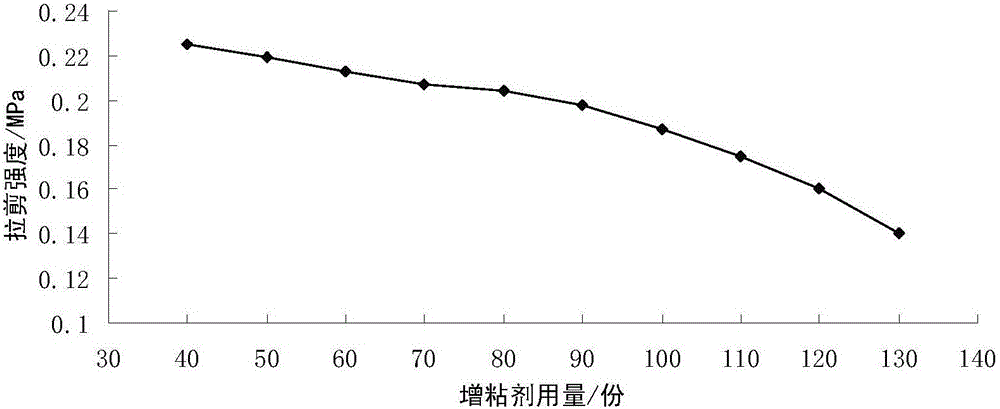

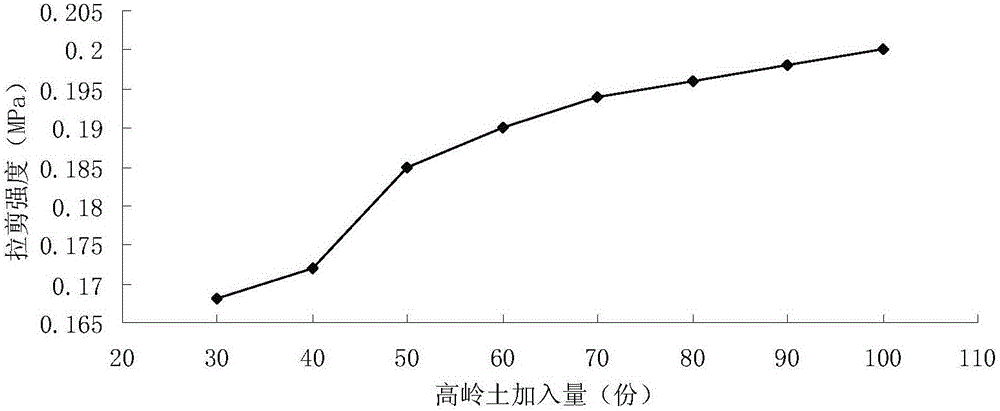

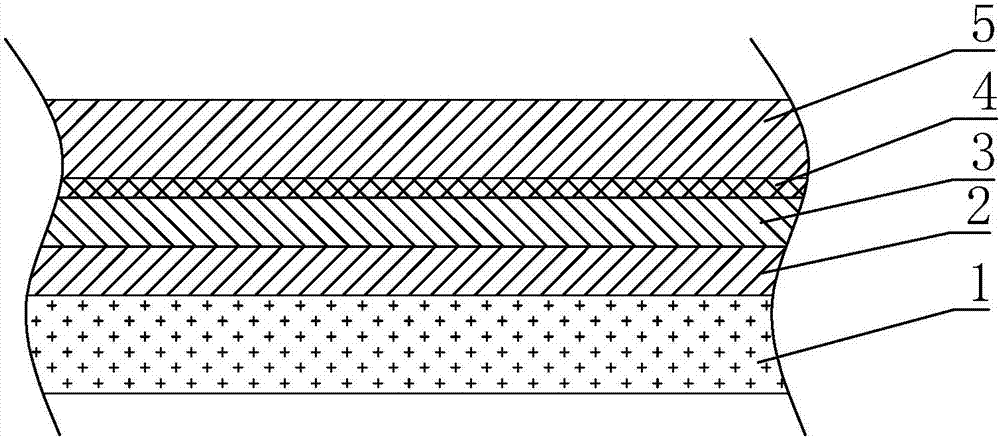

Creeping self-adhesive asphalt water-proof coiled material and preparation method thereof

InactiveCN104194719ASolve the leakExtended service lifeNon-macromolecular adhesive additivesBituminous material adhesivesAsphaltAnti ageing

The invention relates to a creeping self-adhesive asphalt water-proof coiled material and a preparation method thereof. An asphalt sizing material used for the creeping self-adhesive asphalt water-proof coiled material has good adhesive property and creeping property, and the asphalt sizing material is prepared from the following raw materials in percentage by weight: 35%-55% of petroleum asphalt, 5%-25% of softening agent, 5%-25% of modifying agent, 2%-8% of tackifying agent, 0.1%-2% of interface agent, 0.1%-3% of anti-aging agent and 5%-20% of filling agent. The self-adhesive asphalt water-proof coiled material disclosed by the invention has very good initial adhesion, can be well adhered with a base layer under the conditions of the wet base layer and lower temperature even if a little dust is positioned on the surface of the base layer, is difficult to strip after being adhered, and can ensure that a complete sizing material can be retained on the base layer after being stripped, thus meeting the requirement for water-proof property.

Owner:HUIZHOU ORIENTAL YUHONG BUILDING MATERIALS

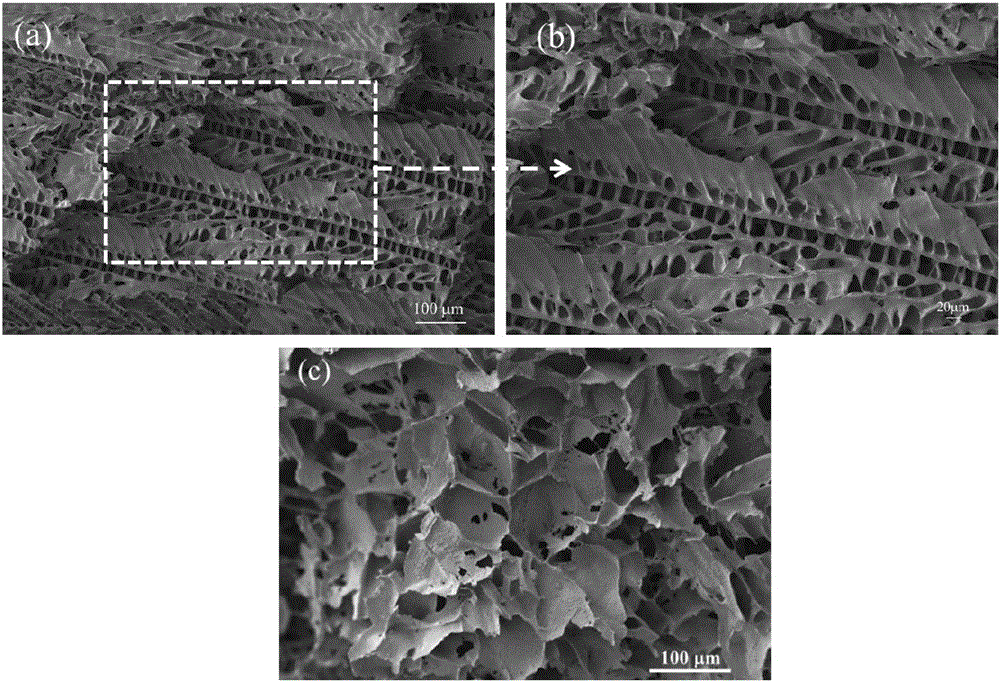

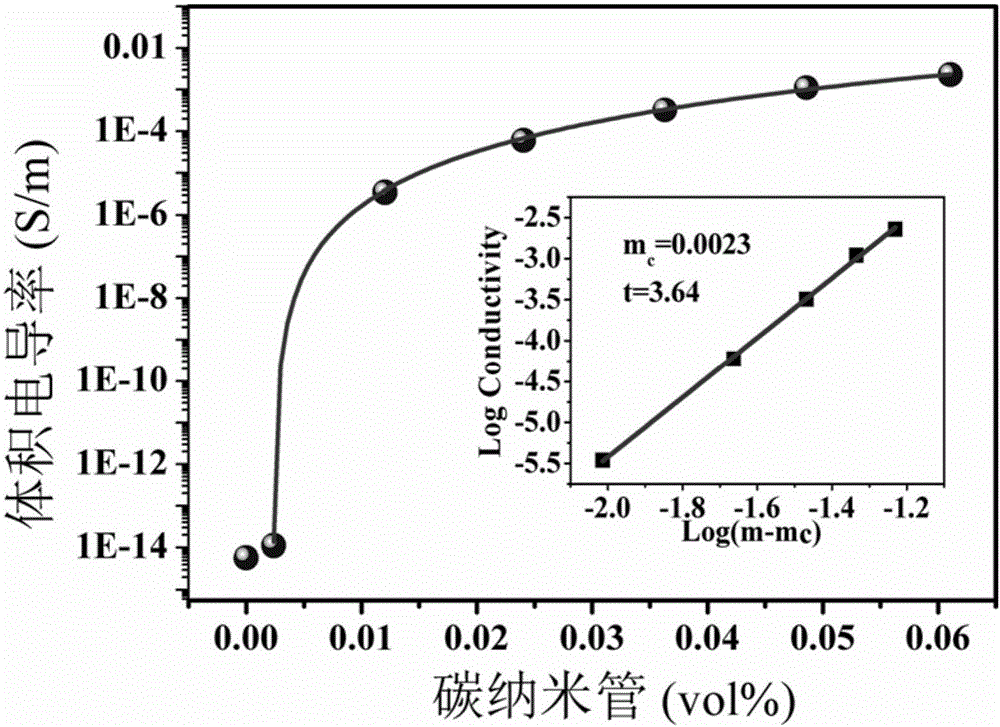

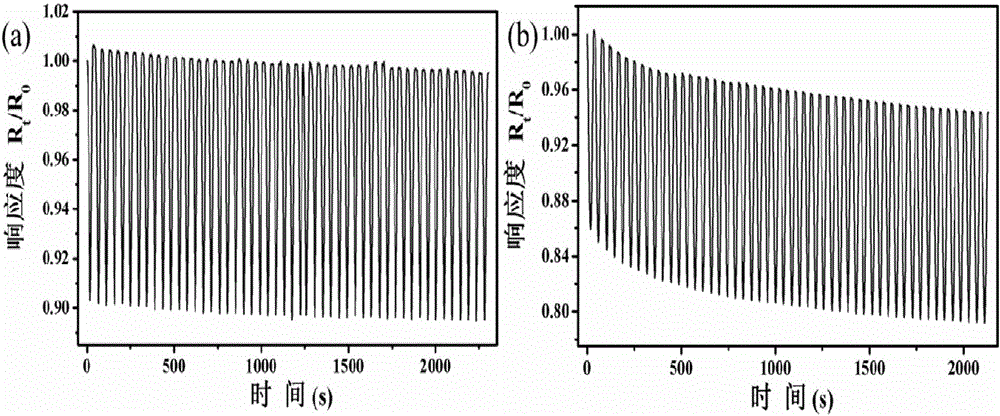

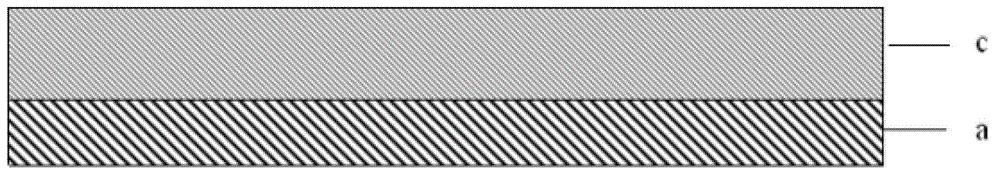

Preparation method of porous conductive polymer material with pressure-sensitive property and application thereof

ActiveCN106009029AImproved and stable electrical performanceLow percolation valueForce measurement using piezo-resistive materialsMaterial strength using repeated/pulsating forcesConductive polymer compositePolymer science

The invention belongs to the field of conductive polymer composites pressure-sensitive materials and particularly relates to a preparation method of a porous conductive polymer material with pressure-sensitive property and an application thereof. The preparation method of the porous conductive polymer material with pressure-sensitive property comprises the following steps: a) suspension preparation; b) unidirectional freezing; and c) low-temperature low-pressure drying. The porous conductive polymer composite with pressure-sensitive property prepared in the invention has excellent stability and resilience and can be used for preparing a light polymer-based strain sensor; and by combining the obtained conductive polymer composite with the circuit board and semiconductor technology, various pressure-sensitive sensors with good stability and long service life can be made.

