Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Short opening hours" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethylene-vinylacetate copolymer resin hot melt adhesive with high melting point, fast curing and low viscosity

InactiveCN102108269AShort opening hoursMeet the needs of the above purposesMineral oil hydrocarbon copolymer adhesivesWaxPaper filter

The invention relates to an ethylene-vinylacetate (EVA) copolymer resin hot melt adhesive with high melting point, fast curing and low melting viscosity. The hot melt adhesive comprises the following components in parts by weight: 40-60 parts of ethylene-EVA copolymer resin, 20-40 parts of tackifying resin and 10-30 parts of synthetic wax. The hot melt adhesive is especially suitable for splicing the paper filter element of the air cleaner.

Owner:上海理日化工新材料有限公司

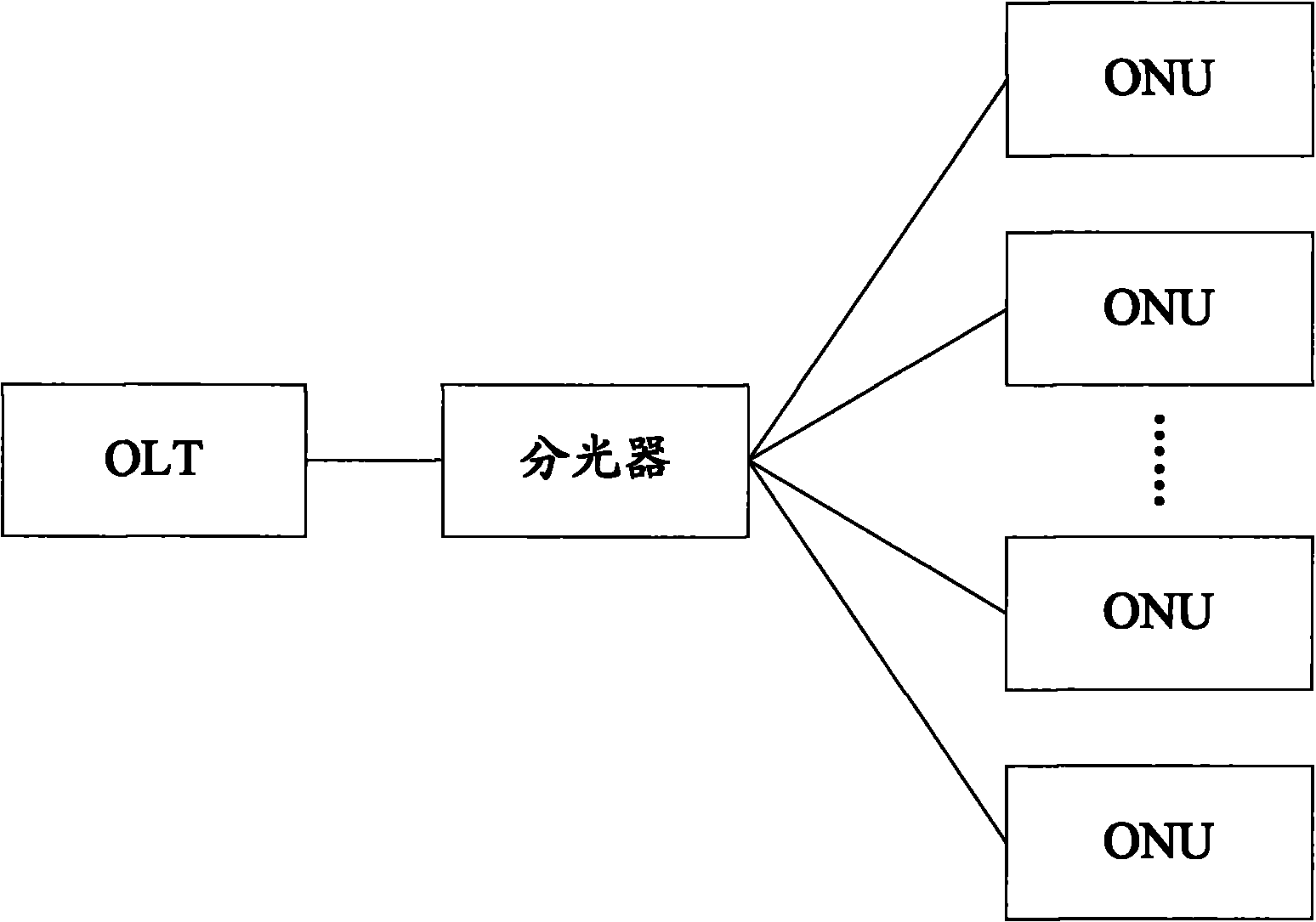

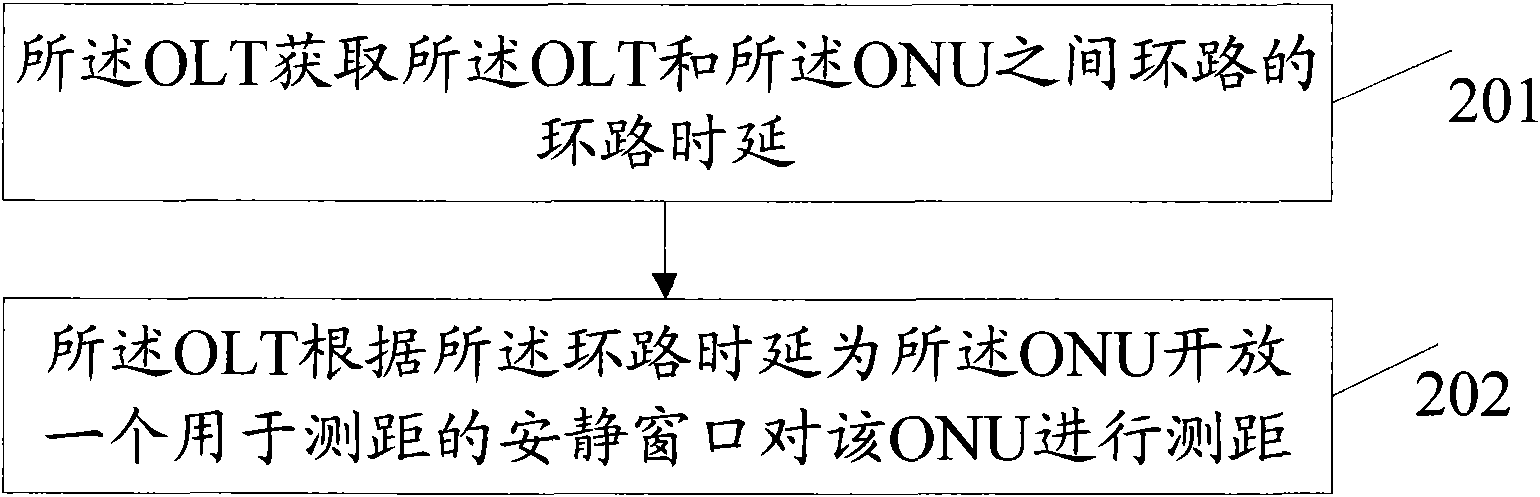

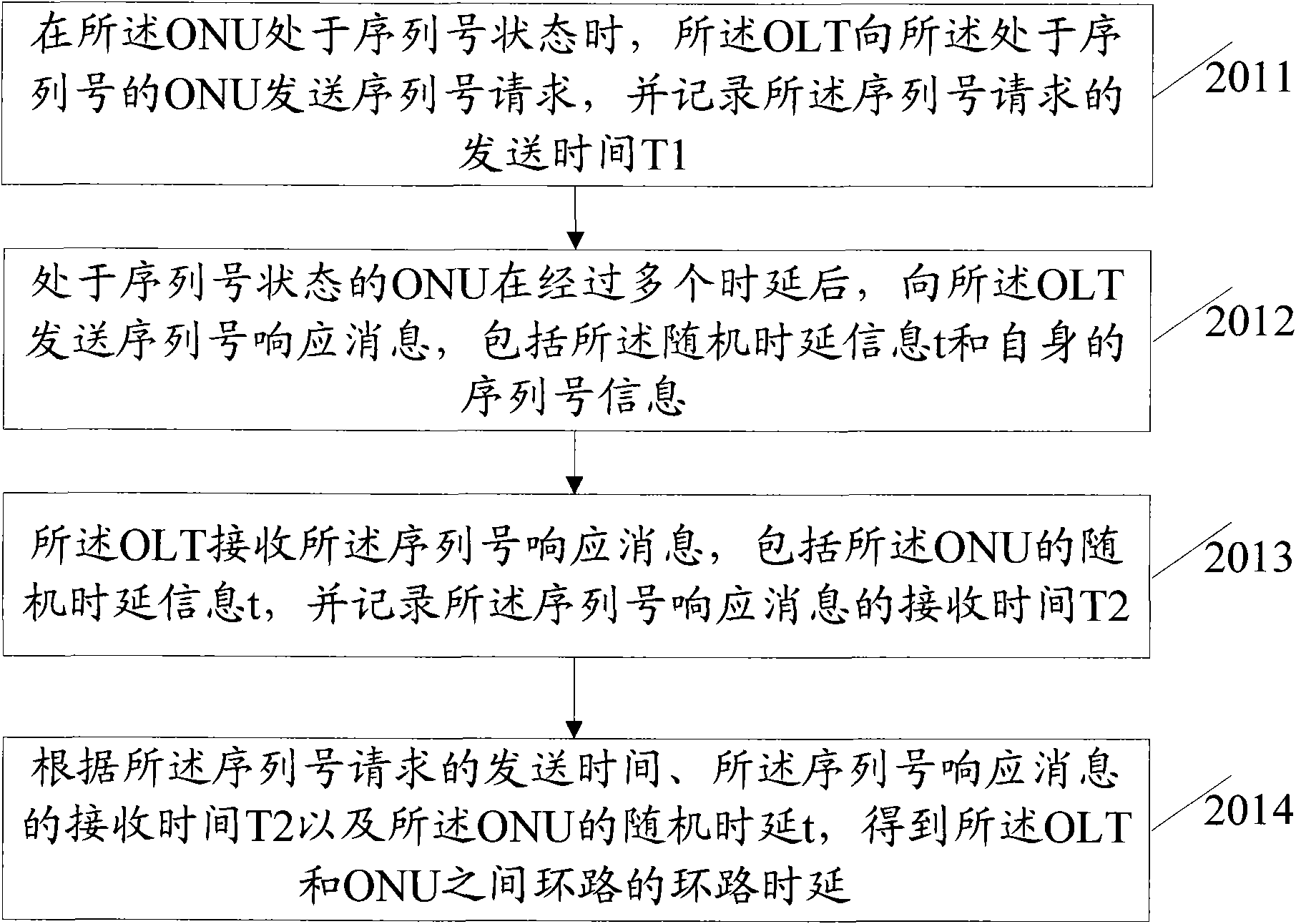

Method and device for measuring distance in passive optical network

ActiveCN102075820AShort opening hoursImprove uplink transmission efficiencyMultiplex system selection arrangementsTime-division multiplexTime delaysOptical network unit

The invention provides a method and a device for measuring distance in a passive optical network, and relates to the field of communication. The method comprises the following steps of: acquiring route time delay (RTD) between an optical line terminal (OLT) and an optical network unit (ONU); and opening a quite window for measuring distance for the ONU according to the RTD to measure the distance for the ONU.

