Concrete pouring fast construction method

A concrete and fast technology, applied in construction, building maintenance, building construction, etc., can solve the problems of reducing traffic capacity and service level, long construction period, complicated construction procedures, etc., achieving a wide range of engineering application prospects and reliable construction quality. , the effect of shortening the opening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

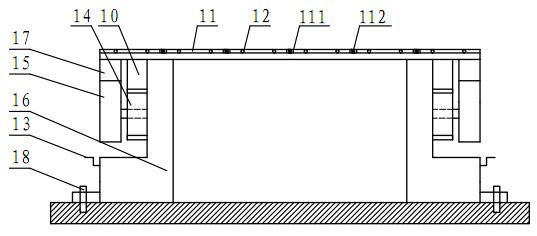

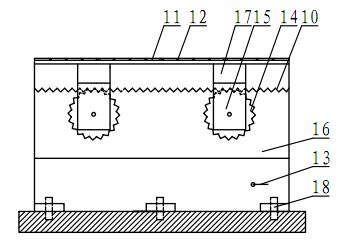

[0041] A bridge deck pavement rapid construction project, the on-site pavement is 6m wide, 15cm thick, and 500m long. 24 pieces of formwork 11 with a size of 100cm×50cm are selected and spliced into a whole plate with a width of 6m and a length of 2m, supporting formwork slides 16 , anchor the formwork slideway 16 on the bridge surface with anchor nails 18, adjust the lifting valve 13 to make the formwork slideway 16 height 15cm, and support the baffle at the end of the movable formwork 11, splice the formwork, and assemble the motor 15 and gears 14, then the whole board is placed on the formwork slideway 16. Concrete mixing plant 32 has a production efficiency of 40m 3 / h, the concrete mobile mixing device 3 is connected to the wet concrete spraying device 2, and then the spray gun 23 is put into the mobile formwork device 1. Put the aggregate into the mobile mixing plant and start producing concrete. The concrete wet spraying machine 22 controls its spraying speed to be ...

Embodiment 2

[0043] The bridge deck pavement of an expressway was seriously damaged, and the old concrete pavement of the bridge deck had to be chiseled out to repair the bridge deck concrete. The design strength of repair concrete for bridge deck pavement is C50, the design thickness is 20cm, and the width of one construction is 7.5m. 10 templates with a size of 150cm×100cm are selected and spliced into a whole board with a width of 7.5m and a length of 2 meters. Support the formwork slideway 16, anchor the formwork slideway 16 on the ground with anchor nails 18, adjust the lift valve 13 to make the formwork slideway 16 height 20cm, and support the baffle at the end of the movable formwork 11. Splice the formwork 11, assemble the motor 15 and the gear 14, and then place the whole plate on the formwork slideway 16. The concrete wet spraying machine 22 controls its spraying speed to be 80m / s, spraying pressure to 0.7Mpa, and the moving speed of the entire slab to be 40m / h. The pouring re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com