Owner:ZHENGZHOU UNIV

Polyurethane binder

Polyurethane adhesive consists of polyurethane performed polymer 70-90wt% and anchoring agent 10-30wt% which contains hydroxyl group or epoxy group and is prepared by polymerizing at least two unsaturated monomers from free radical. At lest one monomer is polymerized unsaturated monomer containing hydroxyl group or epoxy group with hydroxyl group value:15.5-55, functionality:2-6; epoxy equivalent:1420-7000 and functionality:2-6. It achieves good viscidity and thermal stability, and better heat resistance. It can be used for composite plate, foam polypropylene and polyester plastic.

Owner:DINGSHENG SPECIAL CHEM

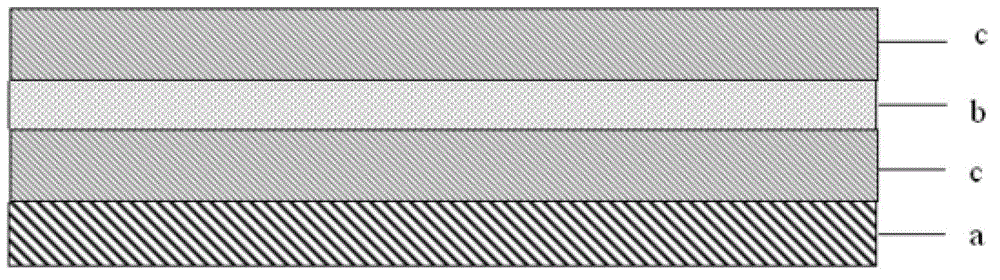

Heat-conducting insulated pressure sensitive tape and preparation method thereof

ActiveCN102746799AWith thermal insulationSensitive to pressureNon-macromolecular adhesive additivesFilm/foil adhesivesHeat conductingHeat sink

The invention relates to a heat-conducting insulated pressure sensitive tape and a preparation method of the tape. The principal technical features are as follows: the heat-conducting insulated pressure sensitive tape comprises a heat-conducting insulated pressure sensitive tape without a base material and a heat-conducting insulated pressure sensitive tape with the base material; and the preparation method comprises the following steps: (1) preparing a polyacrylate adhesive; (2) preparing modified heat-conducting filler dispersion liquid; and (3) mixing the polyacrylate adhesive prepared in the step (1) with the modified heat-conducting filler dispersion liquid prepared in the step (2), coating wet glues with different thicknesses onto a release protection layer by a film coater, and drying in a gradually heating way to prepare the heat-conducting insulated pressure sensitive tape without the base material; or bonding with the both faces of the base material to prepare the heat-conducting insulated pressure sensitive tape with the base material. The heat-conducting insulated pressure sensitive tape is high in heat conductivity, good in bonding performance and excellent in ageing resistance, has excellent die cutting processability, and can be widely applied to bonding of heat radiating fins and heating devices such as a CPU (central processing unit), a power tube, a module power supply and the like, as well as bonding of screens, frames and injection molded boards in electronic products such as a mobile phone, an LED (light emitting diode) device and the like.

Owner:TIANJIN BOYUAN NEW MATERIALS

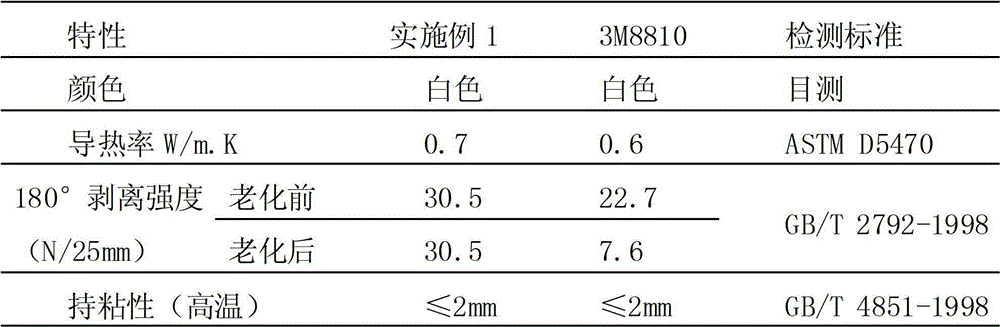

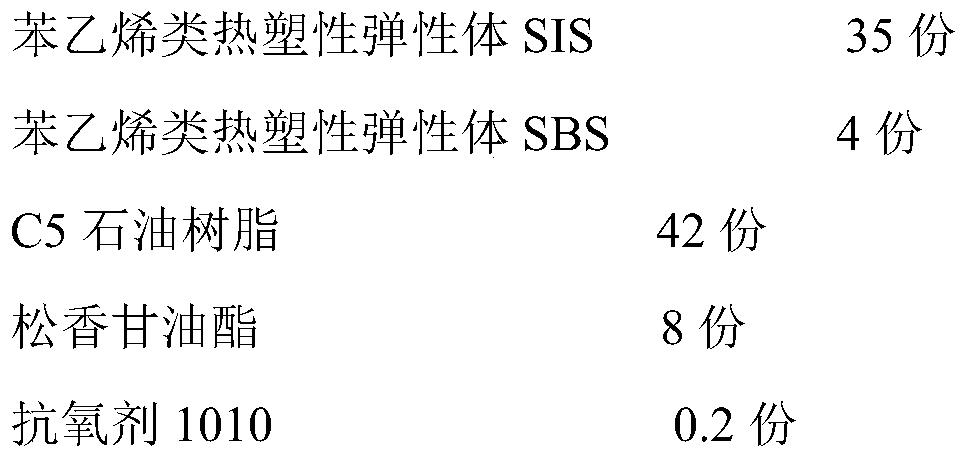

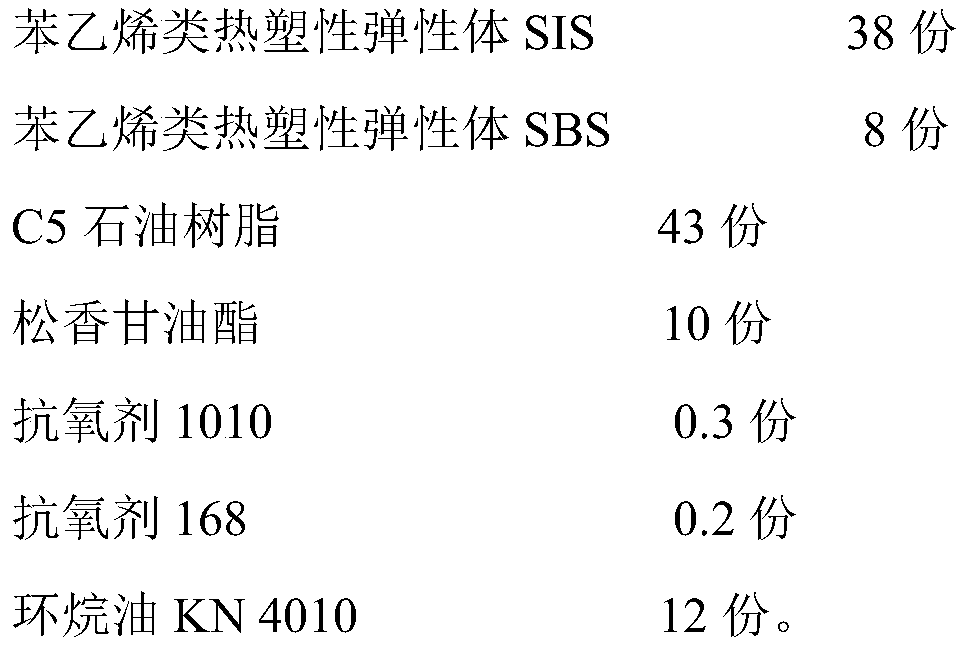

Hot-melt pressure sensitive adhesive for adhesive tapes, and preparation method thereof

InactiveCN110437778AImprove ring tackImprove peel forceMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPetroleum resinAntioxidant

The invention relates to a hot-melt pressure sensitive adhesive, and concretely relates to a hot-melt pressure sensitive adhesive for adhesive tapes, and a preparation method thereof. The hot-melt pressure sensitive adhesive comprises a styrenic thermoplastic elastomer SIS, a styrenic thermoplastic elastomer SBS, petroleum resin, rosin glyceride, a primary antioxidant, an auxiliary antioxidant anda softener, wherein the styrenic thermoplastic elastomer SIS is a linear structure, the styrene content is 20-28%, and the diblock content is 20-28%; and the styrenic thermoplastic elastomer SBS is astar structure, the styrene content is 28-32%, and the diblock content is 12-18%. The purpose of the invention is to solve the problem of poor use performance of the adhesive tapes, caused by failedcombination of the initial adhesion, the permanent adhesion and the aging resistance of existing hot-melt pressure sensitive adhesives for adhesive tapes. The initial adhesion (the initial adhesion includes ring initial adhesion and 180 DEG peel strength) of the hot-melt pressure sensitive adhesive of the invention meets use requirements, and has a high adhesion and a good aging resistance. The present invention also provides the preparation method of the hot-melt pressure sensitive adhesive for adhesive tapes.

Owner:ZIBO LUHUA HONGJIN NEW MATERIAL CO LTD

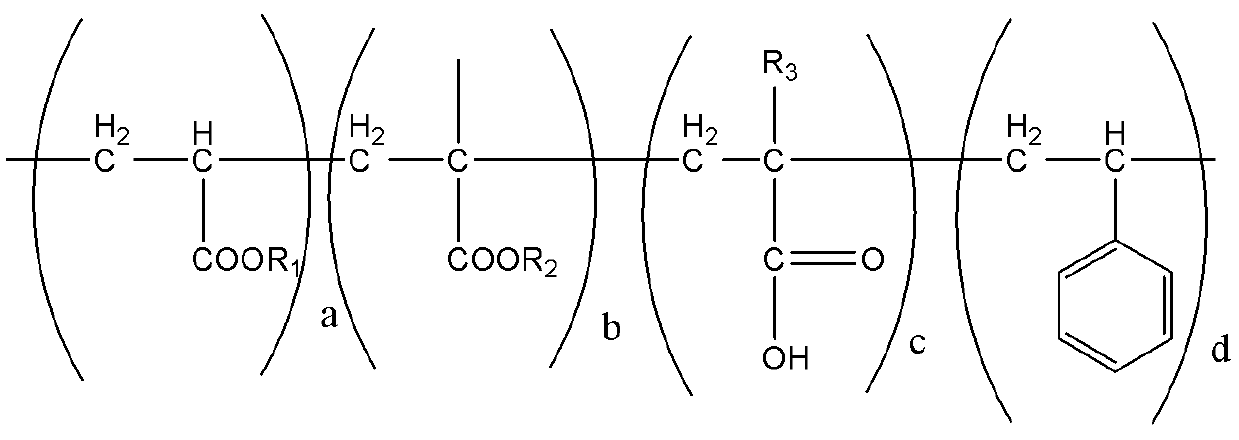

Reactive pressure-sensitive adhesive having performance of structural adhesive after being cured, and preparation method thereof

InactiveCN103275656AGood storage stabilitySensitive to pressureFilm/foil adhesivesEster polymer adhesivesEpoxyAcrylate polymer

The invention relates to a reactive pressure-sensitive adhesive having the performance of a structural adhesive after being cured, and a preparation method thereof. The pressure-sensitive adhesive is prepared from the following materials in parts by weight: a) 100 parts of soluble acrylate copolymer; b) 80 to 120 parts of epoxy resin; and c) 8 to 12 parts of epoxy resin latency curing agent, wherein the soluble acrylate copolymer is formed by polymerizing the following raw materials in a free radical polymerization reaction manner: 50% to 65% of alkyl ester with the acrylic carbon atom number from 1 to 8, 5% to 15% of styrene, 10% to 15% of alkyl ester with the methylacrylic acid carbon atom number from 1 to 8 and 35% to 5% of alkyl acrylate. At the normal temperature, under the action of the plasticization of the epoxy resin to the acrylate polymer, the pressure sensitivity of the acrylate polymer is generated, so that the pressure-sensitive adhesive can be used as an ordinary pressure-sensitive adhesive. After the pressure-sensitive adhesive is heated, the curing agent reacts with the epoxy resin; and the cured epoxy resin is toughened by the acrylic ester, so that the pressure-sensitive adhesive has the adhesion strength of the structural adhesive.