Owner:ZTE CORP

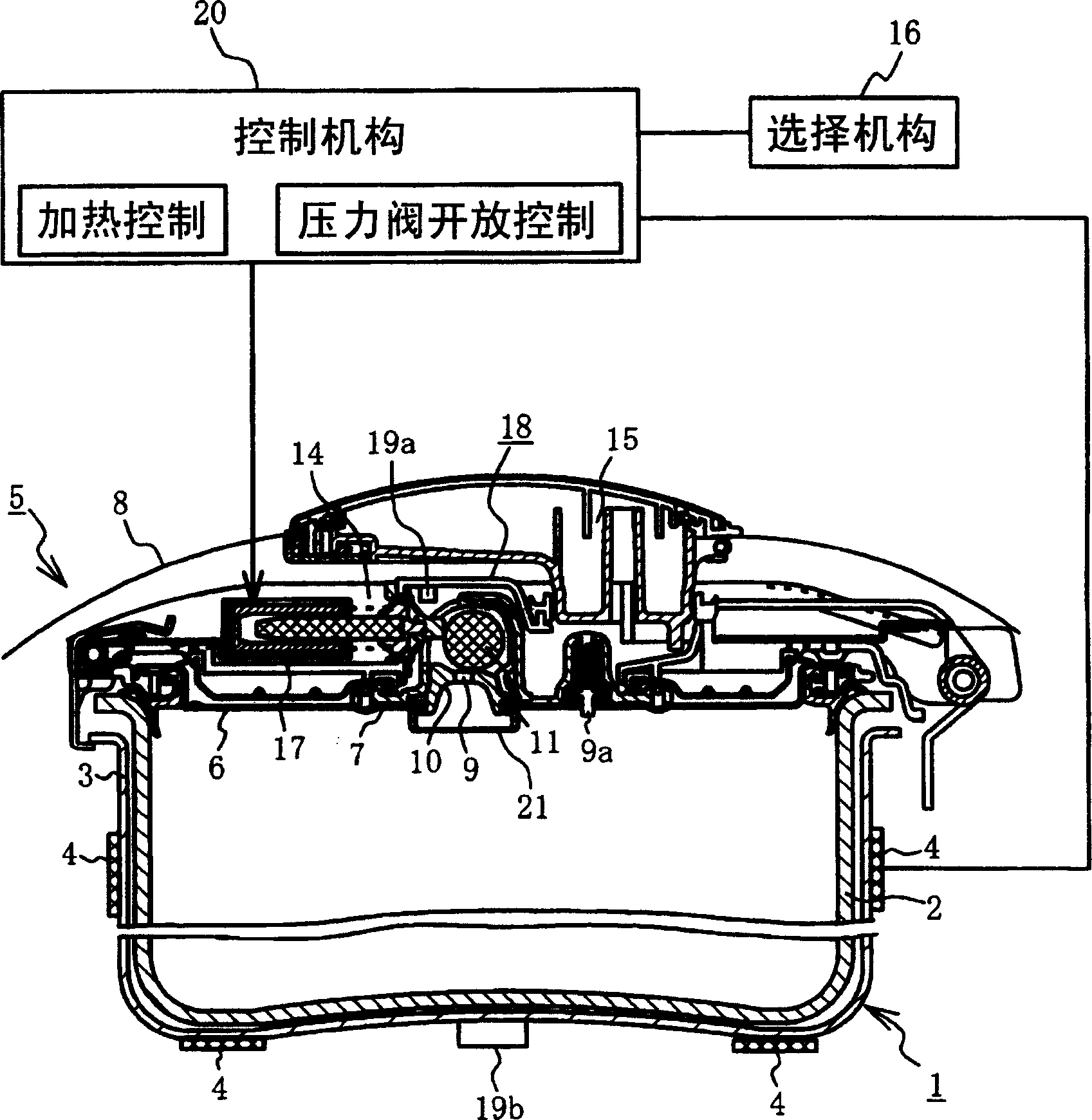

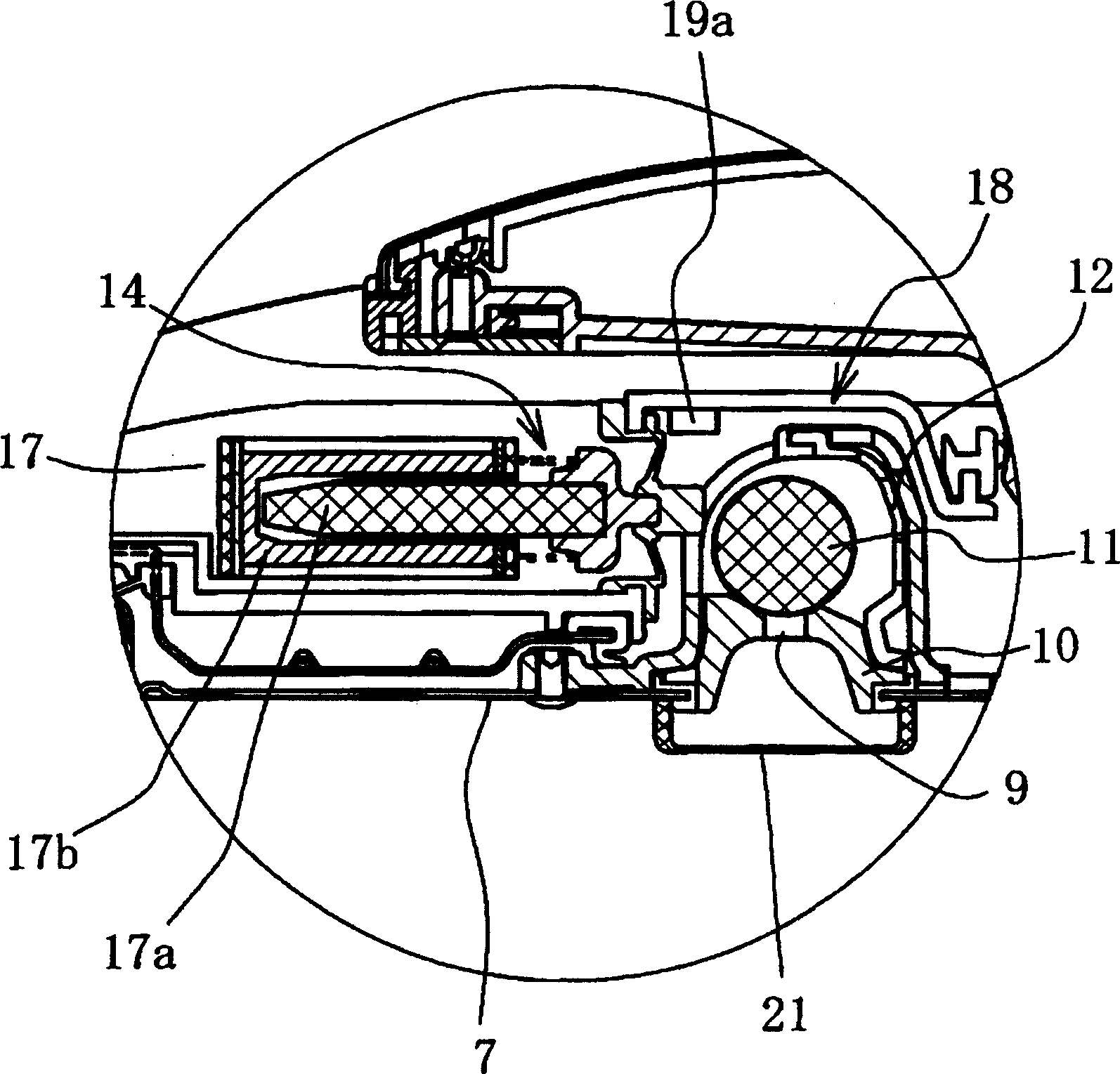

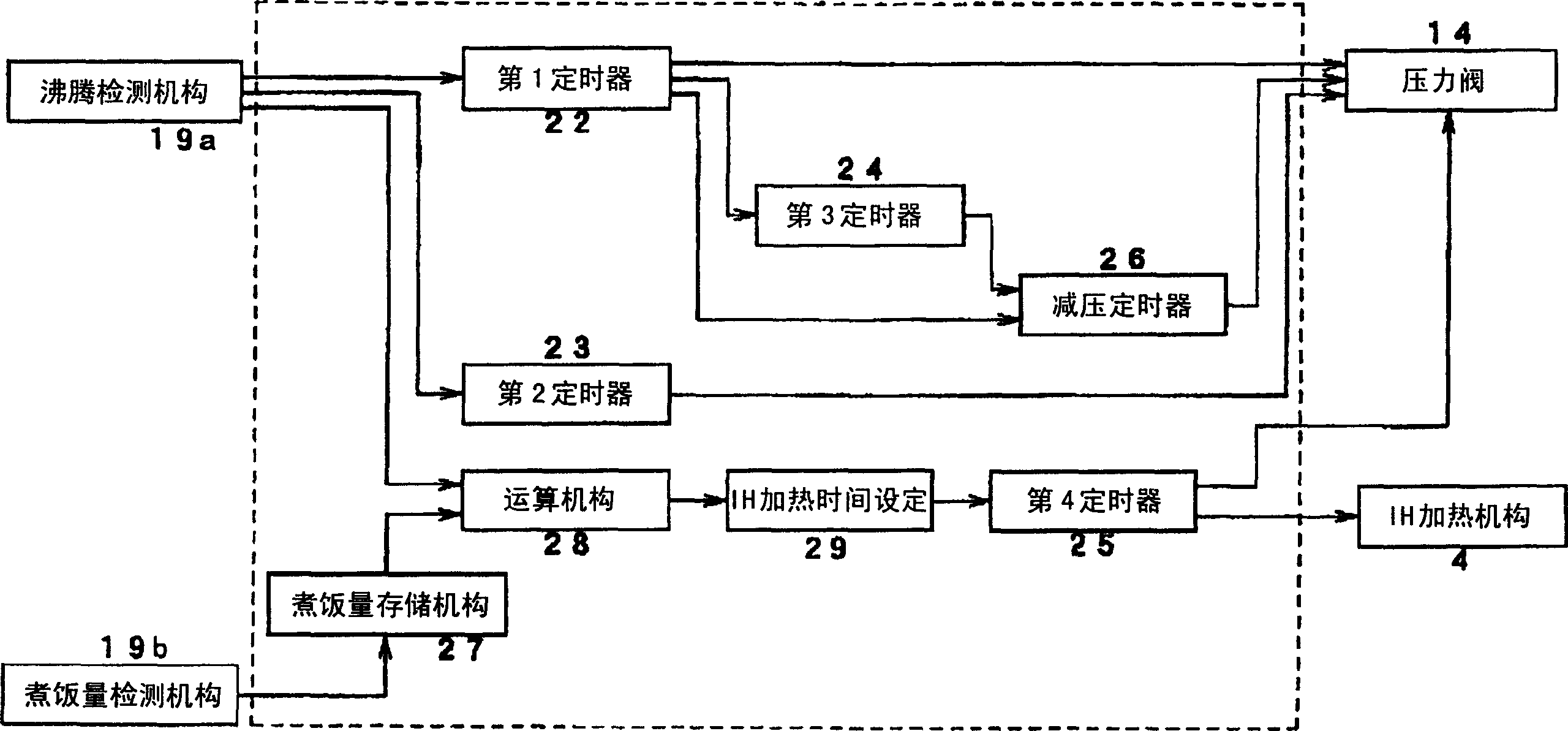

Rice cooker

This rice cooker is equipped with a pot to house water and rice, a heating means, a pressure valve to make the inside of the pot communicate with the outside air or cut off, and a control means for the heating means and the pressure valve. The rice to be cooked is processed by a starting-up process to rapidly heat rice and then a boiling keeping process wherein the rice to be cooked is heated by the heating means when the pressure valve is open.The invention provides a rice cooker in which rice can be sufficiently agitated during boiling and uniformly cooked, and the upper face of cooked rice is flat causing visual artistic effect after rice is completely cooked.

