Vacuum washing rotary classification garbage can with vegetable washing pool on top

A vegetable washing pool and garbage bin technology, which is applied in the directions of trash cans, garbage cleaning, garbage collection, etc., can solve the problem that the vegetable washing pool and the garbage bin are not well sealed, cannot meet various garbage classification requirements, and are not fully utilized, etc. problems, to achieve the effect of inhibiting bacterial growth, avoiding odor leakage, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

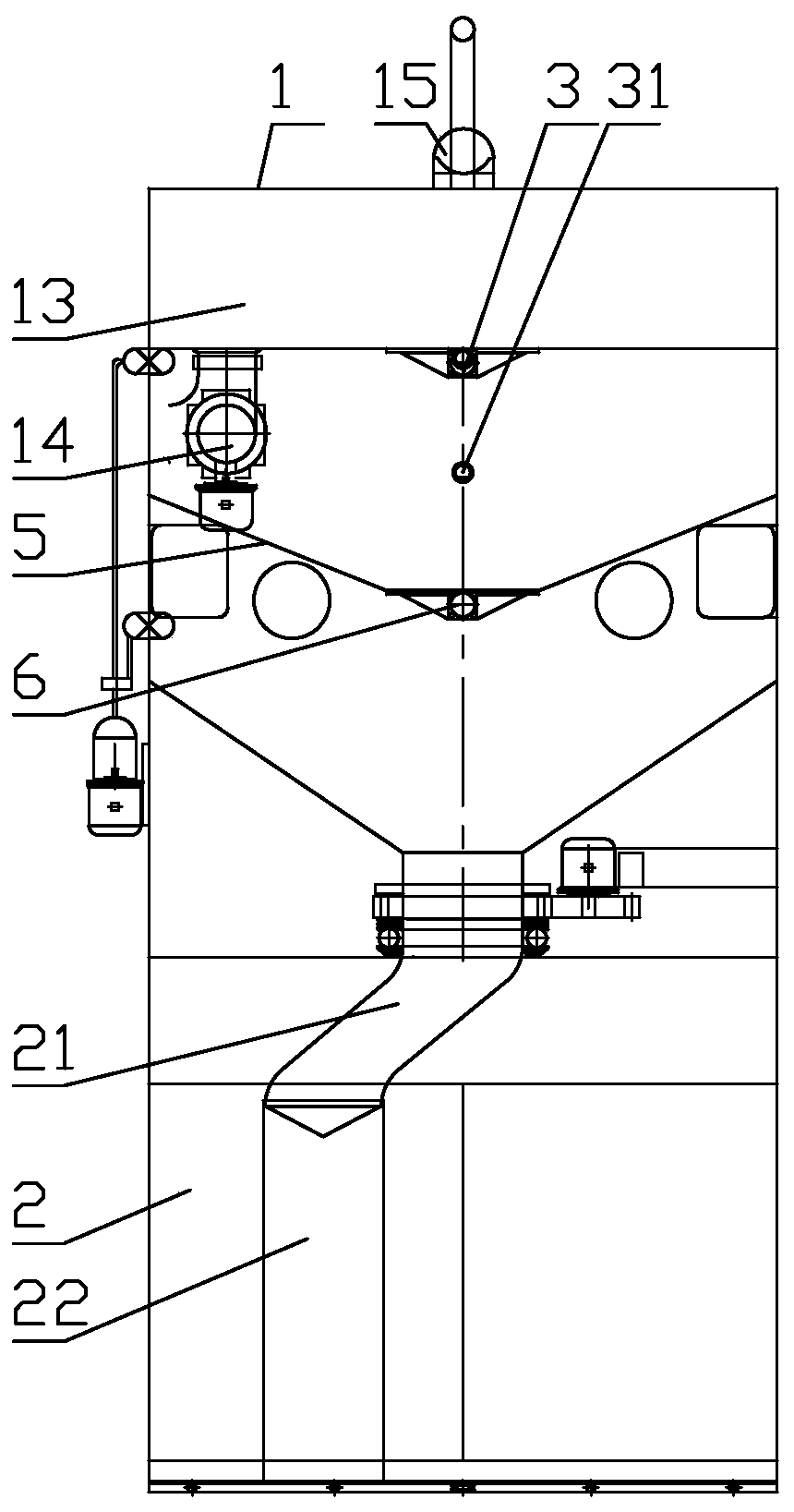

[0065] Such as figure 1 As shown, a top-mounted vegetable washing pool type vacuum flushing rotary sorting garbage bin includes a box body 1,

[0066] The bottom of the box body 1 is provided with a sealed door 2; the top of the box body 1 is provided with a vegetable washing pool 13, and the bottom of the vegetable washing pool 13 is provided with a drainage pipe 14, a delivery port and a delivery door 3; the drainage pipe 14 extends to the box The outside of the body leads to the kitchen sewer mouth, and the vegetable sink 13 is provided with a faucet, which can be opened to wash vegetables directly in the vegetable sink 13, the sewage is discharged from the drain pipe 14, and the garbage enters the casing from the input port and the input door 3;

[0067] A flushing mechanism is provided in the box body 1; as Figure 26 As shown, the flushing mechanism is installed at the positions on both sides of the isolation bucket 5 in the box, and includes a water tank 26 and an air ...

