Heat-conducting insulated pressure sensitive tape and preparation method thereof

A pressure-sensitive tape, thermal insulation technology, applied in the direction of adhesive, adhesive type, film/sheet adhesive, etc., can solve the problems of high cost, insufficient thermal conductivity, edge warping, etc., and achieve high production efficiency , The effect of convenient assembly and production, prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

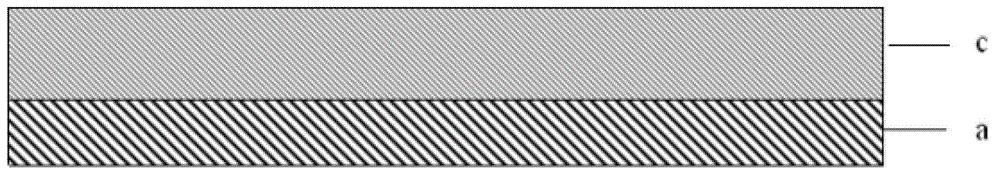

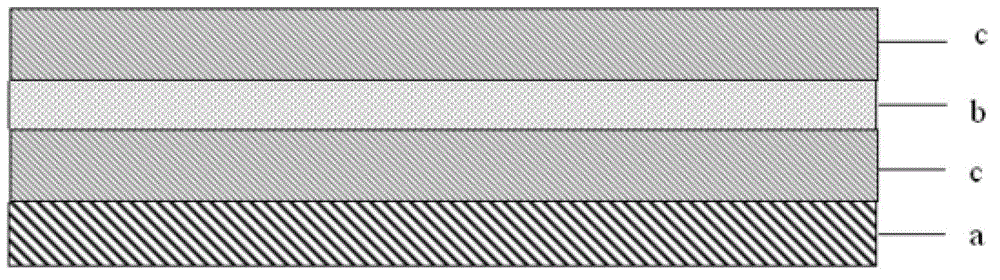

Image

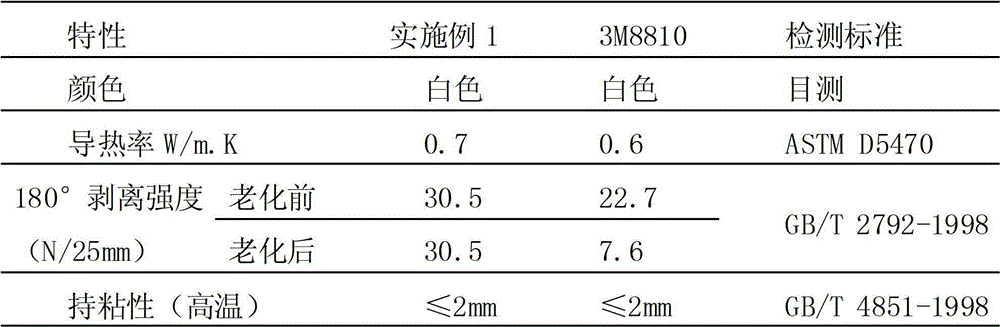

Examples

Embodiment 1

[0034] Step 1: Prepare polyacrylate adhesive as follows:

[0035] First, under a nitrogen environment, in a reaction vessel equipped with a stirrer and a reflux condenser, add 86 g of butyl acrylate, 5 g of acrylic acid, 10 g of 2-ethylhexyl acrylate, 20 g of toluene, 192.5 g of ethyl acetate, and trigger After mixing 0.2g of azobisisobutyronitrile evenly, control the temperature to 78°C, control the stirring speed to 70 rpm, add 0.2g of initiator azobisisobutyronitrile once every 2 hours, and react for 6 hours Cool down to room temperature to obtain a polyacrylate adhesive.

[0036] Step 2: Prepare the modified BN dispersion as follows:

[0037] (2-1) In a beaker, add 30g of BN particles with a micron-sized particle size of 5-15 μm, 10g of BN with a nano-sized particle size of 400-600nm, 10g of BN nanowires with a length of 300-600nm and 100g of ethanol, and carry out Mix evenly, pre-disperse with ultrasonic waves, the dispersion time is 20-40min, and the ultrasonic output ...

Embodiment 2

[0044] Step 1: Prepare polyacrylate adhesive as follows:

[0045] First, under a nitrogen environment, in a reaction vessel equipped with a stirrer and a reflux condenser, add 86 g of butyl acrylate, 5 g of acrylic acid, 10 g of 2-ethylhexyl acrylate, 20 g of toluene, 192.5 g of ethyl acetate, and trigger After mixing 0.2g of azobisisobutyronitrile evenly, control the temperature to 80°C, control the stirring speed to 70 rpm, add 0.2g of initiator azobisisobutyronitrile once every 2 hours, and react for 6 hours Cool down to room temperature to obtain a polyacrylate adhesive.

[0046]Step 2, prepare modified AlN dispersion liquid as follows:

[0047] (2-1) In a beaker, add 30g of AlN particles with a micron-sized particle size of 5-15μm, 10g of AlN with a nano-sized particle size of 400-600nm, 10g of AlN nanowires with a length of 300-600nm and 100g of ethyl acetate , mix evenly, and pre-disperse with ultrasonic waves, the dispersion time is 20-40min, and the ultrasonic outpu...

Embodiment 3

[0056] Step 1: Prepare Polyacrylate Adhesive:

[0057] First, under a nitrogen environment, in a reaction vessel equipped with a stirrer and a reflux condenser, add 86 g of butyl acrylate, 5 g of acrylic acid, 10 g of 2-ethylhexyl acrylate, 20 g of toluene, 192.5 g of ethyl acetate, and trigger After mixing 0.2g of azobisisobutyronitrile evenly, control the temperature to 80°C, control the stirring speed to 70 rpm, add 0.2g of initiator azobisisobutyronitrile once every 2 hours, and react for 6 hours Cool down to room temperature to obtain a polyacrylate adhesive.

[0058] Step 2: Prepare modified AlN, BN mixed dispersion:

[0059] (2-1) In a beaker, add 15g of AlN particles with a micron-sized particle size of 5-15μm, 5g of AlN with a nano-sized particle size of 400-600nm, 5g of AlN nanowires with a length of 300-600nm, 15g of micron-sized particles BN particles with a diameter of 5-15 μm, 5g of BN with a nano-scale particle size of 400-600nm, 5g of BN nanowires with a leng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com