Owner:SANYO ELECTRIC CO LTD +1

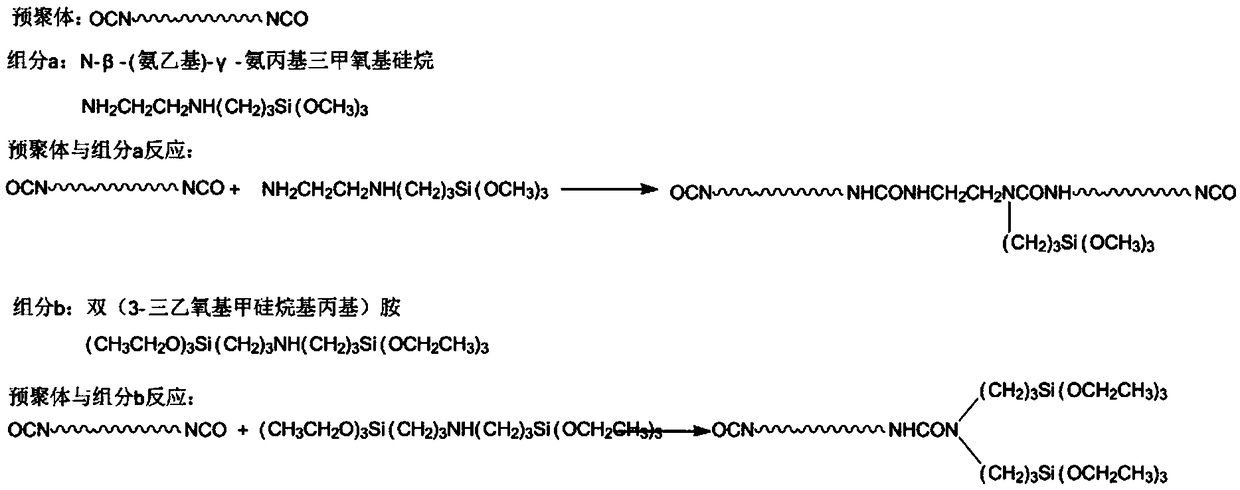

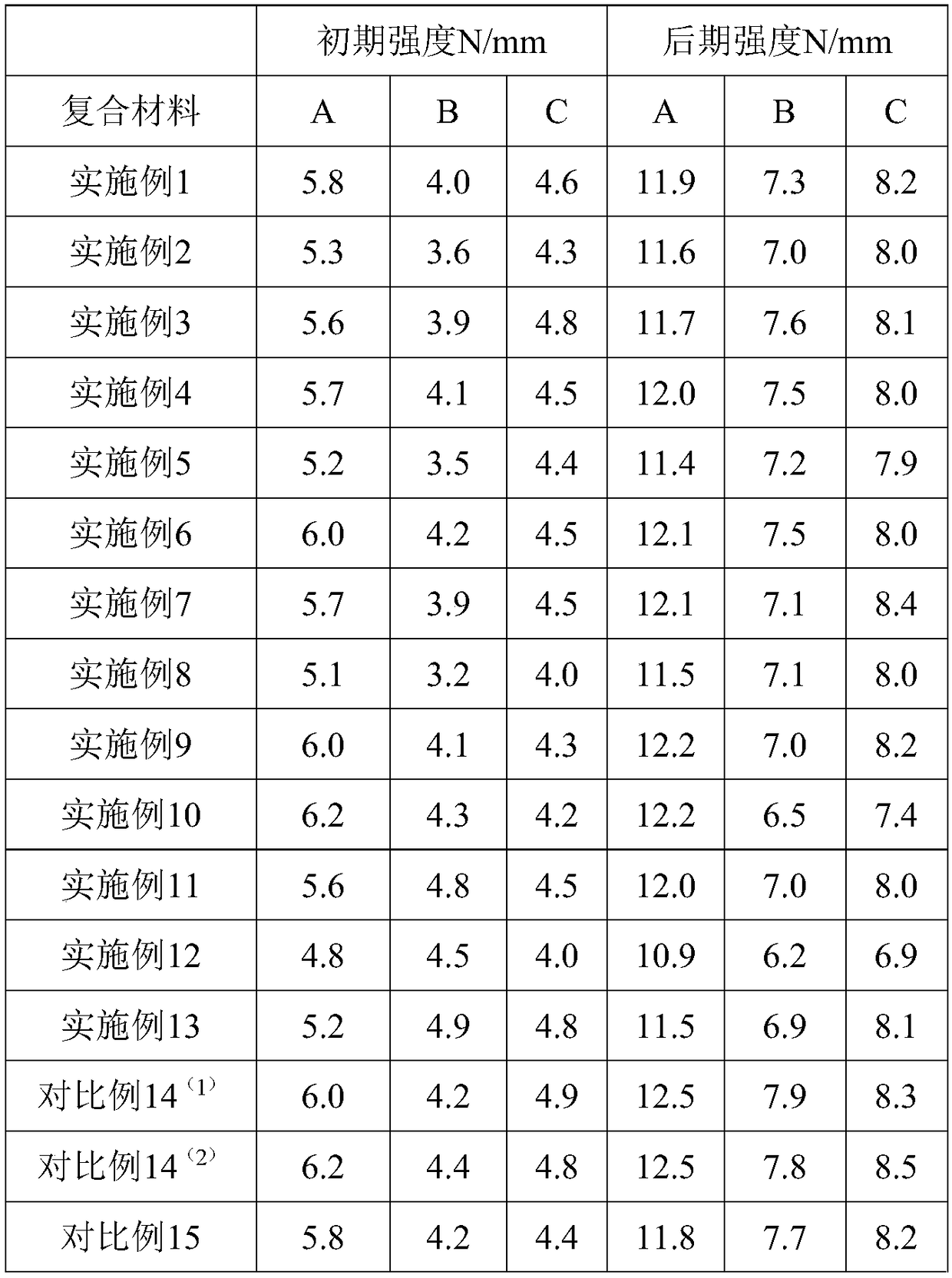

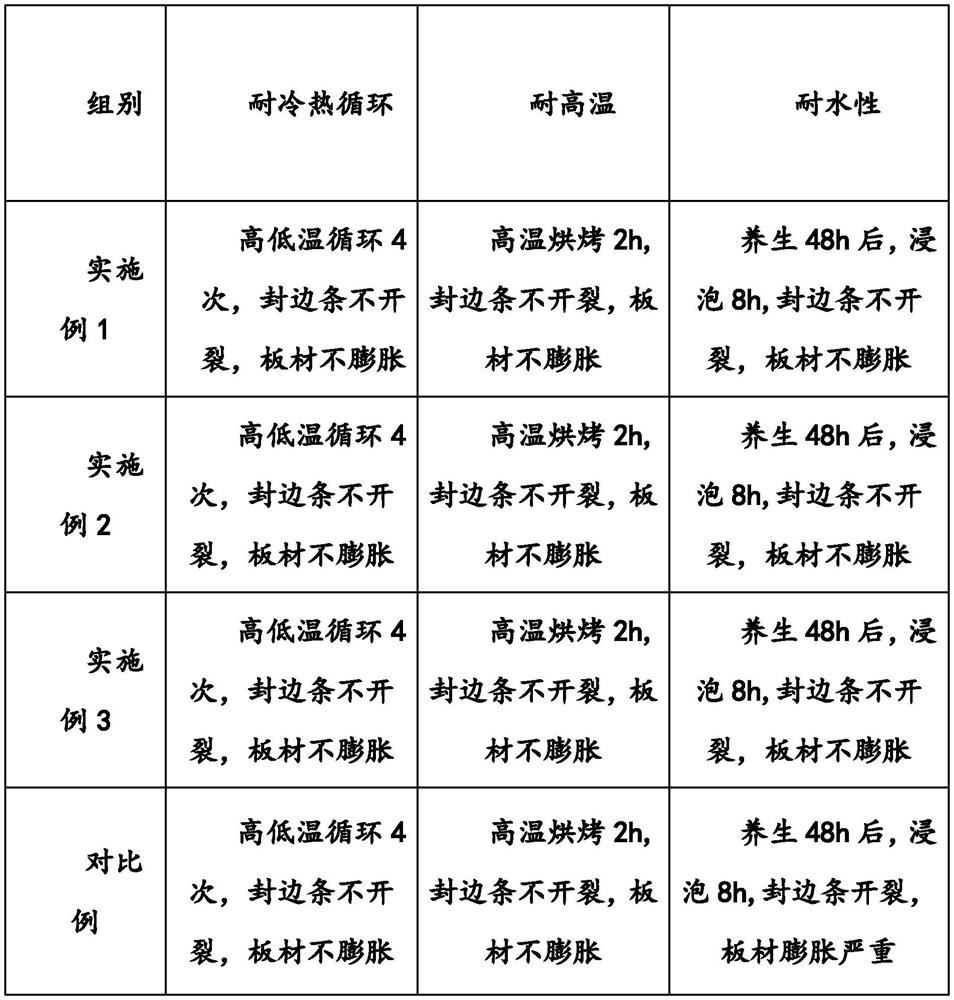

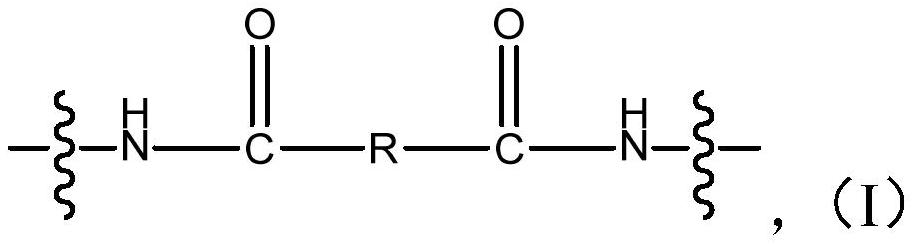

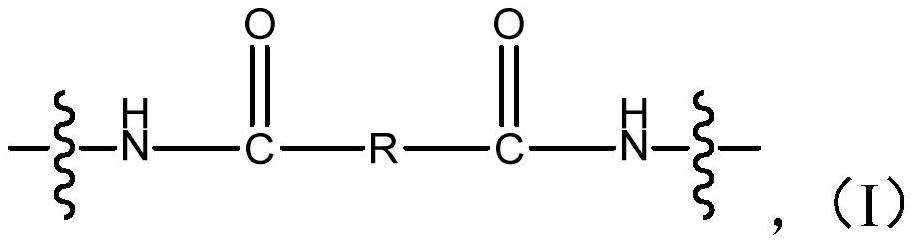

Polyurethane or polyurethane-urea aqueous dispersion with excellent heat-damp resistance performance, and preparation method and application thereof

PendingCN109081897AShort opening hoursMeet performance needsPolyureas/polyurethane adhesivesAdhesiveSealant

The invention relates to a polyurethane or polyurethane-urea aqueous dispersion with excellent heat-damp resistance performance, and a preparation method and application thereof. Polyurethane or polyurethane-urea is prepared through a reaction among at least one siloxane component with at least two NCO reactive functional groups, at least one siloxane component with at least one NCO reactive functional group, at least one polyol component with the functionality of 2-4, at least one polyisocyanate component, at least one hydrophilic compound component, at least one NCO reactive, monofunctional,nonionic and hydrophilic compound and the like. The polyurethane or polyurethane-urea aqueous dispersion has the excellent heat-damp resistance performance, thereby being suitable for preparation ofhigh-quality paint and sealants, especially adhesives.