Owner:BEIJING UNIV OF CHEM TECH

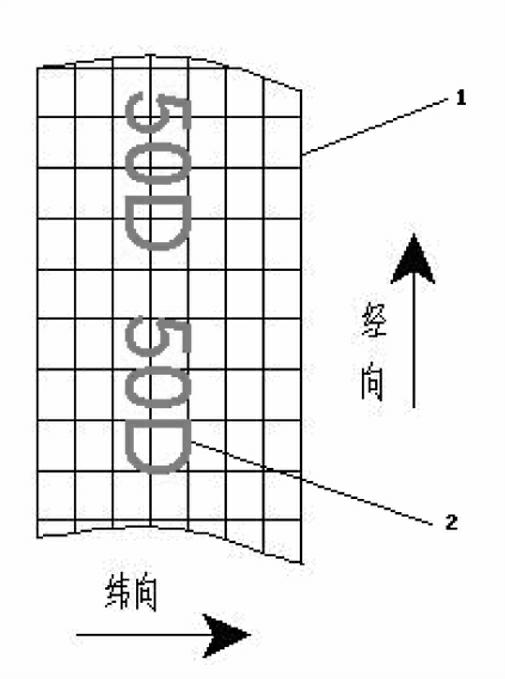

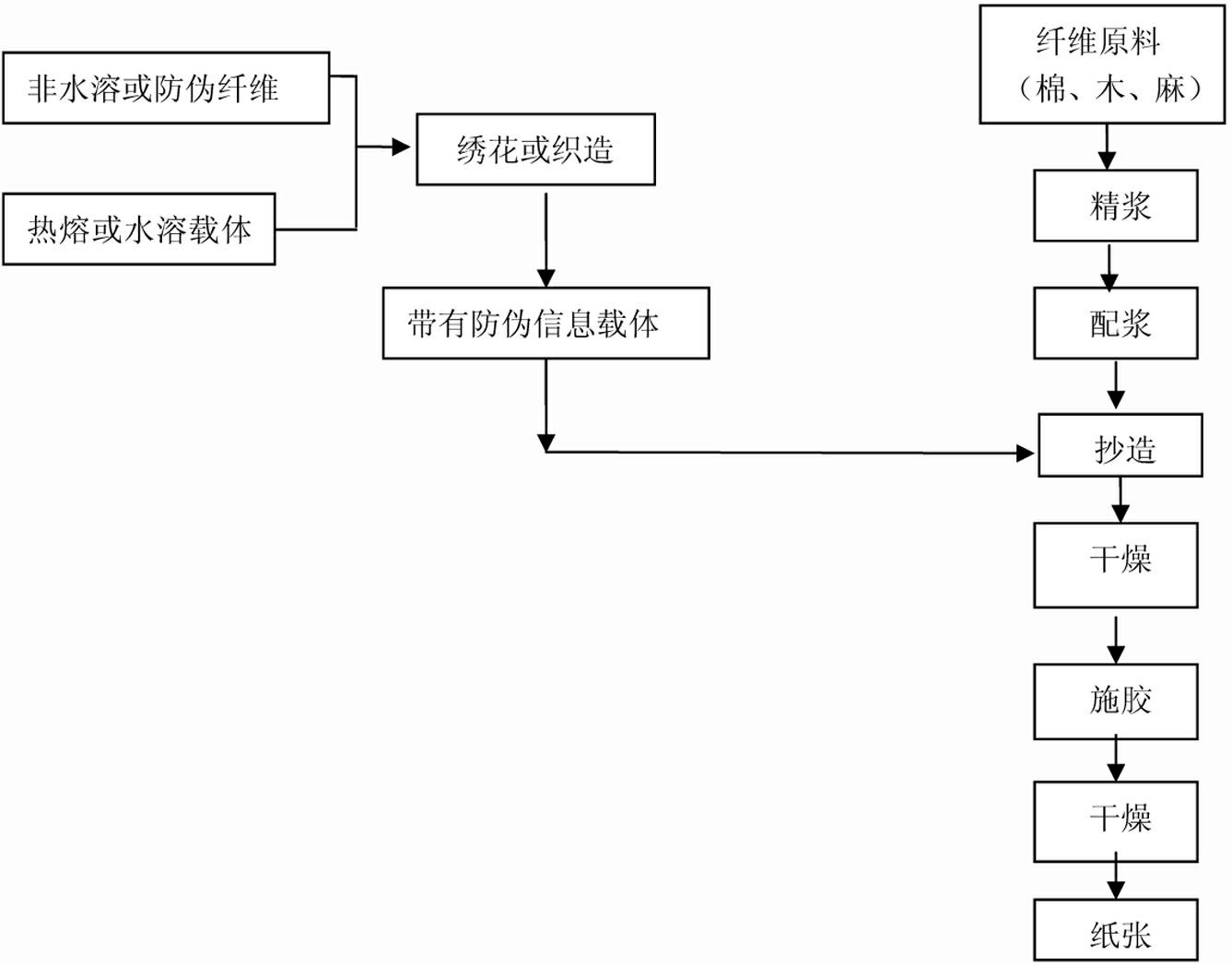

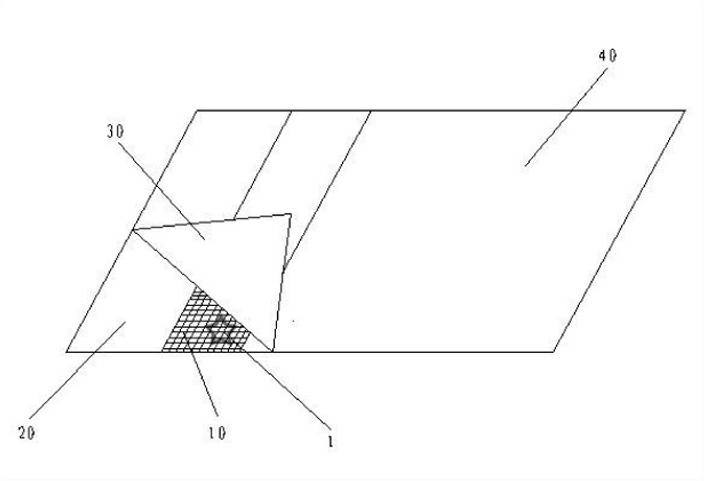

Multiple anti-counterfeit watermark paper and manufacturing method thereof

ActiveCN102191722ACompatible with and strengthen the concave-convex feelingDifficult to forgeNon-fibrous pulp additionFiberPhotoluminescence

The invention relates to multiple anti-counterfeit watermark paper and a manufacturing method thereof. The watermark paper is provided with patterns, figures or lines which are woven or embroidered by non-water-soluble fibers or anti-counterfeit fibers; and the paper has rich levels and a concavo-convex touch feel under transmission light. A film, non-woven fabric or woven fabric made from a water-soluble material or a hot-melting material is used as a carrier, so that the patterns, the figures or the lines are woven or embroidered on the carrier by using the non-water-soluble fibers or the anti-counterfeit fibers; and the carrier with the patterns, the figures or the lines is released in front of a paper machine net through a positioning and releasing device so that the carrier is combined with paper. Compared with the conventional watermark, the patterns, the figures or the lines of the watermark paper are more fine and smooth; meanwhile, during processing of the patterns, the anti-counterfeit fiber loaded with one or more pieces of anti-counterfeit information (such as fluorescence, color, temperature variation, photoluminescence, magnetism and the like) is adopted; therefore, the watermark is integrated with vision, touch and multiple anti-counterfeit effects of the anti-counterfeit material as well as combination of the vision, the touch and the multiple anti-counterfeit effects.

Owner:BAODING BANKNOTE PAPER CO LTD +1

Optically clear hot melt adhesives and uses thereof

InactiveUS20170145267A1Good light transmissionGood optical effectAdhesive processesLayered product treatmentMeth-LED display

Hot melt adhesives with pressure sensitive adhesive properties for electronic devices are described. The hot melt adhesive comprises a styrenic block copolymer with fully hydrogenated and saturated soft blocks, a liquid diluent or a tackifier, a (meth)acrylate monomer or an oligomer having at least two (meth)acrylic functionalities per oligomer chain, and an initiator. The hot melt adhesive is also a reworkable UV curable optically clear adhesive film. The adhesive and film are suitable as a laminating PSA film or encapsulant for LCD display, LED display, touch screen, and flexible thin film photovoltaic module.

Owner:HENKEL IP & HOLDING GMBH

Hot-melt polyurethane adhesive with high initial adhesion and preparation method thereof

InactiveCN106496500AHigh initial bond strengthShort opening hoursPolyureas/polyurethane adhesivesPolyurethane adhesivePrepolymer

The invention provides a hot-melt polyurethane adhesive with high initial adhesion. The hot-melt polyurethane adhesive comprises, by weight, 70 to 90% of polyurethane prepolymer and 10 to 30% of an adhesion promoting agent, wherein the adhesion promoting agent is prepared through addition of rosin acid, one-component or two-component epoxy, and hydrogenated rosin or any cyclic compound with a carboxyl group or natural resin. The invention has the following unique beneficial effects: 1, the active adhesion promoting agent is produced through addition of natural resin or a related cyclic compound with the carboxyl group and epoxy for the first time, and is applied to the reactive polyurethane adhesive; and 2, the novel two-step preparation method has not been reported and used so far. The novel two-step preparation method can prepare a hot-melt polyurethane adhesive product with high initial adhesion without changing a formula for the hot-melt polyurethane adhesive. The hot-melt polyurethane adhesive product has creep resistance reaching the grade of 3, 500 g, and has superior heat stability. Due to high adhesive capability and arbitrarily-adjustable hot opening time of the product, the hot-melt polyurethane adhesive product can be applied to industrial places like the shoemaking industry and engineered floors with high requirements on initial adhesion.

Owner:佛山市顺德区巴德富实业有限公司

Capacitance pen, capacitance touch panel and touch device

ActiveCN103941889APinpoint location informationImprove writing fluencyInput/output processes for data processingCapacitanceEngineering

