Composition and its preparation method and use

The technology of a composition and a water repellent, which is applied in the field of construction engineering, can solve the problems such as the need for improvement of the tile caulking agent, and achieve the effects of good water retention effect, high water reduction rate and moderate air entrainment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Preparation of environment-friendly color tile grout

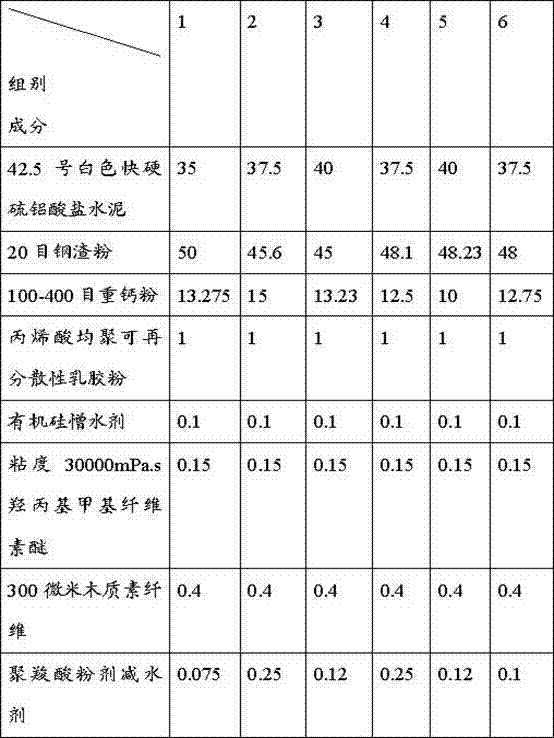

[0035] Table 1 (units are mass percentage%)

[0036]

[0037] Note: 100-400 mesh heavy calcium powder can be 100 mesh heavy calcium powder, 200 mesh heavy calcium powder, 300 mesh heavy calcium powder, 400 mesh heavy calcium powder. All can realize the present invention.

[0038] Weigh each component according to the formula in Table 1, and stir evenly. Add water accounting for 20% of the mass of the powder into the bucket, and mechanically stir while adding the above powder. After stirring into a putty shape, let it stand for 10 minutes to mature, and then mechanically stir for 30 seconds, then it can be used. Due to the fast curing speed of the caulking agent and the short opening time, it is recommended to use it up within 30 minutes after stirring once.

Embodiment 2

[0039] Embodiment 2 Effect experiment

[0040] According to the "Cement mortar strength test method (ISO method)" (GB / T 17671-1999), the test method for the compressive and flexural strength of cement mortar.

[0041] Table 2

[0042] group Flexural strength Compressive strength 1 5.3 27.5 2 6.3 30.6 3 7.2 38.4 4 6.0 28.6 5 5.8 27.8 6 5.0 30.1

[0043] It can be seen from the results in Table 2 that the ceramic tile grout with steel slag powder is tightly bonded to the tiles without cracking. Steel slag powder tile grout has high strength and good working performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com