Owner:WANHUA CHEM GRP CO LTD

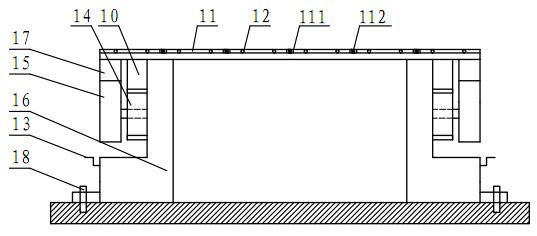

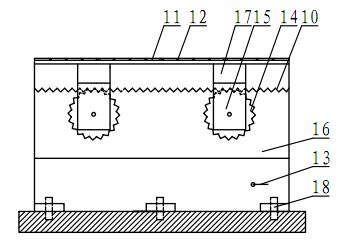

Concrete pouring fast construction method

ActiveCN102359276ASimple structureEasy to useIn situ pavingsClimate change adaptationContinuous/uninterruptedBridge deck

The invention discloses a concrete pouring fast construction system which comprises a moving formwork device, a concrete wet spraying and pouring device and a concrete moving blending device, wherein the concrete moving blending device is connected with the concrete wet spraying and pouring device through a pipeline, the moving formwork device comprises formworks, each formwork is of a thin plate-like unit body, the unit bodies of the formworks are spliced into a whole plate through bolts, and the whole plate is supported by formwork slideways positioned at the two ends of the whole plate. The concrete pouring fast construction system has the advantages of realizing continuous and uninterrupted concrete fast pouring and realizing fast, continuous and emergency repair construction of bridge deck paving, as well as fast construction and emergency repair fast construction of airfield runways and military emergency works. The concrete pouring fast construction system is simple in structure and simple and convenient to operate, and can be used for not only improving the construction efficiency of large-range wide-amplitude thin plate concrete in a slope or a plane, but also greatly shortening the opening time of a concrete repair region and meeting harsh requirements on the construction speed during the large-range application of fast hardening concrete.

Owner:SHIJIAZHUANG TIEDAO UNIV

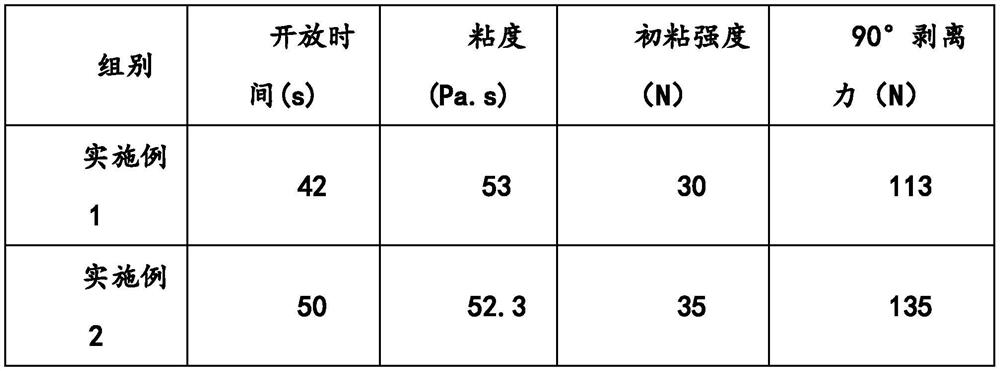

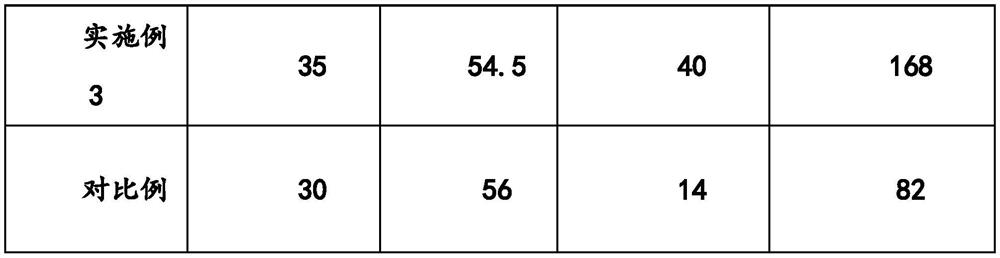

Hot-melt polyurethane adhesive with high initial adhesion and preparation method thereof

InactiveCN106496500AHigh initial bond strengthShort opening hoursPolyureas/polyurethane adhesivesPolyurethane adhesivePrepolymer

The invention provides a hot-melt polyurethane adhesive with high initial adhesion. The hot-melt polyurethane adhesive comprises, by weight, 70 to 90% of polyurethane prepolymer and 10 to 30% of an adhesion promoting agent, wherein the adhesion promoting agent is prepared through addition of rosin acid, one-component or two-component epoxy, and hydrogenated rosin or any cyclic compound with a carboxyl group or natural resin. The invention has the following unique beneficial effects: 1, the active adhesion promoting agent is produced through addition of natural resin or a related cyclic compound with the carboxyl group and epoxy for the first time, and is applied to the reactive polyurethane adhesive; and 2, the novel two-step preparation method has not been reported and used so far. The novel two-step preparation method can prepare a hot-melt polyurethane adhesive product with high initial adhesion without changing a formula for the hot-melt polyurethane adhesive. The hot-melt polyurethane adhesive product has creep resistance reaching the grade of 3, 500 g, and has superior heat stability. Due to high adhesive capability and arbitrarily-adjustable hot opening time of the product, the hot-melt polyurethane adhesive product can be applied to industrial places like the shoemaking industry and engineered floors with high requirements on initial adhesion.

Owner:佛山市顺德区巴德富实业有限公司

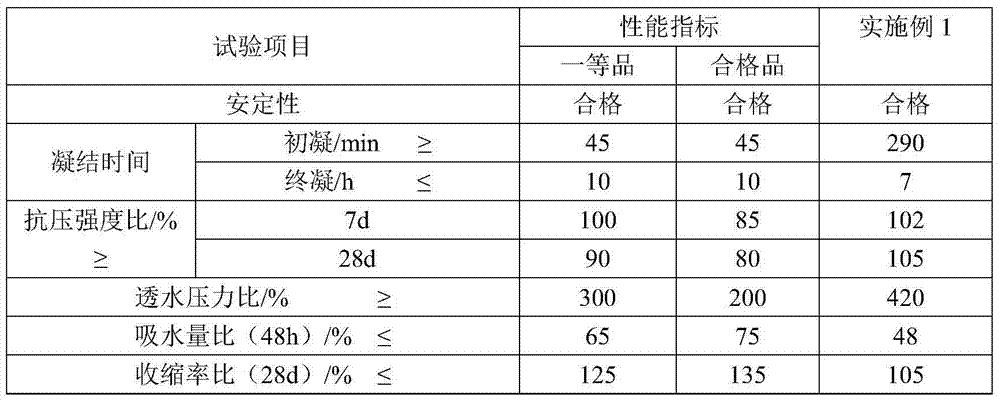

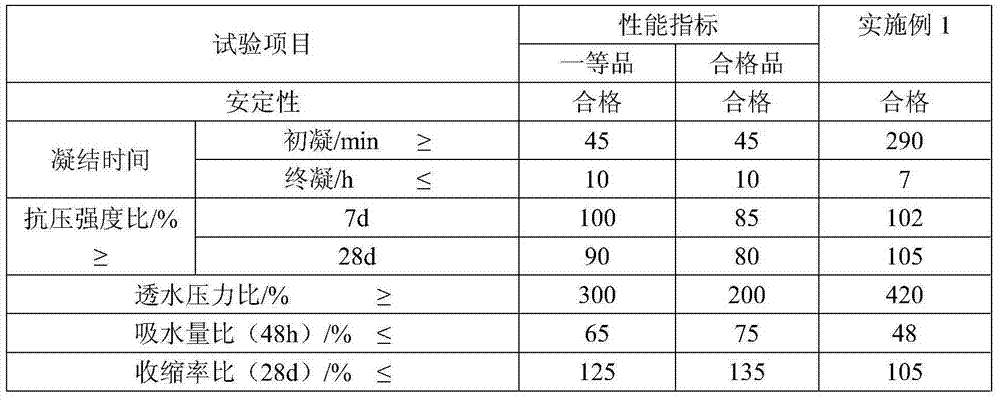

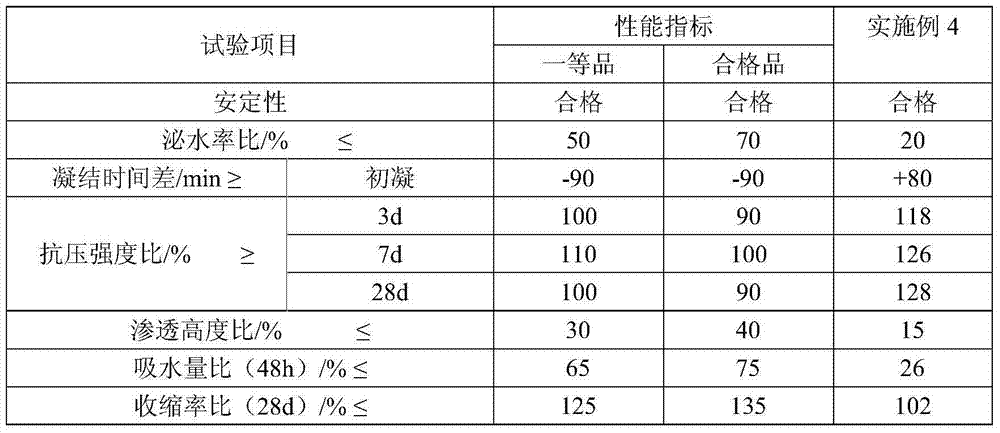

Preparation method of mortar concrete waterproof agent

The invention discloses a preparation method of a mortar concrete waterproof agent, which comprises the following steps: preparing an emulsion with an organosilicon core-shell structure by an acrylic acid unsaturated monomer, unsaturated fatty acid and a nonsaturated organosilicone compound through soap-free polymerization, then adding 10-30 parts of water, 2-5 parts of concrete shrinkage reducing agent, 0.2-1 part of antifoaming agent, 5-15 parts of water reducer, 1-3 parts of cement hydration promoter, 10-20 parts of lithium compound and 0.5-1.5 parts of air-entrainer in 40-60 parts of emulsion with an organosilicon core-shell structure in order, and uniformly mixing. According to the invention, a core-shell spherical particle polymer with nano size can be prepared, and the compound containing the shrinkage reducing agent, the air-entrainer and the lithium salt with different functions is composited with the polymer, so that the obtained waterproof agent can greatly enhance the impermeability, waterproofness and durability of a water proof layer, cracking is avoided, toughness is enhanced, construction is simple, the opening time is short, preparation process is safe and nontoxic, production is simple, no environmental pollution is generated, and cost is low.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Modified polyamide thermosol based on polyester and preparation thereof

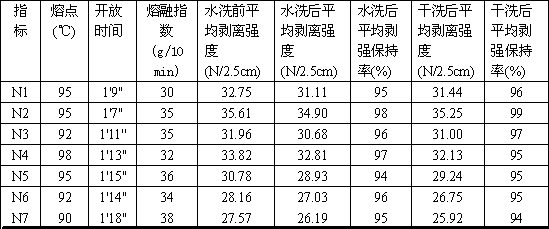

The invention provides a method for preparing a polyester modification-based polyamide hot melt adhesive, characterized by comprising the following steps: facilitating aliphatic dicarboxylic acid having 7-12 carbon atoms, aliphatic monocarboxylic acid having 7-12 carbon atoms, aliphatic diamine having 6-14 carbon atoms, lactam having 6-11 carbon atoms and water to react with a stabilizing agent; adding a proper amount of copolyester after the dehydration, continuing reaction for a particular time; discharging to acquire the polyester modification-based polyamide hot melt adhesive. The polyester modification-based polyamide hot melt adhesive of the invention has the characteristics of short opening hours, rapid curing, outstanding high temperature resistance and washability and the like; the polyester having a molecular weight of 8,100-18,300 is selected for the modification of the synthesized polyamide, which not only obviously shortens the opening hours of the adhesive, but also causes the obtained products to have less than 18% of the peeling strength loss rate after being washed with alkaline water above 80 DEG C, or to have less than 8% of the peeling strength loss rate after being dry-cleaned with tetrachloroethylene.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD

Preparation method of light/humidity dual-curing polyurethane hot melt adhesive

InactiveCN103305174AMulti-step reactionBalance dosagePolyureas/polyurethane adhesivesMolten stateWater vapor

The invention relates to a preparation method of a light / humidity dual-curing polyurethane hot melt adhesive. The preparation method comprises the following steps of: introducing N2 into an HDI (hexamethylene diisocyanate) tripolymer, removing water vapor, carrying out a protective reaction, respectively adding a polymerization inhibitor and a catalyst and dropwisely adding HEA (hydroxyethyl acrylate); after dropwisely adding and reacting, adding polyisocyanate, and stirring uniformly to obtain 3HDI-HEA / polyisocyanate; heating and fusing polyalcohol and stirring for dehydration; adding the 3HDI-HEA / polyisocyanate and the catalyst; discharging after reacting, packaging the sample with an aluminum foil bag for standby application to obtain a light / humidity dual-curing polyurethane hot melt adhesive prepolymer; melting the prepolymer, and adding a photoinitiator, a polymerization inhibitor, a plasticizer and the catalyst, stirring uniformly in a molten state, rising the temperature and removing air bubbles; and ending stirring and discharging to obtain the light / humidity dual-curing polyurethane hot melt adhesive. The obtained hot melt adhesive has high initial bonding strength and final strength.