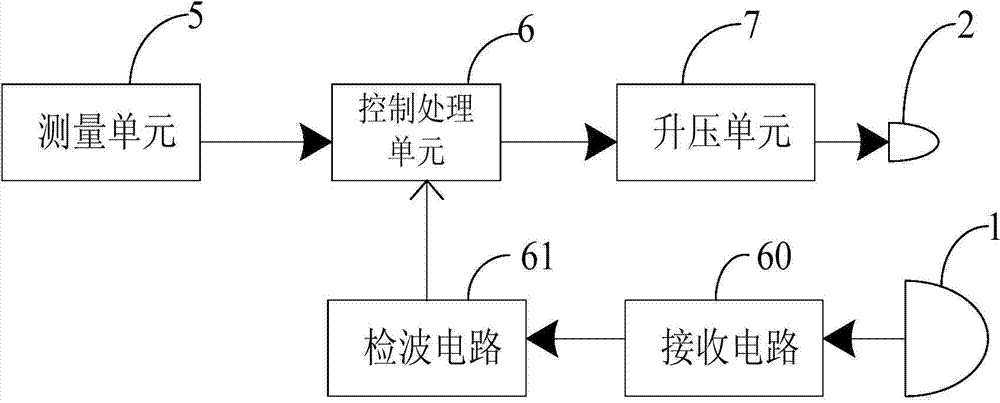

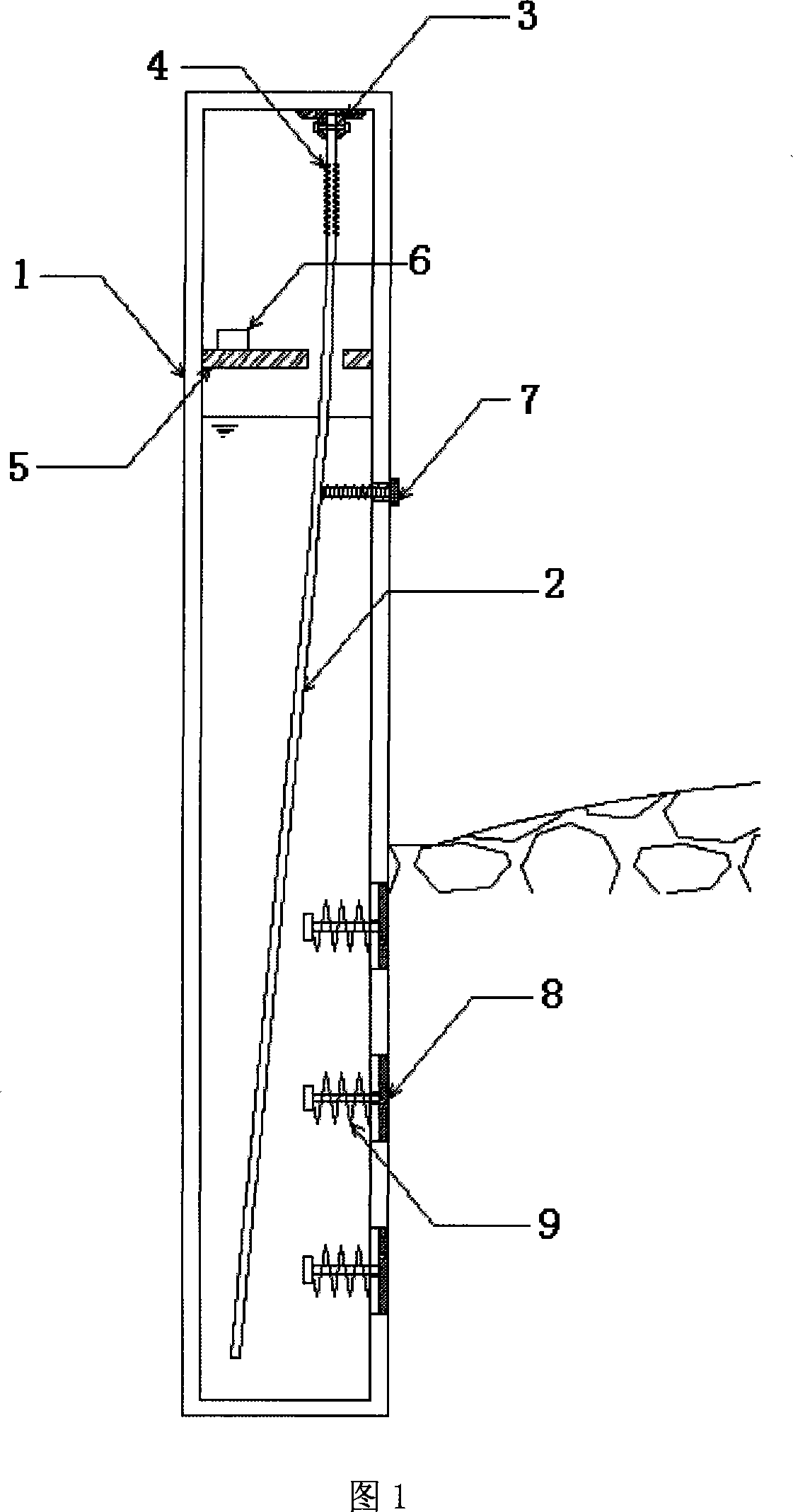

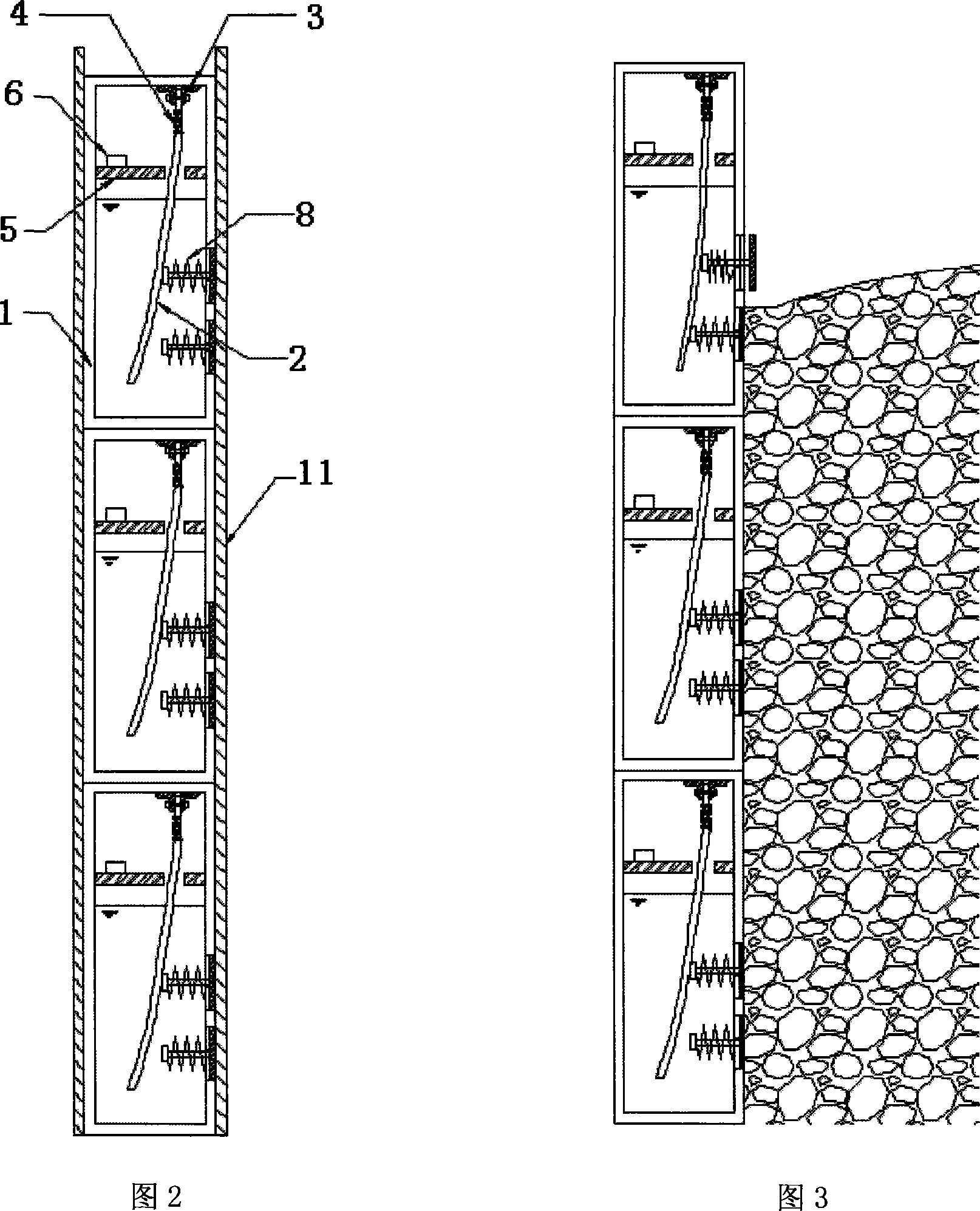

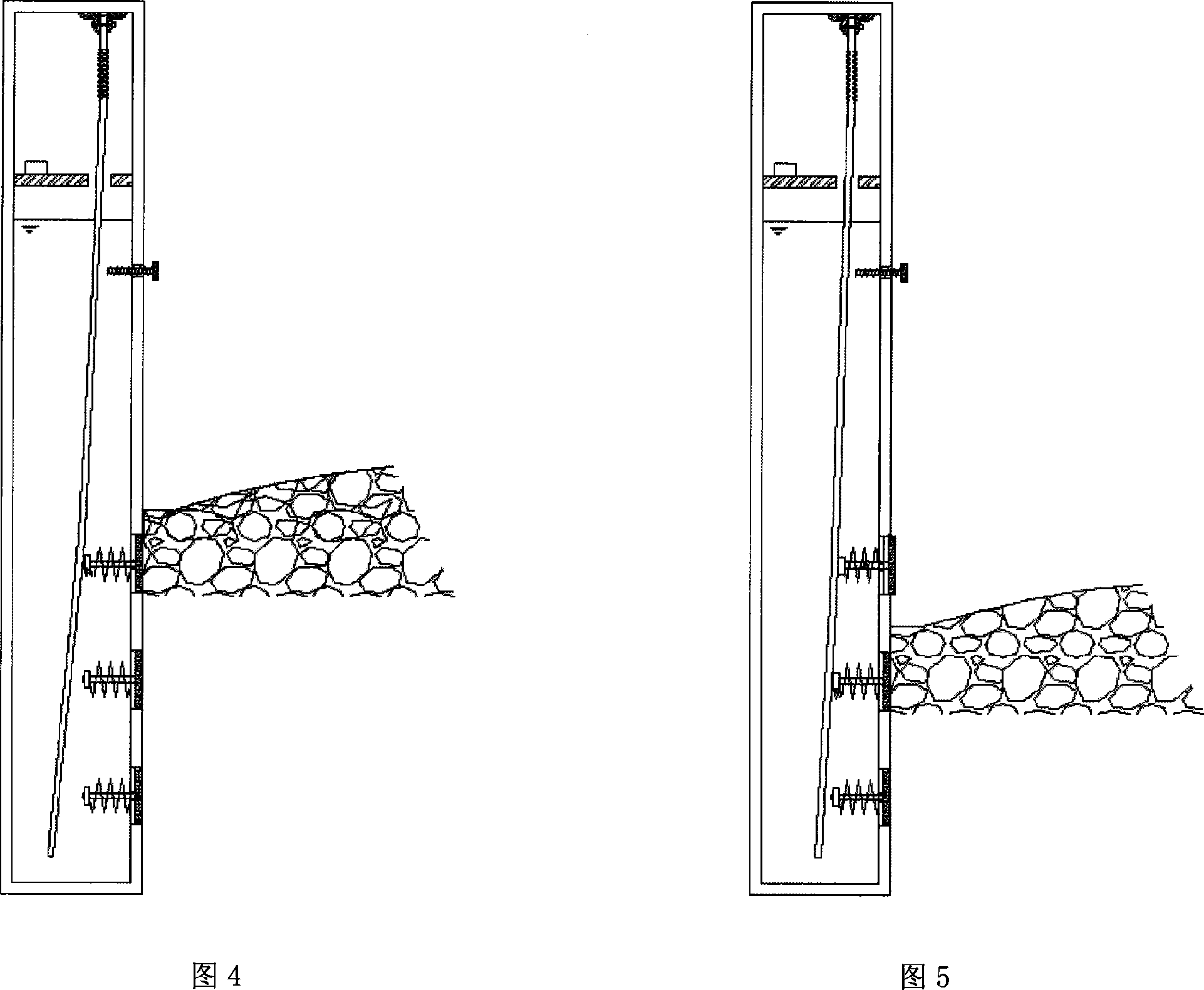

The invention provides a capacitance pen used for carrying out the operation on a capacitance touch panel (200). The capacitance pen comprises a receiving unit (1), a control processing unit (6) and a sending unit (2). The receiving unit (1) is used for receiving an order signal sent by the capacitance touch panel (200). The control processing unit (6) is used for generating a high-voltage signal according to the order signal received by the receiving unit (1). The sending unit (2) is used for sending the high-voltage signal to the capacitance touch panel (200) to enable the capacitance touch panel (200) to obtain the touch information of the capacitance pen (100). According to the capacitance pen, the touch capacitance panel can still precisely determine the position information of the capacitance pen when the pen point is sharp, the capacitance pen has the pressure character, and the writing fluency and using experience of the capacitance pen are greatly improved.

Owner:HANVON CORP

High durability optical fiber grating wash out sensor

InactiveCN101140176AIncreased durabilityHigh precisionUsing optical meansCoupling light guidesFiberCircular disc

The invention provides a high-durability fiber grating scouring sensor which comprises a metal shell and a measuring part arranged in the metal shell and connected with the metal shell, wherein the measuring part is composed of a FRP uniform strength beam and two fiber gratings stuck on the upper and lower surfaces of the FRP uniform strength beam, the leading-out wire of the fiber grating passes through the metal shell and is educed, the inner wall of the metal shell is provided with a metal baffle plate provided with a calcium carbide, the lower part of the metal shell is provided with a dowel bar, a prepressing small-rigidity spring is arranged between one end of the dowel bar and the inner wall of the metal shell, and the other end of the dowel bar is provided with a FRP disc. The scouring sensor has the advantages of the high precision, the convenient arrangement and the adjustable range and resolution, and is applied to the foundation soil scouring monitoring of health monitoring of civil engineering structure and the foundation soil scouring monitoring of structural test.