Embodiment 2

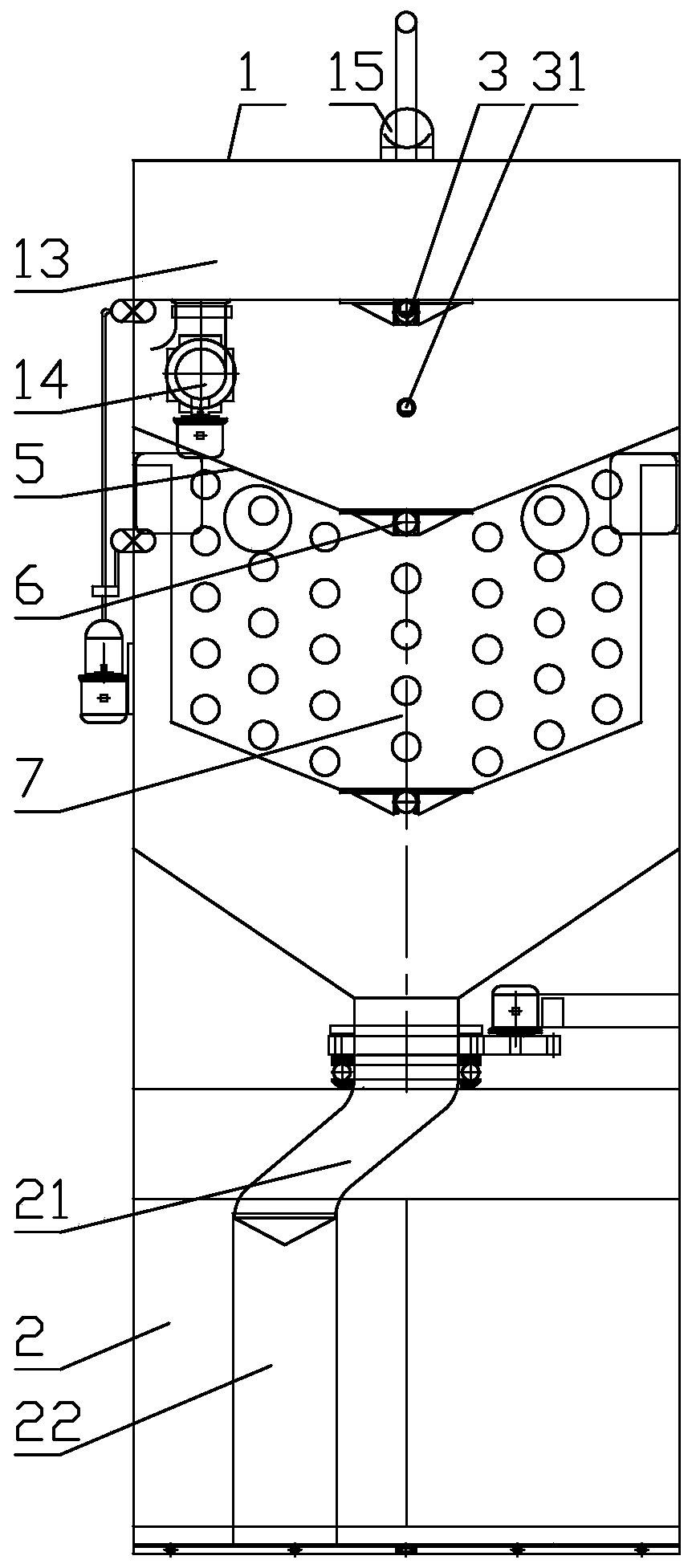

[0076] Such as figure 2 As shown, the difference between this embodiment and embodiment 1 is:

[0077] The box body 1 is provided with a solid-liquid separation box 7 for separating solid garbage and liquid garbage. The side wall of the solid-liquid separation box 7 is provided with some liquid seepage holes, and the bottom of the solid-liquid separation box 7 is provided with a separation door, and the structure of the separation door can refer to the structure of the delivery door. Liquid rubbish can seep downwards from the liquid seeping hole, and solid rubbish stays in the solid-liquid separation box 7, and liquid rubbish can be entered into sorting barrel 22 earlier, then open separation door, and solid rubbish is put into sorting barrel 22. The several sorting barrels 22 are placed on the rotary pallet at the bottom of the casing along the circumference, and the center position of the bottom of the rotary pallet is provided with a supporting bearing. The rotating tray...