Owner:NANJING FORESTRY UNIV

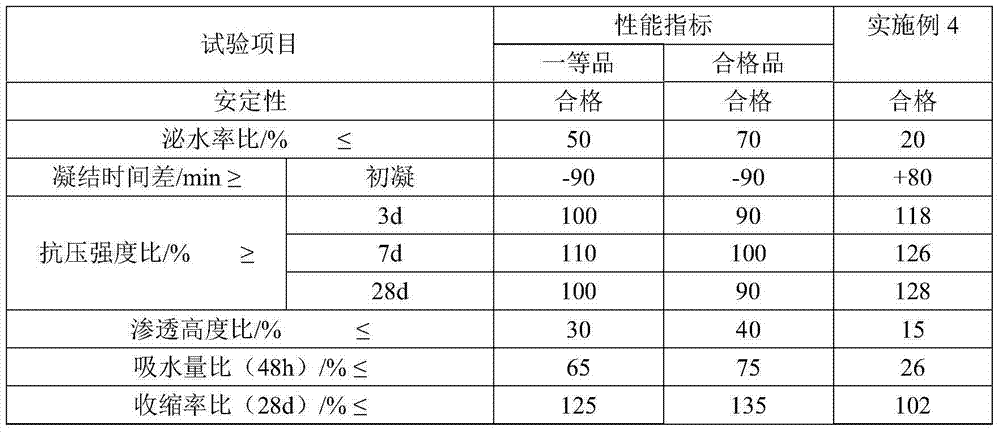

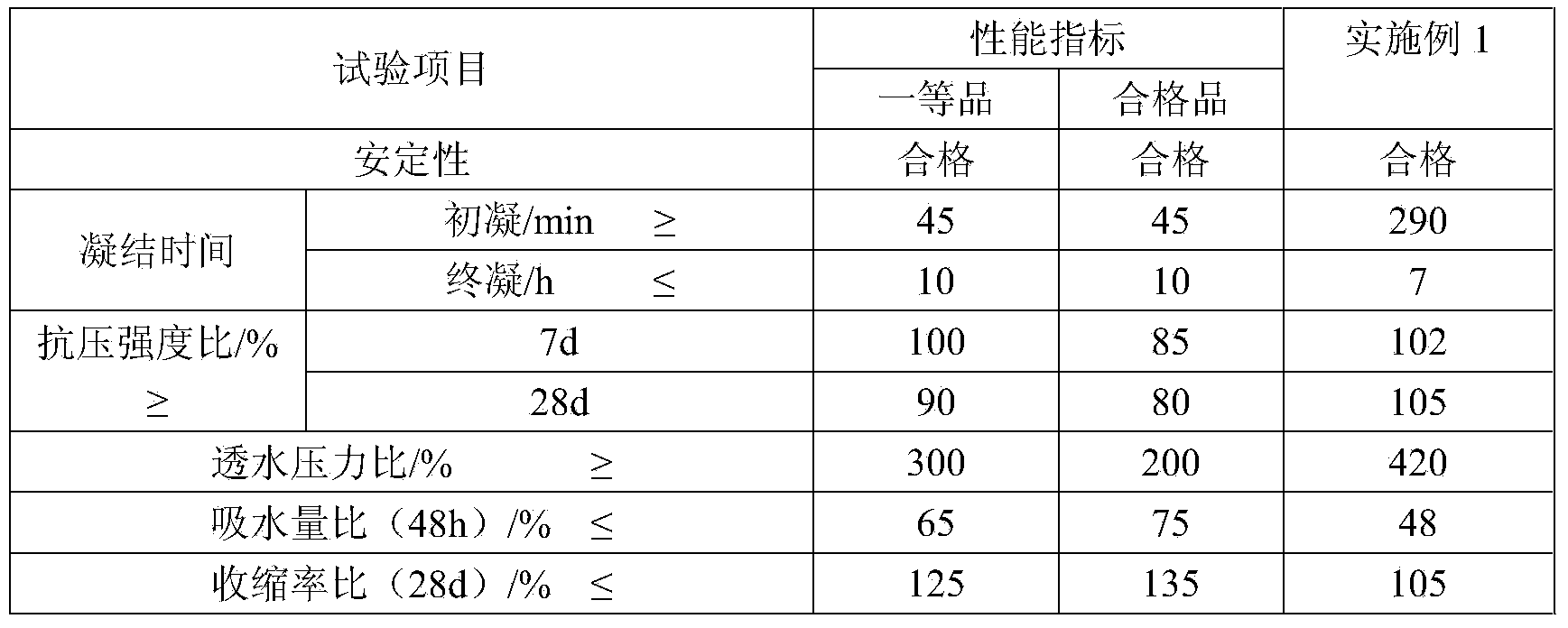

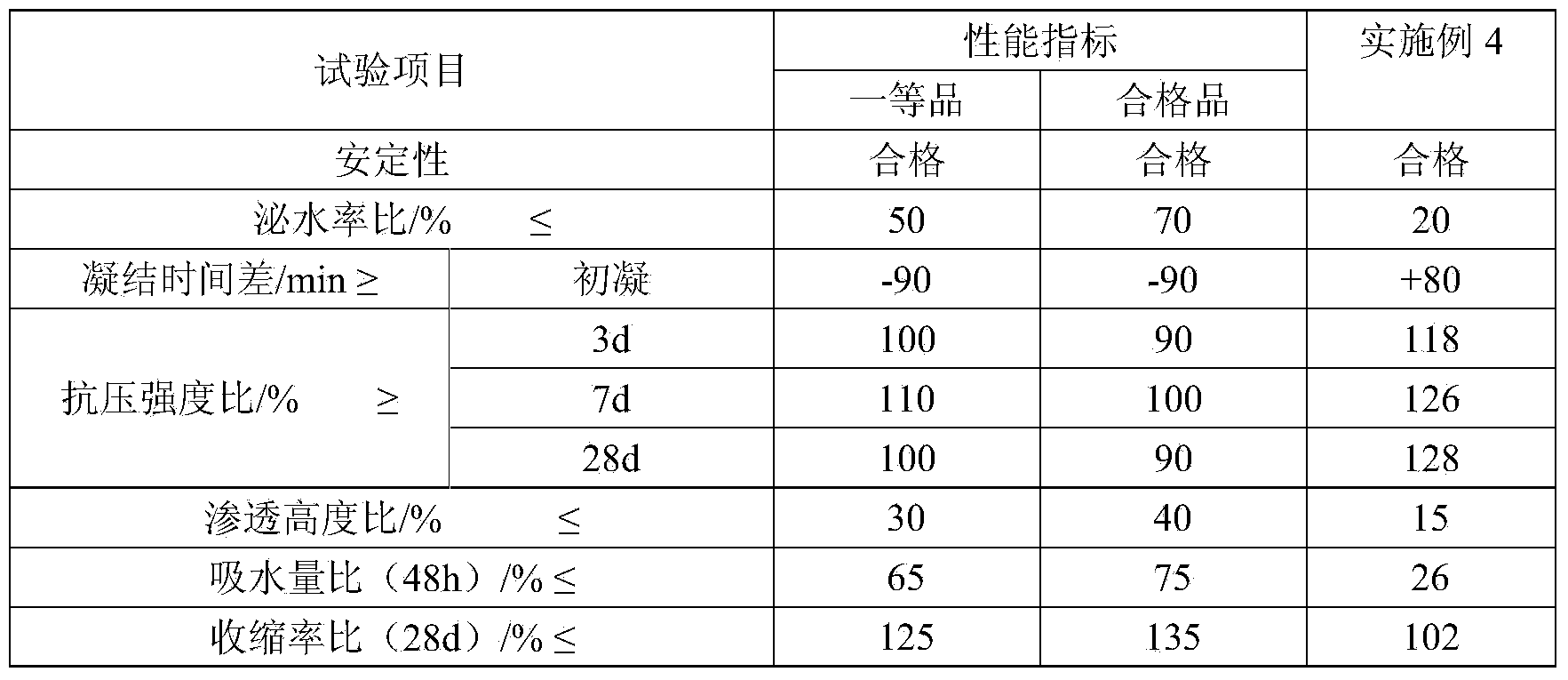

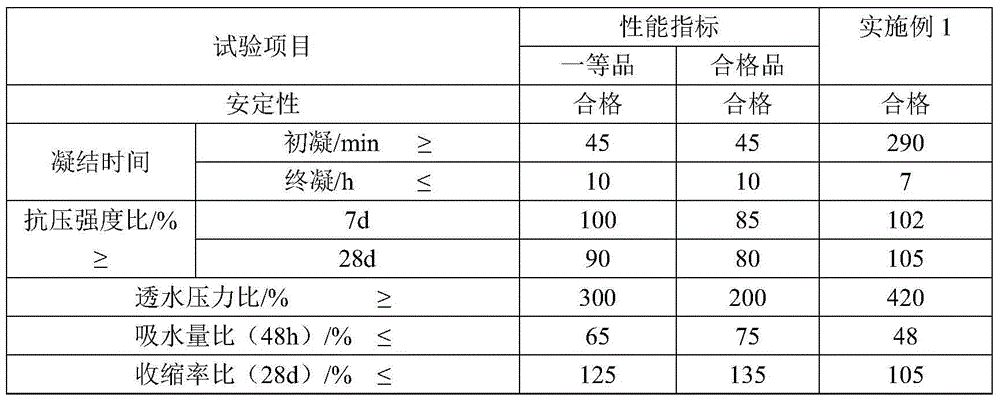

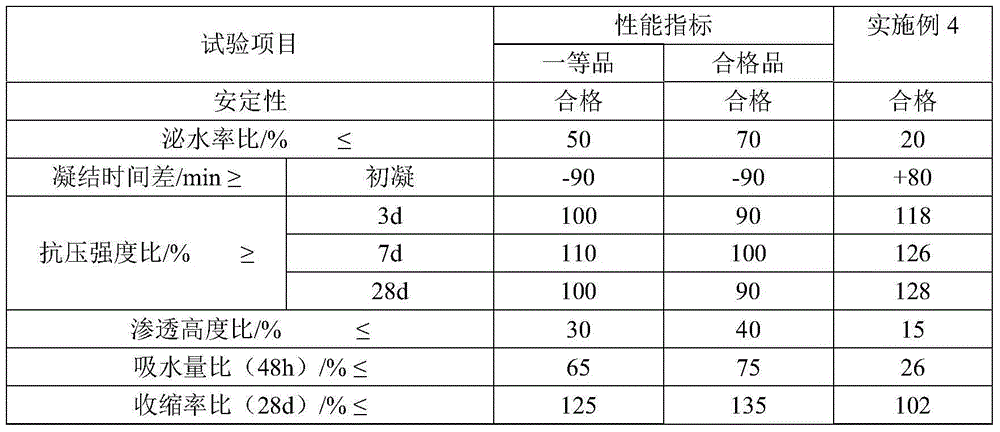

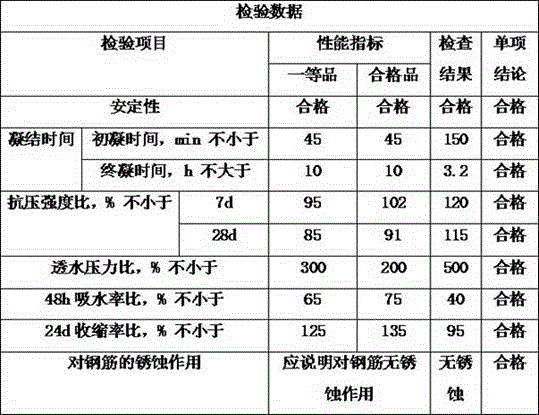

Water-repellent admixture for mortar and concrete

InactiveCN103864340AAvoid destructionNegative Effects of Reduced IntensityAbsorption capacityEmulsion