Owner:HARBIN INST OF TECH

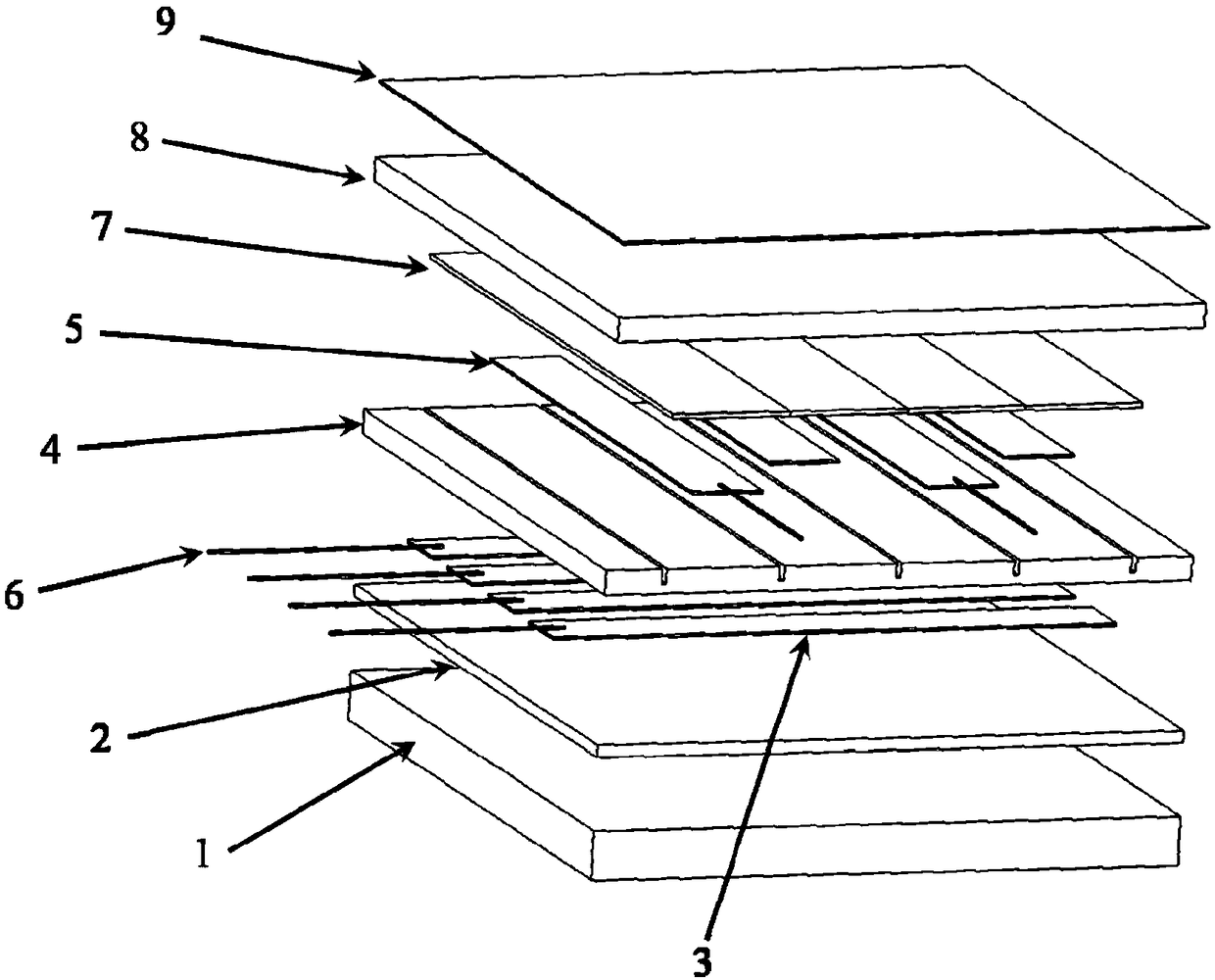

A flexible pressure-temperature integrated film array sensor sensitive element and a preparation method

ActiveCN109068477AHighly integratedSimple structurePrinted circuit aspectsConverting sensor output electrically/magneticallyTemperature sensingFerroelectric thin films

The invention discloses a flexible pressure-temperature integrated film array sensor sensitive element and a preparation method thereof. The pressure sensing function and the temperature sensing function are integrated by utilizing a piezoelectric effect and a pyroelectric effect of a flexible ferroelectric film, and the sensitive element comprises a flexible substrate, a functional film assemblyand a thermal management film assembly. In the method, an insulating layer and a lower electrode are sequentially deposited on a flexible substrate, a wire is connected, a flexible ferroelectric thinfilm is deposited and an insulating groove is etched, an upper electrode is deposited on the flexible ferroelectric thin film, the wire is connected, a thermal control layer, a thermal conductive layer and an infrared reflective layer are sequentially deposited, and finally the sensitive element is polarized and tested through the wire. The sensitive element of the invention realizes the integration of the pressure sensing function and the temperature sensing function on a single sensitive element, and has high integration level and simple use structure, is suitable for large-area preparation,suitable for plane, curved surface, special-shaped surface and other structures, high adaptability, and has the advantages of shock resistance, strong vibration ability, high bionic degree, high reliability and the like.

Owner:SHANGHAI RADIO EQUIP RES INST

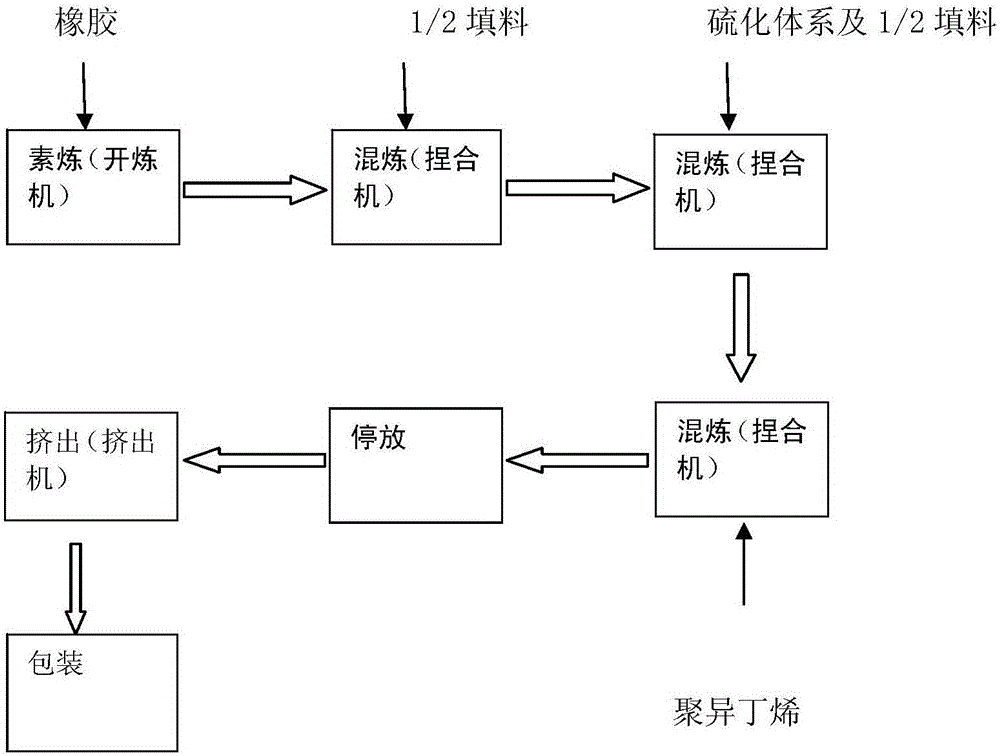

Vacuum bag sealing adhesive tape applicable under room temperature to 220 DEG C, and preparation method thereof

The invention relates to a pressure sensitive vacuum bag sealing adhesive tape applicable under room temperature to 220 DEG C. Chlorinated butyl rubber is adopted as the base adhesive material of the sealing adhesive tape. Tackifying resin, a filler, a vulcanizing agent, an activator, a scorch retarder, a water-absorbing agent, and a coupling agent are added to the base adhesive material. The adhesive tape has the following advantage: the air permeation of chlorinated butyl rubber is the lowest among all general rubbers, such that chlorinated butyl rubber has good air tightness; the sealing adhesive tape has good heat resistance, wherein phenolic resin vulcanized chlorinated butyl rubber has as an application temperature range from room temperature to 220 DEG C; the sealing adhesive tape is pressure sensitive, such that sealing can be realized with finger pressure, wherein the pressure sensitivity is provided by polyisobutylene; the sealing adhesive tape has good adhesiveness on various sealing films and molds. A vacuum bag prepared with the sealing adhesive tape can provide pressure close to 1atm. With the sealing adhesive tape, long-time sealing can be realized under room temperature to 220 DEG C, and leakage is prevented. The sealing adhesive tape is convenient to use.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

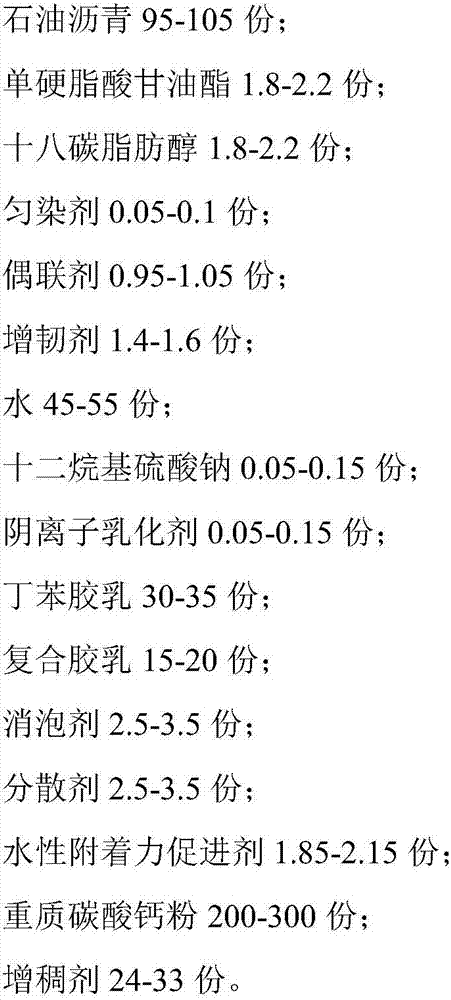

Combined construction process of rubber waterproof paint and non-curing rubber asphalt waterproof paint

ActiveCN107384206AAvoid crackingPrevent uneven coating thicknessFireproof paintsAnti-corrosive paintsBituminous waterproofingMesh grid

The invention discloses a combined construction process of rubber waterproof paint and non-curing rubber asphalt waterproof paint. The combined construction process comprises the following steps: a, cleaning up a base layer, and enabling the base layer to be clean and have no water; b, uniformly blade-coating the surface of the base layer with a layer of rubber waterproof paint as a bottom layer; c, uniformly blade-coating the surface of the bottom layer with a layer of non-curing rubber asphalt waterproof paint layer; d, laying a layer of gridding cloth on the surface of the non-curing rubber asphalt waterproof paint layer; and e, uniformly blade-coating the surface of the non-curing rubber asphalt waterproof paint layer, with the laid gridding cloth, with a layer of rubber waterproof paint as a surface layer. By adopting the combined construction process, the assistance of mechanical equipment is not needed, after a paint barrel is opened, blade-coating can be performed, convenience in construction can be realized, and the combined construction process can be applied to fireproof and explosion-proof places; moreover, no carcinogenic gas is released, and the environmental protection and no pollution are realized; and a broken place can be self-repaired, the completeness of a waterproof layer can be always maintained, the waterproof performance is excellent, a high-elastic creep environment-friendly and energy-saving waterproof system is finally formed, and the combined construction with various coiled materials such as APP and SBS can be realized.

Owner:上海京球新材料科技有限公司

Local monitoring pressure sensitive cement base stress and strain sensor of concrete structure

InactiveCN101050985ASensitive to pressureHigh sensitivityForce measurement using piezo-resistive materialsElectrical/magnetic solid deformation measurementTransducerConductive materials

A stress and strain transducer for monitoring pressure-sensitive cement base in concrete structure is prepared for fixing four mesh metal electrodes in parallel mode in pressure-sensitive cement base, leading each metal electrode out of external surface of said base by wire, setting pressure-sensitive cement base material to be mixture of conduction material and cement material, exerting DC voltage between two mesh metal electrodes at external side, measuring voltage between tow mesh metal electrodes at internal side and setting up relation curve of voltage to pressure stress and strain for realizing monitor on pressure-sensitive cement base.

Owner:HARBIN INST OF TECH

Preparing method of UV moisture dual-cured resin

The invention relates to the technical field of polymer synthesis, and discloses a preparing method of UV moisture dual-cured resin. The method includes the following step of preparing 1 part of polyester glycol, 1 part of polyester triol, 4-4.5 parts of diisocyanate, 0.5-1 part of a hydroxyl monomer, 1-10 parts of a diluent monomer and 0.01-0.1 part of a catalyst. The resin prepared through the preparing method is high-strength, high-toughness and anti-ageing resin for a high-performance adhesive, the obtained UV moisture dual-cured resin has the viscosity of 20-60 Pa s, has high wettability,and can impregnate the surface of a material without being heated; after 1-5% of a photoinitiator is added, curing can be conducted at a room temperature through a UV lamp, the curing energy is 1500mj, attaching is conducted after curing, the PC shearing strength is 0.1-0.15 MPa, the instantaneous positioning effect is realized, and the PC shearing strength is 3-4 MPa 72 hours later; if the material is a light-permeable material, curing is conducted after adhesive applying and attaching, the curing energy is 3000 mj, the PC shearing strength is 1-3 MPa, and the PC shearing strength is 4-7 MPa 72 hours later.