Embodiment 3

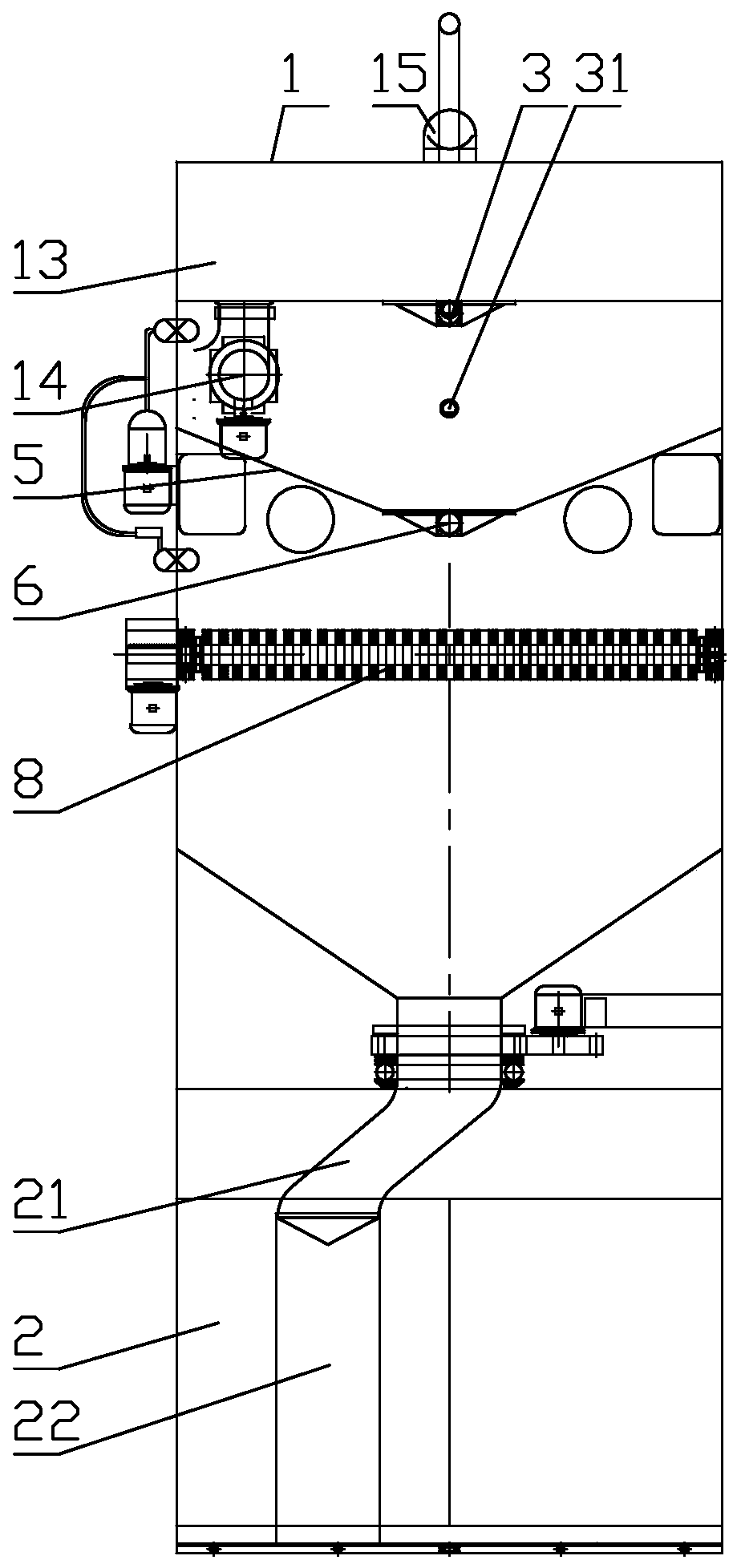

[0079] Such as image 3 As shown, the difference between this embodiment and embodiment 1 is:

[0080] The box body 1 is provided with a crushing mechanism 8 for crushing garbage. The crushing mechanism 8 comprises two toothed turning rollers, the teeth of the two turning rollers fit closely to the gap, the motor drives the two turning rollers to rotate in reverse, and the two turning rollers extrude inwardly to crush the rubbish. The crushing mechanism is a commonly used crushing structure, not limited to one in the drawings of this application, but also other common crushing structures in the industry are within the protection scope of this application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com