The invention discloses a water-repellent admixture for mortar and concrete. The water-repellent admixture for mortar and concrete is compounded of organosilicone emulsion, water, a concrete shrinkages reducing agent, a defoaming agent, a water reducing agent, a cement hydrating accelerant, a lithium compound and an air entraining agent, wherein the organosilicone emulsion is of a core-shell structure and prepared by soap-free polymerization and the particle size of emulsion particle is less than 200nm. When 1% of water-repellent admixture is added to mortar, the permeable pressure ratio of the obtained water-repellent mortar layer is not less than 420%, and the water absorption capacity within 48 hours is not greater than 48%; and when 0.2% of water-repellent admixture is added to concrete, the permeable height ratio of the obtained water-repellent concrete layer is not greater than 15%, the water absorption capacity within 48 days is not greater than 26%, and the shrinkage ratio within 28 days is not greater than 102%. The water-repellent admixture contains a core-shell spherical particle polymer with nanoscale and also contains shrinkages reducing agent, air entraining agent, lithium salt and other compounds which have different functions, and thus the anti-permeability, the water-repellent performance and the durability of the water-repellent layer can be greatly improved, the cracking can be avoided, and the toughness is also improved; and the water-repellent admixture is safe, nontoxic, simple in production, environment-friendly, low in cost, simple in structure, and short in open time.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Method for manufacturing linear copolyester hot melt adhesive

The invention provides a method for preparing linear copolyester hot melt rubber, which includes the following steps: (1) dimethyl terephthalate and diol are done with transesterification reaction under the effect of catalyst; (2) aliphatic series dibasic carboxylic acid and stabilizer are added into the product of step (1), obtaining copolymer by decompression and copolycondensation, and obtaining the hot melt rubber. The method for preparing the linear copolyester hot melt rubber adopts linear symmetrical dibasic carboxylic acid as raw material, and the linear copolyester hot melt rubber obtained with diol is characterized by being strong in adhesive strength, fast in crystallization speed, and resistant in water washing and dry washing, and is especially suitable for preparing the corresponding glue film or two sided rubber net interface product.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD

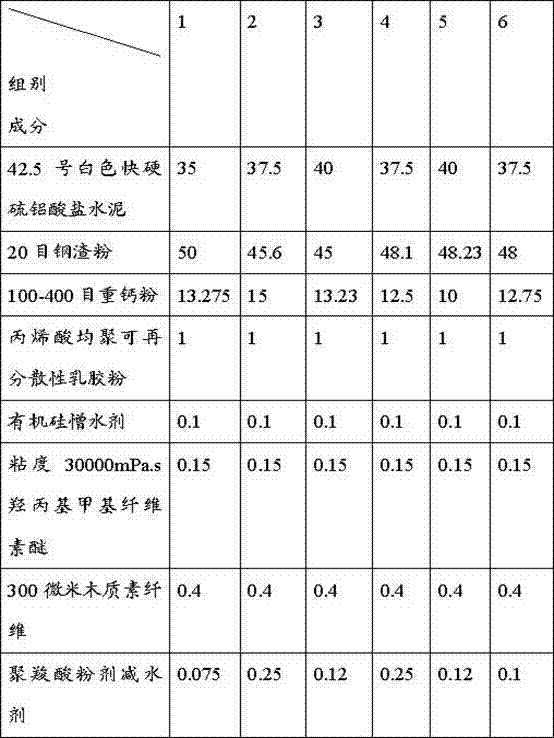

Composition and its preparation method and use

The invention provides a composition and its preparation method and use. The composition comprises, by weight, 35 to 40% of white cement, 45 to 50% of steel slag powder, 10 to 15% of heavy calcium powder, 0.1% of a water repellent, 0.15% of a water-retaining agent, 0.4% of lignin fibers, 1% of re-dispersible latex powder and 0.075 to 0.25% of a water reducer. The invention discloses the preparation method of the composition and a use of the composition as a tile-seam filling agent. The composition can reduces use amounts of an iron oxide pigment and cement, utilizes industrial by-products, realizes resource comprehensive utilization, is environmentally friendly, utilizes wastes, improves tile-seam filling agent workability, improves early-stage and later-stage strength of the tile-seam filling agent, reduces shrinkage cracks of the tile-seam filling agent in later-stage curing, and improves peaceability, application properties and thermal adaptability of a cement mortar system.

Owner:厦门路桥翔通建材科技有限公司

Polyester thermosol and preparation method thereof

The invention provides a polyester hot melt adhesive and a preparation method thereof, comprising the steps that: (1) in the presence of a catalyst, a transesterification is carried out between a dimethyl terephthalate and a diol; (2) a isophthalic acid, a aliphatic dicarboxylic acid and a stabilizer are mixed with the yield products of the step (1), a decompression and a co-condensation process are carried out so as to obtain a copolymer; (3) the mixture of a sorbic acid metal salt and the copolymer of ethylene KEYI acrylic acid are added in the yield products of step (2), then the copolymer is modified so as to obtain the polyester hot melt adhesive. The invention adopts the sorbic acid metal salt and the copolymer of ethylene acrylic acid to modify the colopolymer. The polyester hot melt adhesive obtained therefrom has the advantages of strong bond performance, positive effects of water cleaning and dry cleaning resistances, short opening time and fast solidification. The polyester hot melt adhesive is especially suitable for a production assembly line which calls for rapid bonding.

Owner:南通天洋光伏材料科技有限公司

Low-melting-point copolyamide hot melt adhesive for clothes and processing method thereof

The invention discloses a low-melting-point copolyamide hot melt adhesive for clothes. The hot melt adhesive is prepared from the following raw materials in percentage by weight: 30-40% of dibasic acid or dibasic acid salt, 20-30% of diamine or diamine salt, 20-40% of lactam, 1-8% of a molecular weight modifier, 0.1-0.4% of a stabilizer and 2-6% of water. A processing method for the low-melting-point copolyamide hot melt adhesive comprises the following steps: adding the raw materials into a reaction still, pumping 0.1 Mpa of nitrogen, then slowly emptying to normal pressure, repeatedly replacing to completely remove air in the reaction still, increasing the temperature of the reaction still to 220-250 DEG C, enabling the pressure to be 1.0-1.8 Mpa, reacting for 1.5-3 hours, cooling to 170-190 DEG C, reducing the pressure to 0.003-0.1 Mpa, dehydrating, and discharging to obtain the polyamide hot melt adhesive of which the average molecular weight is 12,000-100,000, the opening time is 1.0-3.0 min, and the melting point is 80-90 DEG C. The hot melt adhesive provided by the invention has the benefits that the melting point is low, the opening time is short, the melting range is short and the wash durability is better.

Owner:温州华特热熔胶股份有限公司

Preparation method of low-melting-point copolyamide hot melt adhesive

InactiveCN110184025AEffective responseShort opening hoursNon-macromolecular adhesive additivesDiaminePolyamide

The invention discloses a preparation method of a low-melting-point copolyamide hot melt adhesive, which includes the steps of adding binary acid consisting of lactam and a mixture of adipic acid andlong carbon chain binary acid having 10 to 14 carbon atoms, diamine consisting of a mixture of short carbon chain diamine having 6 to 8 carbon atoms and long carbon chain diamine having 10 to 14 carbon atoms, a molecular weight modifier, an antioxidant and water to a kettle; first performing nitrogen replacement; then raising the temperature to 120 DEG C and starting to stir; continuing to raise the temperature to 230 DEG C, keeping the pressure rising continuously, and performing reaction at the pressure of 1.3 MPa to 1.5 MPa and temperature of 230 DEG C to 250 DEG C for 1.5 h; reducing the pressure to atmospheric pressure, adding inorganic filler, performing reaction for another 2 hours, and then pressurizing and discharging a material. The obtained copolyamide hot melt adhesive preparedby the preparation method of the invention has the advantages of low melting point, stability, short opening time, appropriate melt index, good bonding effect, and excellent water washing resistanceand dry cleaning resistance.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +2

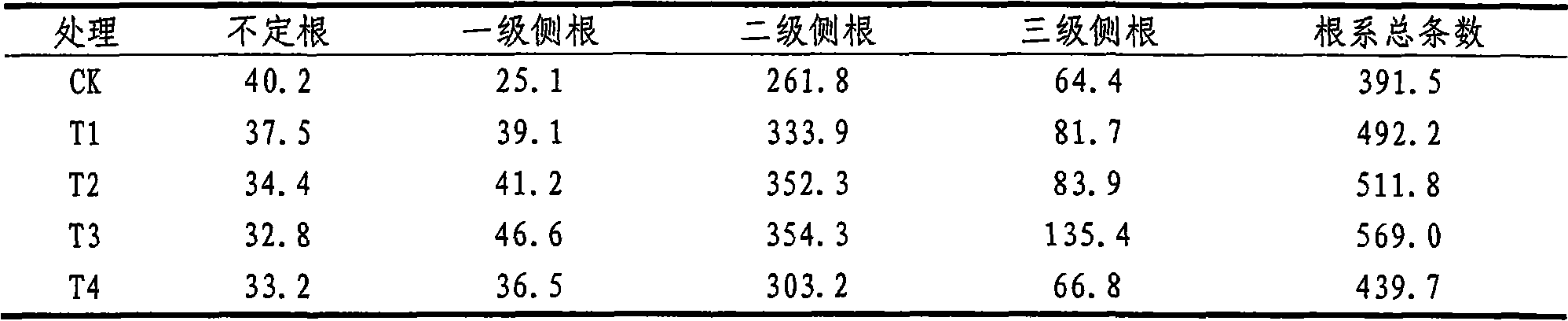

Aeration treating method of tobacco floating seedling

ActiveCN101658122AImprove germination environmentShorten emergence timeCultivating equipmentsSoilless cultivationDisease freeSeedling

The invention discloses an aeration treating method of tobacco floating seedling. The aeration treating method comprises the following steps of: before seeding and panning, mixing calcium peroxide with matrix according to the using amount of 150.0 to 450.0g / m<3> evenly, adding the calcium peroxide with the concentration of 0.09 to 0.27g / L into pond culture solution when the second true leaf and the sixth true leaf respectively grow out of the tobacco seedling, and other operations are respectively conventional technique. The aeration treating method can solve the hypoxic stress of floating seedling to tobacco seedling, improve the environment for the sprouting of tobacco seeds and growing of the root system of the tobacco seedling, improve the uniformity of seedling emergence, strengthen the activity of the root system of the tobacco seedling, enhance the growth of the tobacco seedling, improve the quality of the tobacco seedling, and is beneficial to culturing disease-free strong tobacco seedlings. The tobacco seedling cultured by adopting the method has the advantages of short seedling emergence time, high transplanting survival rate, strong field growth potential and the like. The invention has simple and convenient operation, low cost and good application prospect.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI +1

EVA hot melt adhesive, preparation process and application thereof

InactiveCN111394019AShort opening hoursHigh strengthMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolymer scienceCarton

The invention relates to the technical field of hot melt adhesives, in particular to an EVA hot melt adhesive special for furniture box sealing and a preparation process thereof. The EVA hot melt adhesive at least comprises the following components by weight percentage: 20-50% of a vinyl acetate-ethylene copolymer, 30-60% of tackifying resin, 0.1-2% of an assistant and the balance wax. The hot melt adhesive provided by the invention solves the problems that a common hot melt adhesive is short in opening time and low in strength, is not suitable for the high strength requirement of ultra-largeweight of furniture, is easy to rebound and come apart in carton sealing for large-size furniture, and is not suitable for sealing of cartons with long length. The EVA hot melt adhesive provided by the invention is especially suitable for sealing heavy furniture packaging cartons, and has the advantages of high bonding strength, good strength, bearability of the weight of super-large furniture, environmental protection, long opening time, adaptation to the super-long length of furniture cartons, good toughness, high rebound resistance and the like.