Owner:GUANGZHOU HUITIAN FINE CHEM +3

Structural pressure-sensitive adhesive, structural pressure-sensitive adhesive tape and preparation method of structural pressure-sensitive adhesive and structural pressure-sensitive adhesive tape

ActiveCN102234497ASensitive to pressureWith structural adhesive propertiesFilm/foil adhesivesEster polymer adhesivesEpoxyCarvacryl acetate

The invention discloses a structural pressure-sensitive adhesive, a structural pressure-sensitive adhesive tape and a preparation method of the structural pressure-sensitive adhesive and the structural pressure-sensitive adhesive tape. The structural pressure-sensitive adhesive comprises a constituent A and a constituent B. The constituent A is obtained by polymerizing acrylic acid-2-ethylhexyl ester, butyl acrylate, vinylacetate, methyl methacrylate, acrylic acid, glycerol ester of hydrogenated rosin, dibenzoyl peroxide, ethyl acetate and epoxy resin in a reactor. The constituent A is coatedon a base material to manufacture a pressure-sensitive adhesive tape; the constituent B, which is polyfunctional organic amine epoxy hardener 2,4,6-tri(dimethylamino methyl)phenol, is painted on the surface of a pasted object; the pressure-sensitive adhesive tape is pasted on the surface of the pasted object to form the structural pressure-sensitive adhesive tape. The structural pressure-sensitive adhesive tape disclosed by the invention has pressure sensitivity at the beginning of use, and has the performances of structural adhesives at the later stage of use; the proportion of the tackinessagent A and the curing agent B is unnecessary to be determined, so the adhesive tape is convenient to use; in addition, the bonding strength is large, thus the structural pressure-sensitive adhesive tap is very suitable for field application.

Owner:中国航天科技集团公司第四研究院第四十二所

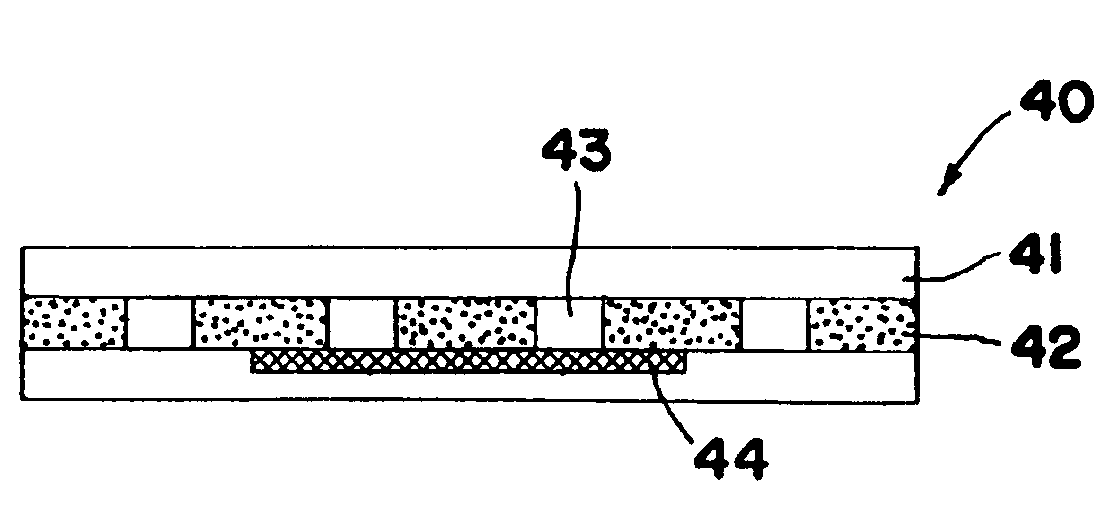

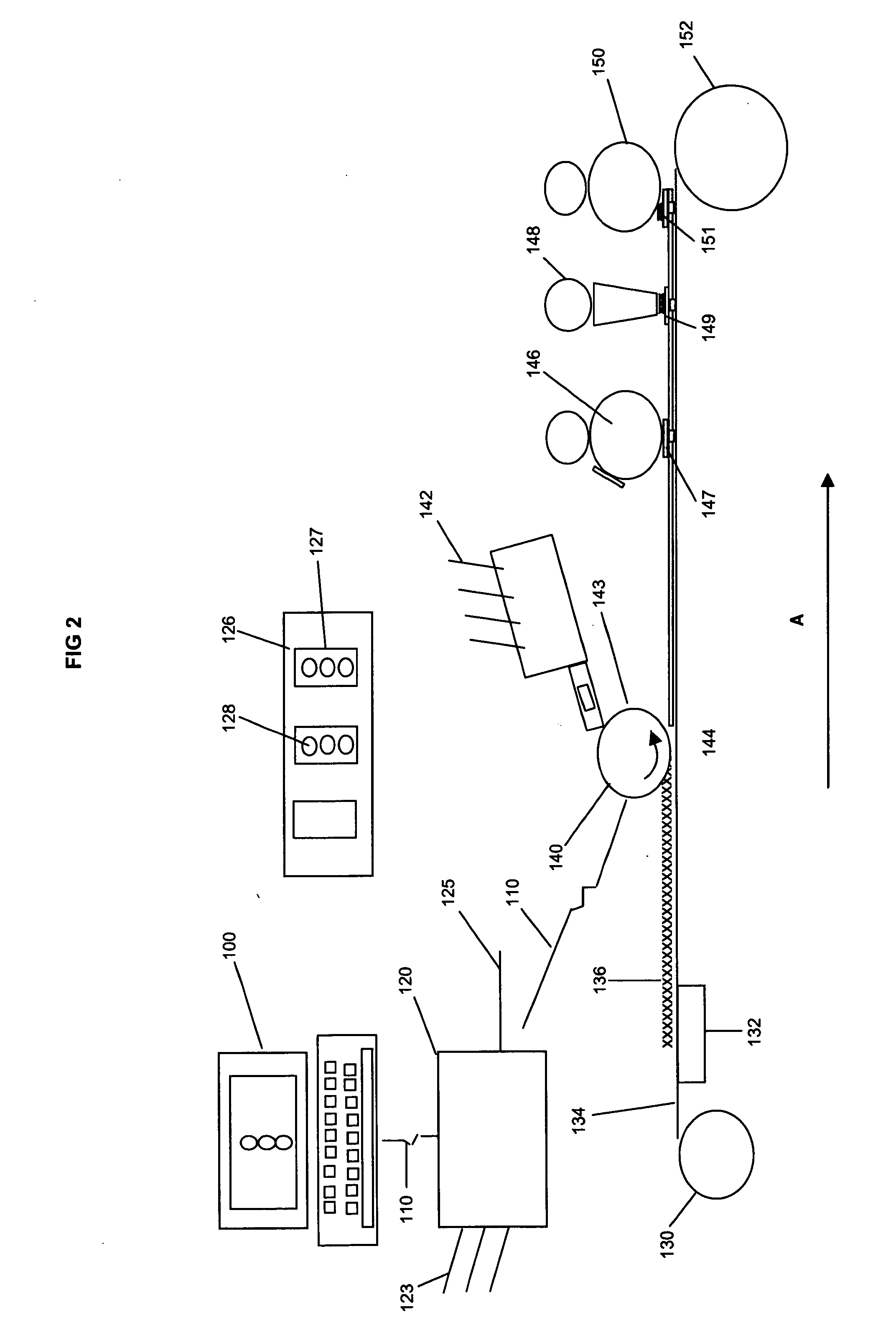

System for preparing prime label pressure sensitive intermediate laminates

InactiveUS20060260753A1Reduce preparation timeHigh image resolution productLamination ancillary operationsPaper/cardboard articlesGraphicsImage resolution

The present invention is in the field of composite manufacturing systems that are used in the preparation of articles, namely pressure sensitive laminates such as prime labels and tags. The system of the instant specification includes a computer for creating a file, an image generation means for rendering typically a graphical depiction on one or more surfaces of a substrate, an inserter for placing ribbon or label segments and a web processing apparatus. The labels of the present invention are produced in part, initially from a pre-imaged or printed sheet that are then converted or merged to a roll type of format. The sheets are printed with high quality graphics or images which are then slit or cut to size to form ribbons or label segments for the prime label application and then are converted to or merged with a continuously advancing web to create a continuous roll format. Then the label segments that have been affixed to the web are provided in one or more intermediate configurations to an end user typically for application to consumer packaged goods. More particularly, the pressure sensitive laminates of the instant application can be used to create individual, prime labels having a high or photo quality resolution level such as those about 300 lines per inch or approximately 2500 to 3500 dots per inch.

Owner:WARDKRAFT

Plastic label adhesive and preparation method thereof

InactiveCN105647441AImprove pass rateHigh viscosityNon-macromolecular adhesive additivesStarch derivtive adhesivesAmmonium sulfateSolvent

The invention discloses a plastic label adhesive which comprises water, hydroxypropyl distarch phosphate, polyvinyl alcohol, vinyl acetate, butyl acrylate, vinyl versatate, dibutyl maleate, ethylene glycol, tributyl citrate, polyisobutylene, alkyl phenol polyoxypropylene, sodium dodecyl benzene sulfonate and ammonium persulfate. The invention also discloses a preparation method of the plastic label adhesive. The preparation method mainly comprises a solvent technique and polymerization reaction. The preparation method is simple and easy to implement, is nontoxic and environment-friendly in the preparation process, and has the advantage of low preparation cost. The label adhesive has higher adhesive force for plastics under the condition that no solvent is allowed, has certain pressure sensitiveness, and is suitable for both manual and mechanical bonding.

Owner:苏州市丛岭胶粘剂有限公司

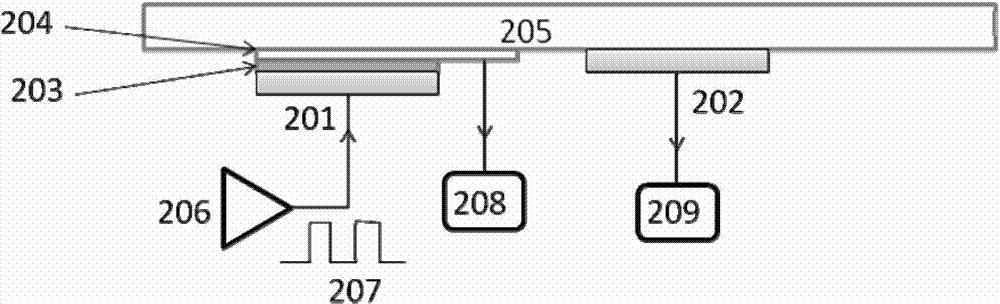

Pressure-sensitive type display screen touch unit, touch screen and manufacturing method of pressure-sensitive type display screen touch unit

ActiveCN104714672ASimple designHigh sensitivityInput/output processes for data processingCapacitanceEngineering

Disclosed are a pressure-sensitive display touch unit, a touch screen, and a manufacturing method thereof. The touch unit mainly comprises a drive electrode, a lower electrode, and a dielectric layer between the drive electrode and the lower electrode. When a pressure is applied between the drive electrode and the lower electrode, a tunnel current IT is formed, and a voltage VT exists between the drive electrode and the lower electrode. By using the touch unit of the present invention, an external pressure can be converted into a current signal, and the pressure becomes an information input manner. Further, by combining the touch unit of the present application with an existing capacitive touch screen or resistive touch screen, the touch unit not only can possess the existing multi-point touch function, but also can sensitively sense the change in pressure and enhance the function of the existing touch screen, providing more operational applications for the touch screen.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

Manufacturing method of self-adhesive butyl rubber waterproof coiled material

ActiveCN105273651AGood aging resistanceSelf-healing ability shock absorptionNon-macromolecular adhesive additivesFilm/foil adhesivesAnti adhesiveOperating temperature

The invention provides a manufacturing method of a self-adhesive butyl rubber waterproof coiled material. Solid waste butyl rubber is utilized, high-temperature desulfurization is not needed, a high shearing force is applied, the operating temperature is controlled below 100 DEG C, and a butyl rubber waterproof coiled material base course is prepared directly and is used as a main waterproof layer; a butyl rubber self-adhesive layer in the middle is a paste-shaped self adhesive which is also prepared from waste butyl rubber and is used as an auxiliary waterproof layer; and the lower surface can be isolated by using removable anti-adhesive paper. The waterproof coiled material provided by the invention has excellent water resistance and outstanding aging resistance, and is energy-saving and environment-friendly.

Owner:DANDONG SANGUAN WATERPROOF MATERIAL CO LTD

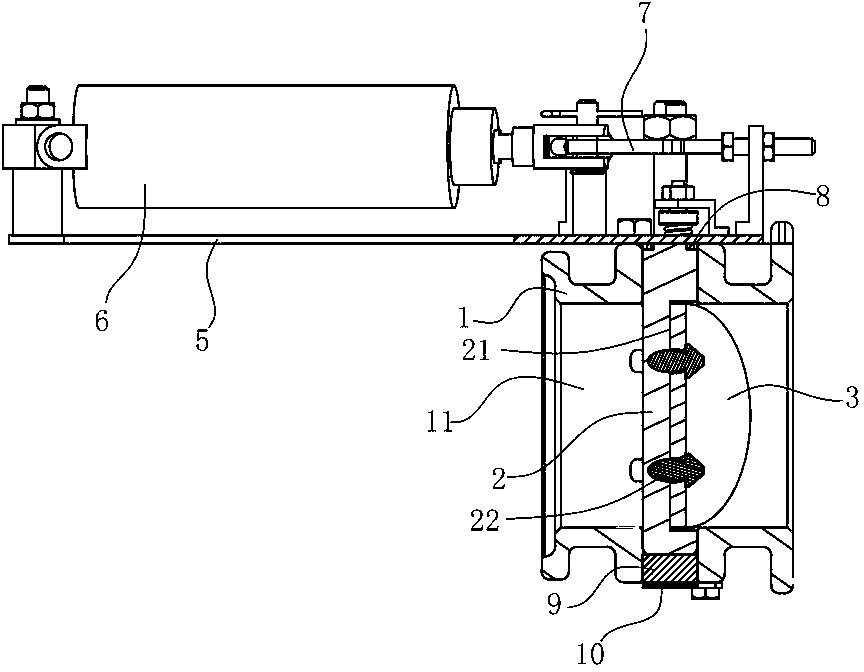

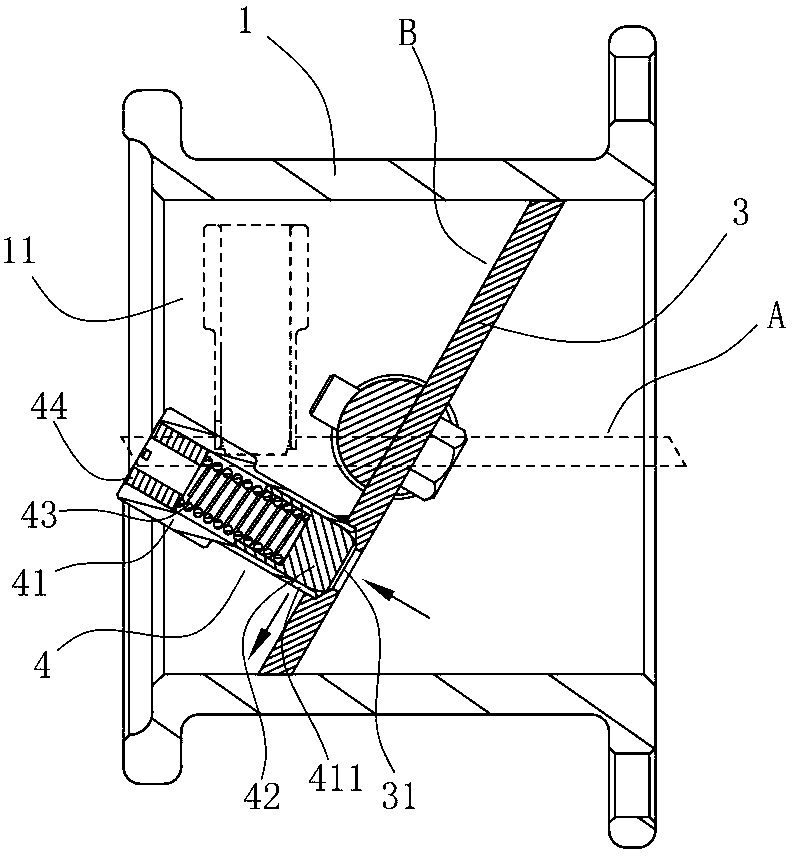

Constant-pressure exhaust braking method and low-cost constant-pressure exhaust braking butterfly valve

ActiveCN103233822ANormal work does not affectSmooth exhaustEngine controllersMachines/enginesExhaust brakeButterfly valve

The invention discloses a constant-pressure exhaust braking method. The method comprises the steps of arranging a valve, arranging a rotary shaft to penetrate through the valve, fixing a valve sheet on the rotary shaft, arranging a gas inlet on the valve sheet, and fixing a constant-pressure exhaust component at the gas inlet; fixing the valve on a mounting plate, fixing the tail end of a cylinder on the mounting plate, fixing a swing arm at the top end of the rotary shaft, and hinging the tail end of an output shaft of the cylinder with the tail end of the swing arm; and fixing the valve at an exhaust port of a motor. When the motor is required to be braked, the rotary shaft is driven by the cylinder, and an exhaust pipe is sealed by the valve sheet, so that back pressure is produced by the motor exhaust, the constant-pressure exhaust component is opened due to gas pressure when the back pressure reaches a set constant-pressure value, and when the back pressure is lower than the set constant-pressure value, the constant-pressure exhaust component is closed, the constant-pressure exhaust component is controlled by the back pressure to be closed and opened repeatedly, and automatic constant-pressure exhaust is achieved. The invention further discloses a low-cost constant-pressure exhaust braking butterfly valve.

Owner:深圳市大为创新科技股份有限公司

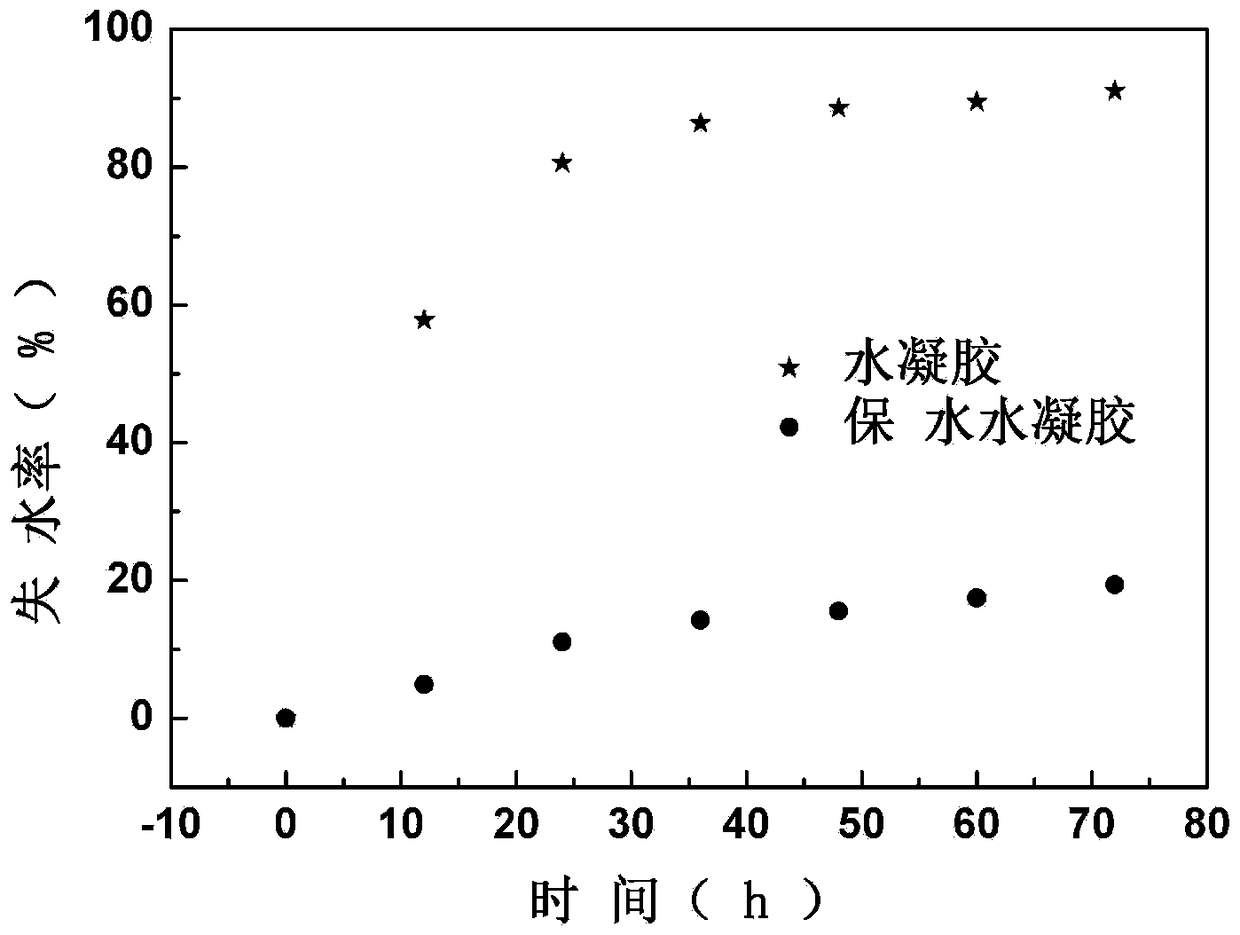

Water-retaining gel material and preparation method thereof

The invention provides a water-retaining gel material and belongs to the technical field of gel materials. The gel material comprises a first water-retaining layer, a conducting layer and a second water-retaining layer in sequence, wherein the first water-retaining layer and the second water-retaining layer are polysiloxane elastomers; the conducting layer is prepared from agar, polyvinyl alcohol,acrylic acid, persulfate, N,N-methylenebisacrylamide, inorganic metal salt and water. Acrylic acid in the raw materials of the conducting layer of the water-retaining gel material is subjected to a polymerization reaction under the action of a cross-linking agent N,N-methylenebisacrylamide, and agar, polyvinyl alcohol, polyacrylic acid and metal ions are subjected to a coordinated complexation reaction. By the aid of the three-dimensional network structure, free H<+> and metal ions of the conducting layer, the hydrogel material has pressure sensitivity, self-healing property and conductivity,and water of the gel material is prevented from losing by means of the water-retaining layers located on the two sides.

Owner:YANSHAN UNIV

Coloured asphalt pavement mixture

The invention relates to a coloured asphalt pavement mixture. The coloured asphalt pavement mixture is prepared from the following raw materials in parts by weight: 20-40 parts of base oil, 15-40 parts of petroleum resin, 10-25 parts of terpene resin, 2-10 parts of a modifying agent, 1-15 parts of inorganic pigment and 15-30 parts of a pressure-sensitive diluent. The coloured asphalt pavement mixture only needs to be simply packaged in barrels or a tank car in transportation and can be mixed and used with stones at normal temperature without being heated before and after use, and then pavement spreading and roller compaction construction are carried out, so that a preparation process of the coloured asphalt pavement mixture is greatly simplified, and the construction of a coloured pavement is changed to be extremely simple and convenient. The coloured asphalt pavement mixture has pressure-sensitive property and is subjected to roller compaction by virtue of a road roller and transit vehicles, the bonding strength between asphalt and aggregate is improved, and the self strength of the mixture is improved.

Owner:SHANDONG DASHAN ROAD & BRIDGE ENG

Method for manufacturing ceramic material with low dielectric loss, large capacitivity and varistor characteristics

The invention discloses a method for manufacturing a ceramic material with low dielectric loss, high permittivity and voltage-sensitive characteristic, and relates to a method for manufacturing oxide ceramic. The method comprises the following steps: 1) taking copper oxide, calcium carbonate and titanium dioxide as raw materials, weighing according to the stoichiometric ratio of (3+x):1:4, wherein x is 0.001-0.01; then adding an additive, carrying out ball-milling in distilled water medium to obtain mixed powder; 2) baking and sieving the mixed powder obtained in the step 1) and then pre-sintering; 3) carrying out ball-milling on the mixed powder pre-sintered in the step 2), sieving and drying to obtain the pre-sintered powder; 4) mixing the pre-sintered powder, a polyvinyl alcohol solution, glycerinum and a defoamer, carrying out ball-milling after so as to obtain floating slurry; 5) fabricating floating slurry pieces; 6) carrying out glue discharging treatment on the floating slurry pieces prepared in the step 5), sintering and cooling, so as to obtain the ceramic material with low dielectric loss, high permittivity and voltage-sensitive characteristic.