Owner:上海路嘉胶粘剂有限公司

Polyester hot melt adhesive for making films and preparation method thereof

ActiveCN102102003AAvoid generatingReduced cyclization rateFilm/foil adhesivesPolymer scienceReaction temperature

The invention discloses a method for preparing a polyester hot melt adhesive for making films, which comprises the following steps of: (1) adding terephthalic acid, butanediol and a titanium catalyst into an esterification kettle for primary esterification, wherein the reaction temperature is 170-195DEG C; (2) adding adipic acid, maleic acid, isophthalic acid, propylene glycol, neopentyl glycol and a p-toluenesulfonic acid catalyst into the kettle for secondary esterification, wherein the reaction temperature is 180-205DEG C; and (3) adding a stabilizing agent, and performing polycondensation under reduced pressure to obtain the polyester hot melt adhesive product which is quick in crystallization and easily forms a film.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +1

Preparation method of polyester hot melt adhesive used for shoes

The invention discloses a preparation method of a polyester hot melt adhesive used for shoes. The preparation method comprises the following steps of: (1) performing an esterification reaction on terephthalic acid, isophthalic acid, adipic acid, butanediol, hexanediol and diethylene glycol under the effects of a tin / titanium composite catalyst; and (2) adding a stabilizer and an antioxidant to the product obtained in step (1) for pressure-reduced condensation polymerization so as to obtain the polyester hot melt adhesive used for the shoes, wherein the polyester hot melt adhesive used for the shoes has a high melting point and is short in opening hours.

Owner:SHANGHAI TIANYANG HOT MELT ADHESIVE CO LTD +2

A kind of mortar concrete waterproofing agent

InactiveCN103864340BAvoid destructionNegative Effects of Reduced IntensityAbsorption capacityEmulsion

The invention discloses a water-repellent admixture for mortar and concrete. The water-repellent admixture for mortar and concrete is compounded of organosilicone emulsion, water, a concrete shrinkages reducing agent, a defoaming agent, a water reducing agent, a cement hydrating accelerant, a lithium compound and an air entraining agent, wherein the organosilicone emulsion is of a core-shell structure and prepared by soap-free polymerization and the particle size of emulsion particle is less than 200nm. When 1% of water-repellent admixture is added to mortar, the permeable pressure ratio of the obtained water-repellent mortar layer is not less than 420%, and the water absorption capacity within 48 hours is not greater than 48%; and when 0.2% of water-repellent admixture is added to concrete, the permeable height ratio of the obtained water-repellent concrete layer is not greater than 15%, the water absorption capacity within 48 days is not greater than 26%, and the shrinkage ratio within 28 days is not greater than 102%. The water-repellent admixture contains a core-shell spherical particle polymer with nanoscale and also contains shrinkages reducing agent, air entraining agent, lithium salt and other compounds which have different functions, and thus the anti-permeability, the water-repellent performance and the durability of the water-repellent layer can be greatly improved, the cracking can be avoided, and the toughness is also improved; and the water-repellent admixture is safe, nontoxic, simple in production, environment-friendly, low in cost, simple in structure, and short in open time.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

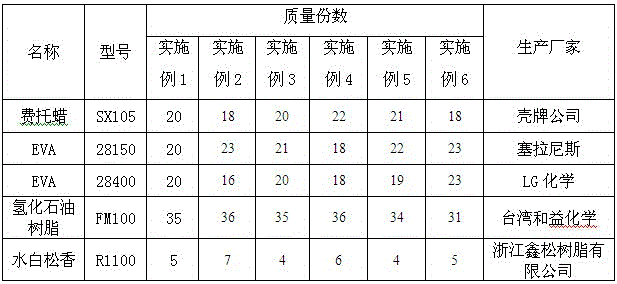

Environment-friendly carton positioning adhesive

InactiveCN106281152AShort opening hoursFast positioningMineral oil hydrocarbon copolymer adhesivesWax adhesivesWaxRosin

The invention provides an environment-friendly carton positioning adhesive which is prepared from the following formula components in parts by mass: 18 to 22 parts of Fischer-tropsch wax SX105, 16 to 23 parts of EVA28150, 16 to 23 parts of EVA28400, 30 to 38 parts of hydrogenated petroleum resin FM and 4 to 7 parts of water-white rosin 1100. The environment-friendly carton positioning adhesive is reasonable in design, good in adhesion effect and high in production efficiency, and the production cost is reduced.

Owner:浙江固特新材料科技股份有限公司

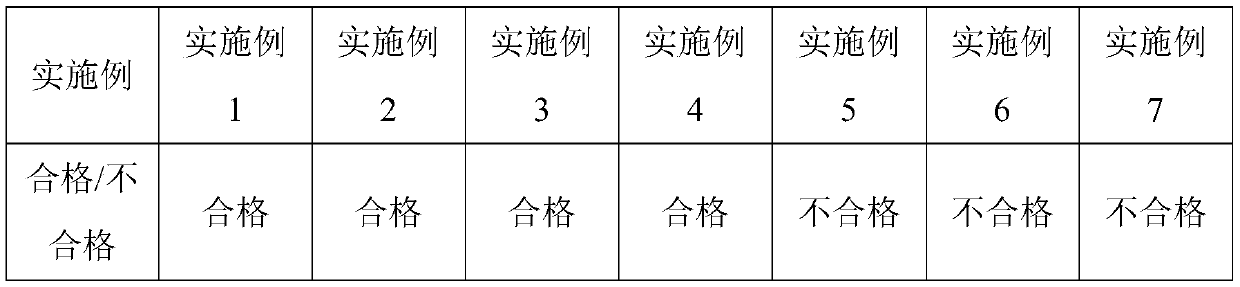

Preparation method and use method of moisture-cured polyurethane edge sealing glue with high initial adhesion

InactiveCN111978907AShort opening hoursFast initial tack and fast curingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePolypropylene glycol

The invention relates to the technical field of edge sealing glue preparation, and discloses a preparation method and a use method of a moisture-cured polyurethane edge sealing glue with high initialadhesion. Polypropylene glycol ether, polytetrahydrofuran, amorphous polyester 7110, poly(neopentyl glycol adipate), poly(hexanediol adipate), terpene resin, copolymerized polyester resin, talcum powder and MDI are used as raw material to prepare the edge sealing glue; and the glue has the characteristics of short opening time, excellent initial adhesion, high curing speed, high peel strength, high temperature resistance, weather resistance, high-low temperature resistance, excellent water resistance, high adaptability and the like. The glue is moderate in viscosity, and is convenient to construct compared with the traditional hot melt glue.

Owner:CHONGQING HANTUO TECH CO LTD

Preparation method of mortar concrete waterproof agent

The invention discloses a preparation method of a mortar concrete waterproof agent, which comprises the following steps: preparing an emulsion with an organosilicon core-shell structure by an acrylic acid unsaturated monomer, unsaturated fatty acid and a nonsaturated organosilicone compound through soap-free polymerization, then adding 10-30 parts of water, 2-5 parts of concrete shrinkage reducing agent, 0.2-1 part of antifoaming agent, 5-15 parts of water reducer, 1-3 parts of cement hydration promoter, 10-20 parts of lithium compound and 0.5-1.5 parts of air-entrainer in 40-60 parts of emulsion with an organosilicon core-shell structure in order, and uniformly mixing. According to the invention, a core-shell spherical particle polymer with nano size can be prepared, and the compound containing the shrinkage reducing agent, the air-entrainer and the lithium salt with different functions is composited with the polymer, so that the obtained waterproof agent can greatly enhance the impermeability, waterproofness and durability of a water proof layer, cracking is avoided, toughness is enhanced, construction is simple, the opening time is short, preparation process is safe and nontoxic, production is simple, no environmental pollution is generated, and cost is low.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

High-permeability concrete sealing waterproofing agent and preparation method thereof

The invention provides a high-permeability concrete sealing waterproofing agent. The high-permeability concrete sealing waterproofing agent is prepared from, by weight, 5-10 parts of epoxy resin, 2-4 parts of polyamide, 0.6-1.2 parts of polyoxyethylene aliphatic alcohol ether, 0.8-1.6 parts of hexadecyltrimethoxysilane, 0.4-0.8 part of methyltrihydroxysilane, 1.5-3.0 parts of polypropylene fibers, 3-5 parts of a water reducing agent, 2-5 parts of triethanolamine, 0.9-1.6 parts of sodium abietate, 0.8-1.4 parts of alkyl sodium sulfonate and 40-60 parts of deionized water. The concrete sealing waterproofing agent is high in permeability and good in hydrophobicity, has the excellent corrosion resistance, water resistance and ageing resistance, is poisonless after being solidified and can permeate cracks, holes and defects of various sizes and be solidified to block a leakage channel to achieve the anti-leakage purpose through raw material selecting and reasonable using amount proportioning.

Owner:湖北汉格新材科技有限公司

Polyurethane or polyurethane-urea aqueous dispersion, preparation method and application thereof

PendingCN112778487AStable storageDecatalysisPolyureas/polyurethane adhesivesPolyesterHydrophilization

The invention belongs to the technical field of polyurethane aqueous dispersions, and particularly relates to a polyurethane or polyurethane-urea aqueous dispersion, a preparation method and application thereof, and the polyurethane or polyurethane-urea is prepared by reaction of raw materials comprising the following components: a) a compound containing a tertiary amine group and at least one NCO reactive functional group, b) polyester polyol having a number average molecular weight of 400-5000 and a functionality of 2-3, c) an organic compound having at least two isocyanate groups, d) a hydrophilic compound containing one or more of an ionic group, a latent ionic group and a nonionic group and containing 2-3 NCO reactive functional groups, and e) a monofunctional nonionic hydrophilic compound containing at least one NCO reactive functional group. The aqueous dispersion disclosed by the invention is stable in storage and long in storage time, the hydrolysis resistance of an adhesive prepared from the dispersion is improved, and meanwhile, relatively good bonding strength and heat resistance of the aqueous dispersion can be maintained.