Owner:XIAMEN UNIV

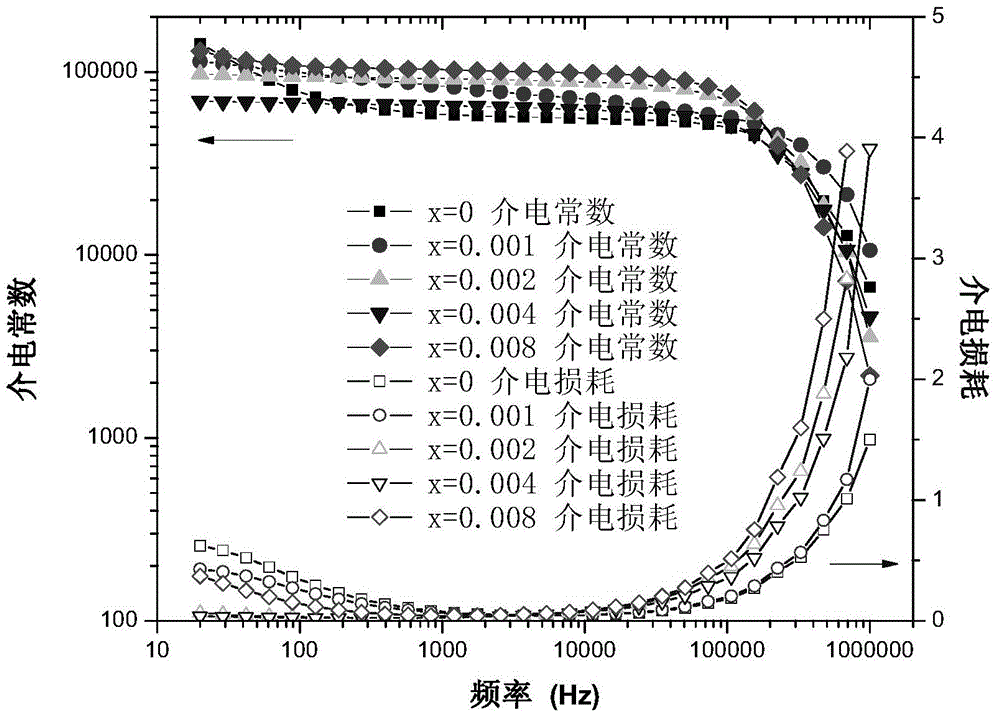

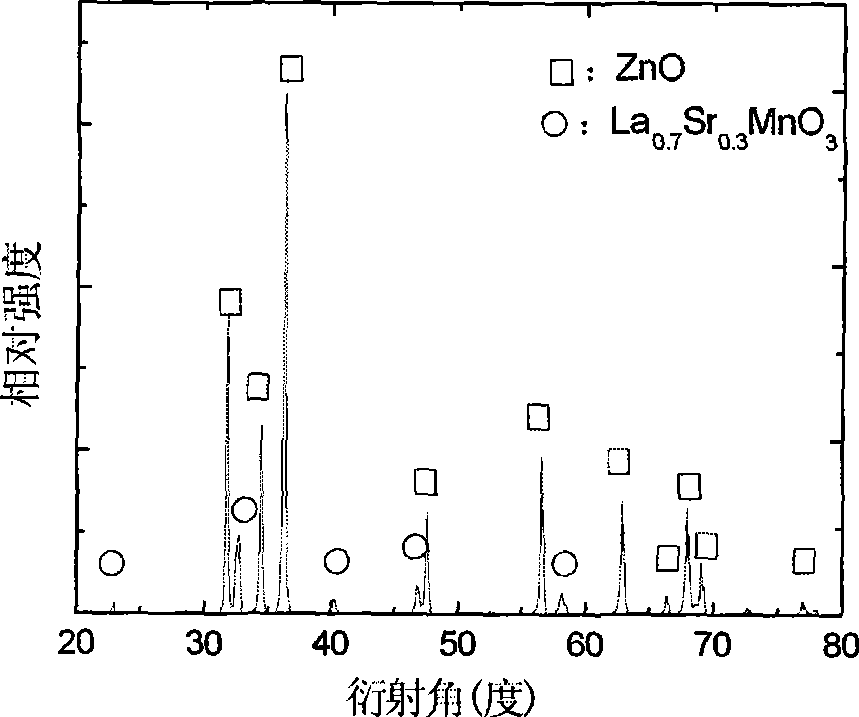

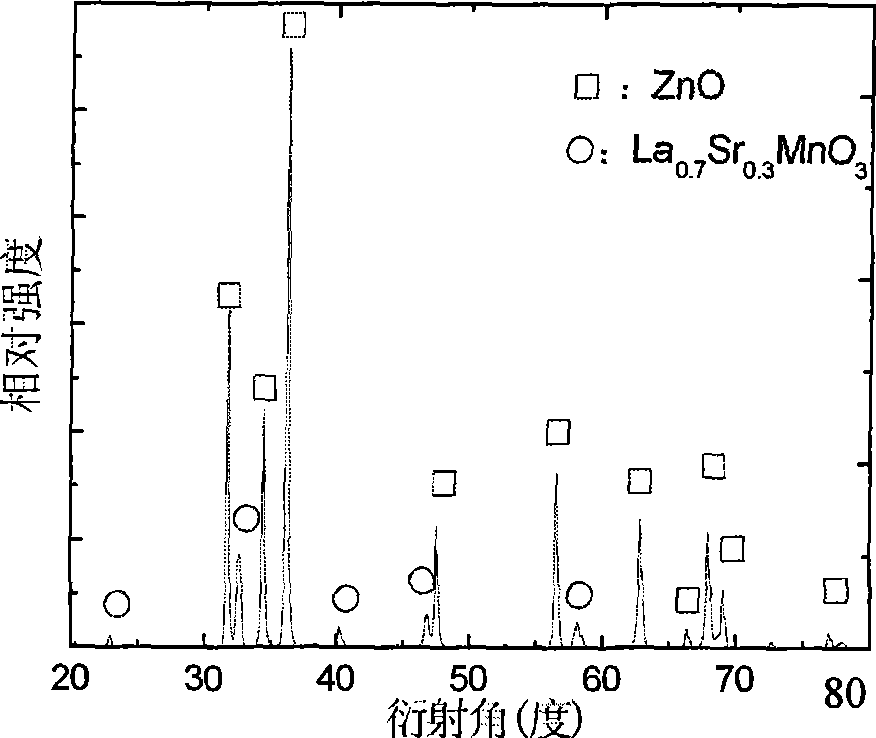

Magnetic ZnO composite piezoresistive material and method of manufacturing the same

InactiveCN101367648ASensitive to pressureExtended service lifeVaristor coresElectrical resistance and conductanceEngineering

The invention discloses a magnetic ZnO compound voltage dependent resistor material and a preparation method thereof. The magnetic ZnO compound voltage dependent resistor material is composed of 100 portion of ZnO (by weight), 1 portion to 10 portions of perovskite manganese oxide (by weight) La0.7Sro.3MnO3. The nonlinearity volt-ampere characteristic is controlled by an applied magnetic field, and the voltage dependent resistor made from the magnetic ZnO compound voltage dependent resistor material can change parameters through changing the applied magnetic field, and expands the use range of the ZnO voltage dependent resistor.

Owner:SOUTHWEST JIAOTONG UNIV

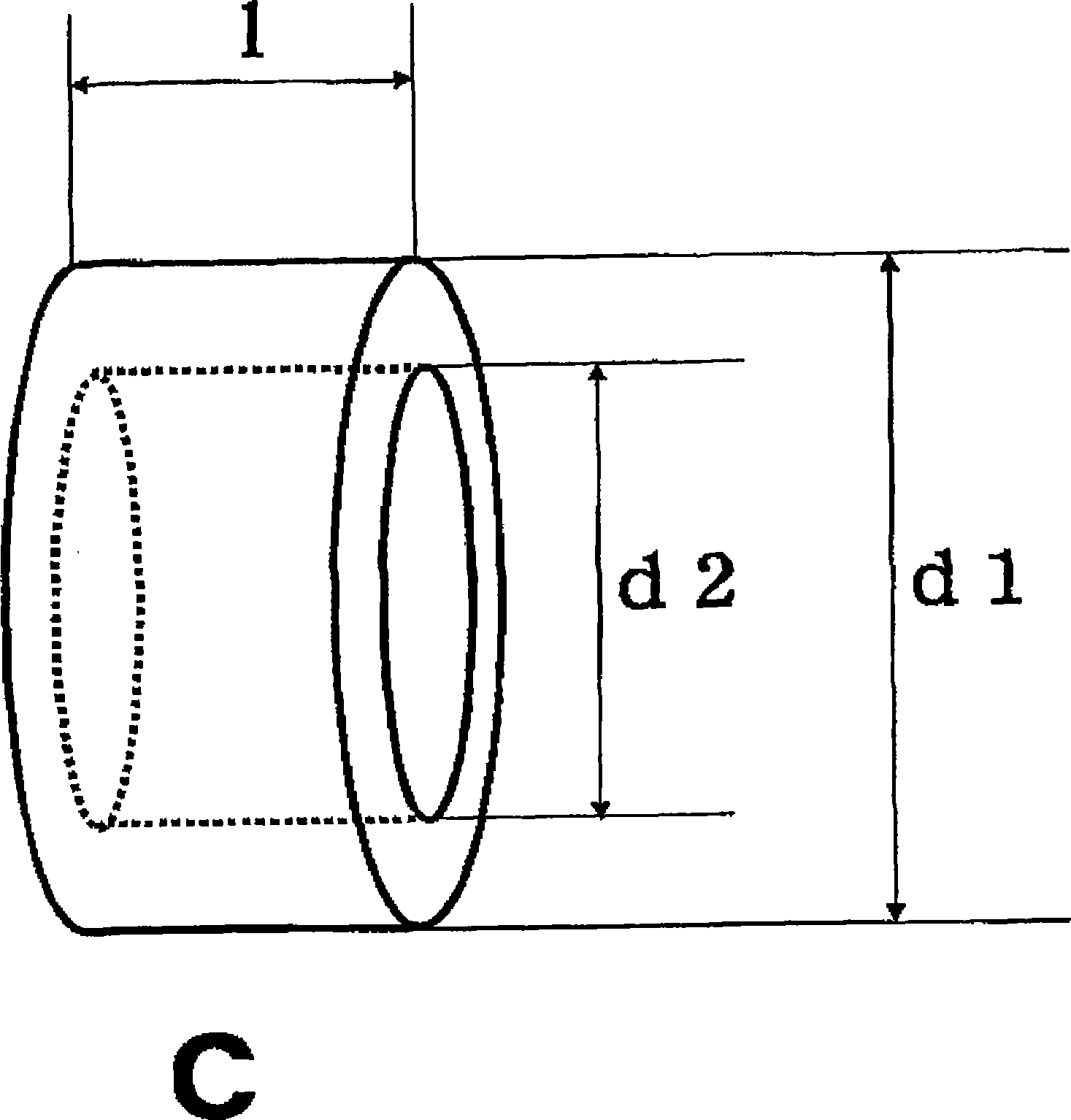

Continuous emulsification method and emulsification apparatus therefor

InactiveCN101421027ASimple structureEasy to assembleFlow mixersMixing methodsEngineeringMechanical engineering

An emulsification method and an emulsification apparatus by which particle size and particle size distribution can be easily controlled, scaling up and maintenance can be conveniently conducted and an emulsified product can be obtained in an industrially practical amount. Namely, a method wherein emulsification is conducted by passing multiple liquids, which are substantially immiscible with each other, continuously and successively through multiple mesh members, which are located at definite intervals, in the presence of an emulsifier; and an apparatus therefor comprising a liquid-feeding pump for feeding two or more liquids, which are substantially immiscible with each other, and a tubular channel into which the two or more liquids as described above are fed from the liquid-feeding pump, characterized in that a definite number of wire mesh members are located at definite intervals in the tubular channel.

Owner:NIPPON OIL CO LTD

La2O3-SnO2-Zn2SnO4 varistor-capacitor bifunctional ceramic material and preparation method thereof

The invention relates to a La2O3-SnO2-Zn2SnO4 varistor-capacitor bifunctional ceramic material. The ceramic material is formed by mixing, pressing and sintering SnO2 powder, Zn2SnO4 powder and La2O3 powder, and the mol ratio of all the components (La2O3, SnO2 and Zn2SnO4) is X:85:15; X=0 / 1-2.5. The La2O3-SnO2-Zn2SnO4 composite ceramic material prepared by mixing, pressing and sintering the SnO2 powder, the Zn2SnO4 powder and the La2O3 powder has good varistor properties, superhigh dielectric constant and low varistor voltage.

Owner:HENAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com