Owner:WANHUA CHEM GRP CO LTD +2

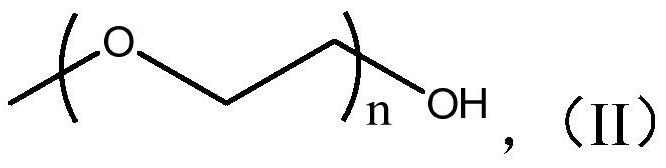

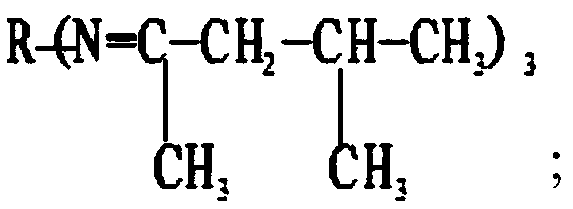

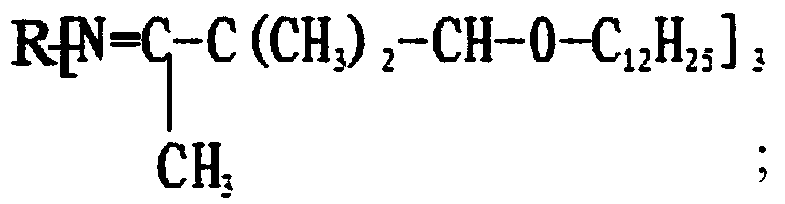

Ketimine latent curing agent, reactive polyurethane hot melt adhesive containing ketimine latent curing agent and application of ketimine latent curing agent

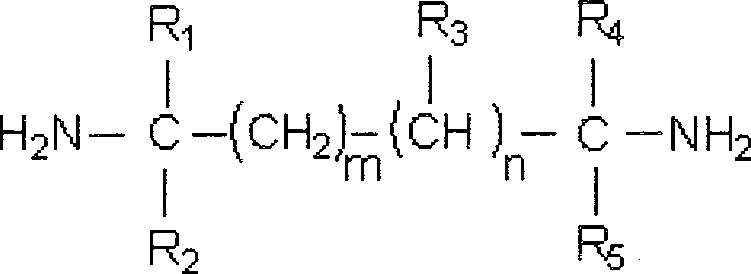

InactiveCN110698622AHigh solid contentShort opening hoursPolyureas/polyurethane adhesivesImino compound preparationArylPolymer science

The invention discloses a ketimine latent curing agent. A general formula of the ketimine latent curing agent is shown in the specification, wherein R1 is any one selected from C1 to C16 alkyl, aryl and cycloalkyl, R2 is any one selected from C1 to C6 alkyl, aryl and cycloalkyl, R3 is any one selected from alkyl, aryl, cycloalkyl, polyethylene oxide and polypropylene oxide, and n is 1 to 8. The invention also discloses a reactive polyurethane hot melt adhesive. The hot melt adhesive is prepared by mixing polyurethane resin and the above ketimine latent curing agent. More environmentally friendly and safer ketimine is used as a the latent curing agent, the reactive polyurethane hot melt adhesive prepared by using the latent curing agent has the advantages of a high solid content, short opening time, high shear strength, strong adhesion, a long validity period, environmental protection and safety.

Owner:北京长润化工有限公司

Method for preparing PNT (para nitro toluene) copolyester hot melt adhesive used for film manufacturing

InactiveCN104479118AHigh melt indexFast crystallizationNon-macromolecular adhesive additivesPolymer sciencePressure reduction

The invention discloses a method for preparing PNT (para nitro toluene) copolyester hot melt adhesive used for film manufacturing. The method comprises the following steps: (1) terephthalic acid, isophthalic acid, neopentyl glycol and 1,3 propylene glycol have an esterification reaction under the action of titanium catalysts; (2) stabilizers and anti-oxydants are added to products of the step (1), so a pressure-reduction condensation polymerization reaction is conducted, and the PNT copolyester hot melt adhesive which is used for film manufacturing and is high in crystallization speed and short in opening time can be obtained.

Owner:ANHUI ZHUCHENG INFORMATION TECH

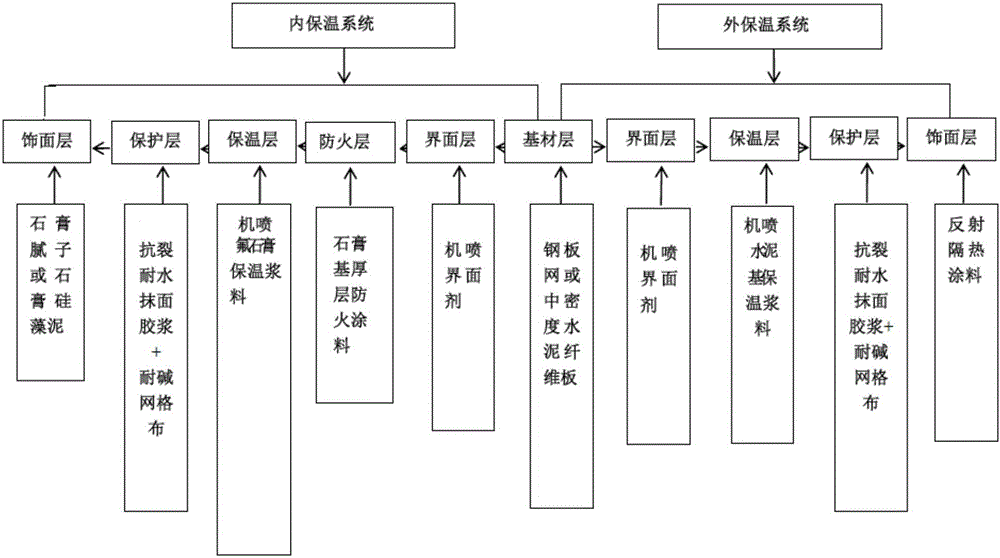

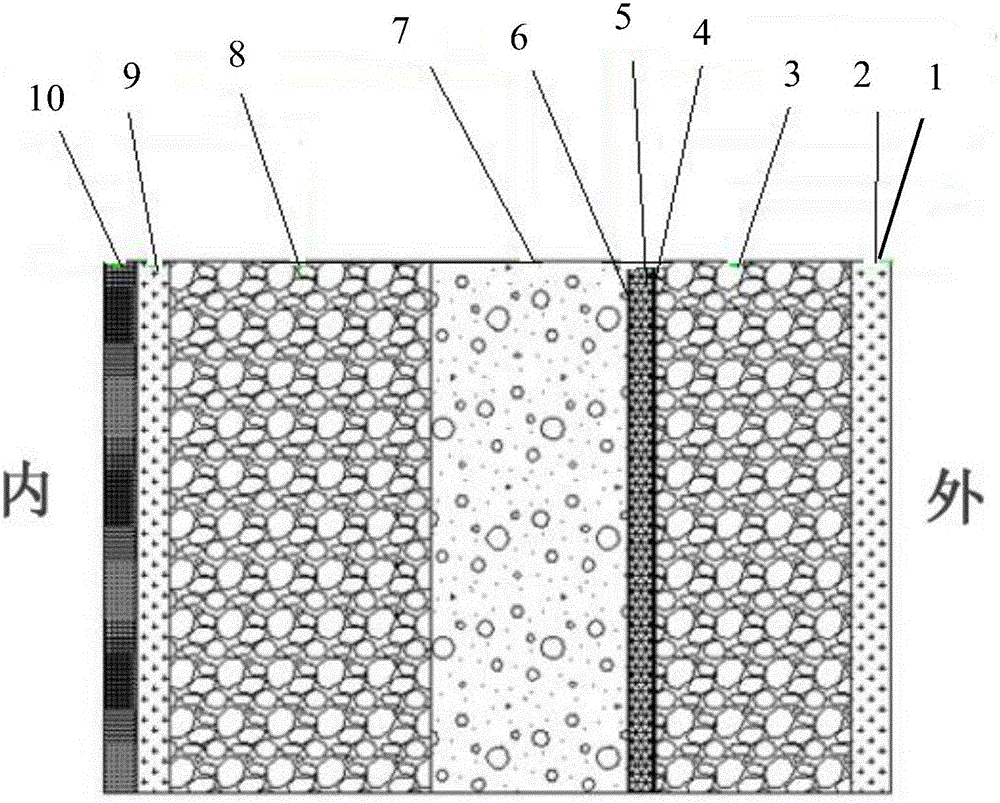

Mechanical spraying-fluorogypsum-reflective insulation paint enclosure insulation composite wall system for steel structure

ActiveCN105906239AAddress water resistanceSolve the strength problemWallsFilling pastesNatural resourceInsulation layer

The invention discloses a mechanical spraying-fluorgypsum-reflective insulation paint enclosure insulation composite wall system for a steel structure. The insulation composite wall system comprises an interior insulation system and an exterior insulation system. The interior insulation system and the exterior insulation system share a substrate layer. The insulation composite wall system successively comprises, from interior to exterior, an interior facing layer, an interior protection, an interior insulation layer, an interior fireproof layer, an interior interfacial layer, the substrate layer, an exterior interfacial layer, an exterior fireproof layer, an exterior insulation layer, an interior protection layer and an exterior facing layer. According to the invention, the insulation composite wall system employs fluorogypsum modification technology, reduces consumption of energy resources and pollution and protects natural resources and ecological environment; moreover, utilization of industrial by-product gypsum is broadened, considerable solid waste is consumed, environmental pollution is mitigated, energy consumption in building is saved, and a steel structure industry is turned into a novel energy-saving environment-friendly large industry with low energy consumption and capacity of consuming industrial solid waste.

Owner:马振义

Vacuum washing rotary classification garbage can with vegetable washing pool on top

PendingCN111086791APrevent leakagePlay the role of isolating odorWaste collection and transferDomestic plumbingInterior spaceProcess engineering

The invention discloses a vacuum washing rotary classification garbage can with a vegetable washing pool on top. The garbage can comprises a box body. A sealing door is arranged on the lower part of the box body. The vegetable washing pool is arranged on the top of the box body. A water discharge pipe, a throwing opening and a throwing door are arranged at the bottom of the vegetable washing pool.A washing mechanism is arranged in the box body. A discharge port is arranged on the lower part of the interior of the box body. A plurality of isolation hoppers are arranged on the part, between thethrowing door and the discharge port, of the box body. The interior of the box body is divided into a plurality of cavities which are arranged vertically. Each cavity is connected with a vacuuming mechanism independently. An isolation door is arranged at the bottom of each isolation hopper. A slant classification pipe is in butt joint with the lower part of the discharge port. On the premise thatthe size of the garbage can is not changed, the internal space of the garbage can is made full use of; more storage barrels are arranged to meet the requirement for classification of various garbage;the vegetable washing pool is used in combination with a garbage can body, the space is made full use of reasonably, the problem that in the prior art, when a user opens a garbage can cover and throws garbage into the garbage can, the smell of the garbage inside goes upwards and spreads outwards is solved, and the indoor air environment is protected.

Owner:山东汉东工业技术有限公司

Toe box and heel cap material for shoes and method of manufacturing toe box and heel cap material for shoes

The invention provides a toe box and heel cap material for shoes and a method of manufacturing the toe box and heel cap material for shoes. The toe box and heel cap material for shoes comprises a sandwich layer and a surface layer wrapping the same, wherein the sandwich layer is made of 100 parts of polyurethane, 60 parts of low-temperature polyester, 5 parts of triethylene diamine, 3 parts of stannous octoate, 5 parts of 1,4-Butanediol, and 6 parts of trimethylolpropane, and the surface layer is made of 100 parts of hot melt glue level polyurethane and 30 parts of thermoplastic elastomer. The hardness and strength of the toe box and heel cap material for shoes are improved further, the toe box and heel cap material is easy to trim and excellent in bending resistance, the toe box and heel cap material is active at low temperature and free of glue overflow, opening time is shortened so that the material can be shaped quickly, and the toe box and heel cap material has high bonding power. Leftover obtained by trimming the material can be recycled and reused. By the method of manufacturing the toe box and heel cap material for shoes, manufacturing procedures are simplified for enterprises, operation is facilitated for shoe makers, and production efficiency and labor intensity are reduced for the shoe makers.

Owner:FOSHAN YUYI SHOE MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com